The global floating dock and pontoon market is experiencing robust growth, driven by rising investments in marina infrastructure, coastal tourism, and offshore developments. According to a 2023 report by Mordor Intelligence, the global floating dock market is projected to grow at a CAGR of over 5.8% from 2023 to 2028, with plastic pontoons gaining traction due to their durability, low maintenance, and resistance to corrosion and marine fouling. As demand surges across recreational, commercial, and industrial sectors, manufacturers are increasingly adopting advanced polymer composites and modular designs to meet evolving performance and sustainability standards. In this competitive landscape, eight key manufacturers have emerged as leaders in innovation, scalability, and product reliability—shaping the future of plastic pontoon solutions worldwide.

Top 8 Plastic Pontoon Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Introducing Harris’s RPM Technology

Domain Est. 2004

Website: harrisboats.com

Key Highlights: Harris’s RPM Technology enhances ride, performance, and maneuverability, forming the foundation of every boat to heighten your on-the-water experience….

#2 Sea

Domain Est. 1995

Website: sea-doo.brp.com

Key Highlights: Discover the all-new Sea-Doo pontoon lineup, designed for fun, water sports and fishing. Live the Sea-Doo life with our innovative pontoon boats….

#3 Plastic Pontoon

Domain Est. 1998

Website: plasticpontoon.com

Key Highlights: Designs, develops, and distributes modular polyethylene pontoons used in a variety of marine applications. Call us toll-free 877-456-2531 or email info© ……

#4 The Creek Company

Domain Est. 1998

Website: creekcompany.com

Key Highlights: Welcome to The Creek Company. The Creek Company manufactures Inflatable Rafts, Pontoon Boats, Float Tubes, Stand Up Paddle Boards and Fly Fishing Accessories….

#5 Pontoonworks

Domain Est. 2007

Website: pontoonworks.co.uk

Key Highlights: Pontoonworks are the UK’s experts in modular and floating pontoon hire solutions for safe access when working on water, for commercial and events….

#6 Tinypontoonboats.com

Domain Est. 2012

Website: tinypontoonboats.com

Key Highlights: Your source for mini and mid sized bolt-together pontoon boat kits, large work barge and house boat base kits, pontoon boat frame parts, and plastic floats ……

#7 Pontoons by Pontoonz

Domain Est. 2019

Website: pontoonzboats.com

Key Highlights: Pontoon boats. Pontoons for rafts, barges, houseboats, swim platforms, jetties, walkways. Use our modular plastic pods to construct your own floating solutions….

#8 Poly Pontoons

Domain Est. 2022

Website: polypontoons.com

Key Highlights: Poly Pontoons Australia is based in Noosa on the Sunshine Coast, We have over 18 years experience in designing and manufacturing boats….

Expert Sourcing Insights for Plastic Pontoon

H2: 2026 Market Trends for Plastic Pontoon

The plastic pontoon market is poised for steady growth and transformation by 2026, driven by innovation, sustainability demands, and evolving consumer preferences. Key trends shaping the market include:

1. Sustainability and Circular Economy Integration

Environmental concerns are pushing manufacturers toward recycled and recyclable materials. By 2026, expect increased use of post-consumer recycled (PCR) polyethylene and development of fully recyclable pontoon designs. Regulatory pressures and eco-conscious buyers will accelerate adoption of circular economy models, including take-back programs and modular designs for easier repair and recycling.

2. Advanced Material Innovations

High-density polyethylene (HDPE) will remain dominant, but enhanced formulations with UV stabilizers, impact modifiers, and anti-fouling additives will gain traction. Research into bio-based polymers and composite blends aims to improve durability while reducing carbon footprint. These innovations will extend product lifespan and reduce maintenance costs.

