The global plastic cups with lid market is experiencing steady growth, driven by rising demand from the foodservice industry, increasing on-the-go consumption, and expanding quick-service restaurant (QSR) chains. According to Grand View Research, the global disposable cups market was valued at USD 9.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030, with plastic variants maintaining significant share due to their durability, cost-efficiency, and suitability for both hot and cold beverages. Additionally, urbanization and the proliferation of delivery services have further amplified the need for leak-resistant, convenient cup-lid systems. As sustainability concerns rise, leading manufacturers are also investing in recyclable and lightweight plastic solutions to align with evolving regulations and consumer preferences. In this competitive landscape, eight manufacturers have emerged as key players, combining scale, innovation, and distribution reach to dominate the plastic cups with lid segment.

Top 8 Plastic Cups With Lid Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

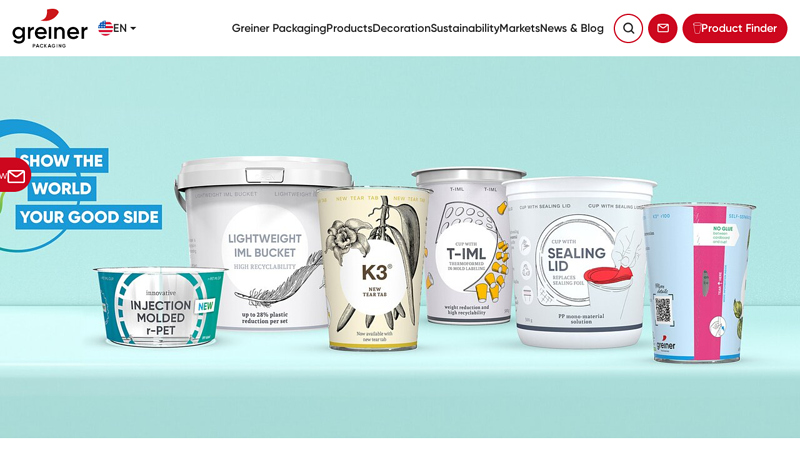

#1 Plastic Packaging Manufacturer

Domain Est. 1999

Website: greiner-gpi.com

Key Highlights: Every pot has its lid – so does every cup. Greiner Packaging offers a variety of lids that not only protect the product but can also include various functions….

#2 Wholesale Plastics Products Supplier & Manufacturer

Domain Est. 2000

Website: packagingsolutions.amcor.com

Key Highlights: Amcor manufactures a vast range of plastic products order samples online and buy at wholesale prices….

#3 Cups

Domain Est. 1995

Website: dartcontainer.com

Key Highlights: Diverse cup options for your hot and cold beverage needs. Plastic, Plastic cup with strawless lid and refreshing beverage, Paper, Paper Hot Cup with coffee….

#4 WinCup

Domain Est. 1995

Website: wincup.com

Key Highlights: Our breakthrough VIO™ Cup establishes the standard for biodegradable* foam manufacturing. Learn more. Environmental. WinCup is committed to sustainable business ……

#5 About SOLO

Domain Est. 1995

Website: solocup.com

Key Highlights: 1936: Leo Hulseman founded the SOLO Cup Company, making paper cone cups. 1970s: The Hulseman family expanded the paper product portfolio to include plastic cups ……

#6 Dixie® Cups, Paper Products & Disposable Tableware

Domain Est. 1998

Website: dixie.com

Key Highlights: With Dixie® disposable tableware, you get the satisfaction of plates, cups and bowls that hold up for meals and the convenience of easy cleanup….

#7 Small Plastic Containers

Domain Est. 2020

Website: navinplast.com

Key Highlights: N-50 Plastic Round Container/Clear Storage Boxes/Plastic Storage Boxes With Lids For Candy, Cake, Mousse & Dessert ( Set Of 12 ). ₹599….

#8 Disposable Food Packaging Solutions: Cups, Lids & Containers

Website: gmz.ltd

Key Highlights: GMZ offers wholesale disposable food packaging solutions, including paper cups with lids, plastic cups with lids, and takeout food containers….

Expert Sourcing Insights for Plastic Cups With Lid

H2: 2026 Market Trends for Plastic Cups with Lids

The global market for plastic cups with lids is expected to undergo significant transformation by 2026, influenced by evolving consumer preferences, regulatory shifts, technological advancements, and sustainability imperatives. This analysis outlines key trends shaping the industry in the coming years.

