The global plastic paver edging market is experiencing steady growth, driven by increasing demand for low-maintenance, durable landscaping solutions in both residential and commercial sectors. According to Grand View Research, the global plastic construction products market—encompassing materials such as recycled and virgin polymers used in hardscaping—was valued at USD 345.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth trajectory is further supported by rising infrastructure development, urbanization, and a shift toward sustainable materials, with plastic edging offering advantages such as corrosion resistance, flexibility, and cost-effectiveness over traditional metal or wood alternatives. Mordor Intelligence also projects robust growth for plastic-based building materials, citing increasing investments in landscaping and outdoor living spaces, particularly in North America and Europe. As demand surges, a select group of manufacturers has emerged as leaders in innovation, scalability, and product quality—setting the standard in the plastic paver edging segment.

Top 9 Plastic Paver Edging Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Master Mark Lawn and Garden Supplies

Domain Est. 1995

Website: mastermark.com

Key Highlights: Master Mark has dozens of edging solutions, so we’re sure to have edging that’s the perfect match for your beds. View Classic Landscape Edging · Paver Edging ……

#2 Oly

Domain Est. 1996

Website: olyola.com

Key Highlights: Constructed of 100% recycled polyethylene, our landscape edgings provide long lasting quality on the job. They divide turf from planting areas, keep mulch & ……

#3 ValleyView Industries

Domain Est. 1997

Website: valleyviewind.com

Key Highlights: ValleyView Industries offers high-quality landscape edging and accessories for professionals and DIYers. Shop durable solutions designed for easy ……

#4 Hardscape & Landscape Edging

Domain Est. 1998

Website: srwproducts.com

Key Highlights: Have peace of mind knowing your project is secured with the nation’s best edging products, including concrete blends, curved landscape pavers, and rails….

#5 Plastic Edging

Domain Est. 1998

Website: surelocedging.com

Key Highlights: This plastic paver edging kit is perfect for sidewalks, patios and even driveway installations. This 1 3/8” tall L shaped profile can be installed with ……

#6 B.E.A.S.T. Plastic Paver Edging

Domain Est. 2007

Website: brickstopedge.com

Key Highlights: Easy to install with 10″ or 12″ nails; Allows natural vegetation growth; 100% recycled plastic. Backed up by a company with experience and staying power. Specs ……

#7 Surefoot Edging

Domain Est. 2007

Website: surefootedging.com

Key Highlights: Surefoot Edging is the most advanced paver edging ever. Installation is quick and effortless – just position edging in place next to the pavers and easily cut ……

#8 About Perma Paver Edging

Domain Est. 2016

Website: permapaveredging.com

Key Highlights: Perma Paver Edging stays under the soil, grass or mulch grade. That means no more visible heaved spikes or hideous plastic edging. • Creates a long lasting edge ……

#9 Snap Edge

Website: sek.us.com

Key Highlights: Snap Edge Paver Restraint is a contractor grade product, designed to be used with pavers or natural stone 2” – 3 1/8” thick. It comes in 8′ pieces….

Expert Sourcing Insights for Plastic Paver Edging

H2: 2026 Market Trends for Plastic Paver Edging

The global market for plastic paver edging is poised for significant transformation by 2026, driven by evolving consumer preferences, sustainability mandates, and advancements in material technology. As urbanization accelerates and landscaping investments rise—particularly in residential and commercial sectors—plastic paver edging is emerging as a preferred alternative to traditional materials like metal, wood, and concrete. Below are the key trends shaping the plastic paver edging market in 2026:

-

Increased Demand for Eco-Friendly Materials

By 2026, environmental sustainability will be a core purchasing criterion. Manufacturers are responding by developing plastic paver edging made from recycled HDPE (High-Density Polyethylene) and other post-consumer plastics. These products minimize carbon footprint and appeal to environmentally conscious consumers and municipalities aiming to meet green building standards. -

Growth in Residential Landscaping

The surge in home improvement activities, especially in North America and Europe, continues to fuel demand. Homeowners are investing in low-maintenance, durable landscaping solutions. Plastic paver edging offers easy installation, resistance to cracking and corrosion, and long-term cost savings—making it ideal for DIY projects and professional installations alike. -

