The global programmable logic controller (PLC) card market is experiencing robust growth, driven by rising automation across industrial sectors such as manufacturing, energy, and infrastructure. According to a 2023 report by Mordor Intelligence, the global PLC market is projected to grow at a CAGR of approximately 5.8% from 2023 to 2028, fueled by the increasing adoption of Industry 4.0 technologies and the need for real-time process control. Complementing this, Grand View Research valued the global PLC market at USD 12.3 billion in 2022 and anticipates a CAGR of 6.1% from 2023 to 2030, citing integration with IoT and advancements in distributed control systems as key growth accelerators. As demand for modular, scalable, and high-performance PLC cards rises, manufacturers are innovating to deliver compact, energy-efficient solutions that support seamless communication and enhanced diagnostics. In this competitive landscape, ten manufacturers have emerged as industry leaders, combining technological expertise, global reach, and reliability to meet the evolving needs of automated systems worldwide.

Top 10 Plc Card Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 AMCI

Domain Est. 2000

Website: amci.com

Key Highlights: AMCI is a leading US based manufacturer with a global presence. AMCI’s expertise with PLC Networked products provides the best PLC integration available….

#2 PLC systems

Domain Est. 1996

Website: br-automation.com

Key Highlights: Powerful and compact CPUs for every application. High-speed precision of open and closed-loop control for machines and systems – at an attractive price: ……

#3 Programmable Logic Controllers from Automation Direct

Domain Est. 1999

Website: automationdirect.com

Key Highlights: Brand Line Card … The XGB PLC is designed and manufactured by LS Electric – a well-established, global PLC manufacturer with over 40 years of experience….

#4 Programmable logic controller (PLC)

Domain Est. 1999

Website: infineon.com

Key Highlights: Discover how Infineon understands the needs of its industrial customers and offers dedicated solutions that overcome the challenges common to PLC….

#5 PLC Direct: Industrial Automation Products

Domain Est. 2020

Website: plc-direct.com

Key Highlights: Get the industrial automation products you need without the wait. PLC Direct has quality programmable logic controllers with less lead time on your orders….

#6 Programmable Controllers MELSEC

Domain Est. 1996

Website: mitsubishielectric.com

Key Highlights: This Active X controller library enables easy communication processing from the PC and tablet to PLC, without the need for communication protocol awareness. MX ……

