The global automotive lift market is experiencing steady expansion, driven by rising vehicle ownership, increased demand for efficient repair solutions, and growth in aftermarket services. According to Grand View Research, the global automotive lifts market was valued at USD 1.36 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.2% from 2023 to 2030. A key contributor to this trend is the rising adoption of pneumatic motorcycle lifts in repair shops and service centers, particularly due to their reliability, ease of maintenance, and safety in handling two-wheelers. As the motorcycle segment continues to gain traction—especially in Asia-Pacific and Latin America—the demand for specialized lifting equipment is escalating. This growing need has spurred innovation and competition among manufacturers, leading to advanced, cost-effective pneumatic solutions. In this evolving landscape, the following eight manufacturers have emerged as leaders, combining engineering excellence, global reach, and data-backed market presence to dominate the pneumatic motorcycle lift sector.

Top 8 Pneumatic Motorcycle Lift Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Motorcycle, ATV, UTV Lifts Archives

Domain Est. 1999

#2 Motorcycle & ATV Lift Tables

Domain Est. 2003

Website: redlinestands.com

Key Highlights: Rating 5.0 (22) · Free deliveryRedline Engineering DT1K Air Drop Tail Motorcycle Lift Table with FREE FRAME JACK. (3 reviews). $1,399.50 … more info….

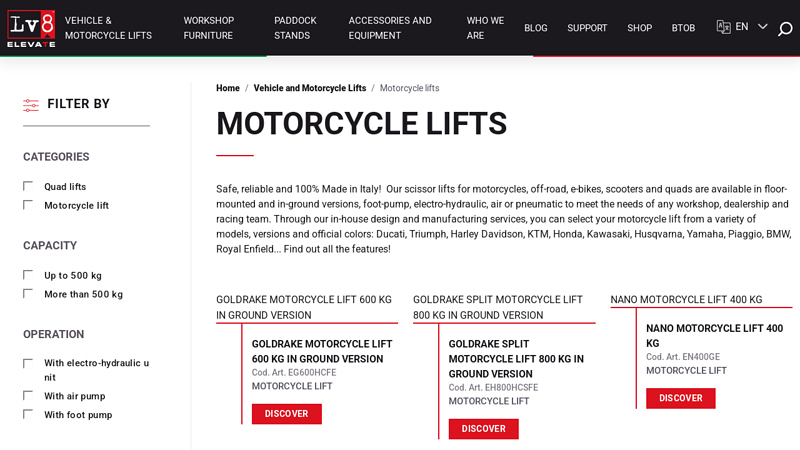

#3 Motorcycle lifts

Domain Est. 2003

Website: lv8.it

Key Highlights: Design and manufacturing of scissor lifts for motorbikes, off-road, e-bikes, scooters and quads. For workshops, dealerships and racing teams….

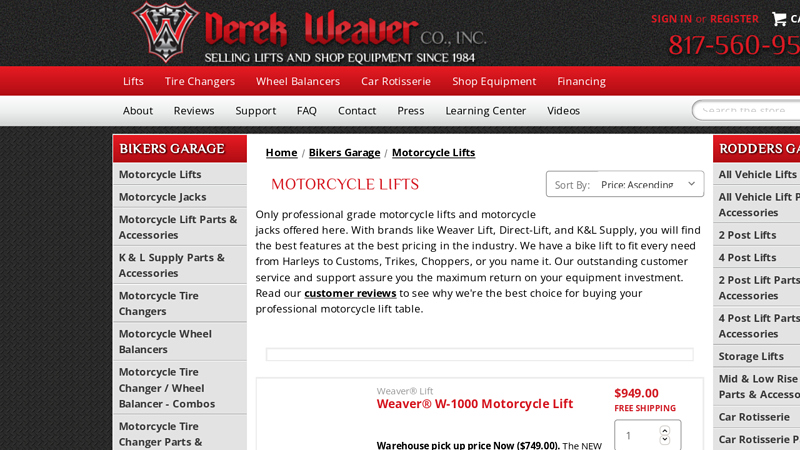

#4 Motorcycle Lifts

Domain Est. 2004

Website: derekweaver.com

Key Highlights: Free deliveryOnly professional grade motorcycle lifts and motorcycle jacks offered here. With brands like Weaver Lift, Direct-Lift, and K&L Supply, you will find the best ……

#5 Professional grade Motorcycle Lift tables and accessories.

Domain Est. 2005

#6 Motorcycle

Domain Est. 2008

Website: titanlifts.com

Key Highlights: Titan Lifts, LLC can be located in Greenwood, Indiana. We manufacture motorcycle and vehicle lifts (2-post, 4-post and scissor), motorcycle chocks, and lift ……

#7 ATV and Motorcycle Lifts

Domain Est. 2009

#8 Air Motorcycle Lifts

Domain Est. 2010

Website: nhproequip.com

Key Highlights: PRO Series Motorcycle Lifts, Elevator Lifts and Titan Lifts include high quality, dependable air-powered lift tables with a wide range of weight capacities ……

Expert Sourcing Insights for Pneumatic Motorcycle Lift

H2: 2026 Market Trends for Pneumatic Motorcycle Lifts

The global market for pneumatic motorcycle lifts is projected to experience steady growth by 2026, driven by increasing demand from motorcycle repair shops, customization garages, and DIY enthusiasts. Key trends shaping the 2026 landscape include technological advancements, rising motorcycle ownership, and a growing emphasis on workshop efficiency and safety.

