The global polyvinyl chloride (PVC) sheet roofing market is experiencing steady growth, driven by rising demand for durable, low-maintenance, and energy-efficient roofing solutions in both residential and commercial construction. According to Grand View Research, the global PVC membrane roofing market size was valued at USD 4.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing infrastructure development, particularly in emerging economies, and a growing emphasis on sustainable building materials with long service life and recyclability. PVC sheets are favored for their excellent waterproofing properties, resistance to UV radiation and chemical exposure, and cost-effectiveness over the building lifecycle. With North America and Europe leading adoption due to stringent building codes and green building certifications, and Asia-Pacific witnessing rapid urbanization, key manufacturers are scaling production and innovation to meet evolving market demands. In this expanding landscape, the following nine companies have emerged as leading producers of PVC sheet roofing, recognized for product quality, global reach, and technological advancement.

Top 9 Polyvinyl Chloride Sheet Roofing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Waterproofing Membranes for Roofs

Domain Est. 1992

Website: dow.com

Key Highlights: Dow waterproofing membrane science delivers solutions for TPO-, PVC- or EPDM-based roofing systems. Explore our products today….

#2 PVC Roofing Membranes

Domain Est. 1996

Website: gaf.com

Key Highlights: Time-tested technology in a PVC roofing system for premium performance and durability. Suitable for all types of single-ply systems….

#3 PVC Roofing Systems

Domain Est. 1997

Website: jm.com

Key Highlights: JM PVC membranes deliver a pliable and durable sheet with excellent weathering characteristics and resistance to harsh chemicals and industrial pollutants….

#4 Manufacturers of multi layer and uPVC Roofing sheet

Domain Est. 2011

Website: dioninc.in

Key Highlights: we pride ourselves on being leaders in the manufacturing of high-quality uPVC Roofing sheets. DION uPVC/ASA sheets are optimum choice for roofing and cladding….

#5 PVC, KEE and TPO Single

Domain Est. 1995

Website: siplast.com

Key Highlights: Siplast Single-Ply Roof Membranes, including PVC, KEE, and TPO, are designed to meet the highest standards of performance, durability, and reflectivity….

#6 PVC Roofing membranes

Domain Est. 1997

Website: protan.com

Key Highlights: A type of single-ply roofing material made from a synthetic polymer called polyvinyl chloride (PVC). See our wide selection of PVC membranes….

#7 PVC Membrane

Domain Est. 1998

Website: versico.com

Key Highlights: PVC (polyvinyl chloride) single-ply membranes provide dependable protection and resistance to chemicals, grease, fire, and punctures – making it an ideal ……

#8 PVC Membrane

Domain Est. 2002

Website: carlislesyntec.com

Key Highlights: PVC (polyvinyl chloride) single-ply membranes provide dependable protection and resistance to chemicals, grease, fire, and punctures – making it an ideal ……

#9 PVC Roofing Systems

Domain Est. 2022

Website: holcimelevate.com

Key Highlights: Elevate’s PVC roofing systems deliver proven single-ply roofing performance, with flexibility and durability to cover any project….

Expert Sourcing Insights for Polyvinyl Chloride Sheet Roofing

H2: Projected Market Trends for Polyvinyl Chloride (PVC) Sheet Roofing in 2026

The global Polyvinyl Chloride (PVC) sheet roofing market is expected to experience steady growth by 2026, driven by increasing demand for durable, energy-efficient, and cost-effective roofing solutions across commercial, industrial, and residential sectors. Key trends shaping the 2026 outlook include advancements in material technology, sustainability initiatives, regional construction dynamics, and regulatory influences.