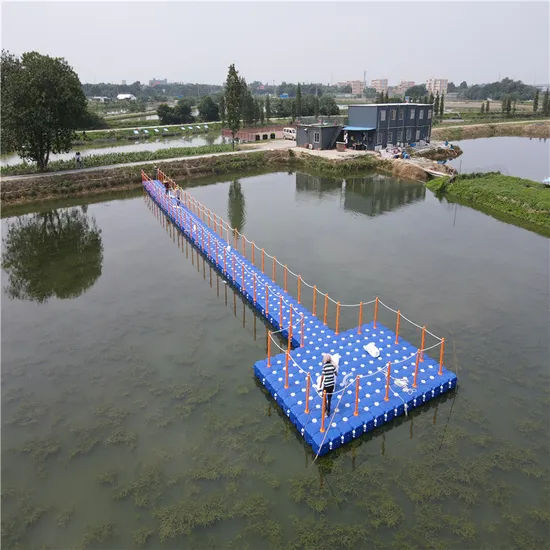

3. Modular and Customizable Designs

Demand for personalized and multi-functional pontoons—used in floating docks, leisure boats, and temporary bridges—will drive modular systems. Consumers seek easy assembly, reconfiguration, and scalability. By 2026, plug-and-play systems with smart connectors and integrated accessories (LED lighting, solar panels) will become standard.

4. Expansion in Non-Recreational Applications

Beyond marine leisure, plastic pontoons will see growing use in aquaculture, floating solar farms, flood resilience infrastructure, and emergency response platforms. Climate change adaptation efforts will boost deployment in flood-prone regions for temporary housing and transport solutions.

5. Regional Market Growth

Asia-Pacific, particularly China and India, will lead market expansion due to urbanization, coastal development, and rising disposable incomes. North America and Europe will focus on premium, eco-friendly products and retrofitting aging marinas with sustainable alternatives.

6. Digital Integration and Smart Features

Emerging trends include IoT-enabled pontoons with sensors for real-time monitoring of structural integrity, water levels, and environmental conditions. These “smart” systems will support predictive maintenance and improve safety, especially in commercial and municipal applications.

7. Competitive Landscape and Consolidation

The market will witness increased competition and strategic partnerships between material suppliers, pontoon manufacturers, and engineering firms. Mergers and acquisitions may consolidate niche players, while innovation hubs drive R&D in material science and sustainable design.

In summary, the 2026 plastic pontoon market will be defined by sustainability, technological integration, and diversification into new applications—positioning it as a critical component of resilient and adaptive water-based infrastructure.

Common Pitfalls When Sourcing Plastic Pontoons (Quality and Intellectual Property)

Sourcing plastic pontoons—especially for marine, recreational, or industrial applications—requires careful attention to both material quality and intellectual property (IP) concerns. Overlooking these aspects can lead to product failure, legal disputes, or reputational damage. Below are key pitfalls to avoid:

Poor Material Quality and UV Resistance

One of the most frequent issues is sourcing pontoons made from substandard plastic materials. Low-grade polyethylene or inadequate UV stabilizers can lead to rapid degradation when exposed to sunlight and saltwater. This results in brittleness, cracking, and reduced lifespan. Always verify resin type (e.g., FDA-approved or marine-grade HDPE) and demand third-party test reports for UV resistance and impact strength.

Inadequate Wall Thickness and Structural Integrity

Some suppliers cut costs by reducing wall thickness, compromising buoyancy and load capacity. This can lead to deformation or sinking under load. Ensure specifications clearly define minimum wall thickness and perform sample pressure or load testing before bulk orders.

Lack of Certification and Compliance

Plastic pontoons for commercial or public use may need to meet regulatory standards (e.g., CE, ISO, or ABYC). Sourcing from manufacturers without proper certifications increases liability risks. Confirm compliance with relevant safety and environmental regulations applicable to your market.

Mold and Design IP Infringement

Many pontoon designs are protected by patents or design rights. Sourcing from manufacturers who replicate branded or patented shapes—especially popular consumer models—can expose your business to intellectual property litigation. Always conduct due diligence on design ownership and obtain written assurances from suppliers that products do not infringe on existing IP.

Hidden Tooling and Mold Ownership

Suppliers may claim they own the molds, but in reality, the tooling could be leased or copied. This creates supply chain vulnerability. Clarify mold ownership in contracts and, if possible, register custom molds under your company’s name to secure exclusive production rights.

Inconsistent Manufacturing Processes

Variability in rotational molding processes—such as uneven heating or cooling—can result in weak spots or inconsistent wall distribution. Visit production facilities or request process audits to ensure consistent quality control and repeatability.

Insufficient Warranty and After-Sales Support

Some low-cost suppliers offer limited or no warranty, leaving buyers responsible for defects. Ensure contracts include clear warranty terms, return policies, and accountability for material failures, especially in harsh environments.

By proactively addressing these pitfalls, businesses can mitigate risks and ensure reliable, legally sound sourcing of plastic pontoons.

