The global polyester fabric market for furniture and upholstery applications is expanding rapidly, driven by rising consumer demand for durable, cost-effective, and low-maintenance materials. According to Grand View Research, the global synthetic textile market—of which polyester is a dominant segment—was valued at USD 87.4 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. This surge is fueled by increased urbanization, growing e-commerce penetration for home furnishings, and the widespread adoption of polyester in residential and commercial furniture due to its resistance to shrinking, stretching, and fading. As polyester emerges as a preferred upholstery material for sofas, especially in ready-to-assemble (RTA) and modular furniture segments, manufacturers are scaling production capacity and investing heavily in eco-friendly and recycled polyester innovations. Against this backdrop, we identify the top 9 polyester sofa material manufacturers leading the market through innovation, vertical integration, and sustainable practices.

Top 9 Polyester Sofa Material Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Davis Fabrics

Domain Est. 2013

Website: davis.pl

Key Highlights: Fabric. Technology. Easy Clean. Water Repellent. Pet Friendly. Recycled Polyester. Basic DAVIS. Outdoor. Color. Search. Area for logged in. Log in. loading……

#2 Flexsteel

Domain Est. 1996

Website: flexsteel.com

Key Highlights: Discover exceptional craftsmanship and style with Flexsteel, your premier manufacturer for high-quality furniture. Explore our extensive range of living ……

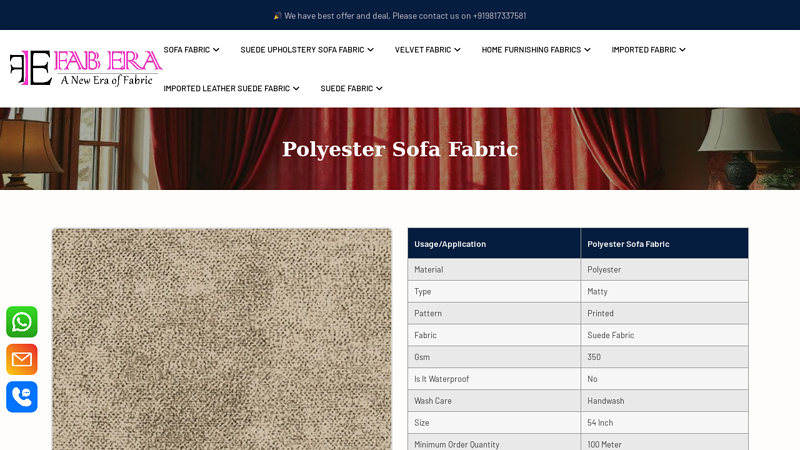

#3 Polyester Sofa Fabric Manufacturer

Website: sofafabricstore.com

Key Highlights: We have a wide variety of sofa fabrics to suit every taste and preference. The range includes luxurious velvet, breathable cotton, premium synthetic blends, ……

#4 CF Stinson

Domain Est. 1996

Website: cfstinson.com

Key Highlights: Stinson is a company of designers, thinkers and makers, dedicated to creating textile solutions that work for our clients and make them look great….

#5 Mayo Furniture

Domain Est. 1997

Website: mayofurniture.com

Key Highlights: Mayo’s quality craftsmanship, top construction components, and advanced processes all contribute to the long-lasting beauty and comfort of our upholstered ……

#6 Polartec®

Domain Est. 1998

Website: polartec.com

Key Highlights: Polartec® is the premium provider of innovative and sustainable textile solutions….

#7 Ruby Mills

Domain Est. 2002

Website: rubymills.com

Key Highlights: Ruby is known for its relentless pursuit of innovation. Exploration and experiments with new blends refined through state-of-the art processing and finishing ……

#8 England Furniture

Domain Est. 2002

Website: englandfurniture.com

Key Highlights: Check out our latest styles & fabrics under New Intros! England Furniture. Search. Dealers. Account. Log In · Log Out · View Account · Favorites. New Intros….

#9 Designtex

Domain Est. 2005

Website: designtex.com

Key Highlights: We design and manufacture applied materials for the built environment. For over sixty years, we have been inspired to improve how materials fit into life….

Expert Sourcing Insights for Polyester Sofa Material

2026 Market Trends for Polyester Sofa Material

The global market for polyester sofa material is poised for notable evolution by 2026, driven by shifting consumer preferences, technological advancements, and sustainability demands. As one of the most widely used synthetic fabrics in the furniture industry, polyester continues to adapt to emerging market dynamics. This analysis explores key trends shaping the polyester sofa material market in 2026 under major strategic themes.