-

Growing Demand in Commercial and Industrial Construction

PVC sheet roofing continues to gain traction in commercial and industrial applications due to its excellent durability, fire resistance, and low maintenance requirements. By 2026, the expansion of logistics centers, cold storage facilities, and manufacturing plants—particularly in emerging markets—will boost demand. The material’s reflective properties also contribute to energy savings, aligning with green building standards such as LEED and BREEAM. -

Sustainability and Recycling Innovations

Environmental concerns are prompting manufacturers to develop recyclable and bio-based PVC formulations. By 2026, the industry is expected to see wider adoption of closed-loop recycling systems, where post-consumer and post-industrial PVC waste is reprocessed into new roofing membranes. Regulatory pressure in regions like the European Union is accelerating these innovations, pushing companies to reduce carbon footprints and improve end-of-life recyclability. -

Technological Advancements in Membrane Performance

Ongoing R&D efforts are focused on enhancing the UV resistance, thermal stability, and mechanical strength of PVC roofing sheets. Innovations such as reinforced scrim layers, improved plasticizer systems (reducing phthalate content), and integration with photovoltaic systems are expected to expand the product’s application scope. Smart roofing solutions incorporating sensors for temperature and moisture monitoring may also emerge by 2026, particularly in high-value commercial installations. -

Regional Market Shifts

North America and Europe will remain dominant markets due to stringent building codes and high retrofitting activity. However, the Asia-Pacific region—led by China, India, and Southeast Asian countries—is projected to register the highest growth rate, fueled by rapid urbanization and infrastructure development. Government initiatives promoting industrial parks and cold chain logistics will further stimulate demand in this region. -

Competition from Alternative Membranes

While PVC maintains a strong position, it faces increasing competition from thermoplastic polyolefin (TPO) and ethylene propylene diene monomer (EPDM) roofing membranes. TPO, in particular, is gaining favor due to its higher reflectivity and absence of chlorine. By 2026, market players will need to differentiate PVC through performance enhancements, lifecycle cost advantages, and environmental certifications to remain competitive. -

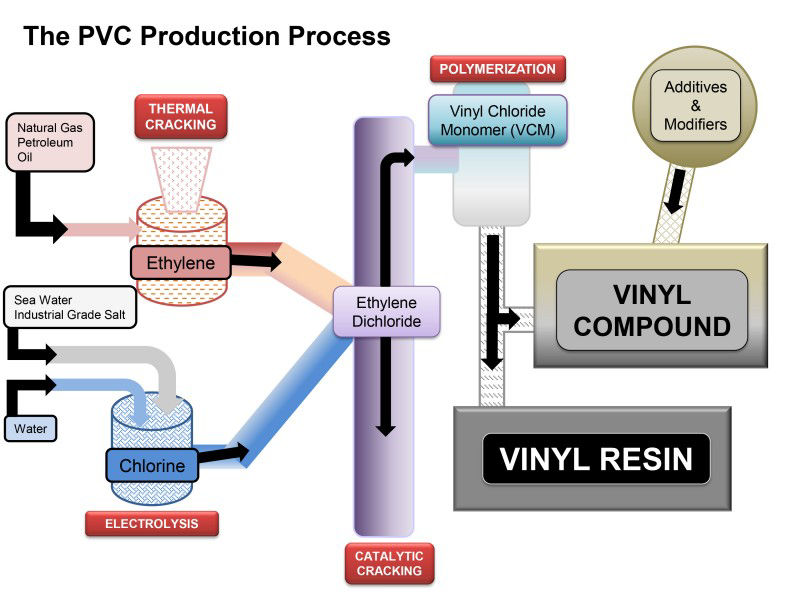

Supply Chain and Raw Material Volatility

Fluctuations in chlorine and ethylene prices—key feedstocks for PVC—will continue to impact production costs. Geopolitical tensions and energy market shifts may exacerbate volatility. As a result, leading manufacturers are expected to pursue vertical integration, long-term supplier contracts, and regional production hubs to ensure supply chain resilience by 2026.

In conclusion, the PVC sheet roofing market in 2026 will be shaped by a confluence of technological innovation, regulatory pressures, and evolving end-user preferences. While challenges remain, strategic investments in sustainability and performance are poised to sustain growth and reinforce PVC’s role in the modern roofing landscape.

Common Pitfalls When Sourcing Polyvinyl Chloride (PVC) Sheet Roofing

Sourcing high-quality Polyvinyl Chloride (PVC) sheet roofing requires careful attention to both material performance and intellectual property (IP) considerations. Overlooking key factors can lead to substandard installations, premature failures, and legal risks. Below are common pitfalls to avoid:

Poor Material Quality and Performance Issues

One of the most frequent challenges in sourcing PVC roofing sheets is ensuring consistent, high-performance material. Low-quality or counterfeit products can compromise the entire roofing system.

