The global plastic windows market is experiencing steady growth, driven by rising demand for energy-efficient and low-maintenance building materials. According to Grand View Research, the global vinyl windows market size was valued at USD 33.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing residential and commercial construction activities, particularly in emerging economies, along with growing awareness of the thermal insulation properties of plastic windows. Additionally, advancements in uPVC (unplasticized polyvinyl chloride) technology have enhanced durability and aesthetic appeal, making plastic windows a preferred choice over traditional materials. As sustainability and energy efficiency become central to building codes and consumer preferences, manufacturers are innovating to meet evolving demands—setting the stage for the leading players shaping the industry.

Top 10 Plastic Windows Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Windows and Doors

Domain Est. 1995

Website: marvin.com

Key Highlights: Marvin creates windows and doors inspired by how people live. Explore our product lines and enhance your new construction, remodel or replacement project….

#2 Replacement Window Manufacturer

Domain Est. 1995

Website: simonton.com

Key Highlights: Recognized for quality, Simonton is an industry-leading brand of energy-efficient replacement vinyl windows & patio doors. Learn more about our products ……

#3 Atrium Windows & Doors

Domain Est. 1996

Website: atrium.com

Key Highlights: Atrium manufactures energy efficient replacement windows, new-construction windows and patio doors designed to increase the comfort and beauty of any home….

#4 Windows USA®

Domain Est. 1998

Website: windowsusa.com

Key Highlights: As a full-service manufacturer and installer, we deliver superior quality, faster turnaround, and lasting value—backed by our Lifetime Limited Warranty….

#5 Door and Window Manufacturer

Domain Est. 1998

Website: crystalwindows.com

Key Highlights: Crystal Windows is a leading U.S. door and window manufacturer delivering custom solutions known for quality, durability, and energy efficiency….

#6 Window and Door Manufacturer

Domain Est. 2000

Website: harveywindows.com

Key Highlights: Explore Harvey Windows + Doors, a leading manufacturer of vinyl and wood windows and doors for replacement and new construction projects….

#7

Domain Est. 1996

Website: jeld-wen.com

Key Highlights: Shop JELD-WEN windows and doors built for quality, energy effi ciency, and timeless design that enhance comfort, style, and performance in every home….

#8 MI Windows and Doors

Domain Est. 2004

Website: miwindows.com

Key Highlights: MI Windows and Doors provides simply better built windows. At MI you will find the best replacement and new construction windows….

#9 Wincore ® Windows

Domain Est. 2006

Website: wincorewindows.com

Key Highlights: EXPERIENCE THE 365 DAYS A YEAR. WOW FACTOR. Explore Products » OK, Mother Nature. HIGH PERFORMANCE IMPACT PRODUCTS BRING IT. DESIGNED FOR COASTAL AREAS….

#10 Thermo

Domain Est. 2006

Website: ttwindows.com

Key Highlights: Windows. Thermo-Tech manufactures vinyl windows in a wide array of standard sizes or we can build to your specifications….

Expert Sourcing Insights for Plastic Windows

2026 Market Trends for Plastic Windows

The plastic windows market is poised for significant transformation by 2026, driven by evolving consumer preferences, regulatory pressures, technological advancements, and sustainability imperatives. Here’s an in-depth analysis of the key trends shaping the industry:

Rising Demand for Energy-Efficient Solutions

With global energy costs climbing and governments intensifying carbon reduction targets, plastic windows—particularly those made from advanced uPVC (unplasticized polyvinyl chloride)—are gaining favor for their superior thermal insulation. By 2026, the integration of multi-chambered profiles, warm-edge spacers, and triple-glazing in plastic window systems will become standard, enhancing energy performance. The European Union’s Energy Performance of Buildings Directive (EPBD) and similar regulations in North America and Asia will drive demand for high-efficiency windows, positioning plastic as a cost-effective alternative to aluminum and timber.

