The global plastic hard case market is experiencing robust growth, driven by rising demand across industries such as consumer electronics, healthcare, defense, and logistics. According to Grand View Research, the global plastic packaging market—encompassing hard cases—was valued at USD 310.4 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. A key segment within this space, rigid plastic cases, benefits from increasing need for durable, lightweight, and customizable protective solutions. Mordor Intelligence further supports this trajectory, forecasting the plastic packaging market to grow at a CAGR of over 4.5% during the 2024–2029 period, citing innovation in materials and manufacturing techniques as a key driver. With Asia-Pacific emerging as a manufacturing and consumption hub, and North America maintaining high demand for premium protective cases, the competitive landscape is evolving rapidly. This growth underscores the importance of identifying leading manufacturers who combine scale, innovation, and quality—setting the stage for the top 10 plastic hard case manufacturers shaping the industry today.

Top 10 Plastic Hard Case Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

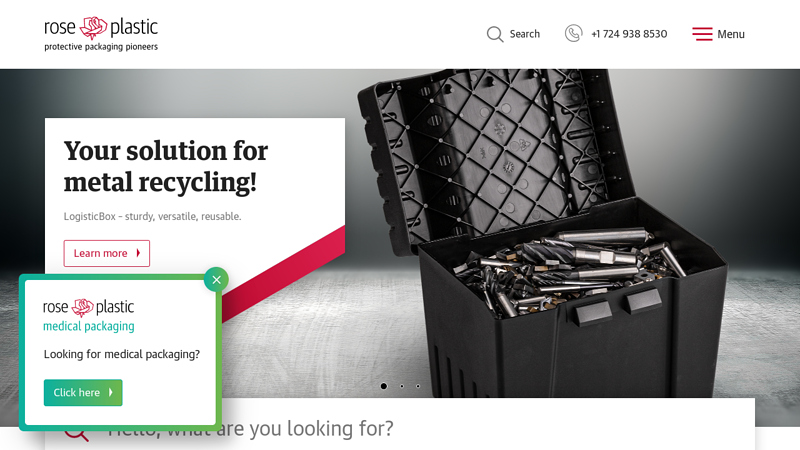

#1 rose plastic

Domain Est. 2002

Website: rose-plastic.us

Key Highlights: rose plastic is one of the world’s leading manufacturers of plastic packaging for cutting tools, industrial components, tools and other products….

#2 US Case

Domain Est. 1997

Website: uscase.com

Key Highlights: US Case Corporation is a manufacturer of custom designed and built ATA certified shipping and carry cases. We believe in America and in keeping our production ……

#3 Bel-Air Cases: Custom Carrying Cases and Shipping Cases

Domain Est. 2002

Website: bel-air-cases.com

Key Highlights: As the original innovator and producer of vacuum-formed plastic shipping cases and carrying cases, we continue to set the standard for case manufacturing….

#4 Gemstar Manufacturing

Domain Est. 2003

Website: gemstarmfg.com

Key Highlights: Gemstar Protective Hard Cases is a manufacturer of plastic cases – using the processes of thermoforming, injection molding, and rotational molding….

#5 Hard Plastic Cases

Domain Est. 2006

Website: s3cases.com

Key Highlights: S3 Cases designs and builds their cases using the most durable materials available on the earth. Made in The USA, our cases thrive in unforgiving environments….

#6 Global Plastic Packaging Solutions for a Sustainable Future

Domain Est. 1997

Website: alpla.com

Key Highlights: ALPLA is a world leader in the development and production of innovative plastic packaging solutions. We produce innovative packaging systems, bottles, caps and ……

#7 Molded Plastic Cases

Domain Est. 1998

Website: pfccases.com

Key Highlights: We offer a range of plastic molded cases, each of which can be customized to meet your exact requirements. Whether you need a small plastic case with foam for ……

#8 Plastic Hard Cases

Domain Est. 1998

Website: ameripack.com

Key Highlights: Ameripack manufactures and sells a variety of plastic hard cases ideal for shipping and storage of sensitive equipment including military equipment and any ……

#9 Foam

Domain Est. 1998

Website: plattcases.com

Key Highlights: Foam Filled Storage Cases are a good option for Transportation. While transporting, the components kept inside the cases will not break as they are ……

#10 Custom ATA Flight & Road Cases

Domain Est. 2012 | Founded: 1952

Website: calzoneanvil.com

Key Highlights: Made in USA since 1952. Custom ATA Spec 300 flight & road cases, shock-mount racks, workboxes, medical & military transit cases. 3 locations. Get a quote….