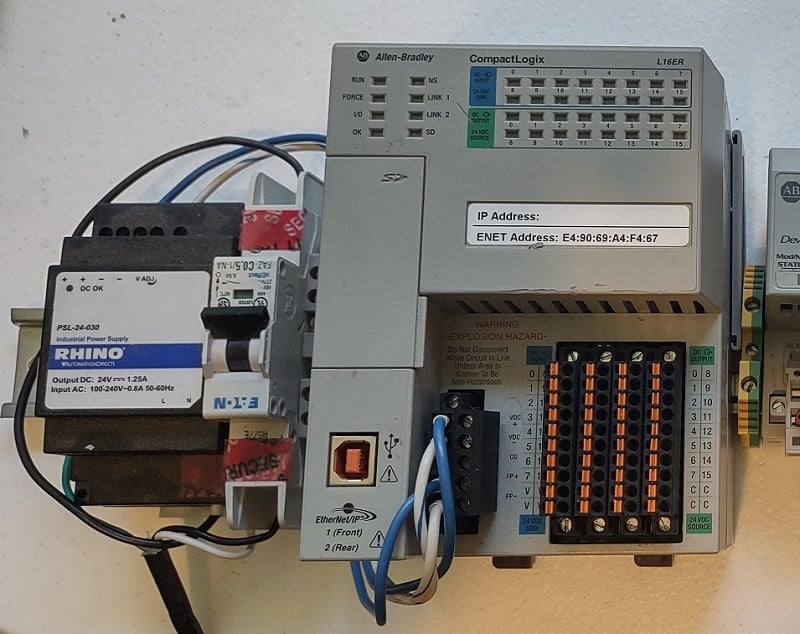

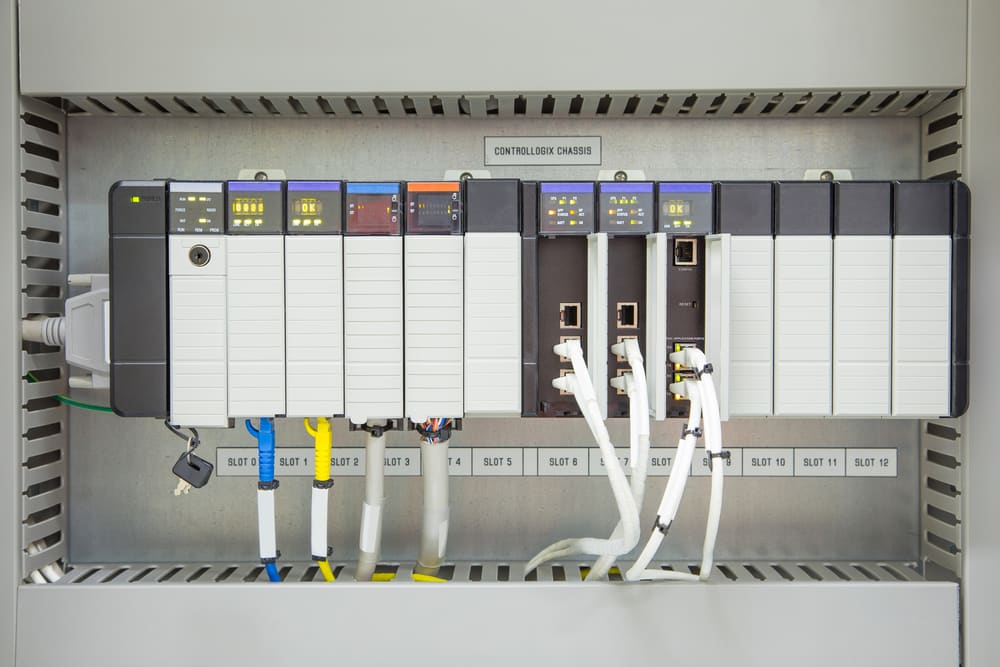

#7 Programmable Controllers

Domain Est. 1997

Website: rockwellautomation.com

Key Highlights: From large to micro, meet varied application needs with our programmable logic controllers (PLC) and programmable automation controllers (…

#8 Products

Domain Est. 2001

Website: deltaww.com

Key Highlights: AH Series PLC provides automation solutions for high-level applications. The combination of modularized hardware structure, advanced functions, and the highly ……

#9 PLC

Domain Est. 2020

Website: ls-electric.com

Key Highlights: Programmable logic controller (PLC) is a general-purpose control device that automatically controls machinery, facilities, and assembly lines by user defined ……

#10 M

Website: bachmann.info

Key Highlights: M-PLC is a complete development environment for programming the M200 controller in accordance with IEC 61131-3….

Expert Sourcing Insights for Plc Card

H2: Analysis of 2026 Market Trends for PLC Cards

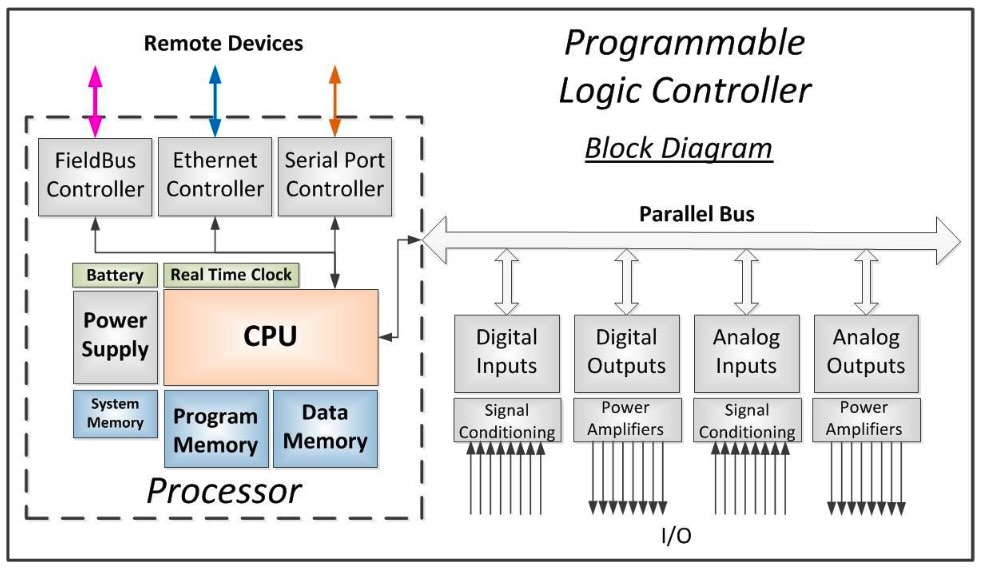

As the industrial automation landscape evolves, Programmable Logic Controller (PLC) cards are poised for significant transformation by 2026. These modular components, essential for input/output (I/O) interfacing, communication, and control in automation systems, are being influenced by digitalization, Industry 4.0 adoption, and the integration of smart manufacturing technologies. Below is a comprehensive analysis of key market trends expected to shape the PLC card industry in 2026.