Sustainability and Circular Economy Pressures

Environmental concerns are reshaping material choices in construction. While traditional PVC has faced criticism due to its carbon footprint and recyclability challenges, the industry is responding with innovations. By 2026, manufacturers will increasingly adopt recycled PVC content in window profiles, with some leading companies targeting 30–50% recycled material in their products. Closed-loop recycling systems and improved end-of-life management will gain traction, supported by Extended Producer Responsibility (EPR) schemes in key markets. Bio-based and biodegradable plastic alternatives may emerge in niche segments, though scalability remains a challenge.

Technological Integration and Smart Features

The rise of smart homes is influencing window design. By 2026, plastic windows will increasingly incorporate embedded sensors, automated ventilation systems, and integration with home automation platforms (e.g., voice control, app-based operation). Innovations such as electrochromic glazing—allowing users to adjust tint electronically—and self-cleaning coatings will enhance functionality. While these features are currently premium offerings, their adoption will grow as production costs decrease and consumer demand for convenience and energy optimization increases.

Regional Market Dynamics

Europe will remain the largest market for plastic windows due to stringent energy codes, a mature renovation sector, and strong consumer acceptance. Germany, France, and the UK will lead in demand. In North America, growth will be fueled by residential retrofits and new green building projects, with increasing code adoption in states like California and New York. Meanwhile, Asia-Pacific—especially China and India—will experience rapid expansion due to urbanization and rising construction activity, though competition from aluminum and wood may limit plastic’s share in premium segments.

