The global plush toys market is experiencing steady expansion, driven by rising consumer demand for high-quality, safe, and sustainable soft toys. According to Grand View Research, the global plush toys market size was valued at USD 9.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. This growth underscores the increasing importance of reliable and innovative stuffing materials, which directly influence the durability, softness, and safety of plush products. As manufacturers strive to meet stringent safety standards and evolving consumer preferences—including hypoallergenic, eco-friendly, and recyclable fillings—the demand for advanced plush stuffing solutions continues to rise. In this competitive landscape, sourcing high-performance filling materials from reputable suppliers is critical for toy and gift producers aiming to maintain product quality and market relevance. Here, we spotlight the top 9 plush stuffing material manufacturers shaping the industry with consistent quality, innovation, and scalable production capabilities.

Top 9 Plush Stuffing Material Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

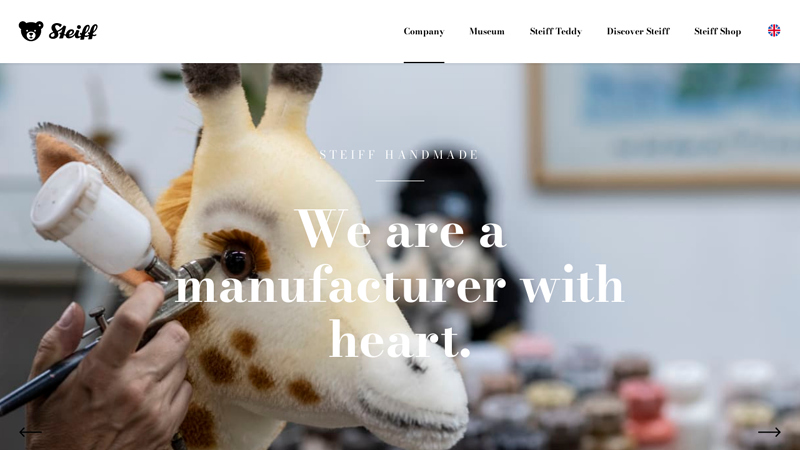

#1 Handmade

Domain Est. 1999

Website: corporate.steiff.com

Key Highlights: Only materials of the highest quality are used in our Steiff toy factory. Starting with the sewing thread, through the filling material ……

#2 Fiber Filling

Domain Est. 2000

Website: thebearfactory.com

Key Highlights: At The Bear Factory, we take pride in offering premium fiber fill to ensure your plush creations are stuffed with care, comfort, and safety….

#3 Polyester Stuffing

Domain Est. 1998

Website: nusso.com

Key Highlights: Collection: Polyester Stuffing. Filter by. All products, Bag · bag of stuffing · Best Seller · bulk polyester fiberfill · bulk polyester stuffing ……

#4 Gann Memorials

Domain Est. 1999

Website: gannmemorials.com

Key Highlights: We can manufacture custom plush for your entertainment brand, event, business, school, church, fundraiser, or literary works….

#5 Make Your Own Stuffed Animal Kit

Domain Est. 2004

Website: bdaybears.com

Key Highlights: Our products are unstuffed teddy bears & unstuffed animal kits, which include: 16 inch plush unstuffed bear or animal skin; stuffing fluff; animal t-shirt ……

#6 Polyester Stuffing

Domain Est. 2005

Website: hometex.ca

Key Highlights: Our stuffing is made from 100% Brand-New, Hypoallergenic Non-Recycled white polyester fiber that has been processed to its maximum, high loft….

#7 Teddy Mountain the Leading DIY wholesale teddy bear provider

Domain Est. 2007

Website: teddymountain.com

Key Highlights: Teddy Mountain is the leader in DIY plush toy wholesale business! Learn how our solutions can boost your sales and bottom line!…

#8 Bulk Fiberfill for Stuffing

Domain Est. 2007

Website: airlitemanufacturing.com

Key Highlights: This fiberfill is manufactured using lightweight 100% recycled polyester or cotton fibers. · Ideal for all fiber filled products: stuffed animals, dolls, home ……

#9 Soft Toys Stuffing

Website: syto.eu

Key Highlights: We offer exceptional soft toy manufacturing, specializing in high-quality fiber filling for plush toys. Our commitment to sustainability and meticulous ……

Expert Sourcing Insights for Plush Stuffing Material

H2: 2026 Market Trends for Plush Stuffing Material

The global market for plush stuffing materials is poised for significant transformation by 2026, driven by evolving consumer preferences, sustainability mandates, technological advancements, and shifting manufacturing dynamics. As the demand for plush toys, decorative items, and comfort products continues to grow—especially in emerging markets—innovations in stuffing materials are reshaping industry standards. Below are the key trends expected to define the plush stuffing material landscape in 2026:

1. Rise of Sustainable and Bio-Based Fillings

Environmental consciousness is a dominant force influencing material selection. By 2026, a growing number of manufacturers are expected to shift from traditional polyester-based stuffing (like polyfill) to eco-friendly alternatives. Bio-based fillers derived from recycled plastics, organic cotton, bamboo fibers, and even algae-based polymers are gaining traction. Brands aiming for carbon neutrality and compliance with stricter environmental regulations—particularly in the EU and North America—are leading this transition.

