The global pneumatic solenoid valves market is experiencing robust growth, driven by increasing automation across industrial manufacturing, automotive, and process industries. According to Mordor Intelligence, the market was valued at USD 3.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. Similarly, Grand View Research estimates the market will expand at a CAGR of 5.4% during 2023–2030, fueled by rising demand for energy-efficient and precision control systems in industrial applications. As industries prioritize reliability, compact design, and smart integration, leading manufacturers are innovating to meet evolving performance and IoT-enabled automation requirements. In this competitive landscape, the top 10 pneumatic solenoid valves manufacturers distinguish themselves through technological advancement, global supply chain reach, and compliance with international standards—making them key enablers of modern industrial efficiency.

Top 10 Pneumatic Solenoid Valves Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pneumatic Solenoid Valves

Domain Est. 1995

Website: pneumadyne.com

Key Highlights: Pneumadyne is a manufacturer of standard miniature pneumatic solenoid valves. We can also assist you with design and engineering of custom pneumatic components….

#2 Solenoid Valves

Domain Est. 1995

Website: ph.parker.com

Key Highlights: Parker’s comprehensive selection of solenoid valves includes a broad range of types and configurations for all manner of applications across many industrial ……

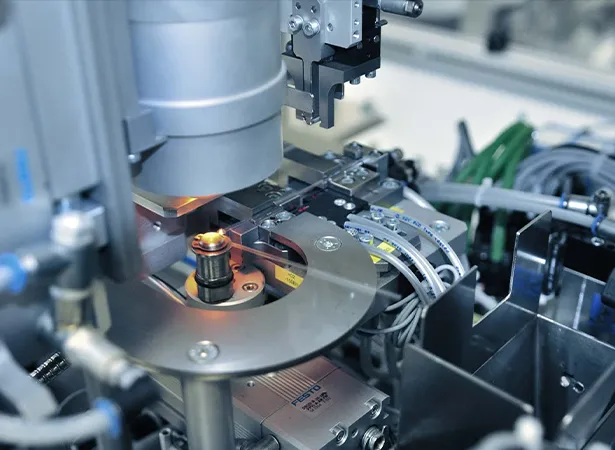

#3 Discover Festo Solenoid Valves

Domain Est. 1997

Website: festo.com

Key Highlights: Explore Festo’s solenoid valves for reliable pneumatic control, featuring compact designs and IP65 protection. Discover our industrial solutions today!…

#4 Air Cylinders, Solenoid Valves and Pneumatics

Domain Est. 1995

Website: smcusa.com

Key Highlights: LPV series is a 2-port solenoid normally closed or normally open pinch valve for fluid control. The LPV series pinch valve also comes with a u-shaped tube slot ……

#5 Solenoid Valves

Domain Est. 1995

Website: emerson.com

Key Highlights: Emerson’s ASCO solenoid valves set industry standards for reliability, adaptability and energy efficiency across many applications and industries….

#6 Pneumatic Safety and Hydraulic Safety

Domain Est. 1996

Website: rosscontrols.com

Key Highlights: The ROSS pneumatic safety valves are advanced valves specifically designed to regulate fluid power energy in accordance with contemporary safety guidelines for ……

#7 ASCO Solenoid Valves

Domain Est. 1998

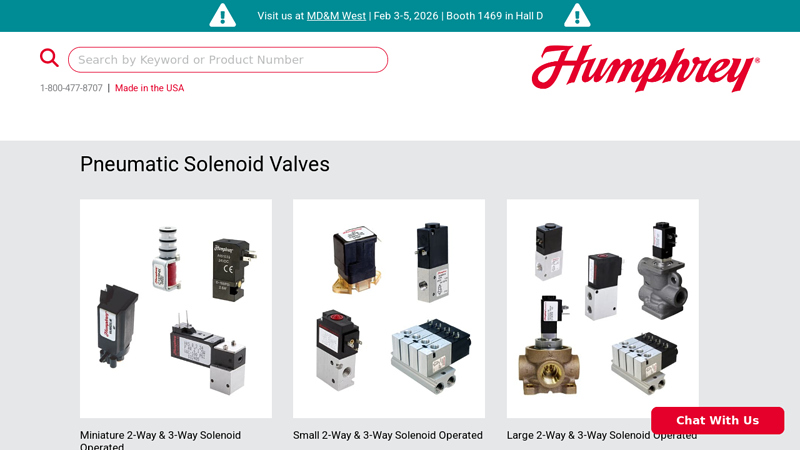

#8 Pneumatic Solenoid Valves

Domain Est. 2000

Website: humphrey-products.com

Key Highlights: Humphrey Products’ pneumatic solenoid valves offer design engineers high-flow efficiency in 2-, 3- and 4-way functions. Our valves accommodate nearly any media, ……