Innovation in Design and Durability

Plastic paver edging is evolving beyond basic functionality. By 2026, expect to see products with enhanced UV stabilization, improved flexibility for curved installations, and aesthetic finishes that mimic stone or wood. These innovations broaden its application in high-end residential and urban design projects. -

Expansion in Commercial and Municipal Use

Cities and commercial developers are increasingly adopting plastic edging for parks, walkways, and public plazas due to its longevity and reduced maintenance costs. Municipal contracts are driving bulk procurement, especially in regions investing in smart city infrastructure and green public spaces. -

Market Penetration in Emerging Economies

Rapid urbanization in Asia-Pacific, Latin America, and the Middle East is creating new growth opportunities. Countries like India, Vietnam, and the UAE are witnessing a boom in real estate development, where plastic paver edging offers a cost-effective and quick-installation solution compared to traditional materials. -

Rising Competition and Price Optimization

As more players enter the market, competition is intensifying. This is leading to price optimization and product differentiation. Private-label and value-branded products are gaining traction, particularly in retail channels like home improvement stores and e-commerce platforms. -

Integration with Smart Landscaping Technologies

Innovative companies are exploring integration with smart irrigation and lighting systems. While still in early stages, plastic edging with embedded channels for wiring or water flow could become a niche trend by 2026, especially in high-tech residential communities.

In conclusion, the 2026 outlook for plastic paver edging is robust, underpinned by sustainability, durability, and design innovation. Market players who prioritize eco-conscious manufacturing, adapt to regional demands, and embrace technological integration are likely to lead the sector in the coming years.

Common Pitfalls When Sourcing Plastic Paver Edging (Quality and Intellectual Property)

Sourcing plastic paver edging can be cost-effective and efficient, but buyers often encounter critical pitfalls related to product quality and intellectual property (IP) concerns. Overlooking these factors can lead to project delays, increased costs, or legal complications.

Poor Material Quality and Durability

Many suppliers offer plastic paver edging made from low-grade or recycled plastics that lack UV resistance, impact strength, or structural integrity. This can result in premature cracking, warping, or fading when exposed to sunlight and weather. Always verify material specifications, such as polyethylene (HDPE or LDPE) composition, UV stabilizers, and load-bearing capacity to ensure longevity.

Inconsistent Dimensional Accuracy

Low-cost manufacturers may cut corners on tooling and quality control, leading to inconsistent lengths, widths, or interlocking mechanisms. This inconsistency complicates installation and creates visible gaps or misalignments in paved areas. Request samples and inspect for uniformity before placing bulk orders.

Lack of Structural Integrity for Load-Bearing Applications

Some plastic edging products are not engineered to withstand soil pressure or foot/vehicle traffic, especially in driveways or commercial installations. Using underspecified edging can lead to shifting, bulging, or failure over time. Confirm that the product meets industry standards for flexural strength and lateral support.

Inadequate UV and Weather Resistance

Plastic edging exposed to direct sunlight degrades faster if not properly formulated with UV inhibitors. Inferior products may become brittle or discolored within months. Ensure the manufacturer specifies UV protection and provides performance data under accelerated weathering tests.

Intellectual Property Infringement Risks

Many plastic paver edging designs—especially interlocking profiles or proprietary installation features—are patented or protected by design rights. Sourcing from manufacturers who replicate branded designs (e.g.,模仿 popular systems like TRUEGRID or other patented edging) exposes buyers to IP litigation. Always verify that the supplier owns or has licensed the design rights.

Misrepresentation of Certifications and Compliance

Some suppliers falsely claim compliance with ASTM, ISO, or environmental standards (e.g., recycled content). This misrepresentation can impact project certifications like LEED or result in non-compliant installations. Request third-party test reports or certification documents to validate claims.

Hidden Costs Due to Short Lifespan

While plastic edging may have a low upfront cost, poor quality can lead to frequent replacements and higher lifetime expenses. Factor in total cost of ownership, including installation labor and maintenance, rather than focusing solely on unit price.

