The global polyethylene foam adhesive market is experiencing robust expansion, driven by rising demand across packaging, automotive, construction, and consumer goods industries. According to Grand View Research, the global adhesive and sealant market was valued at USD 61.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030—with polyethylene foam adhesives representing a key growth segment due to their durability, flexibility, and resistance to moisture and temperature extremes. Similarly, Mordor Intelligence projects the adhesive market to exceed a 5.5% CAGR through 2029, citing increased industrial automation and the proliferation of lightweight materials in manufacturing as primary drivers. As demand for high-performance bonding solutions rises, a select group of manufacturers have emerged as leaders in developing specialized polyethylene foam glues that meet rigorous performance and sustainability standards. Below, we profile the top 10 manufacturers shaping this dynamic sector through innovation, scale, and technical expertise.

Top 10 Polyethylene Foam Glue Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 LAMATEK,Inc.

Domain Est. 1995 | Founded: 1983

Website: lamatek.com

Key Highlights: Polyethylene (PE) Foam Tape … Since 1983, LAMATEK™ has been a preferred manufacturer of foam tapes, sealing gaskets, packaging, and custom foam parts….

#2 Polyethylene Foam

Domain Est. 2000

#3 Polyethylene with Pressure Sensitive Adhesive

Domain Est. 1996

Website: products.allfoam.com

Key Highlights: Polyethylene with Pressure Sensitive Adhesive PE-with-PSA All Foam Products Company | Delivering quality foam with exceptional service.Missing: glue manufacturer…

#4 Polyethylene Foam Adhesives

Domain Est. 1997

Website: gluegun.com

Key Highlights: PE Foam Adhesives to Test. With over fifty years of adhesive expertise, we’ve helped manufacturers solve the challenges related to gluing polyethylene foam….

#5 Worldwide Foam

Domain Est. 2008

Website: worldwidefoam.com

Key Highlights: We offer one-day lead time from our seven strategic locations while providing the widest ranges of closed cell cross-linked polyethylene foam….

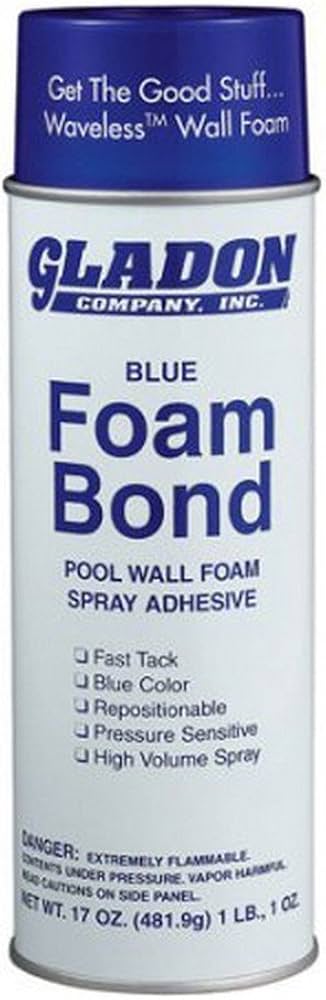

#6 Blue Foam Bond Adhesive

Domain Est. 1996

Website: universityproducts.com

Key Highlights: This Blue Foam Bond adhesive was designed to bond polyethylene foam to a wide variety of surfaces including metal, wood, concrete and more….

#7 Flexible Foams

Domain Est. 1999

Website: americanexcelsior.com

Key Highlights: Flexible foam can provide protection in packaging, comfort in furniture and support in medical and athletic applications….

#8 Polyethylene Foam, Roll, Tubes, Polyethylene Closed Cell Foam …

Domain Est. 2001

Website: thefoamfactory.com

Key Highlights: Polyethylene foam is a strong and resilient closed-cell foam, ideally suited as a shock-absorbing material in packaging and padding….

#9 Polyethylene Foam Tape: It’s Everywhere!

