The global demand for durable and efficient building solutions has fueled steady growth in the pole barn and agricultural construction sectors, directly benefiting suppliers of specialized hardware like sliding door systems. According to Mordor Intelligence, the global construction market is projected to grow at a CAGR of over 5.8% from 2023 to 2028, driven by increasing investments in rural infrastructure, agricultural facilities, and storage buildings—key applications for pole barn structures. As these buildings require robust, weather-resistant, and space-efficient access solutions, sliding door hardware has become a critical component. This growing need has led to increased innovation and competition among manufacturers focused on strength, ease of installation, and longevity. Based on market trends and product performance data, the following are the top 10 pole barn sliding door hardware manufacturers leading the industry in reliability, engineering, and customer adoption.

Top 10 Pole Barn Sliding Door Hardware Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sliding Door Hardware

Domain Est. 1997

Website: abhmfg.com

Key Highlights: A high quality manufacturer of Overhead Holders & Stops, Hospital Latches, Electromagnetic Holders, Pivots, Strikes and Rescue Stops, Aluminum Hinges….

#2 Crown Industrial

Domain Est. 1998

Website: crown-industrial.com

Key Highlights: From unique high end residential to large heavy duty industrial applications; we design, engineer, manufacture, and install to meet the needs of our clients….

#3 RW Hardware

Domain Est. 2000

Website: rwhardware.com

Key Highlights: Since 1880, RW Hardware has been the leading manufacturer of hardware and door accessories. All products covered by industry best 10-year warranty….

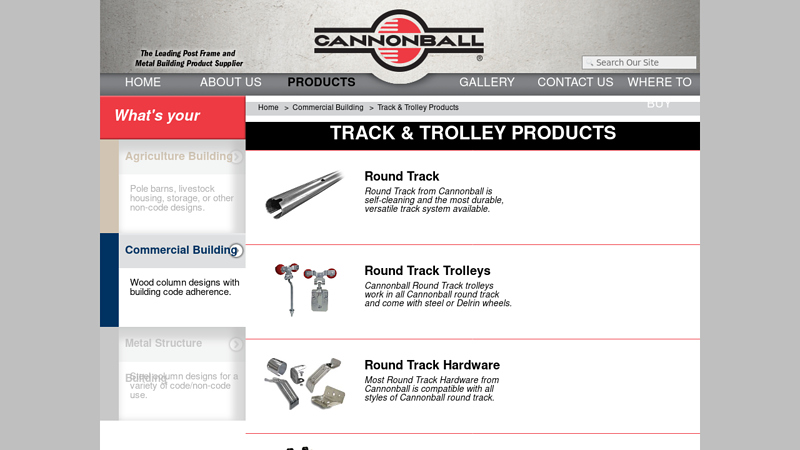

#4 Track & Trolley Products

Domain Est. 1997

Website: cnbhnp.com

Key Highlights: Most Round Track Hardware from Cannonball is compatible with all styles of Cannonball round track. Interior Track Sliding Door Systems. Unique track systems for ……

#5 Slide Doors

Domain Est. 2000

Website: plyco.com

Key Highlights: Whether it’s a complete Slide Door Package, Slide Door Components or Track and Hardware, Plyco has you covered….

#6 National Guard Products

Domain Est. 2000 | Founded: 1935

Website: ngp.com

Key Highlights: National Guard Products, based in Memphis and founded in 1935, is a privately held Life-Safety Products Company serving the commercial construction market….

#7 Renin

Domain Est. 2001

Website: renin.com

Key Highlights: Our products include an extensive selection of bifold, bypass, and pivot closet doors and replacement parts, plus our complete barn door kits and hardware….

