The global greenhouse market is experiencing robust expansion, driven by rising demand for sustainable agriculture, controlled environment farming, and advancements in greenhouse materials such as polycarbonate. According to a 2023 report by Mordor Intelligence, the global greenhouse market was valued at USD 24.9 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 13.6% from 2023 to 2028. Polycarbonate—known for its superior light transmission, impact resistance, and thermal insulation—has emerged as a preferred glazing material, particularly in commercial and high-performance greenhouses.

This growth is further fueled by increasing adoption of protected cultivation techniques in both developed and emerging economies, where food security and climate volatility are accelerating investment in resilient agricultural infrastructure. As one of the fastest-growing segments within the greenhouse industry, polycarbonate greenhouses offer durability and energy efficiency, making them ideal for year-round crop production. Against this backdrop, a select group of manufacturers has risen to prominence, combining engineering expertise with innovative design to meet evolving market demands. The following list highlights the top 10 polycarbonate greenhouse manufacturers shaping the future of modern horticulture.

Top 10 Polycarbonate Greenhouse Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Palram Americas

Domain Est. 1999

Website: palram.com

Key Highlights: Palram is the leading polycarbonate manufacturer and PVC supplier. Explore our wide range of thermoplastic technology solutions….

#2 Corrugated Polycarbonate Greenhouse Packages

Domain Est. 2000 | Founded: 1946

Website: gothicarchgreenhouses.com

Key Highlights: The most trusted name in greenhouses & supplies • Serving the horticulture industry since 1946! Greenhouse Manufacturer, Distributor, Importer-Exporter. Menu….

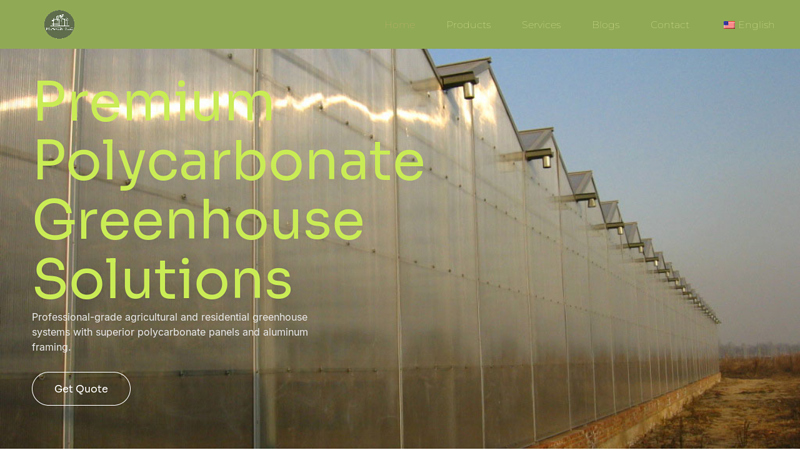

#3 Polycarbonate Greenhouse Systems

Website: polygreenhouse.net

Key Highlights: Leading manufacturer of premium polycarbonate greenhouse solutions. Custom agricultural greenhouses, residential aluminum greenhouses….

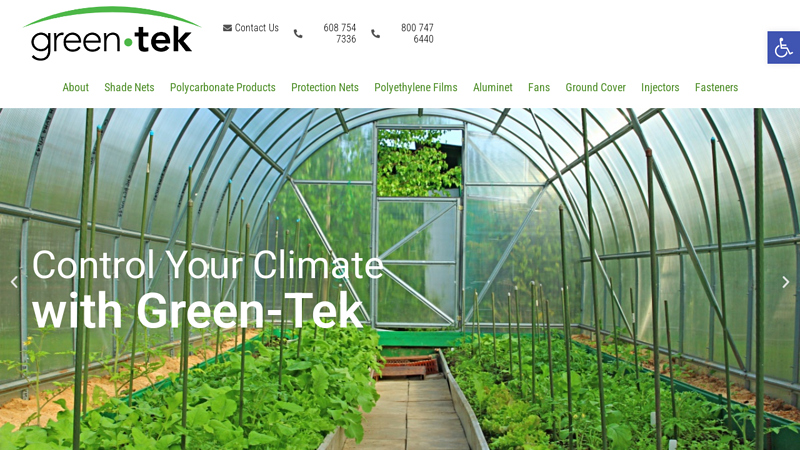

#4 Greenhouse Component Supplier

Domain Est. 1996

Website: green-tek.com

Key Highlights: Our offerings include best-in-class polycarbonate sheeting, high-tech UV stabilized greenhouse film, light filtering shade nets, fans, fertilizer injectors, and ……

