The global demand for plexiglass (PMMA) products has surged in recent years, driven by their widespread use in protective enclosures, retail displays, and industrial applications. According to Grand View Research, the global polymethyl methacrylate (PMMA) market was valued at USD 5.47 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by increasing demand in automotive, construction, electronics, and healthcare sectors—industries that also rely heavily on transparent protective solutions such as plexiglass boxes with lids. As businesses and institutions continue to prioritize hygiene, safety, and aesthetic presentation, the need for high-quality, customizable plexiglass enclosures has intensified. In response, a competitive landscape of manufacturers has emerged, offering durable, precision-engineered boxes with lids for retail, medical, and organizational use. Based on production capacity, geographic reach, innovation, and customer reviews, the following nine manufacturers stand out in the plexiglass box market.

Top 9 Plexiglass Boxes With Lid Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Acrylic Plastic display manufacturer, Acrylic Displays Wholesale,

Domain Est. 1999

Website: ssacrylic.com

Key Highlights: A fully independent, privately owned manufacturing company dedicated to providing quality acrylic products completely made and manufactured in the United ……

#2 China Acrylic Box Supplier

Domain Est. 2014

Website: acrylicdisplayfactory.com

Key Highlights: Acrylic Display Boxes/Cases and dispenser can have many different forms and functions.From bins to risers, covers and acrylic display cases, boxes with lids and ……

#3 Custom Acrylic Box with Lid Manufacturer

Domain Est. 2014

Website: jayiacrylic.com

Key Highlights: Jayi is a popular manufacturer of custom acrylic boxes with lids, and we offer a personalization service with custom sizes, custom colors, and custom printing….

#4 Acrylic Box with Lid Supplier and Great Manufacturer

Domain Est. 2019

Website: weprofab.com

Key Highlights: Weprofab is a popular manufacturer of the acrylic box with Lid. The Lid attached is used to cover and protect valuable things inside the box….

#5 Custom acrylic box/case manufacturer/wholesale acrylic box

Domain Est. 2019

Website: apacrylic.com

Key Highlights: We customize a variety of acrylic boxes that go as per customer request. For example 5-sides or multi-sides box with or without lid, container, led box,…

#6 TekniPlex

Domain Est. 1997

Website: tekni-plex.com

Key Highlights: Discover TekniPlex’s innovative packaging and material solutions for healthcare and consumer products, designed to enhance safety and sustainability….

#7 Pleximart

Domain Est. 2010

Website: pleximart.com

Key Highlights: Create your custom acrylic box with fast turn around times. For retail, work, and home! Get your quote instantly! No minimums and fast turnaround….

#8 Custom Acrylic Boxes & Plexiglass Display Cases

Domain Est. 2014

Website: shoppopdisplays.com

Key Highlights: 4-day deliveryCreate custom acrylic boxes & plexiglass cases tailored to your needs—ideal for trays, pedestals, risers, or covers. Fast shipping available….

#9 The Acrylic Box

Domain Est. 2022

Website: theacrylicbox.com

Key Highlights: The Acrylic Box is a fast growing company that manufactures products, made for protecting and displaying hard-earned collections….

Expert Sourcing Insights for Plexiglass Boxes With Lid

2026 Market Trends for Plexiglass Boxes With Lid

Rising Demand in Retail and Display Applications

The market for plexiglass boxes with lid is projected to experience significant growth by 2026, driven primarily by increased adoption in the retail and merchandising sectors. Businesses are increasingly favoring transparent display solutions to showcase products such as jewelry, collectibles, electronics, and luxury goods. The clarity and durability of plexiglass—also known as acrylic—make it an ideal alternative to glass, offering shatter resistance and lightweight properties. Retailers are investing in customizable, modular plexiglass display cases to enhance visual appeal and security, fueling demand across e-commerce fulfillment centers and brick-and-mortar stores.

Expansion in Home Organization and Decor

Another key trend shaping the 2026 market is the growing consumer interest in home organization and modern interior aesthetics. Plexiglass boxes with lids are increasingly used in households for storing and displaying items like cosmetics, stationery, or decorative objects. Their minimalist, contemporary look complements modern and minimalist design styles. With the rise of social media platforms like Instagram and Pinterest promoting “aesthetic” living spaces, demand for stylish yet functional storage solutions is expected to surge, positioning plexiglass boxes as a preferred choice.

Sustainability and Eco-Friendly Material Innovations

Environmental concerns are influencing material choices across industries, and the plexiglass market is no exception. By 2026, manufacturers are expected to place greater emphasis on recyclable and bio-based acrylic alternatives. Although traditional plexiglass is petroleum-based, advancements in sustainable polymers and closed-loop recycling systems are anticipated to reduce the environmental footprint. Brands marketing eco-conscious plexiglass storage solutions may gain a competitive edge, appealing to environmentally aware consumers and corporate sustainability initiatives.

Growth in E-Commerce and Direct-to-Consumer Packaging

The booming e-commerce sector is contributing to higher demand for protective, transparent packaging. Plexiglass boxes with lids are being adopted not only for product display but also as premium packaging solutions for high-end goods. Luxury brands and direct-to-consumer (DTC) companies are using these boxes to elevate unboxing experiences, combining functionality with aesthetic appeal. As online shopping continues to expand globally, the need for durable, reusable, and visually appealing packaging will drive innovation and market penetration.