Supply Chain and Lead Time Uncertainties

Reliance on overseas manufacturers, particularly without clear contractual terms, can result in production delays, quality variances between batches, or communication challenges. Establish clear quality agreements and consider local suppliers for better oversight and reliability.

Avoiding these pitfalls requires due diligence: request physical samples, audit supplier credentials, verify IP rights, and prioritize long-term performance over initial cost savings.

Logistics & Compliance Guide for Plastic Paver Edging

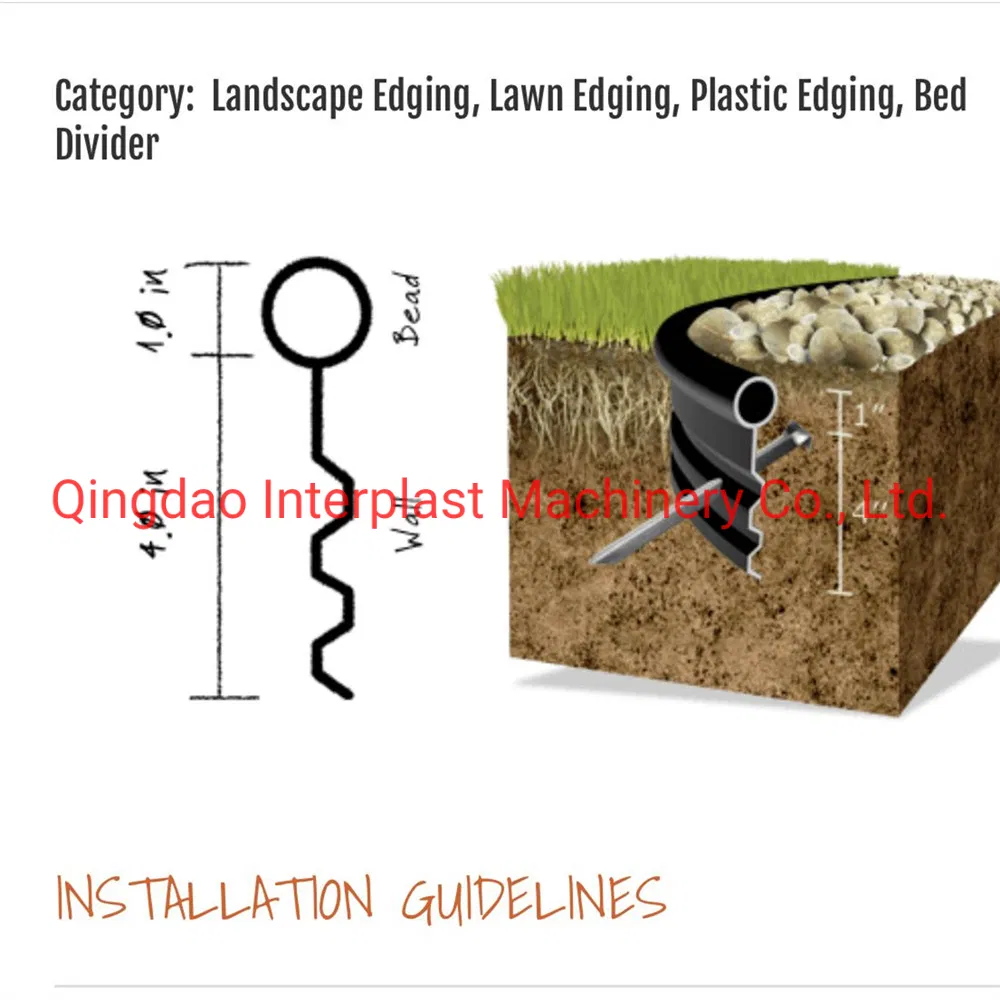

Product Overview

Plastic paver edging is a durable, flexible border solution used in landscaping to contain pavers, gravel, or mulch. Made typically from recycled polyethylene or polypropylene, it offers resistance to UV rays, moisture, and temperature fluctuations. This guide outlines logistical considerations and compliance requirements for the distribution, import/export, and installation of plastic paver edging products.

