The global plate compactor market is experiencing steady growth, driven by rising infrastructure development, urbanization, and increased investments in road construction and residential projects. According to Mordor Intelligence, the construction equipment market—including compaction machinery—is projected to grow at a CAGR of approximately 5.8% from 2024 to 2029. Plate compactors, in particular, remain essential across civil engineering and landscaping applications due to their efficiency in soil and asphalt compaction. Among the key players in this segment, Mikasa has established a strong reputation for durability, performance, and innovation. As demand for reliable and high-performance compaction equipment rises—especially in Asia-Pacific and North America—several manufacturers have emerged as top suppliers of Mikasa-branded plate compactors, combining Japanese engineering standards with global manufacturing scalability. This list highlights the top five Mikasa plate compactor manufacturers based on production capacity, distribution reach, product range, and market presence.

Top 5 Plate Compactor Mikasa Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Plate Comapactor

Domain Est. 1996

Website: mikasas.com

Key Highlights: This is the product page for the overwhelmingly durable plate compactors from Mikasa Sangyo Co.,Ltd., a comprehensive manufacturer of construction equipment….

#2 MQ Mikasa

Domain Est. 1996

Website: multiquip.com

Key Highlights: For 40 years Multiquip has proudly offered Mikasa rammers, plate compactors and rollers, along with concrete vibrators to meet your every compaction and ……

#3 Vibratory Forward Plate Compactors

Domain Est. 2002

Website: cessco.us

Key Highlights: Thousands of satisfied users know that Multiquip’s Mikasa Plate Compactors have it all-top performance, easy handling, low maintenance and long life….

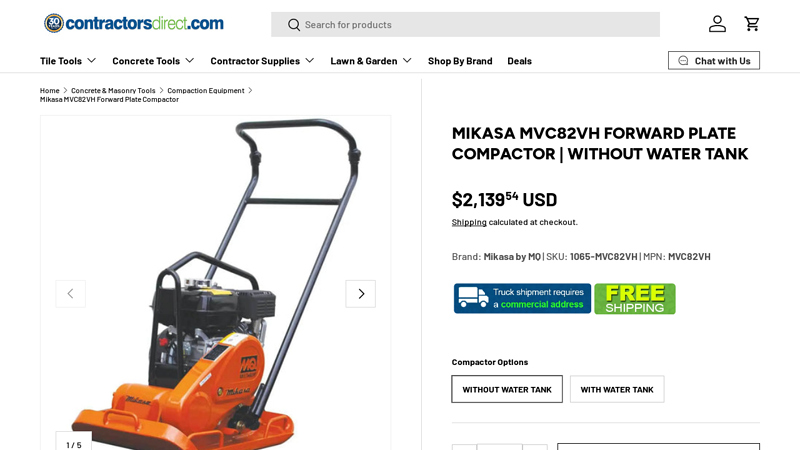

#4 Multiquip MVC82VH Forward Plate Compactor

Domain Est. 1997

Website: contractorsdirect.com

Key Highlights: Free delivery over $500 60-day returnsMikasa MVC82 17.7″ x 22.4″ Forward Plate Compactor by Multiquip. Recognized as the industry standard for compacting granular soils and asphalt…

#5 Mikasa MVH408GH 1000lb Reversible Gas Plate Tamper / Compactor

Domain Est. 2019

Website: goldeninstallations.ca

Key Highlights: MVH408GH 1000lb Reversible Gas Plate Tamper / Compactor. Rates: Daily – $168 Weekly – $680 Monthly – $1980 Minimum Charge (4 hours) – $126…

Expert Sourcing Insights for Plate Compactor Mikasa

2026 Market Trends for Plate Compactor Mikasa

1. Heightened Demand for Fuel-Efficient and Low-Emission Equipment

By 2026, environmental regulations and sustainability goals will continue to shape construction equipment purchasing decisions. Mikasa plate compactors, already recognized for their durable diesel and gasoline engines, will face increased demand for models that offer improved fuel efficiency and lower emissions. Expect market growth for Mikasa’s Tier 5/Stage V compliant engines in Europe and similar EPA-compliant versions in North America. Contractors will prioritize rental fleets and direct purchases of compactors that meet tightening environmental standards, enhancing Mikasa’s appeal in eco-conscious markets.

