The global plug and socket electrical market is experiencing steady growth, driven by rising urbanization, expanding construction activities, and increasing demand for energy-efficient and smart electrical solutions. According to Grand View Research, the global electrical plugs and sockets market was valued at USD 12.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is further fueled by stringent safety regulations, the proliferation of electric vehicles necessitating EV charging outlets, and the adoption of modular and smart wiring devices in residential and commercial infrastructures. As reliability, durability, and compliance become key purchasing criteria, manufacturers are investing heavily in R&D and global standard certifications. Against this dynamic backdrop, the following nine companies have emerged as leaders, combining innovation, global reach, and robust product portfolios to dominate the competitive landscape of plug and socket electrical manufacturing.

Top 9 Plug And Socket Electrical Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Meltric

Domain Est. 1997

Website: meltric.com

Key Highlights: MELTRIC offers a full line of industrial plugs and receptacles, including our signature brand of UL-listed Switch-Rated devices with DECONTACTOR™ ……

#2 Manufacturer of industrial plugs and sockets

Domain Est. 1998

Website: proconect.fr

Key Highlights: French manufacturer of industrial plugs and sockets for 30 years. Our Expertise is due to our experience and our knowledge….

#3 Leviton

Domain Est. 1995

Website: leviton.com

Key Highlights: Leviton offers a wide range of lighting controls, wiring devices and networking to meet the needs of today’s residential, commercial and industrial ……

#4 Leading Electrical Plug Manufacturers

Domain Est. 2001

Website: cordsets.org

Key Highlights: Save time and easily view the leading electrical plug manufacturers and suppliers in the USA who offer a wide selection of custom electrical plugs….

#5 CEE plugs and sockets

Website: walther-werke.de

Key Highlights: The WALTHER range of NEO CEE plugs and sockets offers the right solution for a wide variety of applications: for industrial applications, on construction sites, ……

#6 Electrical and Electronic Connectors

Domain Est. 1996

Website: hirose.com

Key Highlights: Connector Selector Categories, Applications, Customer Support, Partners, Locations, Contact Us, Privacy Policy | Terms of Use | Membership Agreement…

#7 Plugs and sockets

Domain Est. 1997

Website: catalogue.bals.com

Key Highlights: A large selection of Bals connectors. We manufacture plugs and sockets in different variants and thus cover all your needs for different connection solutions ……