-

Increased Demand for Sustainable Alternatives

By 2026, environmental concerns will continue to drive demand for eco-friendly plastic cups with lids. Bioplastics, compostable polymers (e.g., PLA derived from cornstarch), and recyclable polypropylene (PP) are projected to gain market share. Governments and municipalities worldwide are enforcing bans on single-use plastics, pushing manufacturers to innovate with biodegradable or reusable lid-and-cup systems. -

Regulatory Pressure and Policy Shifts

Stricter environmental regulations across North America, Europe, and parts of Asia-Pacific will significantly impact product design and materials. The European Union’s Single-Use Plastics Directive and similar legislation in countries like Canada and Japan will compel brands to adopt sustainable packaging. By 2026, compliance with extended producer responsibility (EPR) schemes will be a key factor for market entry and competitiveness. -

Growth in the Foodservice and On-the-Go Sector

The convenience-driven food and beverage industry—particularly coffee chains, fast-casual restaurants, and delivery services—will remain a primary driver of demand. With the continued rise of takeaway and delivery culture post-pandemic, there will be sustained need for leak-proof, durable plastic cup and lid combinations. Innovations in insulation and heat retention will enhance user experience and brand loyalty. -

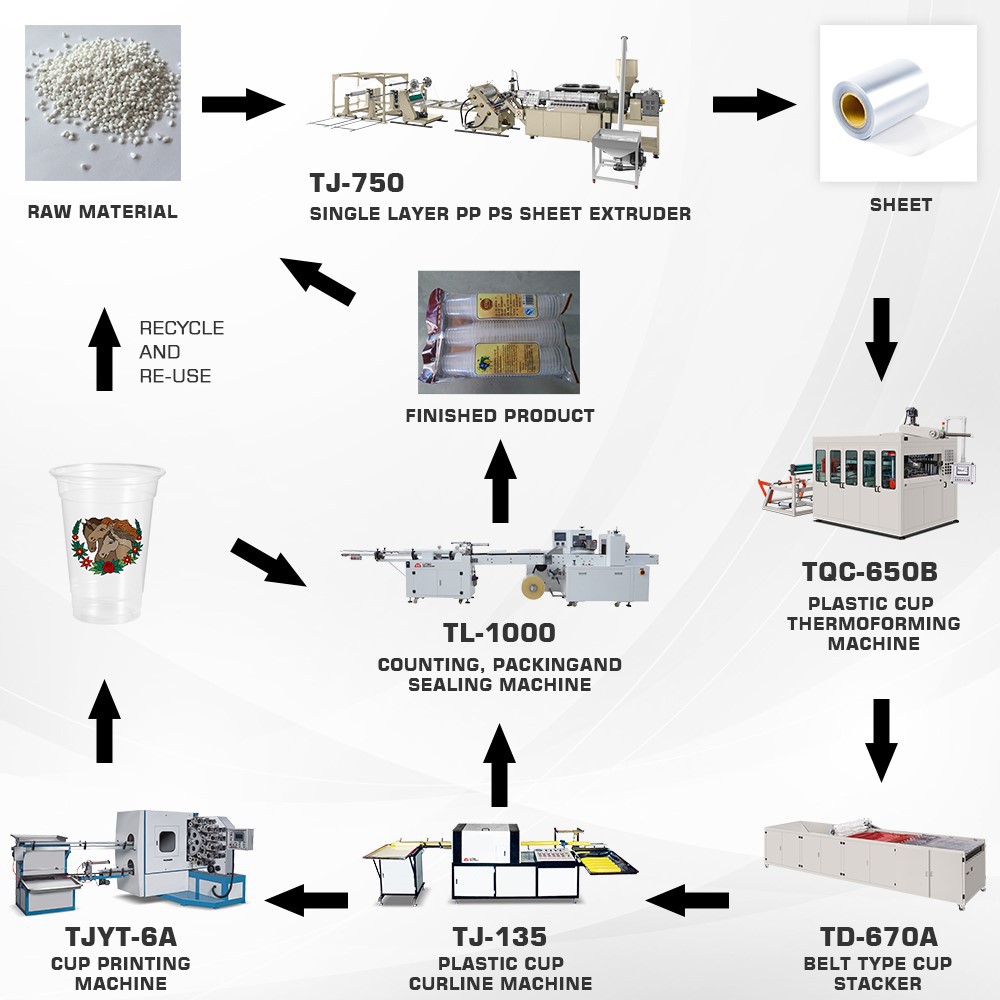

Technological Advancements in Manufacturing

Automation and smart manufacturing techniques will improve production efficiency and reduce waste. Injection molding technologies will advance to allow for thinner, lighter cups and precision-fit lids, reducing material use without compromising functionality. Digital printing will enable greater customization for branding, supporting marketing efforts in a competitive marketplace. -