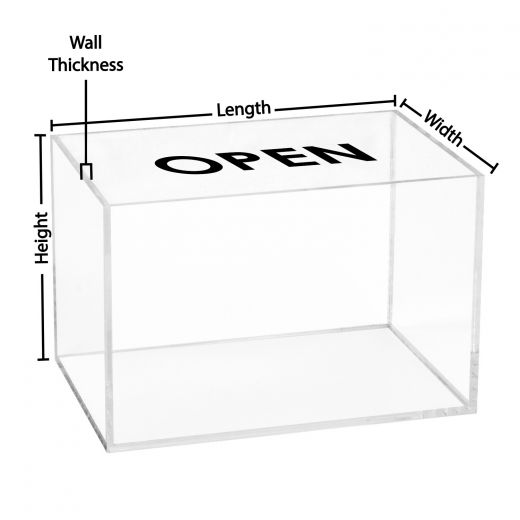

Technological Advancements in Manufacturing

By 2026, automation and precision manufacturing technologies such as laser cutting and CNC machining are expected to lower production costs and improve customization capabilities for plexiglass boxes. These advancements enable faster prototyping, intricate designs, and mass customization—meeting the needs of niche markets and individual consumers. Additionally, improvements in surface treatments (e.g., anti-static, UV-resistant, and scratch-resistant coatings) will enhance product longevity and performance, further boosting adoption across industries.

Regional Market Dynamics

North America and Europe are expected to remain dominant markets due to high consumer spending on home organization and retail innovation. However, the Asia-Pacific region—particularly China, India, and Southeast Asia—is projected to witness the fastest growth. Rapid urbanization, rising disposable incomes, and expanding retail infrastructure are key drivers in this region. Local manufacturers are increasingly investing in design and quality to compete with Western brands, creating a more diversified global supply chain.

Conclusion

The plexiglass boxes with lid market is poised for robust growth by 2026, supported by cross-sector demand, design innovation, and sustainability trends. As industries from retail to home decor continue to prioritize transparency, durability, and aesthetic value, plexiglass solutions will play an increasingly central role. Companies that leverage customization, eco-friendly materials, and digital manufacturing will be best positioned to capitalize on emerging opportunities in this evolving market landscape.

Common Pitfalls When Sourcing Plexiglass Boxes With Lid (Quality, IP)

Logistics & Compliance Guide for Plexiglass Boxes With Lid

Product Classification and HS Code

Plexiglass (acrylic) boxes with lids are typically classified under the Harmonized System (HS) code 3926.30, which covers “Articles of plastics, for the conveyance or packing of goods: Boxes, cases, crates, and similar articles.” Accurate classification ensures correct customs duties and import regulations are followed. Confirm the specific code with local customs authorities, as subcategory details may vary by country.

Material Compliance and Safety Standards

Ensure the plexiglass used meets international safety and quality standards:

– FDA Compliance: Required if boxes are intended for food contact; verify that materials are FDA 21 CFR 177.1010 compliant.

– REACH & RoHS: Comply with EU regulations restricting hazardous substances (e.g., lead, phthalates). Documentation may be required for entry into European markets.

– Proposition 65 (California): Provide warnings if products contain chemicals listed under California law.

Packaging and Shipping Requirements

Proper packaging is essential to prevent damage during transit:

– Use corrugated cardboard outer packaging with internal dividers or cushioning (e.g., bubble wrap).

– Clearly label boxes as “Fragile” and “This Side Up” to guide handling.

– Stack test packaging to ensure stability during container shipping.

Import/Export Documentation

Prepare and retain the following documents for smooth customs clearance:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Product Compliance Certificates (e.g., FDA, REACH)

– Import licenses (if required by destination country)

Labeling and Marking

All units and shipping containers must be correctly labeled:

– Product name and description

– Quantity per package

– Manufacturer/importer name and address

– Country of origin (e.g., “Made in China”)

– Batch or lot numbers for traceability

– Applicable safety symbols (e.g., recyclable plastic code “7” for other plastics)

Environmental and Recycling Regulations

Plexiglass (PMMA) is recyclable but not always accepted in standard curbside programs. Include disposal guidance:

– Label with recycling code “7” and the acronym “PMMA.”

– Provide instructions for proper recycling or disposal per local regulations.

– Comply with extended producer responsibility (EPR) laws in regions like the EU.

Transportation and Handling

Follow best practices for domestic and international freight:

– Avoid extreme temperatures to prevent warping or cracking.

– Use weather-resistant containers for sea freight.

– Confirm carrier-specific restrictions for plastic materials.

Regulatory Approvals by Region

- United States: FTC labeling rules and customs entry via CBP.

- European Union: CE marking not required for packaging, but REACH and packaging waste directives apply.

- Canada: Comply with IC packaging regulations and CBSA import rules.

- Australia/NZ: Meet AS/NZS standards for packaging and import via ABF.

Recordkeeping and Traceability

Maintain records for at least 5 years, including:

– Material sourcing documentation

– Test reports for compliance

– Shipping and customs records

– Customer certifications (if applicable)

Adhering to this guide ensures efficient logistics and compliance across global markets for plexiglass boxes with lids.

In conclusion, sourcing plexiglass boxes with lids requires careful consideration of material quality, dimensional accuracy, durability, and supplier reliability. Assessing factors such as thickness, clarity, UV resistance, and ease of assembly ensures the chosen product meets both functional and aesthetic requirements. Whether for display, storage, or protective purposes, partnering with reputable suppliers who offer customization options, consistent lead times, and competitive pricing is essential. By conducting thorough research and obtaining samples when possible, businesses and individuals can secure high-quality plexiglass boxes that deliver long-term value and performance for their specific application.