2. Expansion of Rental Market Drives Demand for Durable, Low-Maintenance Models

The construction equipment rental sector is projected to grow through 2026, especially in urban infrastructure and residential development. Mikasa’s reputation for reliability and ease of maintenance positions its plate compactors favorably in this segment. Rental companies will seek robust, long-lasting models such as the SV, TH, and SW series that minimize downtime and servicing costs. As rental fleets modernize, Mikasa’s consistent performance and availability of service support will strengthen its market penetration, particularly in Asia-Pacific and North America.

3. Technological Integration and Operator-Centric Design

While plate compactors remain relatively simple machines, subtle technological enhancements are emerging. By 2026, Mikasa may incorporate features such as vibration control systems, ergonomic handle designs with reduced vibration transmission, and smart monitoring via optional IoT tags for fleet tracking. These innovations will appeal to safety-conscious contractors and large-scale operations aiming to improve operator comfort and equipment utilization—key buying factors in competitive markets.

4. Growth in Infrastructure and Urban Development Fuels Regional Demand

Government-led infrastructure programs in regions like Southeast Asia, India, and parts of Africa will drive demand for compact, efficient compaction equipment. Mikasa’s lightweight and mid-sized plate compactors are well-suited for trench backfilling, road repairs, and landscaping—common tasks in these projects. Increased urbanization and smart city development will further boost need for versatile, maneuverable compactors, benefiting Mikasa’s broad product lineup tailored to diverse compaction requirements.

5. Competitive Pressure and Brand Positioning in a Consolidated Market

The global plate compactor market remains competitive, with key players like Wacker Neuson, Bomag, and Honda. In 2026, Mikasa will need to reinforce its value proposition through superior durability, cost-effectiveness, and localized service networks. Strategic partnerships with distributors and inclusion in bundled equipment packages could enhance market visibility. Maintaining a strong presence in emerging markets while defending share in mature regions will be critical for sustained growth.

In summary, Mikasa’s success in the 2026 plate compactor market will depend on its ability to align with environmental standards, cater to the expanding rental economy, enhance user experience through incremental innovation, and leverage global infrastructure trends—all while maintaining its core strengths in reliability and performance.

Common Pitfalls Sourcing Plate Compactor Mikasa (Quality, IP)

When sourcing Mikasa plate compactors—especially from third-party suppliers or international markets—buyers often encounter several critical pitfalls related to quality assurance and intellectual property (IP) concerns. Being aware of these risks is essential to avoid compromised performance, safety hazards, and legal issues.

1. Counterfeit or Replica Equipment

One of the most significant risks is purchasing counterfeit Mikasa plate compactors. Unscrupulous suppliers may replicate Mikasa’s branding, design, and model numbers to pass off inferior machines as genuine. These replicas often use substandard materials and components, leading to poor compaction performance, frequent breakdowns, and safety risks. Buyers may not discover the deception until after purchase, by which time warranty and support options are typically unavailable.