-

Inconsistent Thickness and Gauge: Inferior sheets may have uneven thickness, leading to weak spots prone to punctures, tears, and accelerated UV degradation. Always verify manufacturer specifications and conduct spot checks upon delivery.

-

Substandard Additives: High-performance PVC relies on UV stabilizers, plasticizers, and fire retardants. Cheap alternatives often skimp on these additives, resulting in rapid embrittlement, color fading, and reduced fire resistance.

-

Low Tensile and Tear Strength: Poor-quality PVC lacks the mechanical strength needed for long-term durability, especially under thermal expansion, foot traffic, or wind uplift conditions. Insist on certified test reports (e.g., ASTM or ISO standards).

-

Inadequate Weather Resistance: In regions with extreme temperatures or high UV exposure, non-durable PVC can shrink, crack, or delaminate. Ensure the product is rated for your specific climate zone.

-

Lack of Third-Party Certification: Reputable PVC roofing should carry certifications like FM Global, UL, or CE marking. Avoid suppliers who cannot provide valid, up-to-date certification documents.

Intellectual Property (IP) and Brand Authenticity Risks

Protecting intellectual property and ensuring product authenticity are critical when sourcing branded PVC roofing materials.

-

Counterfeit or “Knock-Off” Products: Unauthorized manufacturers often replicate the appearance of premium brands (e.g., Firestone, Sarnafil, or Carlisle) but use inferior formulations. These products may carry fake labels or misleading names, deceiving buyers.

-

Unauthorized Distribution Channels: Purchasing from non-authorized dealers increases the risk of receiving counterfeit or diverted goods. Always source through official distributors or directly from the manufacturer.

-

Lack of Traceability and Documentation: Genuine products typically include batch numbers, material data sheets, and warranty documentation. Absence of these raises red flags about legitimacy and voids manufacturer warranties.

-

Voided Warranties: Installing non-genuine or uncertified PVC sheets often voids the manufacturer’s warranty, leaving the building owner liable for costly repairs or replacements.

-

Legal and Compliance Exposure: Using counterfeit materials may violate building codes and expose contractors or developers to legal liability in the event of system failure.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: verify supplier credentials, request material test reports and certifications, confirm IP rights and distribution authorizations, and perform product inspections upon delivery. Investing time upfront ensures long-term performance, compliance, and protection against financial and legal risks.

Logistics & Compliance Guide for Polyvinyl Chloride (PVC) Sheet Roofing

Product Overview

Polyvinyl Chloride (PVC) sheet roofing is a single-ply membrane widely used in commercial, industrial, and institutional flat or low-slope roofing applications. Known for its durability, chemical resistance, and energy efficiency (due to reflective surfaces), PVC roofing requires careful handling, storage, and adherence to regulatory standards throughout the supply chain.

Transportation & Handling

Packaging Requirements

PVC roofing sheets are typically rolled and packaged in weather-resistant, UV-protected plastic film. Rolls must be secured on wooden or composite pallets with corner boards and strapped to prevent shifting during transit. Labeling must include product name, thickness, width, length, batch number, and handling instructions (e.g., “Roll Upright Only,” “Protect from Sunlight”).

Transportation Conditions

PVC rolls must be transported in enclosed, dry vehicles to prevent exposure to moisture, extreme temperatures, and direct sunlight. Avoid temperatures exceeding 50°C (122°F) to prevent deformation or fusion of layers. Rolls should remain upright at all times to prevent flat-spotting or edge damage.

On-Site Handling

Use mechanical lifting equipment (e.g., forklifts with roll clamps) to move rolls. Do not drag or drop rolls. Store vertically when possible; if horizontal storage is necessary, limit stack height to two rolls and ensure even support. Protect from sharp objects, chemicals, and weather prior to installation.