#5 Polycarbonate Panels

Domain Est. 1999

Website: rimol.com

Key Highlights: Polycarbonate greenhouse panels offer near-indestructible protection for your crops from wind, snow, hail, rain and harmful ultraviolet rays – after all, this ……

#6 High quality glass and polycarbonate greenhouses

Domain Est. 2003

Website: arcadiaglasshouse.com

Key Highlights: Glass and polycarbonate greenhouses built with strong aluminum frames and welded truss construction for garden, hobby, residential and school greenhouses….

#7 Cellular polycarbonate GREENHOUSE

Domain Est. 2016

Website: polikarbonates.com

Key Highlights: Hydrophilic cellular polycarbonate GREENHOUSE is a high-quality covering material designed specifically for farmers seeking to increase the efficiency of their ……

#8 Polycarbonate Greenhouses

Domain Est. 2021

#9 Polycarbonate Greenhouse Panels Best Manufacturer in China

Domain Est. 2013

Website: weetect.com

Key Highlights: WeeTect is a premier manufacturers of polycarbonate greenhouse panels in China. Our products are trusted by many greenhouse builders and the world’s largest ……

#10 Best Polycarbonate Greenhouses

Domain Est. 2021

Website: planetgreenhouse.com

Key Highlights: Free delivery 30-day returnsPolycarbonate greenhouses are made of a strong, shatterproof material that is highly resistant to impacts, making them ideal for harsh weather condition…

Expert Sourcing Insights for Polycarbonate Greenhouse

H2: Market Trends Shaping the Polycarbonate Greenhouse Industry in 2026

By 2026, the global polycarbonate greenhouse market is poised for significant transformation, driven by converging forces of technology, sustainability, consumer demand, and evolving agricultural practices. Key trends shaping this dynamic landscape include:

1. Sustainability & Circular Economy Integration:

Environmental concerns will be paramount. Expect a surge in demand for recyclable polycarbonate panels and systems designed for disassembly. Manufacturers will increasingly adopt bio-based or recycled-content polycarbonate to reduce carbon footprints. Life cycle assessments (LCAs) will become standard, with growers prioritizing suppliers offering take-back programs and transparent sustainability reporting. Energy efficiency will extend beyond the structure to encompass integrated renewable energy solutions (solar glazing, geothermal).

2. Advanced Material Innovation & Performance Enhancement:

Polycarbonate technology will advance significantly. Multi-wall panels with improved thermal insulation (U-values) and higher light diffusion will dominate, maximizing energy savings and crop quality. Anti-dust, self-cleaning, and anti-fog coatings will become standard, reducing maintenance and optimizing light transmission. Development of UV-stable, impact-resistant formulations with extended lifespans (15-20+ years) will enhance long-term value. Smart polycarbonate with integrated sensors or light-tuning capabilities may emerge.

3. Precision Agriculture & IoT Integration:

Greenhouses will become high-tech hubs. Polycarbonate structures will increasingly be designed as platforms for IoT sensors (climate, soil, plant health) and automated systems (irrigation, ventilation, shading). Seamless integration with AI-driven climate control software will be expected, enabling predictive adjustments for optimal yields and resource efficiency. Data analytics will inform design choices for optimal light diffusion and thermal performance.

4. Urban & Vertical Farming Expansion:

The rise of controlled environment agriculture (CEA) in urban settings will drive demand for modular, space-efficient polycarbonate greenhouses. Rooftop installations and vertical farms will utilize lightweight, high-strength polycarbonate due to structural advantages over glass. These applications will emphasize aesthetic design, sound insulation, and durability in challenging urban microclimates.

5. Regional Market Diversification & Climate Resilience:

Growth will accelerate beyond traditional markets. Hot, arid regions will prioritize polycarbonate’s superior heat reflection and insulation to combat extreme temperatures. Areas prone to severe weather (hail, storms) will leverage its high impact resistance. Government subsidies for food security and sustainable agriculture, particularly in Asia-Pacific and the Middle East, will be key growth catalysts. Designs will increasingly focus on passive cooling strategies and resilience to climate volatility.

