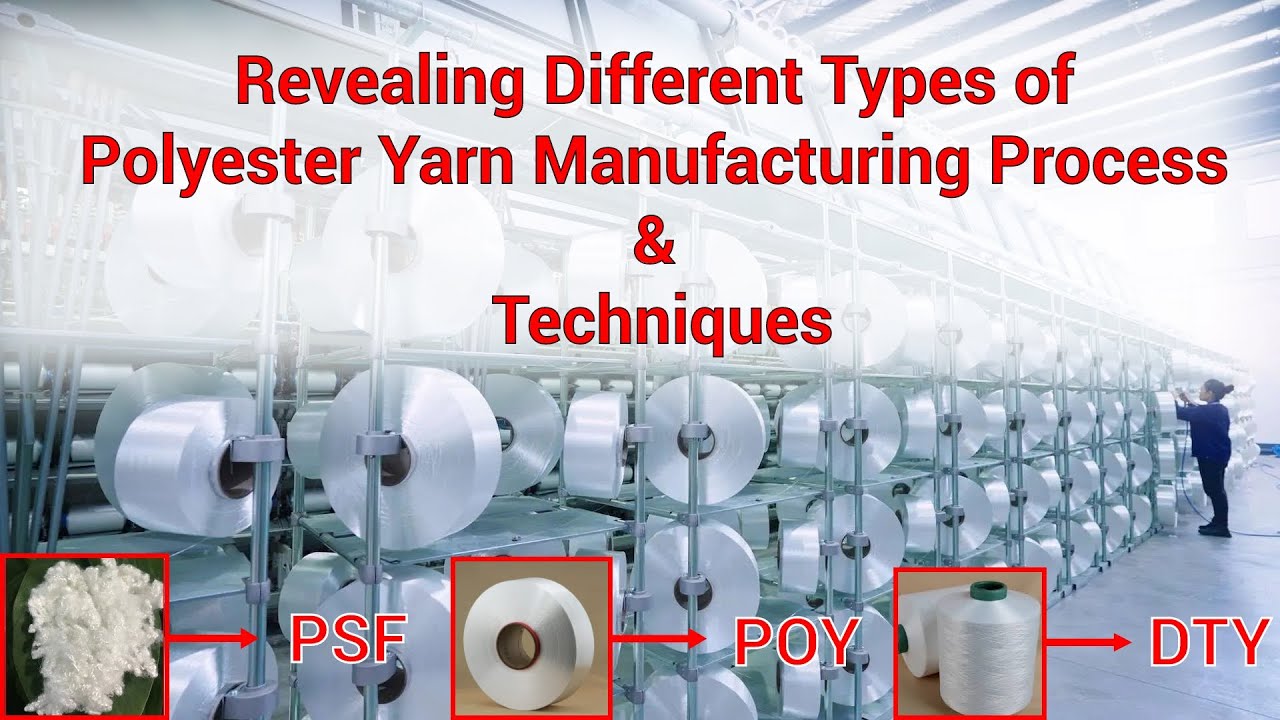

The global polyester yarn market is experiencing robust growth, driven by rising demand in the textile, apparel, and home furnishings industries. According to a report by Grand View Research, the global polyester fiber market was valued at USD 77.9 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is further bolstered by the increasing preference for durable, cost-effective, and low-maintenance synthetic fibers, particularly in developing economies. Among polyester yarn variants, Drawn Textured Yarn (DTY) holds a significant share due to its superior bulk, elasticity, and softness, making it ideal for woven and knitted fabrics in sportswear, activewear, and fashion apparel. As demand surges, a select group of manufacturers have emerged as leaders in DTY production, combining scale, technological innovation, and vertical integration to dominate supply chains worldwide. Based on production capacity, global reach, and market influence, the following are the top 5 polyester yarn DTY manufacturers shaping the industry’s future.

Top 5 Polyester Yarn Dty Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 DTY Yarns Manufacturers, China Polyester DTY Yarns Factory

Domain Est. 2018 | Founded: 2007

Website: dkyarn.com

Key Highlights: As a famous China polyester yarns manufacturers and polyester DTY yarns factory . Hangzhou Dingkai Chemical Fiber Co., Ltd is established in 2007….