2. Increased Demand for Hypoallergenic and Non-Toxic Materials

With heightened awareness around health and safety, especially in children’s products, there is a rising demand for hypoallergenic, odorless, and non-toxic stuffing. Materials certified under OEKO-TEX® Standard 100 or GOTS (Global Organic Textile Standard) are expected to become industry benchmarks by 2026. This trend is particularly strong in premium plush segments and baby product lines.

3. Advancements in Recycled and Circular Materials

The circular economy is influencing plush stuffing innovation. By 2026, stuffing made from 100% post-consumer recycled (PCR) polyester is projected to gain significant market share. Major toy companies are partnering with material science firms to develop stuffing that maintains softness and resilience while reducing reliance on virgin plastics. Closed-loop recycling programs for plush products are also expected to emerge, further driving demand for recyclable stuffing.

4. Regional Shifts in Production and Sourcing

Asia-Pacific, particularly China and India, will remain key manufacturing hubs for plush goods. However, by 2026, localized production is expected to rise in North America and Europe due to supply chain resilience concerns and tariffs. This shift will encourage regional development of stuffing materials, including domestic recycling infrastructure for fiber production.

5. Smart and Functional Stuffing Innovations

Emerging technologies are introducing “smart” stuffing materials with added functionalities. By 2026, expect limited but growing adoption of stuffing infused with temperature-regulating gels, aromatherapy capsules, or antimicrobial agents—especially in therapeutic plush toys and wellness-oriented products.

6. Cost Pressures and Material Substitution

While sustainability drives innovation, cost remains a critical factor, especially in mass-market plush items. By 2026, hybrid stuffing solutions—combining recycled fibers with low-cost natural fillers like kapok or milkweed—may emerge as economically viable, eco-conscious alternatives to pure synthetic fill.

7. Regulatory Influence and Standardization

Stricter regulations on microplastic shedding and chemical use in textiles are expected to impact stuffing material formulations. By 2026, regulatory bodies may impose labeling requirements for stuffing composition, pushing transparency and responsible sourcing across the supply chain.

Conclusion

By 2026, the plush stuffing material market will be defined by sustainability, safety, and innovation. Traditional polyester fill will face increasing competition from bio-based, recycled, and functional alternatives. Companies that invest in green materials, comply with global standards, and respond to consumer demand for ethical products will lead the market. The convergence of environmental responsibility and technological advancement will position plush stuffing not just as a filler, but as a key differentiator in brand value and product performance.

Common Pitfalls When Sourcing Plush Stuffing Material (Quality, IP)

Sourcing plush stuffing material—often polyester fiberfill or other synthetic/organic fillers—requires careful attention to both quality consistency and intellectual property (IP) concerns. Overlooking these aspects can lead to product defects, customer dissatisfaction, legal risks, and brand damage. Below are key pitfalls to avoid:

Inconsistent Material Quality

One of the most frequent issues is variability in stuffing quality between batches. Low-cost suppliers may use recycled or substandard fibers that result in lumpy, flat, or uneven filling. This compromises the plush toy’s softness, shape retention, and durability. Always request material specifications (fiber denier, loft, resilience) and conduct batch testing.

Poor Fiber Cleanliness and Odor

Some stuffing materials, especially lower-grade or recycled polyester, can retain chemical residues or emit unpleasant odors. These may trigger sensitivities in consumers or violate safety standards. Ensure suppliers provide Certificates of Compliance (COC) and conduct odor and VOC (volatile organic compound) testing.

Non-Compliance with Safety Standards

Plush toys are subject to strict safety regulations (e.g., ASTM F963, EN71, CPSIA). Using stuffing that hasn’t been tested for flammability, phthalates, or heavy metals can lead to product recalls. Verify that the stuffing is certified for toy use and meets regional regulatory requirements.

Intellectual Property Infringement Risks

When sourcing stuffing for branded or character-based plush toys, using patented or trademarked materials without authorization can lead to IP violations. For example, some high-resilience fiber technologies (e.g., specific branded fiberfill like “Isolite” or “Holofiber”) are protected. Using counterfeit or unlicensed versions may expose your company to legal action.

Misrepresentation of Material Origin or Type

Suppliers may falsely claim stuffing is “100% virgin polyester” or “eco-friendly,” when it contains recycled content or mixed fibers. This misrepresentation affects product performance and sustainability claims. Conduct independent lab testing and request full material disclosure.