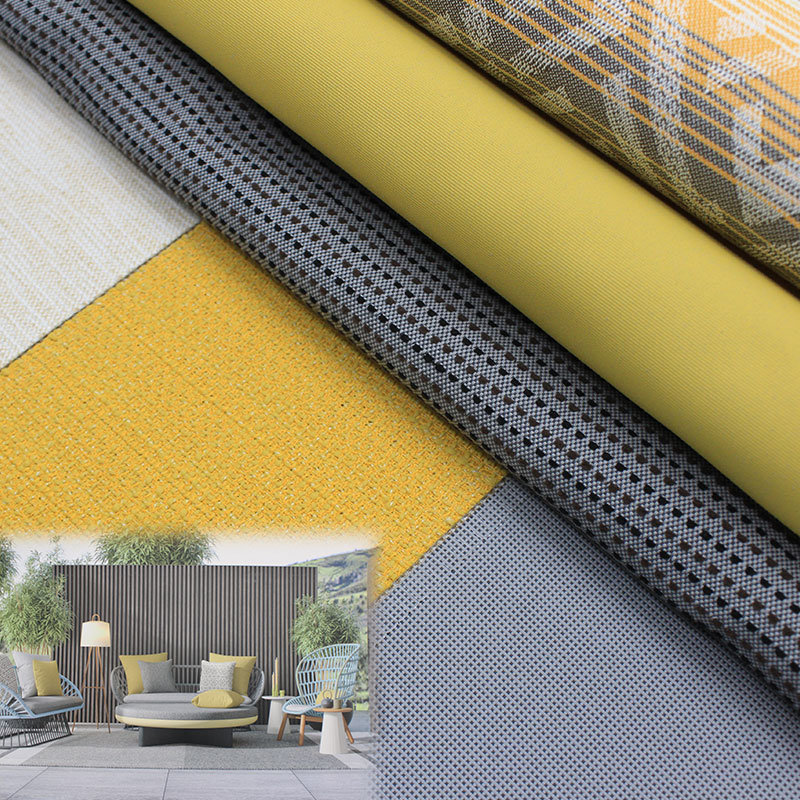

Growing Demand for Affordable and Durable Upholstery

Polyester remains a top choice for sofa upholstery due to its cost-effectiveness and durability. In 2026, increasing urbanization and rising demand for ready-to-assemble (RTA) and modular furniture—especially in developing economies—will bolster the need for affordable, low-maintenance materials. Polyester’s resistance to wear, fading, and moisture makes it ideal for high-traffic households, rental properties, and commercial spaces such as co-working lounges and short-term rentals.

Advancements in Fabric Technology and Performance

By 2026, innovations in textile engineering will enhance the performance of polyester sofa fabrics. Manufacturers are integrating stain-resistant, anti-microbial, and odor-control treatments directly into polyester fibers. Additionally, the development of textured and brushed microfiber polyester is improving the fabric’s resemblance to natural textiles like linen or wool, expanding its appeal in mid-to-high-end furniture segments. These technological upgrades will help polyester compete more effectively with natural and blended fabrics.

Sustainability and Recycled Polyester (rPET) Adoption

Environmental concerns are reshaping the furniture materials market. In 2026, the use of recycled polyester (rPET), derived from post-consumer plastic bottles, is expected to grow significantly. Major furniture brands are committing to circular economy principles, with targets to increase rPET content in their upholstery. Certifications like Global Recycled Standard (GRS) will become key differentiators. Consumers, particularly Millennials and Gen Z, are prioritizing eco-friendly purchasing decisions, pushing manufacturers to adopt sustainable sourcing and transparent supply chains.

Influence of E-Commerce and Direct-to-Consumer Models

The rise of online furniture shopping continues to influence material preferences. Polyester’s consistency in color, texture, and performance makes it well-suited for digital presentation and mass customization. In 2026, direct-to-consumer (DTC) brands will leverage data analytics to offer personalized sofa configurations, often featuring polyester blends for optimal balance of comfort, aesthetics, and price. Fast shipping and easy returns further enhance polyester’s dominance in the online upholstery market.

Regional Market Dynamics

Asia-Pacific will remain the largest producer and consumer of polyester sofa materials in 2026, driven by expanding middle-class populations in India, Indonesia, and Vietnam. Meanwhile, North America and Western Europe will see steady demand, with a growing emphasis on premium, sustainable polyester options. Government regulations on indoor emissions and chemical use (e.g., REACH in Europe) will push manufacturers toward safer, low-VOC polyester formulations.

Competitive Landscape and Material Blending

To overcome traditional drawbacks—such as reduced breathability and static buildup—manufacturers are increasingly blending polyester with natural fibers like cotton or linen. These blends offer improved comfort and aesthetic versatility, capturing a broader customer base. Major chemical and textile companies, such as Toray Industries and Indorama Ventures, are investing in R&D to develop next-generation polyester fibers tailored for furniture applications.