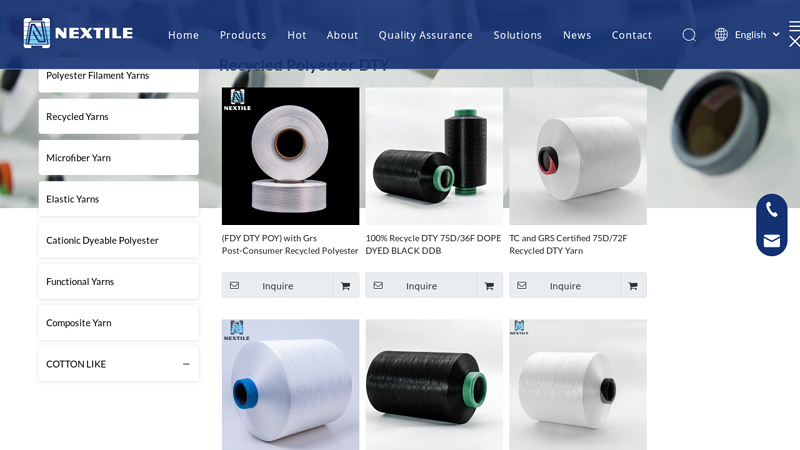

#2 Recycled Polyester DTY

Domain Est. 2020

Website: nextilefiber.com

Key Highlights: Recycled Polyester DTY offered by China manufacturer Shanghai Nextile Fiber Technology Co. Ltd.. Buy high quality Recycled Polyester DTY right now!…

#3 Wholesale Polyester Dope Dyed Yarns Manufacturers, Suppliers

Domain Est. 2006

Website: klthread.com

Key Highlights: The company specializes in producing diversified polyester fibers (POY, FDY, DTY, embroidery thread, carpet yarn,fancy yarn,high fastness yarn etc.)…

#4 Polyester Yarn Solutions for Global Textile Manufacturers and …

Domain Est. 2023

Website: m.poyarn.com

Key Highlights: Poyarn offers high-quality polyester yarn for diverse textile needs like window screens, sofa fabrics, and more. Get eco-friendly, durable polyester yarn ……

#5 Dope dyed polyester yarn

Domain Est. 2013

Website: polyesteryarn.com.cn

Key Highlights: Produce 50-600 denier virgin and recycled dope dyed polyester yarn,polyester fdy yarn,polyester dty yarn,polyester textured yarn….

Expert Sourcing Insights for Polyester Yarn Dty

Market Trends for Polyester DTY Yarn in 2026 (H2 Outlook)

As we approach the second half of 2026, the global market for Polyester Drawn Textured Yarn (DTY) is undergoing significant transformation driven by evolving consumer demand, technological advancements, sustainability pressures, and macroeconomic shifts. Below is a comprehensive analysis of key market trends shaping the Polyester DTY landscape during H2 2026.

1. Demand Recovery in Apparel and Home Textiles

After a period of inventory correction in 2024–2025, demand for Polyester DTY yarn is rebounding in H2 2026, particularly in the apparel and home textiles sectors. Key drivers include:

- Restocking Cycles: Brands and retailers, especially in North America and Europe, are replenishing inventories following lean stock policies in prior years.

- Fast Fashion Resilience: Despite sustainability concerns, fast fashion continues to drive demand for cost-effective, versatile DTY yarns used in knits, sportswear, and casual wear.

- Seasonal Uptick: The back-to-school and holiday seasons are boosting demand for polyester-based garments, positively impacting DTY consumption.

2. Sustainability and Recycled DTY Growth

Environmental regulations and consumer preferences are accelerating the shift toward sustainable textiles. In H2 2026:

- Recycled Polyester DTY (rPET-DTY) is expected to account for over 30% of total DTY production, up from ~22% in 2023.

- Major brands (e.g., Nike, H&M, Uniqlo) are enforcing stricter sustainability mandates, pushing suppliers to adopt certified recycled content.

- Chemical Recycling Technologies are gaining traction, enabling higher-quality rPET-DTY with properties comparable to virgin fiber.