Lack of Traceability and Documentation

Without proper documentation—such as mill certifications, chain-of-custody records, or test reports—it’s difficult to verify quality or defend against compliance issues. Establish supplier agreements that require full transparency and traceability of raw materials.

Overlooking Long-Term Supplier Reliability

Relying on a single low-cost supplier with no quality control processes increases the risk of sudden material changes or supply chain disruptions. Diversify sourcing and conduct regular audits to ensure ongoing compliance and consistency.

By addressing these pitfalls proactively, companies can ensure their plush products meet quality expectations, comply with safety regulations, and avoid costly IP disputes.

Logistics & Compliance Guide for Plush Stuffing Material

Overview

Plush stuffing material—commonly made from polyester fiberfill, cotton, or recycled fibers—is widely used in the manufacturing of toys, pillows, and decorative items. Proper logistics and compliance management are essential to ensure product safety, regulatory adherence, and efficient supply chain operations.

Material Classification & Handling

Plush stuffing is typically classified as a low-hazard, non-toxic material, but it must be handled carefully to maintain quality. It is lightweight, compressible, and sensitive to moisture and contamination. Use sealed, breathable packaging to prevent clumping, mold, or fiber degradation during transport and storage.

Packaging Requirements

- Use polyethylene or polypropylene bags with moisture barriers.

- Vacuum compression may be used to reduce volume and shipping costs.

- Label packages clearly with material type, weight, batch number, and handling instructions (e.g., “Keep Dry,” “Do Not Crush”).

Transportation & Storage

- Store in dry, temperature-controlled environments to avoid moisture absorption.

- Stack properly to prevent compaction and fiber damage.

- Avoid exposure to direct sunlight or extreme heat, which can degrade synthetic fibers.

- Use clean, pest-free transport vehicles; avoid sharing space with chemicals or strong odor sources.

Regulatory Compliance

United States (CPSC & FTC)

- Comply with the Consumer Product Safety Commission (CPSC) regulations, especially for children’s toys.

- Ensure compliance with flammability standards (e.g., 16 CFR Part 1610 for fabric materials).

- Adhere to FTC Care Labeling Rule if the end product requires washing instructions.

European Union (REACH & Toy Safety Directive)

- Conform to REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) standards—ensure no restricted substances (e.g., phthalates, heavy metals) are present.

- For toys, meet EN 71-3 (migration of certain elements) and EN 71-1 (physical and mechanical properties).

- Provide a Declaration of Conformity (DoC) and affix CE marking where applicable.

Other Regions

- Canada: Comply with the Canada Consumer Product Safety Act (CCPSA) and flammability regulations.

- Australia/New Zealand: Meet AS/NZS 60835.210 for toy safety.

- China: Follow GB 18401 (national general safety technical code) and GB 6675 (toy safety).

Labeling & Documentation

- Include fiber content (e.g., “100% Polyester Fiberfill”) on packaging.

- Maintain Safety Data Sheets (SDS) for industrial handling, even if non-hazardous.

- Provide compliance documentation (test reports, Certificates of Compliance) to importers and retailers.

Sustainability & Environmental Considerations

- Recycled stuffing materials must comply with recycled content claims (e.g., FTC Green Guides).

- Ensure proper disposal or recycling of packaging materials.

- Consider certifications like Oeko-Tex Standard 100 for eco-friendly and non-toxic assurance.

Incident Response & Recalls

- Establish a traceability system using batch/lot numbers.

- In case of contamination or compliance failure, initiate recall procedures per regional regulations.

- Notify relevant authorities (e.g., CPSC in the U.S.) and coordinate with supply chain partners.

Conclusion

Effective logistics and compliance for plush stuffing materials require attention to storage, transportation, labeling, and regional regulations. Proactive documentation and adherence to safety standards ensure consumer trust and smooth global distribution.

In conclusion, sourcing plush stuffing material requires a careful balance of quality, cost-effectiveness, sustainability, and supplier reliability. Factors such as softness, durability, washability, and hypoallergenic properties are critical in ensuring the final product meets customer expectations. While traditional materials like polyester fiberfill remain popular for their affordability and performance, there is increasing demand for eco-friendly alternatives such as recycled fibers or organic materials, driven by consumer awareness and sustainability goals.

Establishing relationships with reputable suppliers—ideally those with certifications for ethical and environmental standards—helps ensure consistency and compliance. Additionally, conducting sample testing and evaluating long-term supply capabilities minimizes risks and supports scalable production. Ultimately, the right stuffing material not only enhances the plush toy’s tactile appeal and safety but also aligns with brand values, contributing to customer satisfaction and long-term success in the market.