Consumer Preference for Health and Safety

Post-pandemic hygiene concerns will persist, reinforcing consumer preference for tamper-evident, spill-proof lids. BPA-free, food-grade plastics will become standard, with increased demand for microwave-safe and dishwasher-safe options, especially in reusable cup segments. -

Rise of Reusable Cup Systems

While single-use plastics remain prevalent, the reusable plastic cup with lid segment is expected to grow rapidly by 2026. Retailers and coffee shops will expand “cup subscription” models and deposit-return schemes. Durable, stackable designs made from robust plastics like Tritan or recycled PET will gain traction in urban markets. -

Regional Market Divergence

Market dynamics will vary by region. North America and Europe will lead in adopting sustainable materials and circular economy models. In contrast, Asia-Pacific—especially India and Southeast Asia—will experience strong volume growth driven by urbanization and rising disposable incomes, though regulatory adoption may lag. -

Impact of Material Innovation and Cost Pressures

As fossil fuel prices fluctuate and feedstock costs for traditional plastics rise, manufacturers will increasingly turn to recycled content (rPP, rPET) to lower costs and meet sustainability goals. However, the higher cost of bioplastics may limit widespread adoption unless production scales and subsidies increase.

Conclusion:

By 2026, the plastic cup with lid market will be characterized by a balance between functionality, regulatory compliance, and environmental responsibility. Companies that invest in sustainable materials, innovative design, and circular business models will be best positioned to succeed in an increasingly competitive and regulated landscape.

Common Pitfalls When Sourcing Plastic Cups with Lids (Quality and Intellectual Property)

Sourcing plastic cups with lids may seem straightforward, but overlooking quality standards and intellectual property (IP) issues can lead to significant risks, including product failures, customer dissatisfaction, legal disputes, and reputational damage. Here are key pitfalls to avoid:

Poor Material Quality and Durability

One of the most frequent issues is receiving cups and lids made from substandard plastic materials. Low-quality resins can result in brittleness, cracking, or warping—especially when exposed to hot liquids or temperature changes. Buyers must verify material specifications (e.g., food-grade PP or PET) and ensure products meet safety and performance standards like FDA or EU food contact compliance.

Inconsistent Lid Fit and Leakage

A common quality failure is poor compatibility between cups and lids. Lids that don’t snap securely or seal properly can lead to spills and negative user experiences. This often stems from inconsistent manufacturing tolerances or sourcing components from mismatched molds. Always request physical samples and conduct fit-and-function tests before bulk ordering.

Misrepresentation of Eco-Friendliness or Biodegradability

Many suppliers claim their plastic cups are “eco-friendly,” “biodegradable,” or “compostable” without proper certification. False or misleading environmental claims (greenwashing) can expose buyers to regulatory penalties and consumer backlash. Verify certifications such as BPI (for compostability) or TÜV OK Compost, and request test reports supporting sustainability claims.

Lack of Food Safety Compliance

Plastic cups and lids must comply with food safety regulations in the target market. Pitfalls arise when suppliers use non-approved additives, colorants, or recycled content that leaches harmful chemicals. Always confirm compliance with FDA (USA), LFGB (Germany), or equivalent local regulations and request documentation like Letters of Guarantee or test results.

Intellectual Property Infringement

Copying patented cup or lid designs—such as unique locking mechanisms, ergonomic shapes, or branding features—can lead to legal action. Some suppliers reproduce popular designs without authorization, putting the buyer at risk of IP litigation. Conduct due diligence by reviewing design patents and requiring suppliers to warrant that products do not infringe on third-party IP rights.

Inadequate Packaging and Shipping Damage

Poor packaging can result in crushed cups or deformed lids during transit, especially with lightweight plastic items. Suppliers may underestimate the need for sturdy cartons or internal dividers. Clarify packaging requirements upfront and inspect shipment integrity upon arrival to avoid receiving damaged goods.

Unverified Supplier Credentials and Capacity

Relying on suppliers without proper audits or production capabilities increases the risk of inconsistent quality and delayed deliveries. Always verify factory certifications (e.g., ISO 9001), conduct on-site or third-party inspections, and assess production capacity to ensure reliability and scalability.

By proactively addressing these pitfalls—focusing on material quality, functional performance, regulatory compliance, and IP integrity—buyers can mitigate risks and ensure a successful sourcing process for plastic cups with lids.