3. Capacity Expansion and Regional Shifts

Asia remains the dominant producer, but strategic shifts are evident:

- China: Focus is shifting from volume to value, with investments in high-tenacity, specialty, and functional DTY (e.g., anti-UV, moisture-wicking).

- India and Southeast Asia (Vietnam, Indonesia): Emerging as key growth hubs due to favorable labor costs, government incentives, and rising domestic demand.

- Middle East (e.g., Saudi Arabia): New integrated polyester complexes are increasing DTY export potential, leveraging low-cost feedstock (paraxylene).

4. Feedstock Price Volatility and Margin Pressure

PTA (Purified Terephthalic Acid) and MEG (Monoethylene Glycol)—key raw materials—remain subject to oil price fluctuations and supply dynamics:

- Geopolitical tensions and OPEC+ policies have caused moderate volatility in crude oil prices, affecting PTA and MEG costs.

- In H2 2026, margins for DTY producers are under pressure due to:

- Rising energy costs in Europe and parts of Asia.

- Limited pass-through of cost increases to price-sensitive downstream buyers.

- Vertical integration is becoming a competitive necessity, with leading players (e.g., Indorama, Reliance, Sinopec) securing upstream control to stabilize margins.

5. Technological Innovation and Smart Textiles

The DTY market is witnessing increased R&D in value-added applications:

- Functional Yarns: Antimicrobial, thermo-regulating, and conductive DTY variants are gaining traction in activewear and technical textiles.

- Digitalization: Adoption of AI-driven production optimization and digital yarn tracing (blockchain) for supply chain transparency is rising among Tier-1 suppliers.

- Customization: On-demand DTY production with variable denier, twist, and bulk levels is being enabled by Industry 4.0 technologies.

6. Trade Dynamics and Geopolitical Factors

- De-risking Supply Chains: Western brands are diversifying sourcing away from over-reliance on China, benefiting Indian and Southeast Asian DTY exporters.

- Tariff and Trade Policies: Ongoing U.S.-China trade tensions and EU Carbon Border Adjustment Mechanism (CBAM) are influencing export strategies. Producers with low carbon footprints gain a competitive edge in European markets.

7. Outlook and Forecast (H2 2026)

- Global DTY Demand: Projected to grow at 3.8% YoY in 2026, reaching ~38 million metric tons.

- Average Price Range: $1,350–$1,550/ton, depending on region, quality, and recycled content.

- Key Growth Markets: India, Bangladesh, Turkey, and Eastern Europe for apparel; automotive and geotextiles sectors showing increased DTY adoption.

Conclusion

The Polyester DTY yarn market in H2 2026 is characterized by a dual dynamic: persistent cost and margin challenges offset by strong growth in sustainable, high-performance variants. Companies that invest in recycling infrastructure, vertical integration, and innovation are best positioned to capture value. Meanwhile, geopolitical realignments and ESG compliance will continue to reshape global supply chains, making agility and transparency critical success factors.

Strategic Recommendation: Diversify feedstock sources, scale rPET-DTY capacity, and leverage digital tools for traceability and efficiency to thrive in the evolving 2026 landscape.

Common Pitfalls When Sourcing Polyester Yarn DTY (Quality, IP)

Sourcing Polyester Drawn Textured Yarn (DTY) involves navigating several critical challenges, particularly concerning product quality and intellectual property (IP). Being aware of these pitfalls helps mitigate risks and ensures a reliable supply chain.

Quality Inconsistencies

One of the most frequent issues in sourcing DTY is inconsistent yarn quality across production batches. Variations in denier (thickness), tensile strength, elongation, and dye uptake can lead to defects in downstream manufacturing, such as fabric pilling, uneven dyeing, or broken ends during weaving/knitting. These inconsistencies often stem from inadequate quality control processes, fluctuating raw material inputs, or suboptimal spinning parameters at the supplier’s facility. Buyers must implement strict quality assurance protocols, including on-site audits and third-party lab testing, to verify compliance with technical specifications.