1. Increased Demand for Modular and Scalable PLC Cards

Manufacturers are increasingly prioritizing flexibility and scalability in automation systems. By 2026, modular PLC cards—supporting hot-swapping, easy configuration, and seamless integration—are expected to dominate. This trend is driven by the need for adaptable production lines in sectors like automotive, pharmaceuticals, and consumer goods, where rapid reconfiguration is critical.

2. Integration with IIoT and Edge Computing

PLC cards are evolving beyond basic control functions to support Industrial Internet of Things (IIoT) connectivity. By 2026, PLC cards equipped with embedded communication protocols (e.g., OPC UA, MQTT, TSN) and edge-processing capabilities will be standard. These enhancements allow real-time data acquisition, predictive maintenance, and integration with cloud platforms, enabling smarter decision-making on the factory floor.

3. Rise of Cybersecurity-Enhanced PLC Cards

As industrial systems become more connected, cybersecurity is a growing concern. In 2026, PLC cards will increasingly feature built-in security protocols such as encrypted firmware, secure boot, and role-based access control. Regulatory pressures and high-profile cyberattacks are pushing manufacturers like Siemens, Rockwell Automation, and Schneider Electric to prioritize secure-by-design PLC hardware.

4. Adoption of Energy-Efficient and Compact Designs

Energy efficiency and space optimization are key drivers in modern control cabinets. By 2026, PLC cards will continue to become smaller, more power-efficient, and thermally optimized. This trend supports dense installations in smart factories and reduces total cost of ownership through lower cooling and energy requirements.

5. Growth in Emerging Markets and Localized Manufacturing

Asia-Pacific, particularly China, India, and Southeast Asia, will see accelerated adoption of PLC cards due to expanding industrial infrastructure and government initiatives like “Make in India” and “China 2025.” Localized production of PLC cards by regional players (e.g., Zhejiang Hollysys, ICP DAS) will challenge Western dominance and drive price competition.

6. Open-Source and Interoperable Platforms

The push toward open automation standards (e.g., PLCopen, IEC 61131-3) will gain momentum by 2026. PLC cards supporting open programming environments and cross-vendor compatibility will appeal to users seeking vendor independence and reduced integration costs. Open-source PLC firmware ecosystems may also emerge, fostering innovation.

7. AI and Machine Learning Integration

Advanced PLC cards will begin incorporating AI co-processors or support AI-driven logic execution via integrated software. By 2026, predictive control algorithms, anomaly detection, and adaptive tuning will be possible directly on the PLC card, reducing latency and reliance on external systems.

8. Sustainability and Circular Economy Initiatives

Environmental regulations and corporate ESG goals will influence PLC card design. Manufacturers will focus on recyclable materials, longer product lifecycles, and modular upgrades to reduce electronic waste. Repairability and firmware updates over long periods will be key selling points.

Conclusion

By 2026, PLC cards will be more intelligent, secure, and interconnected than ever before. The convergence of automation, data analytics, and sustainability will redefine their role from simple I/O interfaces to intelligent edge nodes in smart manufacturing ecosystems. Companies investing in next-generation PLC card technologies today will be well-positioned to lead in the competitive industrial automation market of tomorrow.

Common Pitfalls When Sourcing PLC Cards: Quality and Intellectual Property Risks

Poor Quality and Counterfeit Components

One of the most significant risks when sourcing PLC (Programmable Logic Controller) cards is receiving substandard or counterfeit products. These may include used or refurbished cards misrepresented as new, cloned hardware with inconsistent performance, or components built with inferior materials. Such cards often fail prematurely, cause unplanned downtime, or introduce instability into control systems. Buyers may encounter mismatched serial numbers, inconsistent labeling, or poor workmanship—clear indicators of compromised quality. Relying on unauthorized distributors or gray market suppliers increases the likelihood of these issues.