-

Increased Demand from Aftermarket and Customization Sectors

The expanding motorcycle customization industry, especially in North America and Europe, is fueling demand for reliable and efficient lifting solutions. Pneumatic lifts offer faster operation and smoother performance compared to hydraulic alternatives, making them preferable in high-throughput environments. By 2026, specialty garages focused on custom builds and performance tuning are expected to drive adoption. -

Advancements in Pneumatic System Design

Manufacturers are integrating lightweight materials, improved air-pressure regulation, and fail-safe mechanisms to enhance lift stability and user safety. Innovations such as dual-piston configurations and automatic lock-release systems are making pneumatic lifts more reliable and user-friendly. These improvements are expected to broaden their appeal beyond professional workshops to home garages. -

Focus on Space Efficiency and Portability

As urban workshops face space constraints, compact and mobile pneumatic lifts are gaining popularity. By 2026, product designs are likely to emphasize foldability, low-profile bases, and modular components, enabling easier storage and transport—particularly beneficial for mobile mechanics and pop-up service centers. -

Regional Market Expansion

While North America and Western Europe remain dominant markets due to high motorcycle ownership and advanced repair infrastructure, the Asia-Pacific region—especially India, Indonesia, and Thailand—is anticipated to show the fastest growth. Increasing motorcycle sales and the rise of organized repair chains in these regions are creating new opportunities for pneumatic lift suppliers. -

Sustainability and Energy Efficiency Considerations

With growing environmental awareness, manufacturers are exploring energy-efficient compressors and recyclable materials in lift construction. Although pneumatic systems rely on compressed air (which requires electricity), their long-term durability and lower fluid leakage risk compared to hydraulic lifts contribute to a more sustainable profile—a factor that could influence procurement decisions by eco-conscious businesses. -

Integration with Smart Workshop Ecosystems

By 2026, leading pneumatic motorcycle lifts may feature IoT connectivity for usage monitoring, maintenance alerts, and integration with digital workshop management software. While still in early stages, this trend reflects the broader shift toward smart tools in automotive and motorcycle servicing.

In summary, the 2026 market for pneumatic motorcycle lifts will be shaped by innovation in design, rising demand in emerging economies, and the need for efficient, safe, and compact lifting solutions. As the motorcycle service industry evolves, pneumatic lifts are poised to maintain a competitive edge over hydraulic and mechanical alternatives, especially in professional and semi-professional settings.

Common Pitfalls Sourcing Pneumatic Motorcycle Lifts (Quality, IP)

Sourcing a pneumatic motorcycle lift requires careful evaluation to avoid compromising on safety, durability, and performance. Key pitfalls often revolve around quality inconsistencies and intellectual property (IP) concerns, especially when dealing with manufacturers from regions with less stringent enforcement.

Overlooking Build Quality and Material Specifications

One of the most frequent pitfalls is failing to verify the actual build quality and materials used. Many suppliers advertise high-capacity lifts, but the reality may differ significantly. Issues include substandard steel thickness, poorly welded joints, or inadequate surface treatments leading to premature rust and structural failure. Always request material certifications and insist on third-party load testing reports to validate claims.

Inadequate or Misrepresented Safety Features

Safety is paramount when lifting heavy machinery. Some suppliers cut costs by omitting essential safety mechanisms such as dual pneumatic locking systems, overload valves, or fail-safe descent controls. Others may falsely claim compliance with safety standards (e.g., CE, ISO). Verify certifications through independent channels and conduct on-site audits if possible.

Ignoring Intellectual Property (IP) Infringement Risks

Sourcing from certain regions poses a significant IP risk. Many pneumatic motorcycle lifts mimic patented designs from established brands, particularly in terms of hydraulic-pneumatic systems, lifting arms, and lock mechanisms. Purchasing such counterfeit or cloned products exposes buyers to legal liabilities, especially in markets with strong IP enforcement. Always conduct due diligence on the supplier’s design origin and request proof of legitimate IP ownership or licensing.

Relying Solely on Product Samples

While samples are useful, they may not reflect mass production quality. Suppliers often use higher-grade components for samples to win contracts, then switch to cheaper alternatives during full-scale production. Implement a quality control protocol that includes factory inspections and random batch testing during production runs.

Underestimating After-Sales Support and Spare Parts Availability

Low initial pricing can be misleading if spare parts are unavailable or technical support is lacking. Pneumatic systems require maintenance, and sourcing replacement seals, valves, or cylinders can become a challenge with generic or copycat models. Confirm the supplier’s spare parts inventory and response time for technical assistance before finalizing the deal.