Lack of Traceability and Certification

Many suppliers, especially in competitive low-cost regions, may lack proper documentation or traceability for raw materials (e.g., purified terephthalic acid or PTA sources). This exposes buyers to risks related to sustainability claims, recycled content verification (e.g., GRS certification), and chemical compliance (e.g., OEKO-TEX®). Without transparent supply chain documentation, brands may face reputational damage or regulatory non-compliance, particularly under increasing environmental and social governance (ESG) scrutiny.

Intellectual Property (IP) Risks

Sourcing DTY from certain regions—especially where enforcement of IP laws is weak—poses significant risks of counterfeit or reverse-engineered specialty yarns. Proprietary technologies such as cross-section profiles (e.g., trilobal, hollow), functional finishes (e.g., antimicrobial, UV-resistant), or branded fiber innovations (e.g., branded microfibers) may be copied without authorization. Suppliers might falsely claim compliance with patented technologies or provide misleading certifications. Conducting due diligence on supplier legitimacy, verifying technology licenses, and including IP protection clauses in contracts are essential preventive measures.

Hidden Costs from Poor Dyeing Performance

Although not always apparent upfront, poor dyeing reproducibility is a common hidden cost. DTY yarns with inconsistent molecular orientation or inadequate heat-setting may exhibit batch-to-batch color variation, requiring costly reprocessing or leading to customer rejection. Buyers should request lab dip tests and full-scale dye trials before bulk orders and ensure suppliers adhere to standardized dyeing protocols.

Inadequate Technical Support and Responsiveness

Some suppliers, particularly smaller manufacturers, may lack the technical expertise to support troubleshooting or adapt to specific customer requirements (e.g., custom twists, finishes, or packaging). Poor communication and slow response times can delay production timelines, especially when quality issues arise. Establishing clear service-level agreements (SLAs) and requiring dedicated technical account managers can help maintain operational efficiency.

By proactively addressing these pitfalls through rigorous supplier vetting, contractual safeguards, and ongoing quality monitoring, businesses can secure reliable, high-performance DTY yarn while protecting their brand integrity and innovation.

H2: Logistics & Compliance Guide for Polyester DTY Yarn

Polyester Drawn Textured Yarn (DTY) is a widely used synthetic fiber in the textile industry, known for its elasticity, softness, and durability. Efficient logistics and strict compliance are essential when shipping and handling this product across international borders. This guide outlines key logistics considerations and compliance requirements for Polyester DTY Yarn.

1. Product Classification & Identification

- HS Code (Harmonized System Code):

Typically 5402.33 or 5402.34, depending on the specific characteristics (e.g., filament count, denier, twist).

Example: - 5402.33: DTY with linear density ≤ 67 decitex

- 5402.34: DTY with linear density > 67 decitex

Note: Confirm the accurate HS code based on yarn specifications and destination country’s tariff schedule.

- Chemical Composition:

100% polyester (polyethylene terephthalate – PET) – ensure documentation reflects this for customs and safety compliance.

2. Packaging & Handling

Packaging Requirements:

- Standard Packaging:

- Spools or cones wound on cardboard/plastic bobbins.

- Packaged in polypropylene (PP) woven bags or cardboard cartons.

- Inner plastic lining to prevent moisture absorption.

-

Average net weight per package: 10–25 kg.

-

Palletization:

- Stacked on wooden or plastic pallets (standard EUR/ISO dimensions).

- Wrapped with stretch film to prevent shifting during transit.

- Max stack height: 2–3 layers to avoid crushing lower layers.

Handling Guidelines:

- Store in dry, ventilated areas; avoid direct sunlight and moisture.

- Handle with forklifts or pallet jacks to prevent damage.

- Do not drop or roll packages; yarn integrity may be compromised.

3. Transportation Logistics

Shipping Modes:

-

Ocean Freight (FCL/LCL):

Preferred for bulk shipments.

Use 20’ or 40’ dry containers. Ensure proper ventilation and moisture control (e.g., desiccant bags). -

Air Freight:

Suitable for urgent or small-volume consignments. Higher cost; ensure proper packaging to meet airline standards. -

Land Transport (Truck/Rail):

Used for regional distribution. Cover cargo to protect from weather and debris.

Temperature & Humidity:

- Maintain ambient conditions (15–30°C, 40–65% RH) during storage and transit.