Expert Sourcing Insights for Plastic Hard Case

H2: Market Trends for Plastic Hard Case in 2026

The global market for plastic hard cases is poised for significant transformation by 2026, driven by evolving consumer demands, technological advancements, and increased focus on sustainability. As industries ranging from consumer electronics and healthcare to logistics and defense continue to rely on durable protective packaging, the plastic hard case segment is adapting to meet new challenges and opportunities. Here are the key trends expected to shape the market in 2026:

1. Rising Demand for Lightweight and Durable Materials

Manufacturers are increasingly adopting high-performance engineering plastics such as polycarbonate (PC), polypropylene (PP), and acrylonitrile butadiene styrene (ABS) to produce hard cases that are both lightweight and impact-resistant. This trend is particularly strong in the electronics and aerospace sectors, where portability and protection are critical.

2. Sustainability and Circular Economy Integration

Environmental regulations and consumer preferences are pushing companies to shift toward recyclable and bio-based plastics. By 2026, a growing number of plastic hard case producers are expected to incorporate post-consumer recycled (PCR) content and design products for disassembly and recycling. Bioplastics derived from renewable sources, such as polylactic acid (PLA), are also gaining traction in niche applications.

3. Customization and Smart Features

The demand for customized hard cases—tailored to specific devices or industrial equipment—is rising. Advancements in injection molding and 3D printing technologies are enabling cost-effective mass customization. Additionally, integration of smart features such as RFID tags, embedded sensors, and IoT connectivity for tracking and monitoring is emerging, especially in logistics and medical equipment transport.

4. Growth in E-Commerce and Protective Packaging

The continued expansion of e-commerce is fueling the need for robust shipping containers and protective packaging. Hard plastic cases are increasingly being used not only for premium product delivery (e.g., cameras, drones) but also in last-mile logistics for high-value goods. Tamper-evident and reusable designs are becoming standard.

5. Regional Market Shifts

Asia-Pacific is expected to dominate the plastic hard case market by 2026, driven by rapid industrialization, a growing electronics manufacturing base (especially in China, India, and Vietnam), and increasing consumer spending. Meanwhile, North America and Europe are focusing more on sustainable materials and compliance with strict environmental standards such as the EU’s Single-Use Plastics Directive.

6. Cost Pressures and Supply Chain Optimization

Ongoing volatility in raw material prices and supply chain disruptions are compelling manufacturers to optimize production processes, localize sourcing, and invest in alternative materials. Reshoring and nearshoring of production facilities are trends that may reduce dependency on global supply chains.

7. Innovation in Design and Functionality

Modular designs, ergonomic features, and improved sealing technologies (e.g., IP67/IP68-rated waterproof cases) are enhancing user experience across sectors. Military, outdoor, and medical applications are driving innovation in extreme-condition performance.

Conclusion

By 2026, the plastic hard case market will be characterized by a balance between performance, sustainability, and smart functionality. Companies that invest in eco-friendly materials, digital integration, and agile manufacturing will be best positioned to capture growth in this evolving landscape. Regulatory frameworks and consumer awareness will continue to shape product development, making sustainability a core competitive advantage.

Common Pitfalls Sourcing Plastic Hard Cases (Quality, IP)

Sourcing plastic hard cases—commonly used for electronics, medical devices, or industrial equipment—can present significant challenges, especially concerning quality consistency and intellectual property (IP) protection. Overlooking these aspects can lead to product failures, legal disputes, or reputational damage. Below are key pitfalls to avoid.

Poor Material Selection and Quality Control

One of the most frequent issues is the use of substandard or incorrect plastic materials. Suppliers may substitute high-impact polycarbonate or ABS blends with cheaper, lower-grade plastics to cut costs. This can compromise durability, temperature resistance, and structural integrity. Without rigorous quality control (QC) processes—such as incoming material inspection, in-process checks, and final product testing—defects like warping, cracking, or inconsistent wall thickness may go undetected until after shipment.

