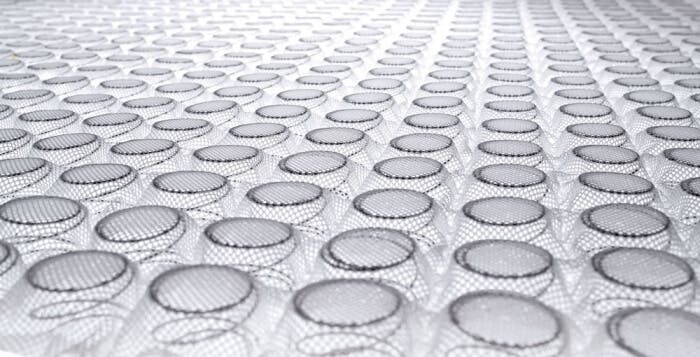

The global pocketed coils mattress market is experiencing robust growth, driven by rising consumer demand for high comfort, motion isolation, and durability in sleep solutions. According to Grand View Research, the global mattress market was valued at USD 44.7 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2030, with innerspring and hybrid mattresses—particularly those utilizing pocketed coil technology—gaining significant traction. Pocketed coils, known for their individual encasement that minimizes motion transfer and provides targeted support, now dominate premium and mid-tier mattress segments. This increasing demand has propelled manufacturers to innovate in coil design, gauge, and automation to enhance performance and scalability. As competition intensifies and e-commerce channels expand, a select group of manufacturers are leading the charge in production capacity, R&D investment, and global supply reach. Here’s a data-driven look at the top 8 pocketed coils manufacturers shaping the modern sleep industry.

Top 8 Pocketed Coils Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Learn More about a Beautyrest Iconic Innovation

Domain Est. 1997

Website: beautyrest.com

Key Highlights: This newfound technology took each coil and individually wrapped it in a material designed to compress the motion and offer added support….

#2 UT+C Springs

Domain Est. 2021

Website: utcsprings.com

Key Highlights: We are a leading manufacturer of high quality pocketed coils providing solutions for business clients worldwide. UTC Springs provides a one-stop solution for ……

#3

Domain Est. 2003

Website: texaspocketsprings.com

Key Highlights: We work closely with our valued customers to supply affordable pocketed spring solutions that add value, and reduce time and cost to the manufacturing process….

#4 HSM expands pocketed coil production to meet rising demand

Domain Est. 2006

Website: hsmsolutions.com

Key Highlights: The products’ ability to contour to the shape of the body offers pressure relief benefits to the back, neck, shoulders and hips – a key feature ……

#5 Micro Coils

Domain Est. 2012

Website: spinkandco.com

Key Highlights: For the best quality of life – Spink & Co’s micro and pocketed coil, all naturally filled mattress is the only true luxury mattress made in America….

#6 Pocket Springs

Domain Est. 2017

Website: beddingcomponents-intl.com

Key Highlights: Pocket innersprings are highly comfortable, supportive, and versatile. Individually wrapped in their own flexible, breathable fabric pockets….

#7 Custom Pocketed Coil Manufacturing

Domain Est. 2021

Website: mattressmakers.us

Key Highlights: Our pocketed coils allow for any sleep position whether it’s a back sleeper, side sleeper, or stomach sleeper. Each one of our pocketed coils are electrically ……

#8 Pocket Spring Mattress FAQs

Website: pocketspringstore.com

Key Highlights: Find answers to common inquiries about pocket springs, mattress assembly, shipping, and more in our comprehensive pocket coil mattress FAQ section….

Expert Sourcing Insights for Pocketed Coils

H2: Projected 2026 Market Trends for Pocketed Coils

Based on current industry dynamics, technological advancements, and evolving consumer demands, the pocketed coil mattress market in 2026 is expected to be shaped by several significant trends:

1. Heightened Focus on Sustainability & Eco-Materials:

Environmental consciousness will be a major driver. Consumers and retailers will increasingly demand transparency in sourcing and manufacturing. Expect significant growth in:

* Recycled Steel: Wider adoption of coils made from high percentages of recycled steel to reduce environmental footprint.

* Biodegradable/Paper-Based Encasings: Replacement of traditional non-woven polyester fabrics with compostable or recyclable cellulose-based materials for coil encasement.

* Plant-Based & Natural Fillings: Integration of pocketed coils with organic cotton, natural latex (especially from sustainable sources), and wool, moving beyond purely synthetic comfort layers.

* Circular Economy Models: Increased emphasis on mattress recyclability and take-back programs, pushing manufacturers to design coils and encasings for easier disassembly.

2. Advanced Hybridization & Material Innovation:

Pocketed coils will be the foundation for increasingly sophisticated hybrid constructions:

* Smart Material Integration: Coils combined with phase-change materials (PCMs), graphene-infused foams, or temperature-regulating gels to enhance comfort and climate control.

* Zoned Coil Systems Evolution: More complex zoning (e.g., 7-zone, 9-zone) with varying coil gauges, heights, and turn counts will become standard in mid-to-high-end models for superior spinal alignment and pressure relief.