Logistics & Compliance Guide for Plastic Pontoon

Overview

Plastic pontoons are widely used in marine, construction, recreational, and industrial applications for buoyancy and floating support. Ensuring efficient logistics and compliance with relevant regulations is critical for safe transportation, deployment, and environmental responsibility. This guide outlines key considerations for handling, transporting, storing, and complying with standards for plastic pontoons.

Material & Construction Specifications

Plastic pontoons are typically manufactured from high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), or polyvinyl chloride (PVC), chosen for their durability, UV resistance, and corrosion resistance. Confirm material certifications (e.g., ASTM D1248) and ensure product compliance with design standards such as ISO 17357 or EN 13590, where applicable.

Packaging & Handling

- Use protective corner guards and edge protectors during packaging to prevent damage.

- Stack pontoons uniformly on pallets; avoid over-stacking to prevent deformation.

- Use soft slings or padded lifting equipment during handling to avoid surface abrasion.

- Clearly label each unit with orientation markings (e.g., “This Side Up”) and weight specifications.

Transportation Requirements

- Secure pontoons on flatbed trucks or in shipping containers using straps or chains to prevent shifting.

- Cover with UV-resistant tarpaulins during transit to limit sun exposure.

- Avoid exposure to extreme temperatures (above 60°C or below -20°C) during transport.

- Follow ADR/RID regulations if transporting in bulk across Europe; for international shipments, comply with IMDG Code guidelines if applicable.

Storage Guidelines

- Store in a cool, dry, shaded area away from direct sunlight and heat sources.

- Elevate pontoons off the ground using wooden pallets to prevent moisture absorption and deformation.

- Rotate stock using a first-in, first-out (FIFO) system to prevent aging-related degradation.

- Limit outdoor storage duration; if unavoidable, cover with UV-blocking materials.

Regulatory Compliance

- Environmental Regulations: Ensure compliance with REACH (EU) and TSCA (US) regarding chemical content. Confirm that materials are free from restricted substances such as phthalates or heavy metals.

- Marine Safety Standards: Adhere to local and international marine safety codes (e.g., U.S. Coast Guard requirements, CE marking under EU Marine Equipment Directive).

- Recycling & Disposal: Follow local waste management regulations for end-of-life pontoons. HDPE/LLDPE components should be recyclable; provide recycling instructions with product documentation.

Certification & Documentation

- Maintain Certificates of Conformity (CoC) for material and manufacturing processes.

- Provide Material Safety Data Sheets (MSDS) upon request.

- Include compliance labels and traceability codes (e.g., batch numbers, production dates) on each unit.

Installation & Deployment Compliance

- Follow manufacturer guidelines for ballasting, anchoring, and connection methods.

- Conduct buoyancy and stability calculations in accordance with ABS, DNV, or other class society rules if used in certified marine structures.

- Inspect for cracks, warping, or UV degradation prior to deployment.

Risk Management & Safety

- Train personnel in safe lifting and handling procedures.

- Implement routine inspection schedules during operational use.

- Address any leaks or structural damage immediately to prevent environmental contamination or failure.

Conclusion

Proper logistics and compliance practices are essential for the safe and effective use of plastic pontoons. Adhering to packaging, transportation, storage, and regulatory standards ensures product integrity, user safety, and environmental protection throughout the product lifecycle.

Conclusion for Sourcing Plastic Pontoon

In conclusion, sourcing plastic pontoons presents a compelling solution for a wide range of marine and floating applications due to their durability, low maintenance, and environmental resistance. High-density polyethylene (HDPE) and other advanced plastic materials offer excellent buoyancy, corrosion resistance, and longevity—especially in harsh aquatic environments—making them superior to traditional materials like wood or metal in many scenarios. Additionally, plastic pontoons are lightweight, easy to install, and often recyclable, contributing to sustainable project development.

When sourcing, it is essential to evaluate suppliers based on material quality, manufacturing standards, customization capabilities, and compliance with environmental and safety regulations. Partnering with reputable manufacturers ensures reliable performance and reduces long-term costs associated with repairs or replacement.

Overall, plastic pontoons represent a cost-effective, sustainable, and versatile choice for floating docks, marine platforms, floating walkways, and similar structures. With careful supplier selection and proper design considerations, plastic pontoons can deliver long-term value and operational efficiency across recreational, commercial, and industrial applications.