Storage Guidelines

Environmental Conditions

Store PVC roofing rolls in a cool, dry, well-ventilated area with temperatures between 5°C and 35°C (41°F–95°F). Avoid prolonged exposure to direct sunlight, ozone sources (e.g., electric motors), and UV radiation, which can degrade the polymer over time.

Stacking & Placement

Store rolls upright on a flat, stable surface to prevent deformation. If stored horizontally, limit stacks to two rolls high with adequate support. Keep rolls at least 0.5 meters (1.6 ft) from walls and heat sources. Ensure storage areas are free from standing water and excessive dust.

Shelf Life

Most PVC roofing membranes have a recommended shelf life of 12 to 24 months from the date of manufacture when stored properly. Check manufacturer documentation for specific guidance and inspect rolls for signs of aging (e.g., brittleness, discoloration) before installation.

Regulatory Compliance

Environmental Regulations

PVC roofing is subject to environmental regulations related to volatile organic compounds (VOCs) and plastic additives. In the U.S., comply with EPA standards under the Clean Air Act. In the EU, adhere to REACH and RoHS directives, particularly regarding restricted phthalates and heavy metals. Ensure material safety data sheets (MSDS/SDS) are available and up to date.

Building Codes & Standards

PVC roofing must meet applicable building codes such as the International Building Code (IBC) and International Plumbing Code (IPC). Key performance standards include:

– ASTM D4434: Standard Specification for Polyvinyl Chloride (PVC) Sheet Roofing

– UL 790 / ASTM E108: Fire resistance testing (e.g., Class A, B, or C ratings)

– FM 4470: Approval standard for thermoplastic single-ply roof membranes

Verify local jurisdiction requirements, as some regions may impose additional energy efficiency or wind uplift standards.

Fire Safety & Flammability

PVC roofing exhibits inherent flame resistance due to chlorine content. However, it must be installed with compatible insulation and substrates that meet fire classification requirements. Maintain compliance with NFPA 285 (if required for combustible components in wall assemblies) and local fire codes.

Installation & Worker Safety

Installation Best Practices

Use manufacturer-approved adhesives, fasteners, and seam welding techniques. Ensure substrate is clean, dry, and structurally sound. Weld seams using hot air equipment with calibrated settings to achieve consistent fusion. Conduct post-installation inspections for leaks, wrinkles, or improper adhesion.

Personal Protective Equipment (PPE)

Workers must wear gloves, safety glasses, and respiratory protection when handling adhesives or performing hot-air welding. Follow OSHA (U.S.) or equivalent national regulations for fall protection when working at heights.

Waste Management

Dispose of off-cuts and packaging in accordance with local waste regulations. PVC is recyclable in many regions; consult local recycling facilities. Avoid open burning, which can release hazardous dioxins.

Documentation & Traceability

Maintain complete documentation including:

– Manufacturer certificates of compliance

– Test reports (fire, wind uplift, etc.)

– Batch-specific SDS

– Installation logs and warranties

Ensure traceability from production lot to installation site to support warranty claims and regulatory audits.

Conclusion

Effective logistics and compliance management for PVC sheet roofing ensures product integrity, regulatory adherence, and long-term performance. By following proper handling, storage, transportation, and installation protocols—and maintaining up-to-date documentation—stakeholders can mitigate risks and support sustainable, code-compliant roofing solutions.

In conclusion, sourcing polyvinyl chloride (PVC) sheet roofing offers a durable, cost-effective, and sustainable solution for a wide range of roofing applications. Its excellent resistance to weathering, UV radiation, chemicals, and fire, combined with low maintenance requirements, makes PVC a reliable choice for both commercial and industrial buildings. The availability of various thicknesses, colors, and installation methods allows for flexibility in design and integration with different architectural styles. Additionally, the long service life and recyclability of PVC contribute to its environmental sustainability, aligning with green building standards.

When sourcing PVC roofing sheets, it is essential to select reputable suppliers who provide high-quality, certified products that meet relevant industry standards (such as ASTM or ISO). Factors such as warranty, technical support, and proper installation practices should also be considered to ensure optimal performance and longevity. Overall, with careful selection and professional installation, PVC sheet roofing presents a smart investment that delivers long-term value, energy efficiency, and peace of mind.