The global wall anchor market is experiencing steady expansion, driven by rising construction activities and increasing demand for durable fastening solutions in residential, commercial, and industrial applications. According to a report by Mordor Intelligence, the global wall anchor market was valued at USD 3.2 billion in 2023 and is projected to grow at a CAGR of 5.4% from 2024 to 2029. This growth is fueled by the surge in infrastructure development, especially in emerging economies, and a growing preference for plastic wall anchors due to their corrosion resistance, ease of installation, and cost-effectiveness. As demand continues to rise, manufacturers are focusing on product innovation and sustainability to gain competitive advantage. In this evolving landscape, the following ten companies have emerged as leading plastic wall anchor manufacturers, combining scale, technological expertise, and global reach to meet expanding market needs.

Top 10 Plastic Wall Anchor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Electrical Construction Hardware Manufacturer & Supplier. Anchors

Domain Est. 1996

Website: minerallac.com

Key Highlights: Concrete/Masonry Anchors · Hollow Wall Anchors · Plastic Anchors · Wall Dog Universal Anchors….

#2 Plastic Anchors Manufacturer

Domain Est. 2011

Website: meigesi.com

Key Highlights: Find our durable plastic anchors, designed for lightweight fastening in drywall and other materials….

#3 FHC

Domain Est. 2019

Website: fhc-usa.com

Key Highlights: Frameless Hardware Company LLC is a manufacturer and supplier to the glass, glazing, and fenestration industries. We provide a complete range of tools and ……

#4 TOGGLER – High

Domain Est. 1995

Website: toggler.com

Key Highlights: SNAPTOGGLE®. Heavy-Duty Toggle Bolts. Hollow Materials. The Perfect TV Mount In Stainless Steel And Zinc Plated Carbon Steel ; TOGGLER®. Plastic Toggle Anchors….

#5 Anchoring and Fastening Systems from DEWALT Anchors & Fasteners

Domain Est. 1997

Website: anchors.dewalt.com

Key Highlights: [HWA Hollow Wall Anchor Setting Tool]; [NP Nylon Plug]; [SHARKIE Plastic Wall Anchor]; [PX Universal Plug]; [ISO Metal Insulation Fixing]. [Dewalt Design ……

#6 Wall Anchors

Domain Est. 1998

#7 Cobra Anchors

Domain Est. 1999

Website: cobraanchors.com

Key Highlights: WORLD’S MOST TRUSTED BRAND FOR ANCHORS & HOOKS · Made in North America: Canada & USA · 20+ Worldwide Patented Products · 100% Pure Anchoring Hardware Innovation….

#8 Drywall Anchors

Domain Est. 2002

Website: allfasteners.com

Key Highlights: 4-day delivery 30-day returnsFrom plastic expansion anchors to the metal toggle type, we have the perfect fasteners for hanging anything on the wall….

#9 EZ Ancor

Domain Est. 2006

Website: easyanchors.com

Key Highlights: Our self-drilling anchors hold up to 100 lbs. in shear applications. Anchors install flush to the wall to prevent wobbling and loose fixtures. Versatile ……

#10 Plastic Anchors in Bulk

Domain Est. 2015

Website: bwindustrialsales.com

Key Highlights: Plastic anchors provide secure support for light duty fastening. Get fast shipping, bulk discounts, and various size options for drywall and masonry walls….