Intellectual Property (IP) and Licensing Violations

Sourcing non-genuine or third-party PLC cards can lead to serious intellectual property concerns. Many PLC cards contain proprietary firmware, software, and design elements protected by patents and copyrights. Unauthorized replication or reverse engineering of these components infringes on the original manufacturer’s IP rights, potentially exposing buyers and integrators to legal liability. Additionally, using cloned or unlicensed cards may void system warranties, compromise cybersecurity, and result in non-compliance with industry regulations, especially in sectors like manufacturing, energy, and pharmaceuticals where traceability and authenticity are critical.

Logistics & Compliance Guide for PLC Card

This guide outlines the essential logistics and compliance considerations for handling, transporting, and managing PLC (Programmable Logic Controller) cards, ensuring operational safety, regulatory adherence, and equipment integrity throughout the supply chain.

Regulatory Compliance

Ensure all PLC cards meet international and regional regulatory standards prior to distribution. Key requirements include:

– RoHS (Restriction of Hazardous Substances): Verify that the PLC card complies with RoHS directives, restricting the use of lead, mercury, cadmium, and other hazardous materials.

– REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals): Confirm that all substances used in the card are registered and compliant with EU chemical regulations.

– CE Marking: Display the CE mark where applicable to indicate conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

– FCC Compliance: For devices marketed in the U.S., ensure electromagnetic interference (EMI) standards set by the Federal Communications Commission are met.

– Export Controls: Adhere to export regulations such as ITAR or EAR when shipping to restricted countries or regions, particularly if the PLC contains dual-use technologies.

Packaging & Handling

Proper packaging and handling are critical to prevent damage during transit and storage:

– Use anti-static packaging (e.g., static-shielding bags) to protect sensitive electronic components from electrostatic discharge (ESD).

– Include desiccant packs in sealed packaging to minimize moisture exposure, especially in humid environments.

– Clearly label packages with “Fragile,” “Electrostatic Sensitive,” and “Do Not Stack” indicators.

– Handle PLC cards only in ESD-protected areas using grounded wrist straps and mats when removing from packaging.

Transportation Requirements

Adhere to best practices for safe and compliant transport:

– Utilize climate-controlled shipping when moving cards across extreme temperature or humidity zones.

– Avoid exposure to temperatures outside the manufacturer’s specified range (typically -20°C to +70°C for storage).

– Use tamper-evident seals on packages to detect unauthorized access during transit.

– Choose shipping partners with experience in handling sensitive electronics and tracking capabilities for end-to-end visibility.

Storage Conditions

Maintain optimal storage environments to preserve card functionality:

– Store in a dry, clean, and temperature-controlled environment (ideally 15°C to 30°C with relative humidity below 60%).

– Keep PLC cards in their original protective packaging until ready for installation.

– Avoid storage near sources of strong electromagnetic fields, dust, or corrosive chemicals.

Documentation & Traceability

Ensure complete documentation for compliance audits and lifecycle management:

– Maintain records of certifications (RoHS, CE, FCC), batch numbers, and serial numbers for traceability.

– Keep a chain of custody log for high-security or regulated installations.

– Provide Material Declarations and Safety Data Sheets (SDS) upon request, especially for international shipments.

Installation & Disposal Compliance

Follow responsible practices from deployment to end-of-life:

– During installation, follow manufacturer guidelines to prevent damage and ensure proper grounding.

– At end-of-life, recycle PLC cards through certified e-waste handlers in accordance with WEEE (Waste Electrical and Electronic Equipment) directives.

– Never dispose of PLC cards in general waste streams due to hazardous material content.

By adhering to this logistics and compliance framework, organizations can ensure the safe, legal, and efficient handling of PLC cards across their operational lifecycle.

Conclusion for Sourcing a PLC Card

In conclusion, sourcing a PLC (Programmable Logic Controller) card requires a comprehensive approach that balances technical specifications, compatibility, reliability, cost, and supplier credibility. It is essential to clearly define the requirements of the automation system, including input/output types, communication protocols, and environmental conditions, to ensure the selected PLC card integrates seamlessly into the existing setup. Evaluating both original equipment manufacturer (OEM) products and reputable aftermarket alternatives can provide cost-effective solutions without compromising performance or safety.

Additionally, verifying the authenticity of components, checking for necessary certifications, and ensuring availability of technical support and warranties are critical steps in the procurement process. By conducting thorough research, consulting with automation experts, and partnering with trusted suppliers, organizations can secure a PLC card that enhances system efficiency, ensures long-term reliability, and supports future scalability. Ultimately, a well-sourced PLC card contributes significantly to the overall effectiveness and stability of industrial control systems.