Domain Est. 2008

Website: adhesiveapps.com

Key Highlights: Polyethylene (PE) foam tape is a type of adhesive tape made with polyethylene foam as its base or carrier. It comes in a variety of thicknesses, colors, and ……

#10 Superior Bonding with Polyethylene Foam Tapes

Domain Est. 2016

Website: magnumtapes.com

Key Highlights: FoamLock polyethylene foam tapes are engineered for strength and flexibility. Trust our PE foam tape for reliable solutions in demanding environments….

Expert Sourcing Insights for Polyethylene Foam Glue

H2: 2026 Market Trends for Polyethylene Foam Glue

The global market for polyethylene foam glue is anticipated to experience steady growth by 2026, driven by increasing demand across various end-use industries such as construction, automotive, packaging, and consumer goods. Several key trends are expected to shape the market landscape during this period.

1. Rising Demand in Construction and Insulation Applications

Polyethylene foam glue is widely used in construction for bonding and sealing insulation materials, roofing systems, and HVAC ductwork. With growing emphasis on energy efficiency and sustainable building practices, demand for high-performance insulation solutions is increasing. This, in turn, is boosting the need for reliable adhesives like polyethylene foam glue that offer strong bonding, durability, and resistance to moisture and temperature fluctuations.

2. Expansion in the Automotive Sector

The automotive industry is adopting lightweight materials to improve fuel efficiency and reduce emissions. Polyethylene foam is increasingly used for interior components such as door panels, headliners, and dashboards. The need for effective adhesives to bond these foams is driving demand for polyethylene foam glue, particularly formulations that provide flexibility, vibration damping, and long-term adhesion under varying conditions.

3. Growth in E-commerce and Protective Packaging

The surge in e-commerce has led to increased use of protective packaging, where polyethylene foam is a preferred material due to its shock-absorbing properties. Polyethylene foam glue plays a critical role in fabricating custom packaging inserts and cushioning layers. As online retail continues to expand globally, demand for adhesive solutions tailored to foam-based packaging is expected to rise through 2026.

4. Technological Advancements and Product Innovation

Manufacturers are focusing on developing environmentally friendly, low-VOC (volatile organic compound), and solvent-free polyethylene foam glue formulations to comply with stricter environmental regulations. Innovations in water-based and hot-melt adhesives are gaining traction, offering improved performance and reduced environmental impact. These advancements are expected to broaden the application scope and enhance market competitiveness.

5. Regional Market Dynamics

Asia-Pacific is projected to be the fastest-growing market due to rapid industrialization, urbanization, and infrastructure development in countries like China, India, and Southeast Asian nations. North America and Europe will also see moderate growth, supported by stringent energy regulations and the automotive industry’s focus on lightweighting and sustainability.

6. Supply Chain and Raw Material Challenges

Fluctuations in the prices of polyethylene and other petrochemical-based raw materials may impact production costs. However, companies are increasingly investing in supply chain resilience and alternative feedstocks to mitigate these risks.

In conclusion, the polyethylene foam glue market in 2026 will be shaped by technological innovation, regulatory pressures, and expanding applications across key industries. Companies that prioritize sustainable product development and regional market expansion are likely to gain a competitive edge.

Common Pitfalls When Sourcing Polyethylene Foam Glue (Quality & Intellectual Property)

Sourcing polyethylene foam glue—particularly for bonding low-surface-energy materials like cross-linked polyethylene (XLPE) or polyethylene foam—requires careful consideration of both quality standards and intellectual property (IP) risks. Overlooking these aspects can lead to product failure, supply chain disruptions, or legal exposure.

Poor Adhesive Performance Due to Inadequate Quality Control

One of the most frequent pitfalls is assuming that all polyethylene foam glues perform similarly. Low-quality or poorly manufactured adhesives may lack the necessary:

- Adhesion strength: Inadequate bonding can lead to delamination in applications under stress or thermal cycling.

- Temperature resistance: Many cheap adhesives fail in high-heat environments, causing bond degradation.

- Chemical and UV resistance: Exposure to solvents, moisture, or sunlight can compromise inferior formulations.

- Consistency: Batch-to-batch variability affects manufacturing reliability and final product quality.

Always request technical data sheets (TDS), safety data sheets (SDS), and third-party test reports. Conduct in-house performance testing under real-world conditions before full-scale sourcing.