Expert Sourcing Insights for Plastic Wall Anchor

H2: 2026 Market Trends for Plastic Wall Anchors

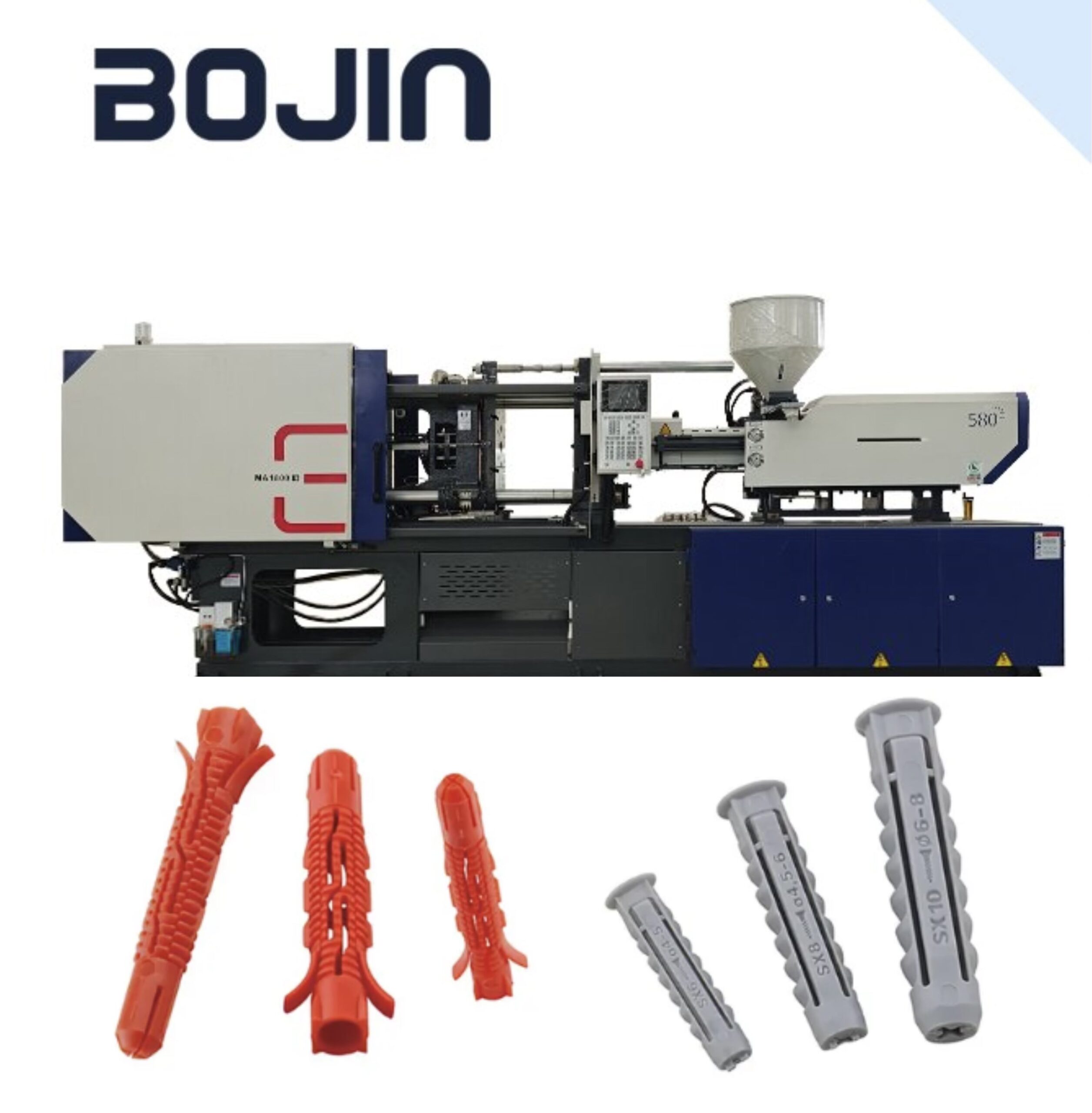

The global market for plastic wall anchors is projected to experience steady growth through 2026, driven by advancements in material science, rising construction activity, and increased demand for lightweight, easy-to-install fastening solutions. Key trends shaping the plastic wall anchor market include:

-

Growth in Residential and Commercial Construction

Expanding urbanization and infrastructure development—particularly in emerging economies in Asia-Pacific, Latin America, and Africa—are fueling demand for construction materials. Plastic wall anchors, known for their ease of use and reliability in drywall and hollow wall applications, are increasingly favored in both residential renovations and new commercial builds. -

Shift Toward Lightweight and Non-Corrosive Fasteners

As building practices evolve, there is a growing preference for non-metallic fasteners that resist corrosion, reduce weight, and avoid electrical conductivity. Plastic wall anchors made from polypropylene, nylon, and other high-performance polymers meet these criteria, making them ideal for use in humid environments, coastal regions, and modern energy-efficient buildings. -