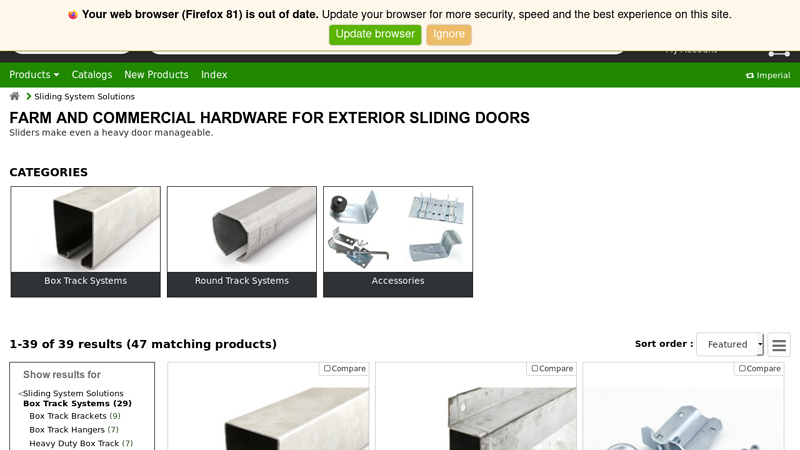

#8 Farm and Commercial Hardware for Exterior Sliding Doors

Domain Est. 2001

Website: onwardhardware.com

Key Highlights: Find one of the widest range of builder’s hardware and related products such as cabinet and furniture hinges, as well as window and door ……

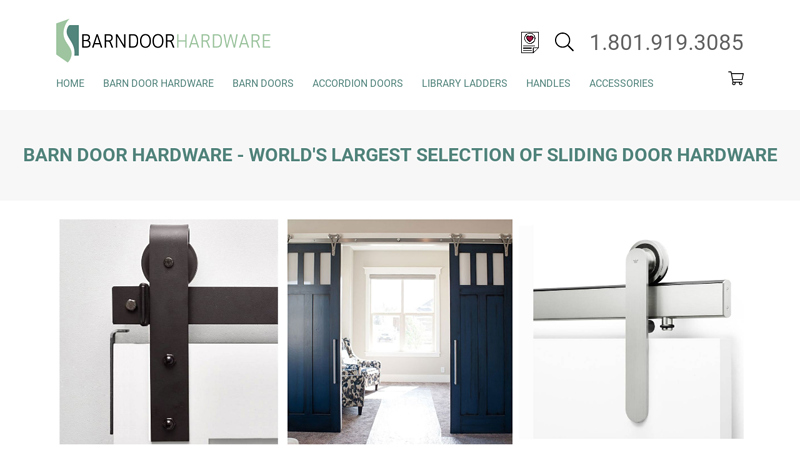

#9 Barn Door Hardware

Domain Est. 2003

Website: barndoorhardware.com

Key Highlights: Free delivery over $200 30-day returns…

#10 Homacer: Sliding Barn Door Hardware Kits

Domain Est. 2017

Website: homacer.com

Key Highlights: Discover expertly crafted sliding barn doors, space-saving hardware kits, and complete all-in-one sets — ideal for closets, bedrooms, and beyond….

Expert Sourcing Insights for Pole Barn Sliding Door Hardware

2026 Market Trends for Pole Barn Sliding Door Hardware

The market for pole barn sliding door hardware is poised for notable transformation by 2026, driven by advancements in materials, evolving construction practices, and increasing demand for durable, low-maintenance solutions. As pole barns continue to serve a variety of purposes—from agricultural storage and workshops to residential garages and commercial buildings—the need for reliable and efficient sliding door hardware systems is growing. This analysis explores key trends expected to shape the pole barn sliding door hardware sector in 2026.

Rising Demand for Durable and Corrosion-Resistant Materials

One of the most significant trends in 2026 will be the increasing preference for hardware made from high-grade materials such as galvanized steel, stainless steel, and aluminum alloys. With pole barns often exposed to harsh weather conditions, hardware longevity is a top priority for consumers. Manufacturers are responding by enhancing corrosion resistance through improved coatings and material engineering. Powder-coated track systems and weather-sealed rollers are becoming standard, especially in regions with high humidity or coastal exposure.

Growth in DIY and Pre-Fabricated Building Kits

The rise of do-it-yourself (DIY) construction and pre-fabricated pole barn kits is significantly influencing hardware design and distribution. In 2026, sliding door hardware is increasingly being sold as part of integrated kits that include tracks, rollers, guides, and installation instructions tailored for non-professionals. These kits emphasize ease of assembly, precise fit, and compatibility with standard pole barn dimensions. As consumer confidence in DIY building grows, hardware suppliers are focusing on user-friendly designs and modular components.

Technological Integration and Smart Features

While still in early adoption, smart technology integration is beginning to emerge in the pole barn door hardware market. By 2026, some high-end sliding door systems are expected to feature motorized operators with remote controls, smartphone app connectivity, and integration with home automation systems. These smart hardware solutions are particularly appealing for residential pole barns used as garages or workshops, where convenience and security are valued. Although not yet mainstream, this trend signals a shift toward enhanced functionality and accessibility.