Failing to Audit Manufacturing Processes

Many suppliers outsource components across multiple subcontractors, leading to inconsistent quality control. Without direct oversight of the manufacturing process, there’s a high risk of defects slipping through. Conduct regular audits of the production line and ensure the supplier has a documented quality management system (e.g., ISO 9001).

By addressing these pitfalls proactively—through rigorous vetting, contractual IP protections, and ongoing quality monitoring—buyers can mitigate risks and secure reliable, compliant pneumatic motorcycle lifts.

Logistics & Compliance Guide for Pneumatic Motorcycle Lift

This guide outlines the essential logistics considerations and compliance requirements for the safe and legal handling, transportation, storage, and use of pneumatic motorcycle lifts. Adherence ensures operational efficiency, user safety, and regulatory compliance.

Product Classification & Regulations

Pneumatic motorcycle lifts are categorized as industrial lifting equipment and are subject to regional and international safety standards. In the United States, compliance with OSHA (Occupational Safety and Health Administration) regulations is mandatory for workplace use. The equipment may also fall under ANSI/ITSDF B56.1 safety standards for low-lift and high-lift trucks and platform lift trucks. In the European Union, adherence to the Machinery Directive (2006/42/EC) and CE marking is required. Always verify local regulatory requirements before import, sale, or operation.

Shipping & Transportation

Due to weight and size, pneumatic motorcycle lifts are typically shipped via freight carriers (LTL or FTL). Units must be securely crated or palletized with protective corner boards and shrink-wrapped to prevent damage. Proper labeling—including “Fragile,” “This Side Up,” and handling instructions—is required. Ensure shipping documentation includes accurate weight, dimensions, and a detailed product description for customs clearance. For international shipments, comply with ISPM 15 regulations for wooden packaging.

Import & Customs Clearance

Importers must provide a commercial invoice, packing list, and bill of lading/airway bill. The Harmonized System (HS) code for pneumatic lifts typically falls under 8428.90 (other lifting appliances). Duties and taxes vary by country. Ensure compliance with destination country’s technical standards and certifications (e.g., CE, UKCA, or EAC). Some regions may require conformity assessment or registration prior to import.

Storage & Handling

Store lifts in a dry, indoor environment to prevent corrosion of metal components and degradation of pneumatic seals. Units should remain on pallets and be protected from dust and moisture. Avoid stacking unless designed for it. Use appropriate material handling equipment (e.g., forklifts) when moving lifts—never drag or roll directly on the lift base. Follow manufacturer guidelines for safe handling during warehouse operations.

Installation & Use Compliance

Installation must be performed on a level, hard, non-slip surface with sufficient overhead clearance. Verify floor load capacity meets manufacturer specifications (typically >5,000 psi concrete). Connect only to a clean, dry compressed air supply meeting the required PSI (usually 100–120 PSI) via a properly sized air hose and safety-rated fittings. Users must be trained on operational procedures, emergency lowering, and weight limits. Always center the motorcycle and use safety locks before working underneath.

Maintenance & Inspection

Conduct regular visual inspections for wear, leaks, cracks, or damaged hoses. Follow the manufacturer’s maintenance schedule, including lubrication of moving parts and checking air pressure regulators. Replace worn seals and damaged components immediately. Keep a maintenance log for compliance and safety audits. After any significant impact or malfunction, inspect thoroughly before reuse.

Safety & Documentation

Provide end-users with the original operator’s manual, safety warnings, and maintenance instructions in the local language. Safety decals must be legible and intact. Employers must train personnel and maintain records as required by OSHA or equivalent bodies. In case of incidents, report according to jurisdictional requirements and preserve equipment for investigation.

Disposal & Environmental Compliance

At end-of-life, dispose of the lift in accordance with local waste regulations. Metal components may be recycled through certified scrap metal facilities. Pneumatic cylinders and hoses may contain materials requiring special handling—consult environmental agencies or the manufacturer for guidance. Never incinerate or landfill components containing hazardous substances.

Conclusion on Sourcing a Pneumatic Motorcycle Lift

Sourcing a pneumatic motorcycle lift is a strategic decision that offers significant advantages for motorcycle repair shops, garages, and enthusiasts requiring reliable and efficient lifting solutions. Pneumatic lifts, powered by compressed air, provide consistent performance, enhanced safety, and reduced maintenance compared to hydraulic alternatives. When sourcing such equipment, it is essential to consider factors including weight capacity, lifting height, build quality, safety certifications, and compatibility with different motorcycle types.

Sourcing from reputable manufacturers or suppliers ensures product reliability, access to technical support, and compliance with industry standards. While initial costs may be higher, the durability, energy efficiency, and long-term operational benefits of pneumatic lifts justify the investment. Additionally, evaluating warranty terms, available spare parts, and customer service can further enhance the value and usability of the lift.

In conclusion, a well-sourced pneumatic motorcycle lift enhances workshop productivity, ensures operator safety, and supports professional-grade maintenance and repair work. Careful supplier selection and due diligence in product specifications will lead to a dependable and cost-effective solution tailored to specific operational needs.