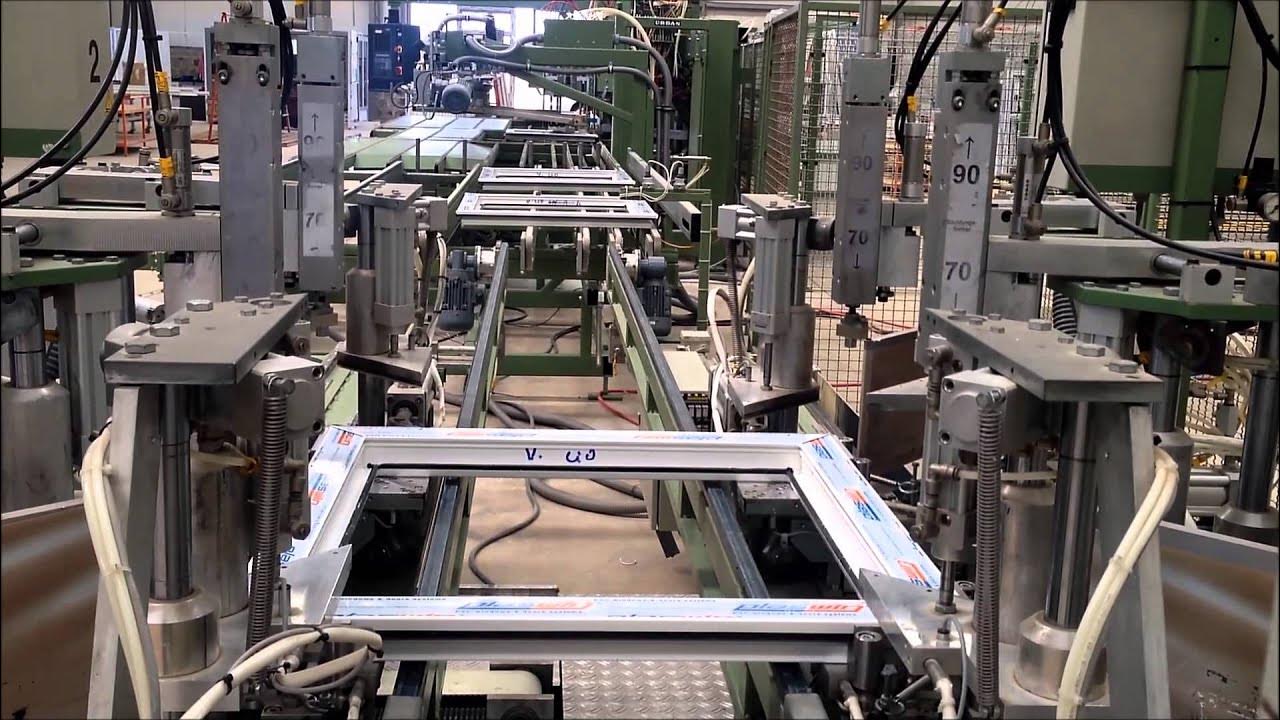

Competitive Landscape and Innovation

The market will see consolidation among major players (e.g., VEKA, REHAU, Aluplast) as companies invest in R&D to differentiate through aesthetics, durability, and performance. Customization will become a key differentiator, with manufacturers offering a wider range of colors, finishes (e.g., wood-grain foils), and design flexibility. Additionally, digital tools such as AI-powered design software and AR visualization will enhance the customer experience, enabling precise fitting and faster project turnaround.

In conclusion, by 2026, the plastic windows market will be defined by a convergence of energy efficiency, sustainability, digitalization, and regional regulatory frameworks. Companies that prioritize innovation, environmental responsibility, and adaptability to local market needs will be best positioned to capture growth in this evolving landscape.

Common Pitfalls When Sourcing Plastic Windows (Quality, IP)

Sourcing plastic windows, particularly for industrial or specialized applications, involves navigating several critical challenges related to product quality and intellectual property (IP). Overlooking these pitfalls can lead to performance failures, safety risks, legal liabilities, and brand damage.

Poor Material Quality and Durability

One of the most frequent issues is receiving plastic windows made from substandard materials. Low-grade polymers may degrade quickly when exposed to UV radiation, extreme temperatures, or chemicals, leading to clouding, cracking, or structural failure. Buyers may unknowingly receive recycled or off-spec resins that compromise optical clarity and mechanical strength. Always verify material specifications (e.g., polycarbonate vs. acrylic), certifications (e.g., UL, FDA, ISO), and request sample testing under real-world conditions.

Inadequate Optical Clarity and Performance

Plastic windows are often selected for their transparency, but poor manufacturing processes can result in uneven thickness, surface distortions, or internal stress marks. These defects impair visibility and reduce the window’s effectiveness in applications like enclosures, displays, or safety barriers. Ensure suppliers provide optical performance data and conduct visual inspections or light transmission tests before bulk ordering.

Lack of Intellectual Property Protection

When sourcing custom-designed plastic windows, there’s a significant risk of IP theft, especially when working with overseas manufacturers. Design blueprints, unique geometries, or proprietary coatings can be replicated and sold to competitors without consent. Always use non-disclosure agreements (NDAs), work with trusted partners, and consider registering design patents or trademarks in relevant jurisdictions.

Non-Compliance with Industry Standards

Different industries require plastic windows to meet specific safety and performance standards (e.g., impact resistance for automotive, flame retardancy for electronics). Suppliers may claim compliance without proper certification. Verify test reports and ensure products meet relevant standards such as ANSI, ASTM, or IEC. Non-compliant parts can lead to product recalls or legal penalties.

Inconsistent Manufacturing Tolerances

Precision is critical for plastic windows that must fit into tight assemblies or maintain seals. Poor mold maintenance or uncontrolled production processes can result in dimensional variations. Request detailed tolerance documentation and perform first-article inspections to catch inconsistencies early.

Hidden Tooling and Mold Ownership Issues

Suppliers may retain ownership of molds used to produce custom windows, giving them leverage over pricing and the ability to produce parts for competitors. Always negotiate and document mold ownership in contracts. Ideally, purchase the tooling outright or ensure exclusive rights to its use.

Supply Chain and Lead Time Risks

Reliance on a single supplier or region can expose buyers to delays, especially if raw material shortages or logistics disruptions occur. Assess supplier redundancy, inventory policies, and production capacity. Diversifying sources and maintaining safety stock can mitigate these risks.

By proactively addressing these pitfalls—through rigorous vetting, clear contracts, and ongoing quality control—companies can ensure they source reliable, high-performance plastic windows without compromising quality or intellectual property.