* Micro-Coils & Dual Gauge Systems: Wider use of smaller-diameter micro-coils in upper layers for enhanced conforming, alongside larger base coils for support, creating a more nuanced feel.

3. Technology-Driven Manufacturing & Customization:

Automation and data will optimize production and enable personalization:

* AI-Optimized Design: Use of AI and simulation software to design coil configurations optimized for specific support profiles, durability, and cost-efficiency.

* Increased Automation: Further automation in coil winding, pocketing, and layer assembly to improve precision, consistency, and reduce labor costs, particularly for high-volume producers.

* Mass Customization: Growth in made-to-order models allowing consumers to select specific coil counts, firmness zones, and comfort layers, facilitated by modular manufacturing systems.

4. Premiumization & Differentiation:

The market will see a clear bifurcation:

* Value Segment Consolidation: Intense competition in the budget/mid-range segment, focusing on efficient manufacturing and cost-effective materials.

* Premium & Luxury Growth: Strong growth in the premium segment, where pocketed coils are key differentiators. Focus will be on unique coil designs (e.g., barrel-shaped, dual-conical), proprietary tempering processes (e.g., for enhanced durability/resilience), and integration with high-end natural or innovative synthetic comfort materials. Brand storytelling around coil engineering will intensify.

5. E-commerce & DTC Dominance with Evolving Logistics:

Online mattress-in-a-box (MIB) will remain dominant, but face new challenges:

* Logistics Optimization: Continued focus on improving compression, rolling, and packaging to reduce shipping costs and damage for larger sizes and heavier hybrid models using pocketed coils.

* Enhanced Try-Before-You-Buy: Expansion of in-home trial periods and improved return logistics, increasing consumer confidence in online coil-based mattress purchases.

* Omnichannel Blurring: More DTC brands establishing physical showrooms or partnerships with retailers for tactile experience, while traditional retailers enhance their online offerings with detailed coil technology information.

6. Health & Wellness Integration:

Pocketed coils will be positioned not just for comfort, but for health benefits:

* Targeted Support Claims: Marketing will increasingly emphasize medical and orthopedic benefits, such as improved circulation (via reduced pressure points), better spinal alignment, and support for specific conditions (e.g., back pain), backed by R&D.

* Partnering with Health Tech: Potential integration (or co-marketing) with sleep trackers and apps, where coil systems are promoted as optimizing the sleep environment for data-driven insights.

Conclusion for 2026:

The pocketed coil market in 2026 will be defined by sustainability, advanced engineering, and personalization. Success will depend on manufacturers’ ability to innovate in eco-materials, leverage technology for design and production, and clearly communicate the superior support, durability, and health benefits of their coil systems within increasingly hybrid and premium mattress offerings. Competition will be fierce, but opportunities abound for brands leading in sustainable practices and technological differentiation.

Common Pitfalls Sourcing Pocketed Coils: Quality and Intellectual Property Risks

Sourcing pocketed coil systems—commonly used in mattresses and premium seating—can present significant challenges, particularly regarding quality consistency and intellectual property (IP) protection. Avoiding common pitfalls is critical to ensuring product performance, brand reputation, and legal compliance.

Quality Inconsistencies and Material Deficiencies

One major risk when sourcing pocketed coils is variability in quality, especially when working with low-cost or unverified suppliers. Key issues include inconsistent wire gauge, poor heat treatment, substandard fabric encapsulation, and imprecise stitching. These defects can lead to premature coil failure, reduced support, noise (squeaking), and customer dissatisfaction. Suppliers may cut corners by using inferior steel or inadequate fabric breathability, impacting durability and comfort. Without rigorous quality control audits and material certifications, buyers may receive coils that fail to meet performance standards.

Intellectual Property Infringement and Design Copying

Pocketed coil technology often involves patented designs, stitching methods, or proprietary configurations (e.g., zoned support, variable coil counts). Sourcing from regions with weak IP enforcement increases the risk of inadvertently procuring counterfeit or copied components. Suppliers may claim original designs while replicating patented technology, exposing the buyer to legal liability, product recalls, or damage to brand integrity. Conducting due diligence on supplier IP compliance, requiring design licenses, and including IP indemnification clauses in contracts are essential safeguards.

Lack of Traceability and Certification

Many suppliers fail to provide traceable documentation for materials (such as steel grade or fire-retardant fabric certifications), making it difficult to verify compliance with safety and environmental standards (e.g., REACH, OEKO-TEX). This opacity can result in regulatory non-compliance, especially in markets like the EU or North America where strict product safety laws apply.

Overlooking Long-Term Supplier Reliability

Choosing suppliers based solely on low cost can backfire if they lack scalability, consistent production capacity, or technical expertise. Poor communication, delayed deliveries, and inability to adapt to design changes can disrupt supply chains and increase total cost of ownership.

To mitigate these pitfalls, buyers should conduct thorough supplier audits, request sample testing, verify IP rights, and establish clear quality and compliance requirements in procurement agreements.