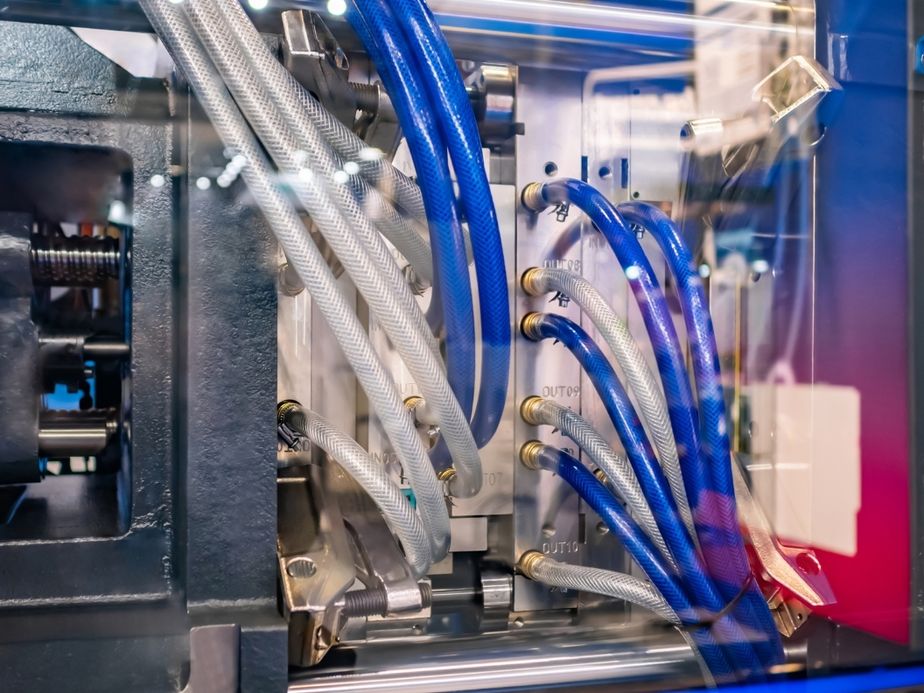

Inadequate Molding Process Oversight

Injection molding is critical to hard case production, and poor process control leads to flaws such as sink marks, flow lines, short shots, or dimensional inaccuracies. Many overseas suppliers lack advanced monitoring systems or skilled technicians to maintain tight tolerances. Without on-site audits or third-party inspections, buyers risk receiving non-conforming batches that don’t fit internal components or fail drop tests.

Lack of IP Protection and Design Theft

Sharing detailed CAD files and tooling specifications with manufacturers exposes your design to IP theft. Unscrupulous suppliers may replicate your case design for competing products or sell tooling to third parties. This is particularly common in regions with lax IP enforcement. Failure to sign comprehensive Non-Disclosure Agreements (NDAs), secure tooling ownership, or register designs can leave your innovation vulnerable.

Tooling Ownership and Replication Risks

Tooling for plastic hard cases is often expensive and custom-made. If not explicitly contractually assigned, suppliers may retain ownership and use the molds to produce cases for other clients. Buyers lose control over production and exclusivity. Some suppliers even create unauthorized duplicate molds, leading to counterfeit or gray-market products.

Inconsistent Surface Finish and Aesthetics

A hard case’s appearance—gloss level, texture (e.g., matte, grain), and color consistency—is often critical. Sourcing from suppliers without standardized color-matching processes (e.g., using Pantone or RAL standards) can result in batch-to-batch variations. Surface defects like splay marks, ejector pin marks, or poor gate vestige also affect perceived quality.

Regulatory and Compliance Gaps

Depending on the application, plastic cases may need to meet flammability (e.g., UL 94), RoHS, REACH, or FDA standards. Suppliers might claim compliance without proper documentation or third-party certifications. Using non-compliant materials can lead to product recalls or market access denial.

Hidden Costs from Design Revisions and Delays

Poor communication or lack of engineering expertise at the supplier level often leads to design flaws discovered only during tooling or production. This results in costly mold modifications, extended lead times, and increased non-recurring engineering (NRE) expenses. Ensuring Design for Manufacturing (DFM) reviews before tooling is essential but often overlooked.

Insufficient Testing and Validation

Suppliers may skip or falsify performance tests—such as impact resistance, ingress protection (IP) ratings, or environmental stress cracking resistance. Without independent validation (e.g., lab testing for IP67 sealing), the final product may fail under real-world conditions, leading to warranty claims and customer dissatisfaction.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Conduct thorough supplier audits and request material certifications.

– Secure IP rights via legal agreements and register designs.

– Maintain ownership of molds and require tooling logs.

– Implement third-party QC inspections at multiple stages.