#9 StcValve Fittings, Solenoid and Pneumatic Valves, Air Regulators

Domain Est. 2001

Website: stcvalve.com

Key Highlights: STC specializes in high quality solenoid valves, stainless steel fittings, air valves, process valves, and air preparation units at excellent prices….

#10 Electric Solenoid Valve

Domain Est. 2013

Website: electricsolenoidvalves.com

Key Highlights: Free delivery over $99 45-day returnsSolenoid Valves Supplier for water, gas, air, & diesel. High-quality valves in all sizes/materials for pro & small projects. Fast shipping (shi…

Expert Sourcing Insights for Pneumatic Solenoid Valves

H2: 2026 Market Trends for Pneumatic Solenoid Valves

The global market for pneumatic solenoid valves is poised for significant transformation by 2026, driven by advancements in automation, energy efficiency demands, and the expansion of smart manufacturing. Several key trends are shaping the trajectory of this sector:

-

Growth in Industrial Automation and Industry 4.0 Adoption

The continued integration of Industry 4.0 technologies across manufacturing, automotive, and logistics sectors is accelerating demand for precise and responsive control systems. Pneumatic solenoid valves, as critical components in automated pneumatic systems, are benefiting from this shift. Smart solenoid valves with integrated sensors and communication capabilities (e.g., IO-Link) are increasingly being adopted to enable real-time monitoring, predictive maintenance, and seamless integration with PLCs and industrial IoT platforms. -

Miniaturization and Compact Design

Equipment manufacturers are prioritizing space-saving and lightweight components. This has led to a rising preference for compact, modular solenoid valve manifolds that offer high performance in smaller footprints. By 2026, leading suppliers are expected to focus on innovative designs that reduce size without compromising flow rates or durability, especially for use in robotics and medical devices. -

Energy Efficiency and Sustainability Initiatives

As industries aim to reduce energy consumption and carbon footprints, manufacturers of pneumatic solenoid valves are developing low-power consumption models and energy-saving pilot designs. Valves with optimized coil technology and improved sealing mechanisms help minimize compressed air leakage—a major source of energy waste in pneumatic systems. -

Expansion in Emerging Markets

Rapid industrialization in Asia-Pacific (particularly China, India, and Southeast Asia), coupled with government initiatives to boost manufacturing, is creating robust demand for automation components. Local production and supply chain localization are expected to increase, prompting global valve manufacturers to establish regional partnerships and manufacturing hubs by 2026. -

Increased Demand from Automotive and Electronics Manufacturing

The automotive sector, especially with the rise of electric vehicles (EVs), relies heavily on precision assembly lines where pneumatic solenoid valves control motion and clamping systems. Similarly, the electronics industry requires clean, reliable valve operation for semiconductor manufacturing and PCB handling. These high-growth end-use industries are expected to remain key drivers of valve demand. -

Advancements in Materials and Durability

To meet the demands of harsh environments (e.g., food and beverage, pharmaceuticals, and chemical processing), manufacturers are incorporating corrosion-resistant materials such as stainless steel, PTFE, and engineered plastics. By 2026, valves with enhanced chemical resistance, IP65/IP67 ratings, and compliance with hygiene standards (e.g., FDA, EHEDG) will see increased adoption. -

Rise of Customization and Digital Configuration Tools

End users are seeking application-specific solutions, prompting suppliers to offer configurable valve manifolds and digital selection tools. Online platforms enabling 3D modeling, performance simulation, and rapid prototyping are streamlining the design and procurement process, improving time-to-market for OEMs.