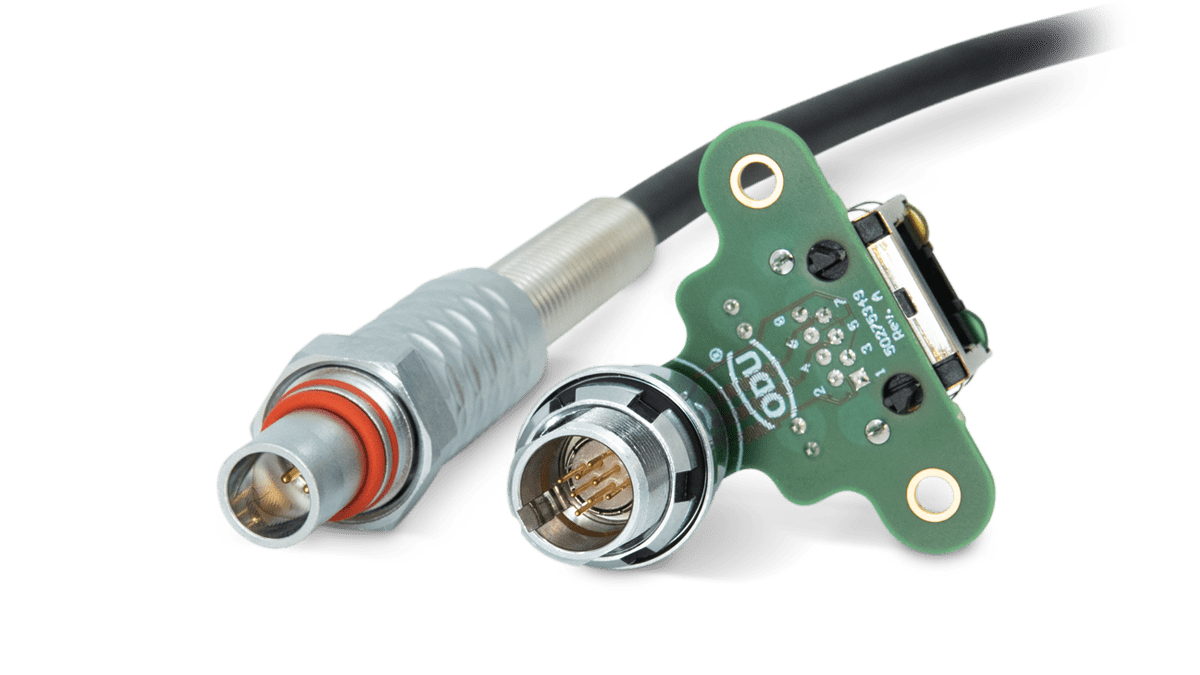

#8 ODU Connector Systems

Domain Est. 2014

Website: odu-connectors.com

Key Highlights: Development & production of connector systems for reliable transmission of ✓power, ✓signals & ✓data → ODU, based in Mühldorf am Inn….

#9 World plugs

Website: iec.ch

Key Highlights: Select a location, electric potential or frequency to discover what plug type(s), voltage and frequency are used there….

Expert Sourcing Insights for Plug And Socket Electrical

H2: 2026 Market Trends for Plug and Socket Electrical Industry

The global plug and socket electrical market is poised for significant transformation by 2026, driven by technological innovation, evolving regulatory standards, and shifting consumer demands. Key trends shaping the industry include the rise of smart electrical systems, increased emphasis on energy efficiency, and the global push toward electrification and decarbonization.

-

Smart Plugs and Sockets Gain Momentum

Smart plug and socket systems are expected to dominate market growth by 2026. Integrated with IoT (Internet of Things) technology, these devices allow remote control via smartphones, voice assistants, and home automation platforms. Consumers and commercial users alike are adopting smart solutions for improved energy monitoring, load management, and convenience. The integration of AI-driven energy usage analytics will further enhance demand, especially in residential and smart building applications. -

Surge in Demand for Energy-Efficient Solutions

With rising energy costs and stricter environmental regulations, manufacturers are focusing on energy-efficient plug and socket designs. Features such as auto-shutoff, overload protection, and low standby power consumption are becoming standard. The European Union’s Ecodesign Directive and similar policies in North America and Asia are accelerating the shift toward high-efficiency electrical accessories. -

Global Electrification and Infrastructure Development

Emerging markets in Asia-Pacific, Africa, and Latin America are investing heavily in power infrastructure, driving demand for reliable plug and socket systems. Urbanization and the expansion of electrical grids are creating new opportunities, especially for weatherproof, child-safe, and high-current-rated sockets tailored to local standards. -

Adoption of Universal and Modular Designs

As global travel and device compatibility increase, there is growing demand for universal plug and socket solutions. Modular socket systems that allow customization (USB-C, wireless charging, surge protection) are gaining popularity in both consumer and commercial sectors. Manufacturers are responding with multi-standard outlets and adaptable faceplates. -

Sustainability and Material Innovation

Environmental concerns are influencing material choices, with a shift toward recyclable plastics, biodegradable composites, and reduced packaging waste. Leading brands are pursuing certifications like RoHS and REACH compliance, and some are introducing take-back programs to support circular economy initiatives. -

Enhanced Safety Standards and Regulations

Safety remains a top priority, especially with the rise in electric vehicle (EV) charging infrastructure and high-power home appliances. By 2026, stricter international standards—such as IEC 60884 updates and regional mandates—are expected to mandate arc-fault detection, tamper resistance, and fire-retardant materials in plug and socket designs. -

Growth in Industrial and Commercial Applications

Beyond residential use, the industrial and commercial sectors are adopting advanced plug and socket systems for data centers, healthcare facilities, and EV charging stations. Waterproof, dustproof (IP67-rated), and high-voltage connectors are in high demand for harsh environments and mission-critical applications.