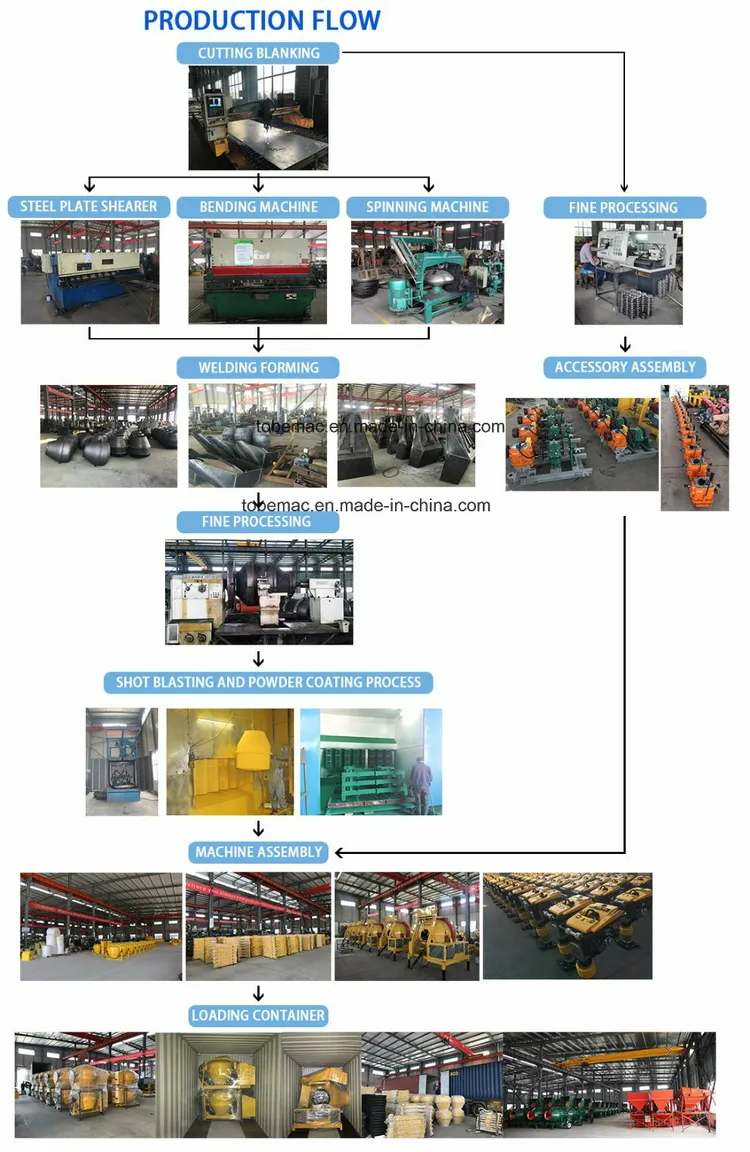

2. Lack of Genuine Quality Control

Genuine Mikasa equipment is manufactured under strict quality control standards, ensuring durability and reliable operation in demanding environments. When sourcing from unauthorized distributors or gray market suppliers, there’s no guarantee the product underwent Mikasa’s quality assurance processes. This increases the risk of receiving machines with manufacturing defects, improper assembly, or incompatible parts that reduce lifespan and operational efficiency.

3. Invalid or Voided Warranties

Purchasing Mikasa plate compactors through unofficial channels often results in invalid or non-transferable warranties. Genuine Mikasa products come with manufacturer-backed warranty support, but this protection is typically voided if the equipment is not purchased through authorized dealers. This leaves buyers responsible for all repair and maintenance costs, which can quickly outweigh initial cost savings.

4. Intellectual Property (IP) Infringement

Distributing or importing replica Mikasa compactors may constitute intellectual property infringement, including trademark and design patent violations. Buyers—even unintentional ones—could face legal exposure, especially in regions with strict IP enforcement. Companies found using counterfeit equipment may suffer reputational damage and be subject to fines or sanctions.

5. Inadequate After-Sales Support and Spare Parts

Genuine Mikasa compactors are supported by a global network of service centers and authorized parts suppliers. Counterfeit or unofficially sourced units often lack access to authentic spare parts and technical support. This leads to prolonged downtime, difficulty in repairs, and the need to compromise with non-OEM components that further degrade performance and safety.

6. Misrepresentation of Specifications and Performance

Some suppliers may misrepresent the technical specifications of replica Mikasa compactors, inflating performance data such as centrifugal force, engine power, or compaction depth. These inaccuracies can lead to equipment being unsuitable for intended applications, resulting in project delays, poor soil compaction, and rework costs.

7. Supply Chain and Compliance Risks

Sourcing from unauthorized channels may involve suppliers with poor compliance practices, including lack of certifications (e.g., CE, EPA, ISO). This poses risks related to equipment safety, emissions regulations, and site compliance—especially in regulated industries or public infrastructure projects.

To mitigate these pitfalls, always source Mikasa plate compactors through authorized dealers, verify documentation (including serial numbers and certificates), and confirm the supplier’s official partnership status with Mikasa or its parent company. Conducting due diligence upfront protects your investment, ensures equipment reliability, and avoids legal complications.