In summary, the 2026 outlook for pneumatic solenoid valves is characterized by technological innovation, digital integration, and expanding industrial demand. Companies that invest in smart, efficient, and adaptable valve solutions are likely to gain a competitive edge in this evolving market landscape.

Common Pitfalls Sourcing Pneumatic Solenoid Valves (Quality, IP)

Sourcing pneumatic solenoid valves involves navigating several potential pitfalls related to quality and intellectual property (IP) that can impact performance, safety, and long-term reliability. Avoiding these issues requires diligence and awareness.

1. Compromised Quality Due to Counterfeit or Substandard Components

One of the most significant risks is receiving valves that appear genuine but are counterfeit or made from inferior materials. These components often fail prematurely under pressure, temperature fluctuations, or continuous duty cycles. Warning signs include significantly lower prices than market averages, inconsistent branding, poor packaging, or lack of traceability (e.g., missing batch numbers or certifications).

2. Misrepresentation of Ingress Protection (IP) Ratings

Suppliers may falsely claim high IP ratings (e.g., IP65, IP67, or IP69K), which indicate protection against dust and water ingress. In reality, the valve may not have undergone proper testing or sealing. This misrepresentation can lead to valve failure in harsh environments, causing downtime or safety hazards, especially in outdoor, washdown, or high-humidity applications.

3. Lack of Genuine Certifications and Documentation

Reputable solenoid valves should come with verifiable certifications such as CE, UL, ATEX (for explosive environments), or ISO standards. A common pitfall is accepting products with forged or generic certification documents. Always request and verify test reports, conformity certificates, and traceable documentation directly from the manufacturer or authorized distributor.

4. Intellectual Property (IP) Infringement Risks

Sourcing from unauthorized or unverified suppliers increases the risk of purchasing valves that infringe on patented designs or trademarks. This not only exposes the buyer to legal liability but also supports unethical manufacturing practices. Using cloned or reverse-engineered valves may void warranties and compromise system compatibility and safety.

5. Inadequate Material and Performance Specifications

Some suppliers provide vague or incomplete technical data, such as incorrect flow rates, pressure ratings, or material composition (e.g., misleading claims about brass, stainless steel, or seals like NBR vs. FKM). This can result in incompatibility with process media (e.g., oils, chemicals) or mechanical failure under operating conditions.

6. Poor Supply Chain Traceability

Without a transparent supply chain, it becomes difficult to verify the origin of components or respond effectively to quality issues or recalls. Reliable suppliers should offer full traceability, including manufacturing location, component sources, and quality control records.

7. Overlooking Long-Term Support and Warranty

Low-cost valves may lack manufacturer-backed warranties or technical support. When failures occur, the absence of reliable after-sales service or spare parts availability leads to extended downtime and higher total cost of ownership.

Mitigation Strategy: Always source from authorized distributors or directly from reputable manufacturers. Conduct supplier audits, request third-party test data, and verify IP ratings and certifications independently. Prioritize long-term reliability and compliance over initial cost savings.

Logistics & Compliance Guide for Pneumatic Solenoid Valves

Overview

Pneumatic solenoid valves are essential components in industrial automation, controlling the flow of compressed air in various systems. Proper logistics management and compliance with international, regional, and industry-specific regulations ensure safe, efficient, and legal transport, storage, and use of these components.

Packaging and Handling

Secure Packaging

Pneumatic solenoid valves must be packaged to prevent physical damage during transit. Use:

– Rigid cardboard or plastic containers

– Internal cushioning (foam inserts, bubble wrap)

– Moisture-resistant wrapping to prevent corrosion

Ensure all ports are sealed with protective caps or plugs to avoid contamination.

Labeling

Clearly label each package with:

– Product name and model number

– Quantity

– Handling instructions (e.g., “Fragile,” “Do Not Invert”)

– Manufacturer and supplier information

Include barcodes or QR codes for tracking and inventory management.

Transportation

Domestic and International Shipping

- Use carriers experienced in industrial component logistics.

- For international shipments, comply with Incoterms® (e.g., FOB, DDP) as agreed with the customer.

- Declare accurate HS codes (e.g., 8481.80 for valves) for customs clearance.

- Provide commercial invoices, packing lists, and certificates of origin when required.