6. Supply Chain Optimization & Localized Manufacturing:

Geopolitical factors and sustainability pressures will push towards regionalized production to reduce logistics emissions and mitigate disruptions. Manufacturers will invest in automation and lean manufacturing to improve cost-efficiency and scalability. Digital platforms for design, configuration, and supply chain tracking will enhance speed and transparency.

7. Consumer-Driven Aesthetics & Design Flexibility:

Beyond agriculture, demand for residential and commercial ornamental greenhouses will grow, fueled by wellness trends and urban gardening. This segment will demand customizable, architecturally appealing designs with polycarbonate offering color options, curved profiles, and high light quality. User-friendly DIY kits will also gain traction.

In summary, by 2026, the polycarbonate greenhouse market will be defined by smarter, more sustainable, and highly integrated systems. Success will depend on innovation in materials, seamless technology integration, responsiveness to climate challenges, and meeting the diverse needs of a rapidly evolving agricultural and consumer landscape.

Common Pitfalls When Sourcing Polycarbonate Greenhouses (Quality and Intellectual Property)

Sourcing polycarbonate greenhouses—especially from international suppliers—can present significant challenges related to material quality and intellectual property (IP) protection. Being aware of these pitfalls helps ensure you receive a durable, effective structure and avoid legal or financial risks.

Poor Quality Polycarbonate Material

One of the most frequent issues is receiving substandard polycarbonate panels. Low-quality sheets may lack essential properties such as UV protection, impact resistance, or proper thickness. This results in premature yellowing, brittleness, and reduced light transmission, ultimately shortening the greenhouse’s lifespan. Always verify material certifications (e.g., UV-stabilized, multi-wall construction) and request sample testing before bulk orders.

Inadequate Structural Integrity

Beyond the panels, the aluminum frame and connectors must meet engineering standards. Some suppliers cut costs by using thin-walled or non-anodized aluminum, leading to warping, corrosion, or collapse under snow/wind loads. Insist on detailed specifications, structural calculations, and third-party testing reports to confirm durability.

Misrepresentation of Product Specifications

Suppliers may exaggerate product claims—such as light diffusion rates, insulation values (U-value), or expected lifespan—without technical backing. This misrepresentation can lead to underperforming greenhouses. Always cross-check specifications with independent lab reports or industry benchmarks and include performance warranties in contracts.

Lack of Intellectual Property Protection

Many innovative greenhouse designs, connectors, or ventilation systems are protected by patents, trademarks, or design rights. Sourcing from manufacturers that replicate patented features without authorization exposes buyers to IP infringement risks. This can result in shipment seizures, legal action, or reputational damage. Conduct due diligence on the supplier’s right to produce and sell the design, and request proof of IP clearance.

Use of Counterfeit or Knockoff Designs

Some suppliers offer “branded” greenhouse models at suspiciously low prices, which are often unauthorized copies. These counterfeit products typically use inferior materials and lack technical support. Verify the supplier’s authorization with the original brand or patent holder and avoid deals that seem too good to be true.

Inconsistent Manufacturing Standards

Batch-to-batch inconsistencies in panel thickness, tolerances, or coating application are common with unvetted manufacturers. These variations complicate assembly and affect performance. Implement strict quality control measures, such as pre-shipment inspections and approved sample approvals, to maintain consistency.

Absence of After-Sales Support and Warranties

Low-cost suppliers may not offer comprehensive warranties or spare parts support. If panels degrade or components break, replacements may be unavailable, leaving the greenhouse unusable. Ensure the supplier provides a clear warranty (e.g., 10-year UV protection, 5-year structural) and accessible customer service.

By addressing these common pitfalls proactively—through supplier audits, material verification, IP checks, and contractual safeguards—you can source high-quality, legally compliant polycarbonate greenhouses that deliver long-term value.

Logistics & Compliance Guide for Polycarbonate Greenhouse

Product Classification and HS Code

Polycarbonate greenhouses are typically classified under the Harmonized System (HS) for international trade. The most common HS code is 3926.30, which covers “Other articles of plastics, used for the conveyance or packing of goods.” However, classification may vary by country and specific greenhouse design (e.g., whether it’s a complete kit or modular components). Always verify with local customs authorities or a licensed customs broker to ensure accurate classification and avoid delays or penalties.