Conclusion

By 2026, the polyester sofa material market will be defined by innovation, sustainability, and adaptability. While challenges related to environmental impact and perception as a “low-end” material persist, ongoing advancements in recycling, fabric quality, and eco-design are repositioning polyester as a smart, modern choice for sofa upholstery. Stakeholders who prioritize sustainability, performance, and consumer engagement will lead the market in the coming years.

Common Pitfalls When Sourcing Polyester Sofa Material (Quality & IP)

Sourcing polyester sofa material may seem straightforward, but overlooking key quality and intellectual property (IP) aspects can lead to costly mistakes, customer dissatisfaction, and legal risks. Here are the most common pitfalls to avoid:

Poor Fabric Quality and Durability

One of the biggest risks is selecting polyester fabric that lacks the necessary durability for furniture use. Low-quality polyester may appear attractive initially but can pill, fade, or tear quickly under regular use. Buyers often fall into this trap by prioritizing low cost over performance metrics like rub count (Martindale test), UV resistance, and abrasion resistance. Fabrics with low double rub ratings (under 15,000–20,000) are unsuitable for sofas in high-traffic environments.

Misrepresentation of Fiber Content and Blend Ratios

Suppliers may inaccurately label fabric composition, claiming a higher percentage of polyester than actually present or mixing in lower-grade fibers without disclosure. This affects not only durability but also care requirements and appearance retention. Always request and verify mill certificates or third-party lab test reports to confirm fiber content claims.

Inadequate Colorfastness and Stain Resistance

Polyester fabrics vary widely in their ability to resist fading from sunlight (UV exposure) and staining from spills. Sourcing materials without proper testing for colorfastness (AATCC or ISO standards) can result in sofas that fade unevenly or stain easily, leading to customer complaints. Ensure the fabric has undergone rigorous testing for lightfastness and includes durable stain-resistant finishes if required.

Overlooking Breathability and Comfort

While polyester is durable, some variants can trap heat and feel less comfortable compared to natural fibers. Sourcing tightly woven, non-breathable polyester without considering end-user comfort—especially in warm climates—can impact the perceived quality of the sofa. Look for fabrics with improved weaves or blended fibers (e.g., with cotton or rayon) to enhance comfort.

Ignoring Flammability and Safety Standards

Different markets have strict regulations regarding flammability (e.g., CAL 117 in the U.S., BS 5852 in the UK). Sourcing polyester fabric that doesn’t meet local fire safety standards can result in product recalls or legal liability. Always confirm compliance with regional safety certifications before finalizing procurement.

Intellectual Property (IP) Infringement Risks

A critical but often overlooked pitfall is sourcing fabrics that replicate protected designs, patterns, or textures without authorization. Many premium sofa fabrics feature copyrighted or trademarked designs. Using counterfeit or imitation materials—even unknowingly—can expose your brand to lawsuits, customs seizures, and reputational damage. Always verify the supplier’s right to produce and sell the fabric design, and request proof of IP clearance when applicable.

Lack of Supply Chain Transparency

Relying on intermediaries or unclear supply chains increases the risk of receiving substandard or non-compliant materials. Without traceability from mill to finished fabric, it’s difficult to ensure ethical sourcing, consistent quality, or authenticity. Establish direct relationships with reputable mills or require full documentation from suppliers.

Inconsistent Dye Lots and Batch Variability

Polyester dyeing processes can result in color variations between production batches. Sourcing without strict lot-control measures can lead to visible mismatches in sofa upholstery, especially in large production runs. Insist on batch consistency and retain approval swatches for quality control during production.

Avoiding these pitfalls requires due diligence, clear specifications, and verified supplier credentials. Investing time in quality assurance and IP compliance upfront protects your brand, ensures customer satisfaction, and prevents costly downstream issues.

Logistics & Compliance Guide for Polyester Sofa Material

This guide outlines key considerations for the logistics and compliance aspects when handling, transporting, and importing/exporting polyester sofa material. Adherence to these guidelines ensures efficient operations and regulatory compliance across the supply chain.

Material Classification & Regulatory Compliance

Polyester sofa material—typically a woven or non-woven fabric made from polyethylene terephthalate (PET)—must meet regional and international safety and environmental standards. Key compliance areas include:

- REACH (EU): Ensure the material is free from substances of very high concern (SVHCs) listed under REACH Annex XIV. Suppliers must provide a Declaration of Compliance (DoC).

- RoHS (EU): Although primarily for electronics, certain flame retardants used in textiles may fall under RoHS restrictions if integrated into electronic sofa components.

- CPSIA (USA): While focused on children’s products, general safety standards apply. Ensure no lead or phthalates are present in coatings or treatments.

- California Proposition 65: Provide appropriate warnings if the material contains chemicals listed by the state of California.