Logistics & Compliance Guide for Plastic Windows

This guide outlines the key logistics considerations and compliance requirements for the transportation, handling, and regulatory adherence of plastic windows during manufacturing, distribution, and installation.

Product Classification and HS Code

Plastic windows are typically classified under the Harmonized System (HS) code 3925.30, which covers “Other articles of plastics, used for building or construction: Windows, French windows and their frames, and parts thereof.” Accurate classification is critical for international shipping, customs clearance, and determining import duties.

Packaging and Handling Requirements

Plastic windows must be packaged to prevent surface scratches, warping, and structural damage. Use:

– Corrugated cardboard corner protectors

– Stretch wrap or shrink film to secure components

– Wooden or plastic pallets for stability during transport

– Waterproof covering for outdoor storage or sea freight

Handle units with forklifts or pallet jacks—never drag or drop. Maintain vertical storage when possible to avoid bowing.

Transportation and Shipping

- Domestic Transport: Use enclosed trailers to protect from weather and debris. Secure loads with straps to prevent shifting.

- International Shipping: Comply with ISPM 15 regulations if using wooden pallets (require heat treatment and stamping). Consider container freight for ocean shipments, ensuring proper ventilation to reduce condensation.

- Temperature Control: Avoid prolonged exposure to extreme heat (>60°C) or cold (<-20°C), which may cause deformation or material brittleness.

Regulatory Compliance

Environmental Regulations

- REACH (EU): Comply with registration, evaluation, and restriction of chemicals. Ensure no restricted substances (e.g., certain phthalates) are present in PVC formulations.

- RoHS (EU): Although primarily for electronics, verify absence of hazardous substances if components include electrical elements (e.g., sensors).

- TSCA (USA): Adhere to Toxic Substances Control Act, particularly regarding vinyl chloride monomer limits in PVC.

Building and Safety Standards

- EN Standards (Europe): Comply with:

- EN 14351-1: Windows and doors – Product standard

- EN 12608: Plastics windows – Factory production control

- AAMA/WDMA (North America): Follow certification programs for performance, air/water infiltration, and structural integrity.

- Energy Efficiency: Meet local energy codes (e.g., NFRC ratings in the U.S., CE marking with energy performance in EU).

Documentation and Labeling

Ensure all shipments include:

– Commercial invoice with correct HS code

– Packing list detailing quantities, dimensions, and weights

– Certificate of Conformity (CE, AAMA, etc., as applicable)

– Material Safety Data Sheet (MSDS) for plastic components

– Label each unit with product ID, batch number, handling instructions, and compliance marks

Import/Export Considerations

- Verify destination country regulations (e.g., China Compulsory Certification (CCC) may apply in some cases).

- Prepare for potential customs inspections—maintain traceability records.

- Account for tariffs and anti-dumping measures, especially on PVC products from certain regions.

Storage and Inventory Management

- Store indoors or under cover in a dry, well-ventilated area.

- Keep away from direct sunlight to prevent UV degradation.

- Rotate stock using FIFO (First In, First Out) to minimize aging effects.

End-of-Life and Recycling Compliance

- Design for recyclability where possible; use marked plastics (e.g., PVC-U labeled “PVC”).

- Comply with WEEE and packaging waste directives in applicable regions.

- Provide take-back or recycling program information if required by local law.

Adherence to this guide ensures safe, efficient logistics and full regulatory compliance for plastic window products across global markets.

In conclusion, sourcing plastic windows requires a careful evaluation of material quality, supplier reliability, cost-efficiency, and compliance with industry standards. Plastic windows, particularly those made from uPVC, offer advantages such as energy efficiency, low maintenance, and resistance to weathering, making them a popular choice for residential and commercial applications. To ensure optimal performance and longevity, it is essential to partner with reputable suppliers who provide certified, durable products and comply with environmental and safety regulations. Additionally, considering factors like customization options, lead times, and after-sales support will contribute to a successful procurement process. Ultimately, a strategic sourcing approach will help achieve the best balance between cost, quality, and sustainability in plastic window selection.