Packaging & Labeling Requirements

Proper packaging ensures product integrity during transit and supports compliance with shipping regulations. Plastic paver edging should be:

– Bundled securely using recyclable strapping or shrink wrap.

– Packaged in moisture-resistant materials to prevent degradation.

– Labeled with product specifications, batch numbers, manufacturing date, and handling instructions (e.g., “Keep Dry,” “Do Not Stack Excessively”).

– Marked with supplier name, country of origin, and any relevant certifications (e.g., recycled content claims).

Transportation & Handling

Efficient transportation minimizes damage and ensures timely delivery:

– Stack pallets no higher than recommended to prevent collapse.

– Use enclosed or covered vehicles to protect from precipitation and extreme temperatures.

– Avoid exposure to direct sunlight for prolonged periods during transit to prevent warping.

– Use forklifts or pallet jacks for loading/unloading; do not drag bundles on the ground.

Storage Conditions

Proper storage maintains product quality:

– Store in a cool, dry, shaded area away from direct sunlight.

– Elevate pallets off the ground using wooden skids to prevent moisture absorption.

– Maintain adequate ventilation to reduce condensation.

– Keep away from open flames or high-heat sources due to the flammable nature of plastics.

Import/Export Compliance

For international shipping, adhere to the following:

– Ensure Harmonized System (HS) Code classification (e.g., 3926.30 for other articles of plastics used in construction).

– Prepare accurate commercial invoices, packing lists, and certificates of origin.

– Comply with destination country’s import regulations, including potential duties and anti-dumping measures.

– Verify compliance with REACH (EU), TSCA (USA), or other chemical safety regulations if applicable.

Environmental & Regulatory Compliance

Plastic paver edging must meet regional environmental standards:

– Recycled Content: If marketed as recycled, provide documentation verifying percentage and source (e.g., post-consumer or post-industrial).

– RoHS Compliance: Ensure the product is free from restricted substances (e.g., lead, cadmium) if sold in the EU or similar markets.

– UV Stabilization: Confirm product contains UV inhibitors to meet durability claims and reduce environmental degradation.

– Disposal & Recycling: Provide end-of-life guidance; label with resin identification code (e.g., #2 HDPE or #5 PP).

Safety & Handling Documentation

Include with shipments:

– Safety Data Sheet (SDS) in compliance with GHS standards, even if low hazard.

– Installation manual with recommended practices and safety precautions.

– Warranty information and contact details for customer support.

Certifications & Standards

Verify adherence to industry standards where applicable:

– ASTM standards for plastic materials (e.g., ASTM D638 for tensile properties).

– ICBO or ICC-ES evaluation reports if required for use in structural applications.

– Environmental product declarations (EPD) or Declare labels for green building projects (e.g., LEED certification support).

End-of-Life & Sustainability

Promote responsible lifecycle management:

– Design for disassembly and recyclability.

– Partner with take-back or recycling programs where available.

– Avoid use of mixed plastics that complicate recycling streams.

Conclusion

Effective logistics and compliance management for plastic paver edging ensures product quality, regulatory adherence, and environmental responsibility. By following this guide, distributors, contractors, and manufacturers can support sustainable construction practices while minimizing supply chain disruptions and legal risks.

Conclusion for Sourcing Plastic Paver Edging:

After evaluating various options, sourcing plastic paver edging proves to be a cost-effective, durable, and environmentally responsible choice for landscape and hardscape projects. Its resistance to rot, UV degradation, and insect damage ensures long-term performance with minimal maintenance. Additionally, plastic edging is lightweight, easy to install, and flexible, allowing for clean curves and smooth finishes in diverse design applications. Many suppliers now offer recycled or recyclable plastic edging, supporting sustainability goals. When sourcing, it is important to consider product quality, UV stabilization, supplier reliability, and compliance with environmental standards. Overall, plastic paver edging offers an efficient, low-maintenance solution that balances performance, affordability, and ecological considerations, making it a practical choice for both residential and commercial landscaping projects.