- Avoid condensation inside containers (use moisture barriers if shipping across climates).

4. Regulatory & Compliance Requirements

Customs Documentation:

- Commercial Invoice (with complete product description, HS code, value, origin)

- Packing List

- Bill of Lading (B/L) or Air Waybill (AWB)

- Certificate of Origin (often required for preferential tariffs under trade agreements)

- Phytosanitary Certificate (not typically required for synthetic yarns, but confirm with destination)

Import Regulations:

- REACH (EU): Confirm compliance with SVHC (Substances of Very High Concern) under REACH regulations. Polyester DTY is generally compliant, but verify any additives or finishes used.

- Oeko-Tex® Standard 100 (if applicable): Required for yarns intended for apparel or home textiles in Europe. Certification may be requested by buyers.

- Customs Duties & VAT: Check duty rates and import taxes in destination country. Some countries offer reduced tariffs for industrial inputs.

Environmental & Safety Compliance:

- GHS/CLP Regulations: Although polyester DTY is non-hazardous, SDS (Safety Data Sheet) may be required per buyer or local regulations.

- Waste & Recycling: Comply with local regulations for plastic packaging waste (e.g., EU Packaging Waste Directive).

5. Labeling & Traceability

- Each package must be labeled with:

- Product name: “100% Polyester DTY Yarn”

- Specifications: Denier, filament count, color, twist (TPI), lot/batch number

- Net weight

- Manufacturer name and address

- Country of origin

-

Handling symbols (e.g., “Protect from Moisture”, “Do Not Drop”)

-

Maintain batch traceability for quality control and recall preparedness.

6. Risk Mitigation & Best Practices

- Insurance: Cover cargo for loss, damage, or delay (All-Risk coverage recommended).

- Incoterms: Clearly define responsibilities (e.g., FOB, CIF, DDP) in sales contracts.

- Quality Inspection: Conduct pre-shipment inspection (PSI) if required by buyer or destination regulations.

- Vendor Compliance: Ensure suppliers comply with social and environmental standards (e.g., BSCI, ZDHC, or ISO 14001).

7. Key Markets & Special Considerations

- USA: No specific chemical restrictions for raw polyester, but Customs and Border Protection (CBP) may inspect textile entries.

- EU: Strict on chemical compliance (REACH) and labeling. Prefer Oeko-Tex® or bluesign® certified products.

- India/China: Local tariffs and documentation may vary; use local customs brokers.

- Turkey/Bangladesh: Major textile hubs; ensure smooth customs clearance with accurate documentation.

Conclusion

Successful logistics and compliance for Polyester DTY Yarn require attention to proper classification, packaging, documentation, and regulatory standards. By adhering to this guide, exporters and importers can ensure smooth cross-border movement, reduce delays, and maintain product quality and legal compliance.

Always consult with freight forwarders, customs brokers, and regulatory experts for destination-specific requirements.

Conclusion for Sourcing Polyester DTY Yarn

Sourcing Polyester Drawn Textured Yarn (DTY) requires a strategic approach that balances quality, cost, reliability, and sustainability. As a widely used synthetic fiber in the textile industry, DTY offers excellent elasticity, softness, and bulkiness, making it ideal for a diverse range of applications including apparel, home textiles, and technical fabrics.

Key considerations when sourcing DTY yarn include selecting reputable suppliers with consistent production standards, ensuring compliance with environmental and social certifications, and evaluating logistical efficiency to minimize lead times and transportation costs. With major production hubs in countries like China, India, and Indonesia, global sourcing presents both opportunities and challenges—particularly in the face of fluctuating raw material prices and supply chain disruptions.

To ensure a resilient supply chain, buyers should diversify their supplier base, invest in long-term partnerships, and stay informed about market trends and innovations in recycled and eco-friendly polyester. Additionally, conducting regular quality audits and leveraging digital sourcing tools can enhance transparency and efficiency.

In conclusion, successful sourcing of polyester DTY yarn hinges on a holistic strategy that integrates quality assurance, cost-effectiveness, sustainability, and supply chain agility. By prioritizing these factors, textile manufacturers and brands can secure a reliable supply of high-performance DTY yarn to meet evolving market demands.