Emphasis on Low Maintenance and Long-Term Value

Homeowners and commercial users alike are prioritizing long-term value over initial cost. In 2026, sliding door hardware that requires minimal maintenance—such as self-lubricating rollers, sealed bearings, and rust-proof tracks—is gaining market share. Consumers are willing to pay a premium for hardware that reduces upkeep and extends operational life. This focus on durability is reshaping product development and marketing strategies, with manufacturers highlighting lifecycle costs and warranty terms.

Regional Market Variations and Customization

Market demand for pole barn sliding door hardware varies significantly by region, influencing product offerings in 2026. In rural and agricultural areas, heavy-duty industrial hardware dominates, built to withstand frequent use and large door sizes. In suburban and residential markets, aesthetics and quiet operation are becoming more important, leading to quieter nylon rollers and sleek track designs. Customization options—such as track length, load capacity, and finish color—are increasingly available to meet diverse customer needs.

Sustainability and Eco-Friendly Manufacturing

Sustainability is an emerging trend affecting the pole barn hardware supply chain. By 2026, manufacturers are under growing pressure to adopt eco-friendly practices, including recycling metal scraps, reducing energy consumption during production, and using non-toxic coatings. Some companies are beginning to market hardware with recycled content or carbon-neutral certifications, appealing to environmentally conscious consumers and aligning with broader green building trends.

Conclusion

The 2026 market for pole barn sliding door hardware reflects a convergence of durability, ease of use, technological innovation, and sustainability. As construction methods evolve and consumer expectations rise, hardware manufacturers must adapt by offering robust, user-friendly, and increasingly intelligent solutions. Whether serving agricultural, residential, or commercial applications, sliding door hardware will continue to play a critical role in the functionality and longevity of pole barn structures.

Common Pitfalls When Sourcing Pole Barn Sliding Door Hardware (Quality, IP)

Sourcing sliding door hardware for a pole barn involves more than just finding a low price. Overlooking critical factors related to quality and intellectual property (IP) can lead to long-term performance issues, safety hazards, and potential legal risks. Here are common pitfalls to avoid:

Overlooking Material Quality and Durability

Many suppliers offer hardware made from thin-gauge steel, low-grade aluminum, or uncoated metals that are prone to rust, warping, or premature wear. This is especially problematic in outdoor pole barn environments exposed to moisture, temperature swings, and heavy use. Choosing subpar materials results in frequent maintenance, misalignment, and costly replacements.

Ignoring Load Capacity and Structural Compatibility

A frequent mistake is selecting hardware rated below the actual weight and size of the door. Underestimating load requirements leads to track deformation, roller failure, and doors that jam or derail. Always verify the hardware’s load rating matches or exceeds your door’s specifications, considering future modifications.

Assuming All “Heavy-Duty” Labels Are Equal

The term “heavy-duty” is unregulated and often used loosely. Without third-party testing data or clear engineering specifications (e.g., ASTM standards), it’s difficult to assess real-world performance. Rely on documented specs—such as roller bearing types, track thickness, and wheel load limits—rather than marketing language.

Failing to Verify Corrosion Resistance

In pole barn applications, hardware is exposed to humidity, precipitation, and ground-level moisture. Hardware lacking proper corrosion protection—such as galvanization, powder coating, or stainless steel components—will degrade quickly. Ensure coatings are rated for outdoor use and inspect for consistent coverage, especially on welded joints and moving parts.

Overlooking Intellectual Property (IP) Infringement Risks

Some suppliers offer hardware that closely mimics patented designs (e.g., specific track profiles, roller mechanisms, or bracket configurations) at a lower price. While tempting, using such products may expose the buyer to IP infringement claims. Always source from reputable manufacturers that respect patents and offer legally compliant products.

Skipping Manufacturer Reputation and Support

Choosing hardware based solely on price from unknown vendors can backfire. Reputable manufacturers provide detailed installation guides, customer support, and warranties. Without these, troubleshooting issues or replacing failed parts becomes difficult, increasing downtime and total cost of ownership.

Neglecting Compatibility with Door Design and Installation Environment

Not all sliding hardware systems work with every door type or wall structure. Pitfalls include incompatible track mounting methods for pole barn post-and-beam frames, inadequate clearance for door swing, or systems that require precise floor tracks—problematic in uneven or dirt-floor barns. Confirm compatibility with your specific construction before purchasing.

Underestimating the Importance of Smooth Operation and Maintenance

Low-quality rollers and tracks often lead to stiff, noisy, or inconsistent door movement. Look for hardware with sealed ball bearings and alignment adjustability. Also, consider long-term maintenance—sealed components reduce the need for lubrication and cleaning, crucial in dusty or high-debris environments.