Innovation in Anchor Design and Performance

Manufacturers are investing in R&D to improve load-bearing capacity, installation efficiency, and compatibility with a wider range of substrates. Expandable plastic anchors, self-drilling variants, and anchors with integrated screws are gaining traction due to their user-friendly design and enhanced holding power. -

Sustainability and Recyclability

Environmental regulations and consumer demand for sustainable building products are pushing manufacturers to develop recyclable or bio-based plastic anchors. By 2026, eco-conscious product lines—using post-consumer recycled plastics or biodegradable polymers—are expected to gain market share, particularly in Europe and North America. -

E-Commerce and DIY Market Expansion

The surge in do-it-yourself (DIY) home improvement projects, accelerated by online retail platforms and social media tutorials, is increasing demand for consumer-friendly plastic anchors. Retail packaging now emphasizes ease of use, compatibility charts, and installation guides, supporting non-professional users. -

Regional Market Dynamics

Asia-Pacific is anticipated to be the fastest-growing region due to rapid urbanization in countries like India and Vietnam. North America and Europe will maintain strong demand, supported by aging infrastructure requiring retrofitting and mounting solutions for smart home devices.

In summary, the plastic wall anchor market in 2026 will be characterized by innovation, sustainability, and responsiveness to evolving construction and consumer trends. Companies that focus on product differentiation, material efficiency, and digital distribution channels are likely to lead the market.

Common Pitfalls When Sourcing Plastic Wall Anchors (Quality and Intellectual Property)

Sourcing plastic wall anchors may seem straightforward, but overlooking key quality and intellectual property (IP) factors can lead to product failures, safety hazards, legal issues, and reputational damage. Here are common pitfalls to avoid:

Overlooking Material Quality and Specifications

One of the most frequent mistakes is assuming all plastic wall anchors are created equal. Sourcing low-grade materials—such as recycled or substandard polymers—can compromise tensile strength, durability, and performance under load. Poor material choice may lead to anchor failure, especially in critical applications like mounting heavy fixtures. Always verify material specifications (e.g., virgin polypropylene or nylon), UV resistance, temperature tolerance, and compliance with industry standards (e.g., ASTM, ISO).

Ignoring Manufacturing Consistency and Tolerances

Inconsistent manufacturing processes result in variable anchor dimensions and performance. Anchors that are too brittle, oversized, or undersized may not expand properly in the wall cavity, leading to poor grip or installation damage. Without strict quality control and process validation (e.g., ISO 9001), suppliers may deliver inconsistent batches. Ensure the manufacturer adheres to tight tolerances and conducts regular in-line inspections.

Failing to Conduct Real-World Performance Testing

Relying solely on supplier claims without independent testing is risky. Anchors must be tested under realistic conditions—different wall substrates (drywall, concrete, brick), load types (shear, pull-out), and environmental factors (humidity, temperature). Skipping due diligence can result in anchors that perform poorly in the field, leading to customer complaints and potential liability.

Neglecting Intellectual Property Rights

Many established plastic wall anchor designs are protected by patents or utility models. Sourcing generic or “look-alike” versions from suppliers who replicate patented designs can expose your company to IP infringement claims, legal disputes, and product seizures. Always conduct patent landscape analyses and ensure suppliers can provide proof of design freedom or licensed technology.

Relying on Unverified Supplier Claims

Suppliers may exaggerate certifications, material origins, or testing results. Without third-party verification or factory audits, you risk receiving non-compliant or counterfeit products. Request documentation such as material data sheets (MDS), test reports, and compliance certificates—and validate them through independent labs when necessary.

Underestimating Packaging and Labeling Compliance

Improper packaging can damage anchors during transit, while inadequate labeling may fail to convey critical usage instructions or safety warnings. In regulated markets, missing compliance marks (e.g., CE, UKCA) or multilingual labeling can delay shipments or lead to non-compliance penalties. Ensure packaging protects product integrity and meets regional regulatory requirements.

Skipping Supplier Due Diligence and Long-Term Viability

Choosing a supplier based solely on price without assessing their financial stability, production capacity, or track record can backfire. A supplier unable to scale or maintain quality over time may disrupt your supply chain. Conduct thorough due diligence, including site visits, reference checks, and evaluation of their quality management systems.