Logistics & Compliance Guide for Pocketed Coils

Overview

Pocketed coils, also known as wrapped or encased coils, are a popular type of innerspring unit used in mattresses and seating applications. Ensuring efficient logistics and strict compliance with regulations is essential for manufacturers, distributors, and importers to maintain product quality, meet customer expectations, and avoid legal or financial penalties.

Packaging Requirements

- Individual Wrapping: Each coil must be securely wrapped in a non-woven fabric sleeve to prevent noise and allow independent movement.

- Compressed Bundling: Coils are typically compressed and bundled into uniform stacks for efficient transport.

- Protective Materials: Use moisture-resistant wrapping (e.g., polyethylene film) and corner protectors to prevent damage during transit.

- Labeling: Clearly label each bundle with product specifications (gauge, height, coil count), batch/lot number, manufacturing date, and handling instructions (e.g., “This Side Up,” “Fragile”).

Storage Conditions

- Environment: Store in a dry, well-ventilated area with controlled temperature (15–25°C / 59–77°F) and relative humidity below 65% to prevent rust and fabric degradation.

- Stacking: Limit stack height to prevent crushing; use pallets and ensure even weight distribution.

- Rotation: Practice FIFO (First In, First Out) inventory management to minimize aging and material fatigue.

Transportation Guidelines

- Mode of Transport: Suitable for truck, rail, sea, and air freight depending on volume and destination.

- Securing Loads: Use straps, stretch wrap, and dunnage to prevent shifting during transit.

- Temperature Control: Avoid exposure to extreme temperatures and direct sunlight; consider climate-controlled containers for long-distance or international shipments.

- Documentation: Include packing lists, commercial invoices, and transport certifications (e.g., bill of lading) with every shipment.

International Compliance (Imports/Exports)

- Harmonized System (HS) Code: Typically classified under HS 9404.21 (mattress supports) or 8302.50 (steel springs), depending on end-use and construction.

- Customs Declarations: Provide accurate product descriptions, material composition, country of origin, and declared value.

- Import Restrictions: Comply with destination country regulations (e.g., REACH in the EU, CPSIA in the U.S.) regarding chemicals and materials.

- Certificates of Origin: Required for preferential tariff treatment under trade agreements (e.g., USMCA, RCEP).

Safety & Environmental Standards

- Flammability Compliance: Ensure compliance with regional fire safety standards such as:

- USA: 16 CFR Part 1633 (Mattress Flammability Standard)

- EU: EN 597-1/-2

- UK: BS 7177

- Chemical Restrictions:

- REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals — ensure no restricted substances (e.g., certain phthalates, heavy metals).

- RoHS (if applicable): Monitor for lead, cadmium, and other hazardous substances in metal components.

- VOC Emissions: Comply with low-emission standards such as Greenguard Gold or OEKO-TEX® STANDARD 100 for indoor air quality.

Quality Assurance & Traceability

- Batch Tracking: Assign unique batch/lot numbers to enable traceability in case of recalls or quality issues.

- Inspection Protocols: Conduct pre-shipment inspections to verify coil count, tension, height, and absence of defects.

- Documentation Retention: Maintain records of material certifications, test reports, and compliance documentation for a minimum of 5 years.

Sustainability & Disposal

- Recyclability: Steel coils are highly recyclable; encourage end-of-life recycling programs.

- Packaging Materials: Use recyclable or biodegradable materials where possible (e.g., recyclable PE film, cardboard).

- Carbon Footprint: Optimize logistics routes and consolidate shipments to reduce emissions.

Regulatory Contacts & Resources

- U.S. Consumer Product Safety Commission (CPSC): www.cpsc.gov

- European Chemicals Agency (ECHA): echa.europa.eu

- International Organization for Standardization (ISO): www.iso.org

- Customs Authorities: Consult local customs brokers or government trade portals for import requirements by country.

Conclusion

Efficient logistics and rigorous compliance are critical for the successful distribution of pocketed coils. By adhering to packaging, storage, transportation, and regulatory standards, businesses can ensure product integrity, reduce risks, and support sustainable operations across global supply chains.

Conclusion for Sourcing Pocketed Coils

Sourcing pocketed coils requires a strategic approach that balances quality, cost, customization, and supply chain reliability. These components are critical to the comfort, support, and longevity of high-performance mattresses, making supplier selection a key factor in product success. After evaluating various options, it is evident that partnering with experienced and certified manufacturers—whether domestic or overseas—ensures consistent product quality and compliance with industry standards.

Key considerations include material quality (particularly high-carbon steel), gauge options, durability, and the ability to customize coil counts and configurations. Additionally, evaluating a supplier’s production capacity, lead times, and sustainability practices supports long-term scalability and brand integrity.

In conclusion, a well-vetted supplier with technical expertise, strong quality control processes, and transparent communication will not only meet current demands but also support innovation and growth in the competitive sleep products market. Investing time in building strong supplier relationships ultimately leads to superior end products and greater customer satisfaction.