Misrepresentation of Adhesive Type or Technology

Suppliers—especially in competitive or less-regulated markets—may mislabel adhesives or exaggerate performance claims. For example:

- Marketing a cyanoacrylate (super glue) or PVA as suitable for polyethylene, despite poor inherent adhesion.

- Claiming a “specialty polyolefin adhesive” without providing evidence of surface treatment compatibility (e.g., corona, flame, or plasma treatment).

- Offering solvent-based adhesives with high VOC content, contrary to environmental regulations or safety standards.

Verify the actual chemistry (e.g., modified acrylics, reactive urethanes, or primers) and ensure it aligns with your substrate and application method (spray, roll-on, etc.).

Intellectual Property Infringement Risks

Sourcing low-cost alternatives can inadvertently lead to IP violations:

- Patented Formulations: Leading manufacturers (e.g., 3M, Henkel, Sika) hold patents on specific adhesive chemistries or application methods. Using a knock-off that replicates a patented formula—even unknowingly—can expose your company to litigation.

- Trademark Infringement: Some suppliers may use brand-like names or packaging that mimics well-known products, misleading buyers into thinking they are purchasing an authorized product.

- Reverse Engineering Violations: Adhesives that appear to replicate the performance of branded products may be the result of illegal reverse engineering, especially if they copy trade-secret formulations.

Conduct due diligence on suppliers: request proof of IP ownership or licensing, and avoid vendors offering “exact equivalents” at suspiciously low prices.

Lack of Regulatory Compliance

Polyethylene foam glue may be subject to regional regulations such as:

- REACH and RoHS in the EU

- TSCA in the US

- VOC emissions standards (e.g., SCAQMD, EPA)

Non-compliant adhesives can result in shipment rejections, fines, or recall of finished goods. Ensure suppliers provide up-to-date compliance documentation and material disclosures.

Insufficient Technical Support and Traceability

Low-cost suppliers may lack the technical infrastructure to support troubleshooting or batch traceability. If adhesive failure occurs in production or in the field, the absence of lot tracking or expert support can delay root cause analysis and corrective action.

Choose suppliers who offer technical datasheets, application guidance, and batch-specific traceability to mitigate post-sourcing risks.

Conclusion

To avoid these pitfalls, prioritize reputable suppliers with verifiable quality certifications (e.g., ISO 9001), transparent IP practices, and robust technical support. Always validate performance independently and conduct IP risk assessments—especially when sourcing from new or non-traditional markets.

Logistics & Compliance Guide for Polyethylene Foam Glue

Product Overview

Polyethylene Foam Glue is a solvent-based or water-based adhesive specifically formulated for bonding polyethylene foam materials. It is commonly used in packaging, insulation, automotive, and crafting industries. Proper handling, storage, transportation, and compliance with regulatory standards are essential to ensure safety and legal adherence.

Hazard Classification (GHS)

Polyethylene Foam Glue may contain flammable solvents (e.g., toluene, acetone) or acrylate monomers, leading to the following potential hazard classifications:

– Flammable Liquid (Category 2 or 3) – if solvent-based

– Skin Irritation (Category 2)

– Eye Damage (Category 1)

– Specific Target Organ Toxicity (Single Exposure) (Category 3 – Respiratory Tract Irritation)

– Hazardous to the Aquatic Environment (Chronic, Category 2 or 3)

Note: Always consult the Safety Data Sheet (SDS) provided by the manufacturer for precise classification.

Storage Requirements

- Temperature: Store in a cool, dry, well-ventilated area between 10°C and 25°C. Avoid exposure to direct sunlight and heat sources.

- Containers: Keep in tightly closed, original containers made of compatible materials (typically HDPE or metal).

- Segregation: Store away from oxidizers, strong acids, and bases. Do not store near ignition sources.

- Flammables Cabinet: If solvent-based and classified as flammable, store in a flammable liquids storage cabinet complying with NFPA 30 or local fire codes.

- Shelf Life: Typically 12–24 months; monitor expiration dates and rotate stock (FIFO).

Transportation Guidelines

- Classification:

- UN Number: Varies by formulation (e.g., UN1263 for flammable liquid, n.o.s.)