- Flammability Standards: Comply with regulations such as:

- 16 CFR Part 1633 (USA): Standard for the flammability of mattresses; may be referenced for upholstered furniture.

- UK Furniture & Furnishings (Fire Safety) Regulations 1988: Requires fire resistance testing and permanent labels.

- REACH SVHC & SCIP Notification: If the material contains SVHCs above 0.1% weight by weight, notification to the SCIP database may be required.

Packaging & Handling Requirements

Proper packaging safeguards material quality and ensures safe handling during logistics operations:

- Roll or Fold Packaging: Polyester fabric is typically shipped in rolls protected with plastic film or in folded form with kraft paper wrapping.

- Moisture Protection: Use moisture barrier packaging (e.g., polyethylene film) to prevent mold and mildew during sea freight.

- Palletization: Secure rolls or folded bundles on wooden or plastic pallets. Stretch-wrap to prevent shifting.

- Labeling: Include:

- Material composition (e.g., 100% polyester)

- Lot/batch number

- Weight and dimensions

- Care and handling instructions (e.g., “Keep Dry,” “Do Not Stack Excessively”)

- Compliance marks (e.g., Oeko-Tex Standard 100, if certified)

Transportation & Logistics Considerations

Efficient and compliant transportation is critical to minimize delays and maintain material integrity:

- Mode of Transport:

- Sea Freight: Most cost-effective for bulk shipments. Use dry container units with desiccant packs to control humidity.

- Air Freight: For urgent or low-volume shipments. Higher cost but faster transit.

- Road/Rail: Ideal for regional distribution. Ensure vehicles are clean, dry, and secure.

- Temperature & Humidity Control: Avoid extreme conditions. Polyester is durable but prolonged exposure to high humidity can lead to packaging degradation or mildew.

- Stacking & Weight Limits: Do not exceed pallet weight limits. Avoid stacking heavy items on fabric rolls to prevent deformation.

- Customs Documentation: Prepare accurate shipping documents, including:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin

- Material Safety Data Sheet (MSDS), if required

- Textile Declaration (e.g., FTC labeling requirements in the USA)

Import/Export Regulations

Cross-border movement of polyester fabric is subject to trade regulations and tariffs:

- HS Code Classification: Use the appropriate Harmonized System (HS) code:

- Typical code: 5407.42 (Woven fabrics of polyester staple fibers, unbleached or bleached).

- Confirm exact code based on weight, width, and finishing (e.g., dyed, printed).

- Tariff Rates: Check destination country tariffs. Many countries apply low to moderate duties on polyester textiles.

- Import Restrictions: Some countries impose quotas, anti-dumping duties, or require pre-shipment inspections (e.g., SPS measures).

- Textile Labeling Laws: Ensure compliance with destination market labeling requirements (e.g., fiber content, country of origin, care instructions).

Sustainability & Environmental Compliance

Increasing regulatory and consumer focus on sustainability affects polyester material sourcing and logistics:

- Recycled Content: If using recycled polyester (rPET), document chain of custody (e.g., via GRS – Global Recycled Standard).

- Chemical Restrictions: Comply with ZDHC (Zero Discharge of Hazardous Chemicals) MRSL if supplying to eco-conscious brands.

- Waste Management: Ensure packaging is recyclable. Provide end-of-life guidance for fabric scraps.

- Carbon Footprint: Optimize transport routes and consider carbon offset programs for large shipments.

Quality Assurance & Traceability

Maintain quality and compliance throughout the supply chain:

- Incoming Inspection: Verify material against purchase specifications (color, weight, width, shrinkage, pilling resistance).

- Lot Traceability: Implement a system to track material from supplier to end product.

- Third-Party Testing: Conduct periodic testing for:

- Colorfastness

- Tensile strength

- Flammability

- VOC emissions (if applicable)

Conclusion

Effective logistics and compliance management for polyester sofa material requires attention to regulatory standards, proper packaging, accurate documentation, and sustainable practices. Proactive planning and supplier collaboration ensure smooth customs clearance, product safety, and customer satisfaction. Regular audits and updates to compliance protocols are recommended to adapt to evolving international regulations.

In conclusion, sourcing polyester sofa material offers a cost-effective, durable, and versatile solution for furniture manufacturing and retail. Its resistance to wear, fading, and moisture makes it ideal for high-traffic environments and households with children or pets. Additionally, polyester is available in a wide range of colors, textures, and finishes, allowing for design flexibility and aesthetic appeal. With advancements in fabric technology, modern polyester materials can closely mimic the look and feel of natural fibers while requiring less maintenance and offering greater longevity. When sourced from reputable suppliers who adhere to ethical and environmental standards, polyester can also support sustainable production practices. Overall, polyester stands out as a practical and reliable choice for sofa upholstery, balancing performance, affordability, and style in the competitive furniture market.