Temperature and Environmental Conditions

- Store and transport in dry, temperature-controlled environments.

- Avoid exposure to extreme temperatures (typically -20°C to 60°C unless otherwise specified).

- Prevent condensation during climate transitions.

Regulatory Compliance

CE Marking (European Union)

Ensure valves comply with:

– Pressure Equipment Directive (PED) 2014/68/EU – if used in pressurized systems above specified thresholds.

– Electromagnetic Compatibility (EMC) Directive 2014/30/EU – for solenoid electrical components.

– RoHS (2011/65/EU) – restriction of hazardous substances in electrical equipment.

– REACH (EC 1907/2006) – registration, evaluation, and restriction of chemicals.

Documentation: Issue an EU Declaration of Conformity.

ATEX Directive (2014/34/EU)

If valves are used in explosive atmospheres:

– Certify for appropriate zones (e.g., Zone 1, Zone 2).

– Mark with ATEX symbol, equipment group, and category.

UL / CSA Certification (North America)

For use in the U.S. and Canada:

– Obtain UL Listed or CSA certification where applicable.

– Comply with standards like UL 508 (Industrial Control Equipment).

China CCC Mark

For sale in China, certain industrial valves may require China Compulsory Certification (CCC). Confirm category applicability.

Other Regional Requirements

- UKCA Marking: Required for valves placed on the UK market post-Brexit (similar to CE).

- INMETRO (Brazil), PSE (Japan), or KC (South Korea) may apply depending on destination.

Documentation and Record Keeping

Maintain the following for compliance audits and traceability:

– Technical files (design, materials, testing)

– Test reports (pressure, cycle life, insulation resistance)

– Certificates of conformity and origin

– Material declarations (RoHS, REACH SVHC)

– Safety Data Sheets (SDS) for any hazardous materials used

Retain records for at least 10 years, per EU directives.

Import and Export Controls

Export Compliance

- Screen customers against denied party lists (e.g., U.S. BIS, EU Consolidated List).

- Obtain export licenses if valves contain controlled technology (rare, but possible with smart valves or integrated electronics).

Sanctions and Embargoes

Avoid shipping to embargoed countries (e.g., Iran, North Korea) without proper authorization.

Storage and Inventory Management

Warehouse Conditions

- Store in a clean, dry, climate-controlled environment.

- Use first-in, first-out (FIFO) inventory rotation.

- Protect from dust, moisture, and mechanical stress.

Shelf Life

Monitor for expiration if seals or lubricants degrade over time. Most solenoid valves have a recommended shelf life of 2–5 years when properly stored.

End-of-Life and Recycling

WEEE Compliance (EU)

If solenoid valves contain electrical components:

– Comply with Waste Electrical and Electronic Equipment (WEEE) Directive 2012/19/EU.

– Provide take-back options or partner with certified recyclers.

Recycling Guidance

- Separate metal (brass, stainless steel) and plastic components.

- Dispose of electronic coils per local e-waste regulations.

Summary

Effective logistics and compliance for pneumatic solenoid valves require attention to proper packaging, regulatory certification, accurate documentation, and adherence to international trade laws. Proactive management ensures product reliability, legal market access, and customer satisfaction.

Conclusion for Sourcing Pneumatic Solenoid Valves:

Sourcing pneumatic solenoid valves requires a strategic approach that balances performance, reliability, cost-efficiency, and compatibility with the intended application. After evaluating various suppliers, product specifications, and industry standards, it is clear that selecting the right valve involves considering key factors such as operating pressure, flow rate, voltage requirements, duty cycle, environmental conditions, and certifications (e.g., IP ratings, explosion-proof ratings for hazardous areas).

Prioritizing suppliers with a proven track record of quality, technical support, and timely delivery ensures long-term system efficiency and minimizes downtime. Additionally, opting for valves from manufacturers offering standardized designs and global service networks can simplify maintenance and replacement processes.

In conclusion, a well-informed sourcing decision—based on thorough technical evaluation, lifecycle cost analysis, and supplier reliability—will enhance the performance and durability of pneumatic systems. Investing in high-quality pneumatic solenoid valves from reputable sources ultimately leads to improved operational efficiency, reduced maintenance costs, and greater overall system reliability.