Logistics & Compliance Guide for Plate Compactor Mikasa

Product Overview

The Mikasa plate compactor is a high-performance construction machine designed for soil compaction in trenches, foundations, and confined areas. Proper logistics handling and compliance with international and local regulations are essential for safe transportation, importation, and operation.

Transportation & Packaging

- Packaging: Mikasa plate compactors are typically shipped in robust wooden crates or steel-reinforced cartons to protect against impact and moisture during transit.

- Weight & Dimensions: Confirm exact model specifications (e.g., MTP-45, MTP-65) for accurate freight classification. Average weights range from 90 kg to 180 kg.

- Handling Requirements: Use forklifts or pallet jacks for loading/unloading. Avoid tilting beyond 30 degrees to prevent fuel/oil leakage.

- Storage Conditions: Store in dry, covered areas with temperatures between -10°C and 40°C. Keep away from direct sunlight and corrosive substances.

Import & Export Compliance

- HS Code: Use Harmonized System code 8429.40.00 (Ramming or tamping machinery) for customs declarations. Verify with local customs authority as codes may vary by country.

- Documentation: Provide commercial invoice, packing list, bill of lading/airway bill, and certificate of origin. Include product specifications and engine details (if applicable).

- Emissions Standards: Mikasa compactors with gasoline engines must comply with EPA (USA), CE (EU), or equivalent regional emission regulations. Confirm compliance labels are affixed.

- Import Duties & Taxes: Check destination country regulations for applicable duties, VAT, and import restrictions on construction equipment.

Safety & Operational Compliance

- CE Marking: Ensure all units intended for the European market carry valid CE certification, indicating compliance with EU machinery and emissions directives.

- Operator Safety: Provide operators with training on safe use, including vibration exposure limits (per ISO 8041) and hearing protection.

- Noise Emissions: Mikasa compactors typically meet EU noise standards (e.g., <100 dB(A)). Verify noise levels in product documentation for regulatory reporting.

- Vibration Levels: Document hand-arm vibration values (measured in m/s²) per ISO 5349-1 for workplace safety assessments.

Environmental & Disposal Regulations

- Fuel & Oil Handling: Follow local regulations for transporting and storing gasoline and hydraulic oil. Prevent spills during transit and operation.

- End-of-Life Disposal: Comply with WEEE (EU) or local e-waste directives. Recycle metal components and dispose of engine oil and filters through certified waste handlers.

- Battery Handling (if applicable): Units with electric starters require proper disposal of lead-acid batteries per hazardous waste guidelines.

Maintenance & Documentation

- Service Records: Maintain logs of routine maintenance, part replacements, and emissions checks to support compliance audits.

- User Manuals: Include multilingual operation and safety manuals in shipments to meet regulatory requirements in target markets.

- Warranty & Support: Register equipment with Mikasa regional distributors to ensure access to service networks and compliance updates.

Regulatory Contacts & Resources

- Consult national transportation authorities (e.g., FMCSA in USA, DVSA in UK) for vehicle loading rules.

- Engage certified customs brokers for import clearance.

- Refer to Mikasa official website or distributor for updated compliance certificates and technical support.

Conclusion for Sourcing a Plate Compactor (Mikasa):

After a thorough evaluation of available options and supplier capabilities, sourcing a Mikasa plate compactor proves to be a strategic and reliable choice for achieving high performance, durability, and efficiency in compaction tasks. Mikasa’s reputation for engineering excellence, robust construction, and widespread service support makes their equipment particularly suitable for demanding construction and infrastructure projects.

Key advantages of sourcing Mikasa plate compactors include consistent product quality, availability of spare parts, strong after-sales service, and proven performance across diverse soil conditions. Additionally, Mikasa offers a range of models suitable for various project scales, allowing for flexibility in procurement and application.

In conclusion, selecting Mikasa as the supplier for plate compactors ensures long-term operational efficiency, reduced maintenance costs, and enhanced productivity on-site. It is recommended to proceed with sourcing Mikasa plate compactors through authorized distributors to guarantee authenticity, warranty coverage, and technical support.