Logistics & Compliance Guide for Plastic Cups With Lid

Product Classification and HS Code

Plastic cups with lids are typically classified under the Harmonized System (HS) Code 3924.10, which covers “Tableware, kitchenware, other household articles and hygienic or toilet articles, of plastics: Of a kind used for tableware or kitchenware.” Accurate classification is essential for import/export declarations, tariff assessment, and customs clearance. Always verify the specific HS code with local customs authorities, as sub-classifications may vary by country.

Regulatory Compliance Requirements

Plastic cups with lids must comply with food contact material (FCM) regulations in the target market. Key standards include:

– United States: FDA 21 CFR Part 177 – Indirect Food Additives: Polymers

– European Union: Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food

– Canada: Food and Drug Regulations (SOR/78-113), Division 23

– United Kingdom: UK FCM Regulations 2012 (as amended post-Brexit)

Manufacturers must ensure that all materials used (e.g., polypropylene, polystyrene) are approved for food contact and free from restricted substances such as BPA (where prohibited), phthalates, or heavy metals.

Packaging and Labeling Standards

Proper packaging is crucial to prevent contamination and damage during transit. Plastic cups with lids should be:

– Packaged in sealed, tamper-evident polybags or shrink-wrapped bundles

– Stored and shipped in sturdy corrugated cardboard boxes to avoid crushing

– Labeled with:

– Product name and description

– Material type (e.g., PP, PS)

– Food-safe certification marks (e.g., FDA-compliant, EU-compliant)

– Recyclability symbol (e.g., Resin Identification Code)

– Manufacturer/importer information and batch/lot number

In some jurisdictions, labeling must also include usage instructions or temperature limitations.

Import and Export Documentation

Essential documents for international trade include:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– FDA Prior Notice (for U.S. imports)

– Declaration of Compliance (DoC) with food contact regulations

– Test reports from accredited laboratories (e.g., migration testing)

Ensure all documents are accurate and match shipment contents to avoid customs delays.

Transportation and Handling

- Stack pallets securely using stretch wrap; avoid overstacking to prevent deformation

- Protect from extreme temperatures, especially in hot climates, to avoid warping

- Store in dry, clean environments away from direct sunlight and contaminants

- Use clean, enclosed transport vehicles to prevent exposure to dust, moisture, or pests

Recommended pallet configuration: standard EUR/ISO pallets (1200 x 800 mm or 48 x 40 in) with load heights not exceeding 1.8 meters.

Environmental and Sustainability Regulations

Many regions have restrictions on single-use plastics. Key considerations:

– EU Single-Use Plastics Directive (SUPD): Certain plastic cup types may be restricted; check applicability

– Recyclability requirements: Products should be designed for recyclability; avoid multi-material laminates

– Extended Producer Responsibility (EPR): Registration and reporting may be required in countries such as Germany (LUCID), France (Adelphe), and others

Consider offering recyclable or compostable alternatives to meet sustainability goals.

Quality Assurance and Testing

Implement routine quality control checks, including:

– Dimensional accuracy (cup and lid fit)

– Leak testing under simulated use conditions

– Compliance testing for food contact safety (e.g., overall migration, specific migration)

– Drop and compression tests for packaging integrity

Retain test records for at least three years to support compliance audits.

Disposal and End-of-Life Guidance

Provide end-users with disposal instructions:

– Rinse before disposal to avoid contamination

– Separate cup and lid if made from different materials

– Follow local recycling guidelines based on resin codes

– Do not incinerate in open fires due to potential toxic emissions

Include disposal information on packaging or in accompanying literature.

Summary and Best Practices

To ensure smooth logistics and regulatory compliance:

1. Confirm correct HS code and product classification

2. Obtain all required regulatory approvals and certifications

3. Maintain full documentation throughout the supply chain

4. Use durable, compliant packaging and proper labeling

5. Monitor evolving regulations, especially on single-use plastics

6. Partner with certified suppliers and testing laboratories

Regular compliance audits and staff training are recommended to maintain standards and avoid penalties.

In conclusion, sourcing plastic cups with lids requires careful consideration of several key factors including material quality, environmental impact, cost-effectiveness, supplier reliability, and compliance with regulatory standards. Choosing the right type of plastic—such as PET, PP, or biodegradable alternatives—ensures both functionality and safety for the intended use. Evaluating suppliers based on their production capacity, certifications, and sustainability practices helps establish a dependable and responsible supply chain. Additionally, balancing upfront costs with long-term value, especially in light of increasing environmental regulations and consumer preferences, is crucial. Ultimately, a well-informed sourcing strategy that aligns product specifications with business needs and sustainability goals will lead to a successful and responsible procurement outcome.