Import Regulations and Duties

Import regulations for polycarbonate greenhouses vary by destination country. Key considerations include:

– Tariff Rates: Duty rates depend on the HS code and trade agreements between countries (e.g., USMCA, EU free trade agreements). Rates can range from 0% to 10% or more.

– Import Licenses: Most countries do not require special licenses for greenhouse imports, but agricultural or environmental regulations may apply in some regions.

– Country of Origin Marking: Products must be clearly marked with the country of manufacture per destination country rules (e.g., “Made in China” for U.S. imports under 19 CFR 134).

Shipping and Transportation Logistics

- Packaging: Greenhouses should be shipped in durable, weather-resistant packaging. Panels, frames, and hardware must be separated and secured to prevent damage.

- Containerization: Use standard 20’ or 40’ dry containers. Maximize space with flat-packed components. Consider palletization for easier handling.

- Freight Options: Ocean freight is most cost-effective for bulk shipments. Air freight may be used for urgent, smaller orders but significantly increases costs.

- Incoterms: Clearly define responsibilities using standard Incoterms (e.g., FOB, CIF, DDP). FOB (Free On Board) is common for exporter-managed logistics up to the port of origin.

Compliance with Safety and Environmental Standards

- Material Safety: Polycarbonate must comply with REACH (EU), RoHS (EU/UK), and other regional chemical safety regulations. Ensure no restricted phthalates or heavy metals are present.

- Structural Standards: While not always legally required, adherence to greenhouse engineering standards (e.g., wind and snow load guidelines per ASCE 7 or Eurocode) enhances safety and marketability.

- UV Protection: Polycarbonate panels must include co-extruded UV protection layer to prevent degradation. Verify manufacturer certifications for UV resistance (e.g., 10-year warranty).

Documentation Requirements

Ensure the following documents accompany each shipment:

– Commercial Invoice (with detailed description, value, and HS code)

– Packing List (itemizing quantities, weights, and dimensions)

– Bill of Lading (for sea freight) or Air Waybill (for air freight)

– Certificate of Origin (may be required for preferential tariff treatment)

– Product Compliance Certificates (e.g., REACH, RoHS, ISO 9001 if applicable)

Destination Country-Specific Considerations

- European Union: Comply with CE marking requirements if the greenhouse is considered a construction product. Registration under the EU Customs Union is mandatory.

- United States: No general certification required, but FTC labeling rules apply. Lacey Act compliance may be necessary if wood components are included.

- Canada: Must meet standards under the Canadian Greenhouse Certification Program if applicable. Use of bilingual (English/French) labels may be required.

- Australia/New Zealand: May require biosecurity clearance. Check AQIS (Australian Quarantine and Inspection Service) for import conditions.

Warranty and After-Sales Compliance

Provide clear warranty terms (typically 10 years for polycarbonate panels) and installation instructions. Ensure customer support complies with consumer protection laws in the destination market (e.g., EU Consumer Rights Directive, U.S. Magnuson-Moss Warranty Act).

Sustainability and End-of-Life Considerations

Polycarbonate is recyclable (resin identification code #7). Provide guidance on proper disposal or recycling options. Some regions may require Extended Producer Responsibility (EPR) compliance—check local e-waste or plastic waste regulations.

Summary

Successful logistics and compliance for polycarbonate greenhouses require accurate classification, adherence to international standards, proper documentation, and awareness of regional regulations. Partnering with experienced freight forwarders and legal advisors ensures smooth global distribution and minimizes compliance risks.

In conclusion, sourcing a polycarbonate greenhouse involves careful consideration of several key factors including material quality, structural design, supplier reliability, and long-term value. Polycarbonate offers significant advantages such as excellent light transmission, superior insulation, impact resistance, and durability, making it an ideal choice for both commercial and hobbyist growers. When selecting a supplier, it is essential to evaluate product certifications, warranty terms, customer support, and installation services to ensure optimal performance and longevity. Additionally, comparing pricing, lead times, and customization options can help secure a solution that meets specific growing needs and budget constraints. Ultimately, investing in a high-quality polycarbonate greenhouse from a reputable source contributes to increased crop yields, energy efficiency, and year-round growing success, making it a wise and sustainable choice for modern horticulture.