– Specify and verify compliance with relevant industry standards.

– Perform pre-production sampling and rigorous performance testing.

Proactive due diligence in both quality and IP protection is essential to ensure reliable, secure sourcing of plastic hard cases.

Logistics & Compliance Guide for Plastic Hard Case

This guide outlines the essential logistics and compliance considerations for the safe, legal, and efficient handling, transportation, and sale of Plastic Hard Cases.

Product Classification & Regulatory Compliance

Identify and adhere to all applicable regulations based on the product’s composition and intended use. Plastic Hard Cases may fall under various regulatory frameworks depending on materials (e.g., ABS, polycarbonate), additives (e.g., flame retardants), and end-use applications (e.g., consumer goods, industrial, medical, or military). Ensure compliance with global standards such as REACH (EU), RoHS (EU), Prop 65 (California), and TSCA (USA) regarding restricted substances. Verify if the product requires specific safety certifications (e.g., IP ratings for dust/water resistance, MIL-STD for durability) based on marketing claims.

Packaging & Labeling Requirements

Use durable, protective packaging to prevent damage during transit. Clearly label each unit and shipping container with essential information, including product name, model/variant, quantity, weight, dimensions, handling symbols (e.g., “Fragile,” “This Side Up”), and compliance markings (e.g., recycling codes, CE marking if applicable). Include safety data sheets (SDS) if required due to material composition or large-scale shipment. Ensure all labeling complies with destination country language and regulatory requirements.

Transportation & Handling

Plastic Hard Cases are generally non-hazardous but must be handled to avoid impact damage, deformation from stacking, or exposure to extreme temperatures. Secure loads appropriately in containers or trucks using stretch wrap, dunnage, or bracing. Follow carrier-specific guidelines for weight limits, palletization, and stacking heights. Choose transport modes (air, sea, ground) based on urgency, cost, and destination. For international shipments, complete necessary documentation such as commercial invoices, packing lists, and certificates of origin.

Import/Export Documentation & Duties

Prepare accurate customs documentation to avoid delays. Classify the product using the correct Harmonized System (HS) code—typically under Chapter 39 (Plastics and Articles Thereof), such as 3923.10 or 3923.90, depending on design and use. Declare value, origin, and quantity correctly to determine applicable tariffs, import VAT, or anti-dumping duties. Verify if free trade agreements (e.g., USMCA, RCEP) offer duty reductions. Retain records for audit and compliance purposes.

Environmental & Sustainability Considerations

Design and manage logistics with environmental impact in mind. Use recyclable or biodegradable packaging materials where feasible. Clearly label plastic components with resin identification codes (RIC) to support end-of-life recycling. Comply with Extended Producer Responsibility (EPR) regulations in applicable regions, which may require reporting or financing recycling programs. Explore closed-loop logistics options for returnable or reusable cases.

Quality Control & Traceability

Implement quality checks during manufacturing and pre-shipment to ensure consistency and compliance. Maintain batch/lot traceability to support recalls or compliance audits. Include unique identifiers (e.g., serial numbers, barcodes) on products or packaging when required for tracking across the supply chain.

Storage & Inventory Management

Store Plastic Hard Cases in a dry, temperature-controlled environment away from direct sunlight to prevent warping or discoloration. Use first-in, first-out (FIFO) inventory practices to minimize aging and obsolescence. Protect from dust and contaminants, especially if intended for cleanroom or sensitive applications.

Conclusion for Sourcing Plastic Hard Cases:

After a thorough evaluation of suppliers, material options, manufacturing capabilities, and cost considerations, sourcing plastic hard cases presents a viable and cost-effective solution for protecting and transporting sensitive equipment, electronics, or other high-value items. High-impact plastics such as polycarbonate, ABS, or polypropylene offer excellent durability, lightweight properties, and resistance to environmental factors.

Key advantages include customization options (size, color, foam inserts), scalability for bulk production, and compliance with industry standards for protection and safety. Additionally, partnering with reliable manufacturers—whether domestic or overseas—can ensure consistent quality and on-time delivery, especially when due diligence is applied in vetting suppliers and conducting sample testing.

In conclusion, with careful selection of materials, attention to design specifications, and strategic supplier partnerships, sourcing plastic hard cases can meet both performance requirements and budgetary goals, making it a practical choice for a wide range of commercial and industrial applications. Ongoing monitoring of supply chain efficiency and quality control will further optimize long-term sourcing success.