Logistics & Compliance Guide for Plastic Wall Anchor

Product Overview

Plastic wall anchors are fastening devices used to secure objects to hollow walls such as drywall, plaster, or paneling. Typically made from polypropylene or nylon, these anchors expand when a screw is inserted, creating a firm hold. They are commonly used in residential, commercial, and industrial applications for mounting shelves, fixtures, and light fixtures.

Material Composition & Environmental Compliance

Plastic wall anchors are generally manufactured from thermoplastics like polypropylene (PP) or nylon (PA6/PA66). These materials are recyclable under certain conditions. Manufacturers must ensure compliance with REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives, particularly regarding phthalates, heavy metals, and other restricted substances. Certifications such as ISO 14001 (Environmental Management) may be required for environmentally responsible production.

Packaging & Labeling Requirements

Proper packaging must protect the anchors from moisture, dust, and physical damage during transport. Common packaging includes blister packs, plastic bags, or cardboard boxes. Labels must include:

– Product name and type

– Quantity per pack

– Material composition (e.g., PP, PA6)

– Manufacturer name and contact information

– Country of origin

– Compliance markings (e.g., CE mark if applicable)

– Handling and storage instructions

Multilingual labeling may be required for international distribution.

Transportation & Storage

Plastic wall anchors are non-hazardous goods and can be shipped via standard freight (air, sea, or land). They should be stored in a dry, cool environment away from direct sunlight to prevent material degradation. Palletized storage with stretch wrapping is recommended to prevent shifting during transit. Ensure inventory rotation (FIFO) to avoid aging-related brittleness.

Regulatory Compliance (Region-Specific)

- European Union: Must comply with CE marking requirements if part of a construction kit or system. Adherence to EN standards (e.g., EN 17039 for mechanical anchors) may be applicable.

- United States: No federal certification required for standalone anchors, but must comply with FTC labeling rules. California Proposition 65 compliance is necessary if the product contains listed chemicals.

- Canada: Must meet labeling requirements under the Consumer Product Safety Act.

- Other Regions: Check local construction product regulations; some countries may require conformity assessment or third-party testing.

Import & Export Documentation

Key documents for international trade include:

– Commercial invoice

– Packing list

– Bill of lading or air waybill

– Certificate of Origin

– Material Safety Data Sheet (MSDS), if requested

– Test reports or compliance certificates (e.g., RoHS, REACH)

Ensure Harmonized System (HS) code classification (typically 3926.30 for plastic fittings) is accurate to avoid customs delays.

Quality Assurance & Testing

Manufacturers should conduct routine quality control tests, including:

– Dimensional accuracy

– Tensile and pull-out strength testing

– Impact resistance

– Temperature stability (for performance in extreme conditions)

Third-party testing may be required for certifications or entry into regulated markets.

Sustainability & End-of-Life Considerations

Promote recycling by providing information on proper disposal. Encourage customers to separate plastic anchors from metal screws for appropriate waste stream handling. Explore options for using recycled content in manufacturing to support circular economy goals.

Summary

Successful logistics and compliance for plastic wall anchors require attention to material safety, accurate labeling, proper storage, and adherence to regional regulations. Proactive documentation and quality assurance ensure smooth international distribution and market acceptance.

Conclusion on Sourcing Plastic Wall Anchors:

Sourcing plastic wall anchors requires a strategic approach that balances cost, quality, availability, and application requirements. After evaluating various suppliers, materials, and product specifications, it is clear that selecting the right anchor depends on the intended use—whether for light-duty household applications or more demanding commercial installations. Key factors such as load capacity, base material (e.g., drywall, plaster, or masonry), and environmental conditions must inform the sourcing decision.

Sourcing from reputable suppliers—either locally or internationally—ensures product consistency and compliance with industry standards. While local suppliers may offer faster delivery and easier communication, overseas manufacturers can provide cost advantages, especially for bulk orders. However, this must be weighed against lead times, shipping costs, and quality control risks.

Ultimately, a reliable supply chain, supported by sample testing and supplier audits, is essential for maintaining performance and safety in wall anchoring applications. By prioritizing quality assurance, cost-efficiency, and supplier reliability, organizations can ensure a successful and sustainable sourcing strategy for plastic wall anchors.