In conclusion, the 2026 plug and socket electrical market will be shaped by digitalization, sustainability, and safety. Companies that innovate in smart connectivity, energy efficiency, and compliance with global standards will be best positioned to capture market share in this evolving landscape.

Common Pitfalls Sourcing Plug and Socket Electrical Components (Quality, IP Rating)

Sourcing plug and socket electrical components involves more than just matching voltage and current ratings. Overlooking critical quality and Ingress Protection (IP) factors can lead to safety hazards, premature failures, and non-compliance. Below are key pitfalls to avoid:

Inadequate Quality Verification

Many suppliers, especially from low-cost regions, may provide components that appear compliant but fail under real-world conditions. Buyers often rely solely on datasheets or basic certifications without verifying actual build quality. Issues include substandard materials (e.g., brittle plastic, undersized contacts), poor internal construction, and inconsistent manufacturing. Always request samples, conduct independent testing, and verify compliance with recognized standards (e.g., IEC, UL, CE) through accredited third-party labs.

Misunderstanding or Misrepresenting IP Ratings

The Ingress Protection (IP) code indicates a product’s resistance to dust and water. A common mistake is assuming that a higher IP number (e.g., IP67) guarantees suitability for harsh environments without examining test conditions. For example, IP67-rated devices are protected against temporary immersion, not continuous submersion. Additionally, some suppliers falsely claim high IP ratings without proper testing. Always verify IP claims with test reports and ensure the rating matches the intended application—outdoor, washdown, or industrial settings demand appropriate sealing and gasket integrity.

Overlooking Environmental and Mechanical Stress

Plugs and sockets used in industrial or outdoor applications are exposed to vibration, temperature extremes, UV radiation, and physical impact. Sourcing components not designed for such conditions leads to cracking, contact degradation, or seal failure. Ensure materials are UV-stabilized, rated for the operational temperature range, and mechanically robust. Consider locking mechanisms or strain relief features where movement or tension is present.

Ignoring Compatibility and Interchangeability

Not all plugs and sockets claiming the same standard (e.g., IEC 60309) are truly interchangeable. Differences in pin dimensions, tolerances, or mating forces can cause poor connections, overheating, or arcing. Always test mated pairs from the intended supplier and verify compatibility with existing equipment. Mixing brands without validation risks unreliable connections and safety issues.

Failing to Assess Long-Term Supplier Reliability

Even high-quality initial samples can degrade if the supplier lacks consistent quality control. Relying on a supplier without auditing their manufacturing processes or quality management systems (e.g., ISO 9001) increases the risk of batch-to-batch variability. Establish long-term partnerships with suppliers who offer traceability, consistent documentation, and responsive support for quality issues.

Neglecting Regulatory and Regional Compliance

Electrical components must meet regional safety and electromagnetic compatibility (EMC) regulations. Assuming global compliance based on a single certification (e.g., CE) is risky—some certifications may be self-declared or outdated. Confirm that products meet local requirements such as UL listing in North America, UKCA in the UK, or CCC in China, and verify authenticity through official databases.

Avoiding these pitfalls requires due diligence in supplier selection, rigorous testing, and a clear understanding of both quality benchmarks and environmental demands—especially regarding IP ratings.

Logistics & Compliance Guide for Plug and Socket Electrical Products

Product Classification and Regulatory Standards

Plug and socket electrical products are classified as electrical equipment and are subject to stringent international and regional safety regulations. These products must comply with standards such as IEC 60884 (International Electrotechnical Commission), BS 1363 (UK), NEMA standards (North America), AS/NZS 3112 (Australia/New Zealand), and GB 2099 (China). Compliance ensures safe operation, mechanical durability, temperature resistance, and proper insulation. Manufacturers must obtain certification from accredited bodies (e.g., CE, UKCA, UL, CCC, SAA) before placing products on the market.

Packaging and Labeling Requirements

All plug and socket units must be securely packaged to prevent damage during transit. Packaging should be moisture-resistant and include protective materials such as foam inserts or corrugated dividers. Each unit must bear legible labels indicating the manufacturer’s name, model number, voltage and current ratings (e.g., 250V~, 13A), applicable certification marks, and country of origin. Bilingual labeling may be required for certain markets (e.g., French in Canada, Spanish in Latin America). Barcodes and batch/lot numbers must also be included for traceability.