By carefully evaluating both product quality and IP legitimacy, buyers can avoid costly mistakes and ensure their pole barn sliding doors operate safely and reliably for years.

Logistics & Compliance Guide for Pole Barn Sliding Door Hardware

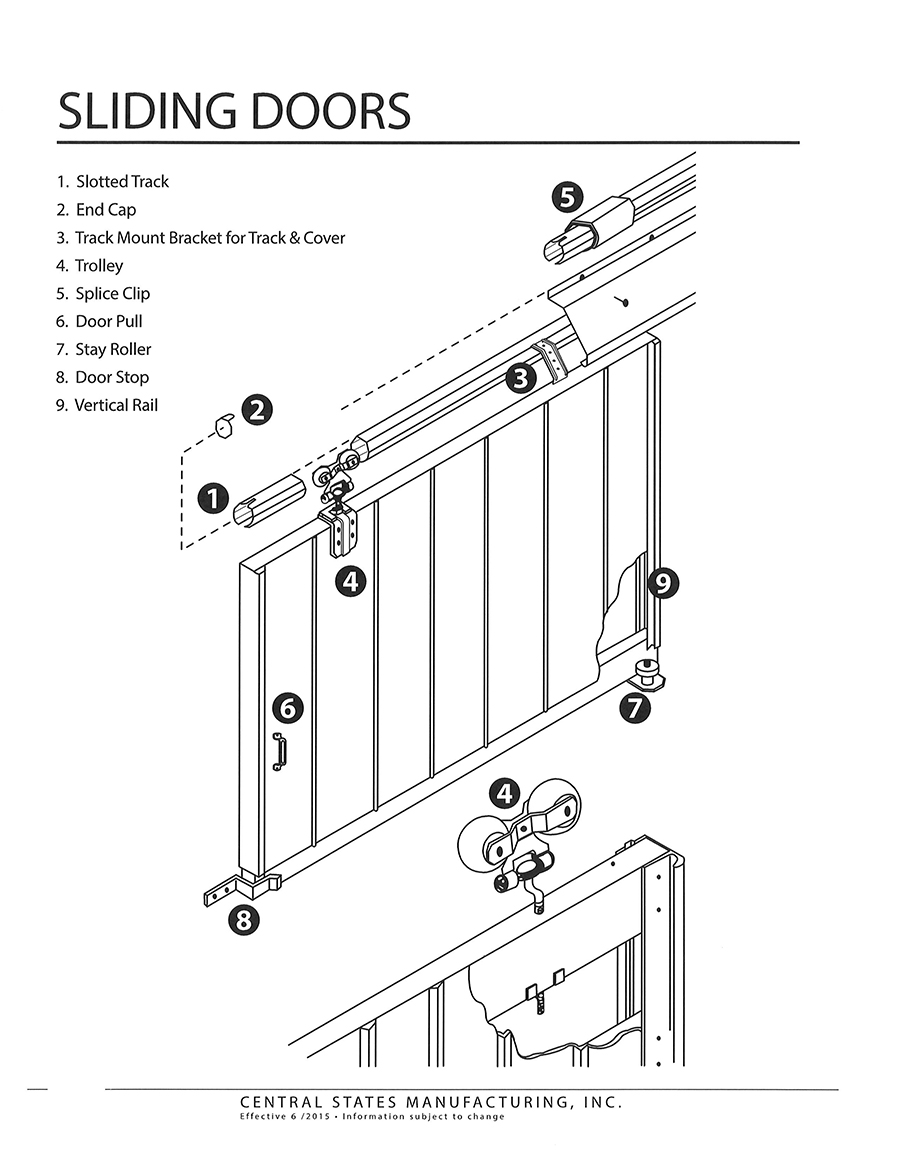

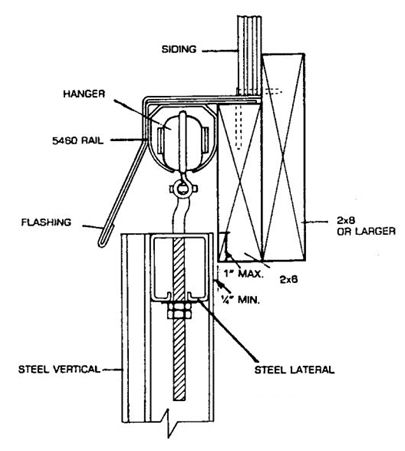

Product Overview and Specifications

Pole barn sliding door hardware includes track systems, rollers, hangers, stops, and mounting brackets designed for heavy-duty agricultural and commercial applications. These components support doors weighing from 100 to over 1,000 pounds, depending on the model. Common materials include galvanized steel and powder-coated aluminum for corrosion resistance. Ensure compatibility with door thickness, height, and weight prior to ordering.