- Proper Shipping Name: “Flammable liquid, n.o.s. (Polyethylene Foam Glue)”

- Class: 3 (Flammable Liquid), Packing Group II or III depending on flash point

- Packaging: Use UN-certified packaging with compatible seals. Inner containers must prevent leakage; outer packaging must withstand normal handling.

- Labeling:

- Diamond-shaped GHS labels with flame pictogram (for flammable versions)

- Transport hazard labels per DOT (49 CFR), ADR/RID (Europe), or IATA/IMDG (air/sea) as applicable

- Documentation:

- Safety Data Sheet (SDS) required for all shipments

- Shipper’s Declaration for Dangerous Goods (if required by mode of transport)

- Segregation: Do not transport with oxidizers, compressed gases, or foodstuffs.

Handling & Personal Protective Equipment (PPE)

- Ventilation: Use in well-ventilated areas or with local exhaust ventilation. Avoid vapor accumulation.

- PPE Requirements:

- Chemical-resistant gloves (nitrile or neoprene)

- Safety goggles or face shield

- Respiratory protection (organic vapor cartridge respirator) if ventilation is inadequate

- Protective clothing to prevent skin contact

- Spill Procedures:

- Contain spill with absorbent material (e.g., sand, spill pads).

- Do not allow entry into drains or waterways.

- Collect contaminated material and dispose of as hazardous waste.

- Ventilate area and avoid ignition sources.

Regulatory Compliance

- OSHA (USA): Comply with Hazard Communication Standard (29 CFR 1910.1200). Provide SDS and employee training.

- EPA (USA): Follow regulations under TSCA and CERCLA for chemical reporting and spill notification (if applicable).

- REACH & CLP (EU): Ensure registration, labeling, and safety data sheet compliance. Notify SCIP database if SVHCs are present above threshold.

- GHS Implementation: All labels and SDS must be GHS-compliant (Rev. 9 or latest).

- DOT (49 CFR): Adhere to hazardous materials transportation rules for domestic shipments.

Disposal & Environmental Considerations

- Waste Classification: May be classified as hazardous waste due to flammability or toxicity (check local regulations).

- Disposal Method: Dispose through licensed hazardous waste contractors. Do not pour down drains or dispose of in regular trash.

- Empty Containers: Rinse thoroughly and manage as hazardous waste unless fully decontaminated.

- Environmental Precautions: Prevent release into soil or water. Report significant spills to environmental authorities per local laws.

Emergency Response

- Inhalation: Move to fresh air. Seek medical attention if symptoms persist.

- Skin Contact: Wash with soap and water. Remove contaminated clothing.

- Eye Contact: Rinse immediately with water for at least 15 minutes. Consult a physician.

- Ingestion: Do not induce vomiting. Rinse mouth and seek immediate medical help.

- Fire Fighting: Use foam, CO₂, or dry chemical extinguishers. Water may be ineffective. Evacuate area and wear full protective gear.

Training & Documentation

- Ensure all personnel handling the glue are trained in:

- SDS review

- Spill response

- Fire safety

- PPE use

- Maintain records of training, SDS, shipping documents, and incident reports for minimum of 3 years (or as required by jurisdiction).

Always consult the manufacturer’s SDS and local regulatory authorities for site-specific requirements.

In conclusion, sourcing the appropriate adhesive for polyethylene foam requires careful consideration of several factors, including bond strength, flexibility, environmental resistance, application method, and compatibility with both the foam and substrate materials. Due to polyethylene’s low surface energy and non-porous nature, standard adhesives often fail, making it essential to select specialized products such as cyanoacrylates (super glues), polyurethane-based adhesives, solvent-based contact cements, or modified acrylics designed for difficult-to-bond plastics. Surface preparation—such as cleaning, abrasion, or plasma treatment—can significantly improve adhesion. Additionally, evaluating suppliers based on product consistency, technical support, cost-effectiveness, and availability ensures reliable performance in both small-scale and industrial applications. Ultimately, successful bonding of polyethylene foam hinges on pairing the right adhesive with proper application techniques and a trusted supply chain.