Import and Export Documentation

For international shipment, essential documentation includes a commercial invoice, packing list, bill of lading/air waybill, and certificate of conformity (CoC). A test report from an accredited laboratory (e.g., SGS, TÜV, Intertek) may be required at customs. Some countries mandate additional documents such as a letter of authorization from the brand owner or a product registration certificate (e.g., SONCAP for Nigeria, BIS for India). Ensure all documentation reflects the correct HS (Harmonized System) code—commonly 8536.69 for electrical switches and sockets.

Customs Clearance and Duties

Customs authorities scrutinize electrical products due to safety concerns. Ensure declared values are accurate to avoid delays or penalties. Duties and taxes vary by destination; for example, the EU applies a standard VAT rate (e.g., 20% in Germany), while the U.S. may impose tariffs under HTSUS 8536.69. Pre-clearance through bonded warehouses or using a licensed customs broker is recommended. Provide technical specifications and compliance certificates proactively to expedite inspection.

Transportation and Handling

Use freight forwarders experienced in handling electrical goods. Products should be shipped in dry, ventilated containers with temperature monitoring if necessary. Avoid stacking heavy items on top of packages. For air freight, comply with IATA regulations—lithium batteries, if included (e.g., in smart sockets), require special handling and UN38.3 testing. Ground transport must follow ADR regulations in Europe or DOT rules in the U.S. if hazardous materials are involved.

Storage and Inventory Management

Store plug and socket products in dry, temperature-controlled environments away from direct sunlight and corrosive substances. Use first-in, first-out (FIFO) inventory practices to minimize obsolescence. Maintain records of stock movements and conduct regular audits to ensure compliance with traceability requirements. Implement a recall readiness plan in case of non-conforming batches.

Market-Specific Compliance Considerations

Different markets have unique plug types and regulatory frameworks:

– European Union: Requires CE marking, compliance with the Low Voltage Directive (LVD) and RoHS, and registration in the RAPEX system if non-compliant.

– United Kingdom: UKCA marking is mandatory; BS 1363 standard applies for 13A sockets.

– United States: UL listing under UL 498 is typically required; NRTL certification is enforced by OSHA.

– Australia/New Zealand: SAA approval and compliance with AS/NZS 3112 are mandatory.

– China: CCC certification is required for most plug and socket products.

Sustainability and End-of-Life Compliance

Adhere to WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions. Producers must register with national WEEE schemes and finance the collection and recycling of end-of-life products. Packaging should be recyclable and minimize plastic use. Provide take-back programs or partner with e-waste recyclers to meet environmental obligations.

Audit and Continuous Compliance

Conduct regular internal audits of production, labeling, and documentation processes. Maintain up-to-date technical files and test reports. Monitor regulatory changes through official sources (e.g., EU NANDO database, U.S. CPSC alerts). Engage third-party auditors annually to validate ongoing compliance and readiness for market surveillance checks.

Conclusion for Sourcing Plugs and Sockets (Electrical):

Sourcing electrical plugs and sockets requires a comprehensive approach that balances safety, compliance, quality, cost, and supply chain reliability. It is essential to prioritize products that meet international and local electrical standards (such as IEC, UL, BS, or other regional certifications) to ensure user safety and regulatory compliance. Attention must be given to material quality, durability, current rating, and environmental suitability (e.g., IP ratings for moisture or dust resistance).

When selecting suppliers, factors such as manufacturing capability, quality control processes, certifications (e.g., ISO, ROHS, REACH), and traceability should be carefully evaluated. Establishing long-term relationships with reputable suppliers can enhance consistency and reduce risks associated with electrical components, which are critical for end-product performance and safety.

Additionally, staying informed about evolving regulations and energy efficiency trends can support sustainable and future-proof sourcing strategies. In conclusion, a strategic and diligent sourcing process for plugs and sockets not only mitigates risks but also ensures reliable, safe, and cost-effective electrical solutions across various applications.