Shipping and Handling Guidelines

- Packaging: Components are typically shipped in corrugated boxes or bundled steel tubing to prevent bending. Track sections may be cut to standard lengths (e.g., 4′, 6′, 8′) or custom sizes.

- Weight & Dimensions: Individual kits range from 10 to 50 lbs. Long track sections may require oversize shipping; confirm freight class with the carrier.

- Fragility: Rollers and hangers are precision parts; avoid dropping or stacking heavy items on packages.

- Carrier Options: Standard ground shipping via LTL freight recommended for bulk orders. Expedited and liftgate services available upon request.

Storage and On-Site Handling

- Store hardware indoors in a dry, temperature-controlled environment to prevent rust and material degradation.

- Keep track sections flat and supported at multiple points to avoid warping.

- Organize small parts (bolts, washers, stoppers) in labeled bins to prevent loss prior to installation.

- Use appropriate lifting equipment when handling long or heavy track sections.

Import and Export Compliance

- HTS Codes: Typical classifications include 7308.90 (other structural elements of iron/steel) and 8302.41 (iron or steel mountings for doors). Confirm exact codes with your customs broker.

- Country of Origin: Clearly label packaging with manufacturing origin (e.g., USA, China, Mexico) per 19 U.S.C. 1304.

- Duty Rates: Vary by country; check current USTR tariff schedules. Some components may qualify for duty exemptions under free trade agreements (e.g., USMCA).

Safety and Regulatory Standards

- Load Ratings: All hardware must meet or exceed published load capacity under ASTM E1155 or equivalent standards. Never exceed maximum door weight specifications.

- OSHA Compliance: Installation at heights above 4 feet requires fall protection. Use PPE (gloves, safety glasses) during assembly and mounting.

- ADA Considerations: If used in public-access buildings, ensure door operation force complies with ADAAG 404.2.6 (max 5 lbs. force to open).

Environmental and Material Compliance

- RoHS & REACH: Galvanized and powder-coated components must comply with restrictions on hazardous substances (e.g., lead, cadmium) in the EU and applicable U.S. states.

- California Prop 65: Labels required if hardware contains listed chemicals (e.g., lead in certain steel alloys).

- Sustainability: Recyclable steel content typically exceeds 75%. Provide material safety data sheets (MSDS) upon request.

Installation and Use Compliance

- Follow manufacturer’s installation manual for proper track alignment, hanger spacing, and anchor bolt specifications.

- Use only recommended fasteners (e.g., lag screws, structural bolts) rated for wood or steel framing.

- Inspect hardware biannually for wear, corrosion, or misalignment—especially in high-moisture or coastal environments.

Warranty and Liability Information

- Standard warranty: 5 years against manufacturing defects. Excludes damage from misuse, improper installation, or environmental factors.

- Disclaimers: Hardware is intended for sliding doors only; not rated for overhead or fire-rated door applications.

- Product liability insurance: Ensure installer and distributor carry appropriate coverage.

Documentation and Recordkeeping

Maintain copies of:

– Certificates of compliance (material and load testing)

– Shipping manifests and bill of lading

– Warranty registration forms

– Safety data sheets (SDS) for all materials

Adherence to this guide ensures safe, legal, and efficient handling, installation, and use of pole barn sliding door hardware. Always consult local building codes and manufacturer specifications for project-specific requirements.

In conclusion, sourcing pole barn sliding door hardware requires careful consideration of durability, size, climate conditions, and ease of installation. Choosing high-quality materials such as galvanized steel or powder-coated components ensures long-term resistance to rust and wear, especially in harsh outdoor environments. It’s essential to match the hardware—包括滑轮、导轨、止动器和门把手—to the weight and dimensions of the door to ensure smooth operation and safety. Additionally, purchasing from reputable suppliers or manufacturers with positive reviews helps guarantee reliability and access to customer support. By investing time in researching and selecting the right sliding door hardware, you enhance both the functionality and longevity of your pole barn doors, improving overall convenience and structural integrity.