The global plastic casket market is experiencing steady growth, driven by increasing demand for cost-effective, lightweight, and environmentally resistant burial solutions. According to a report by Mordor Intelligence, the global casket market—encompassing metal, wood, and alternative materials like plastic—is projected to grow at a CAGR of approximately 4.1% from 2023 to 2028, with non-traditional materials gaining traction due to shifting consumer preferences and rising funeral costs. Plastic caskets, in particular, are benefiting from advancements in polymer technology, offering durability, moisture resistance, and lower production costs compared to conventional options. Additionally, Grand View Research highlights the growing adoption of eco-friendly and biodegradable plastics in funeral products, further supporting market expansion. As demand rises across both developed and emerging economies, a select group of manufacturers have emerged as leaders in innovation, scalability, and product diversity. Below are the top 9 plastic casket manufacturers shaping the industry through strategic output, material innovation, and global distribution networks.

Top 9 Plastic Casket Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Trigard

Domain Est. 1996

Website: trigard.com

Key Highlights: Trigard is a leading burial vault manufacturer located in Danville, IL. Trust a nationwide leader for protecting and personalizing your funeral products….

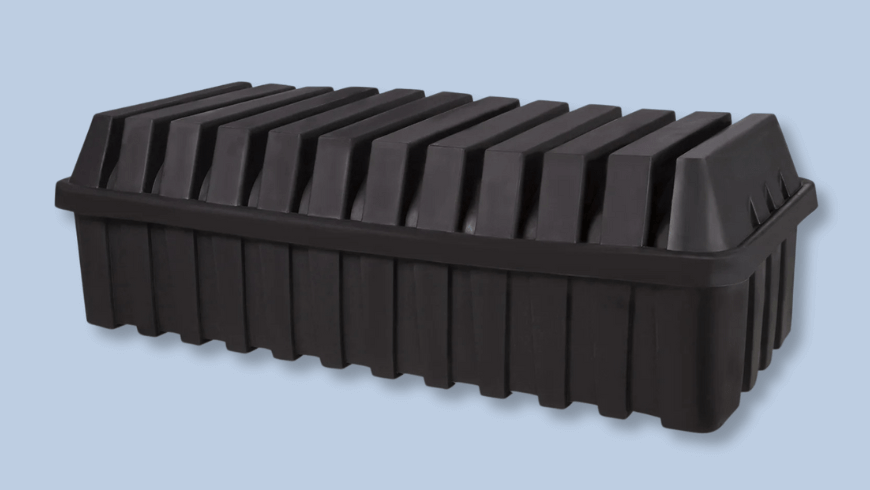

#2 Northern Casket

Domain Est. 1998

Website: northerncasket.com

Key Highlights: Discover Northern Casket, a leading Canadian manufacturer of premium caskets. Explore our range of meticulously crafted products, blending tradition with ……

#3 Plastics for Casket Manufacturing

Domain Est. 1997

Website: primexplastics.com

Key Highlights: Primex offers a wide range of plastics for casket manufacturing. Explore our offerings, including color compounding, sheet extrusion, and fabrication….

#4 Dixline Corporation

Domain Est. 1997 | Founded: 1924

Website: dixline.com

Key Highlights: Since 1924 Dixline Corporation has been producing casket hardware. We are proud of what we do, and strive for the best quality. Dixline has ……

#5 Polyguard Vaults

Domain Est. 2002

Website: polyguardvaults.com

Key Highlights: Polyguard & Co. uses eco-friendly materials to manufacture that meets or exceeds cemetery requirements, while helping to preserve cemetery aesthetics….

#6 Burial Vaults

Domain Est. 2008

Website: richardswilbert.com

Key Highlights: Precise engineering and more than 40 hours of hand-crafting produce Wilbert’s supreme and only triple-reinforced burial vault….

#7 Northwoods Casket Company

Domain Est. 2010

Website: northwoodscasket.com

Key Highlights: Free delivery 30-day returnsWe handcraft fine wooden caskets and cremation urns in a manner that preserves and protects our precious natural resources and the Earth’s beautiful lan…

#8 Biodegradable Caskets, Coffins, Scattering Tubes, Urns

Domain Est. 2010

Website: passagesinternational.com

Key Highlights: Go green with Passages Int’l: biodegradable urns, scattering tubes, and unique designs for eco-friendly cremation or burial options….

#9 Clear View Caskets™

Domain Est. 2014

Website: clearviewcaskets.com

Key Highlights: Our caskets are made in America with the highest-quality craftsmanship offering unparalleled elegance and convenience….

Expert Sourcing Insights for Plastic Casket

H2: Market Trends for Plastic Caskets in 2026

The global plastic casket market is expected to undergo significant transformation by 2026, driven by evolving consumer preferences, environmental concerns, and advancements in material science. As part of the broader death care industry, plastic caskets—often marketed as economical, durable, and eco-conscious alternatives to traditional wood or metal caskets—are gaining traction, particularly in North America, Europe, and select emerging markets.

-

Growing Demand for Affordable Funeral Solutions

Economic pressures and rising funeral costs are pushing consumers toward cost-effective end-of-life products. Plastic caskets, typically priced lower than wooden or metal counterparts, are increasingly viewed as a practical solution for budget-conscious families. This trend is especially pronounced in the U.S. and parts of Asia, where cremation rates are rising and direct cremation services often utilize simple, non-metal receptacles—many of which are made from recyclable plastics. -

Rise in Cremation Rates

The shift from burial to cremation continues to accelerate globally. According to industry reports, cremation rates are projected to exceed 60% in the U.S. and 80% in countries like the UK by 2026. Since plastic caskets are commonly used in direct cremations (where the body is cremated without a formal viewing), demand for lightweight, combustible, and environmentally compliant plastic alternatives is expected to grow. -

Sustainability and Eco-Friendly Innovation

Environmental awareness is reshaping the funeral products market. In response, manufacturers are developing biodegradable and recyclable plastic caskets using materials such as polypropylene (PP) and bio-based polymers. By 2026, regulatory pressures and consumer demand for greener options are likely to encourage the adoption of plastic caskets that meet stringent emissions standards during cremation and reduce carbon footprints across the supply chain. -

Technological and Design Advancements

Innovations in polymer engineering are enhancing the aesthetics and functionality of plastic caskets. Modern designs now mimic the appearance of wood or metal through advanced texturing and coloring techniques, making them more socially acceptable. Additionally, modular and lightweight designs improve handling and transportation, appealing to funeral homes and crematoriums seeking operational efficiency. -

Regional Market Dynamics

While North America and Western Europe lead in adoption due to high cremation rates and established death care infrastructure, emerging markets in Southeast Asia and Latin America are beginning to explore plastic caskets as part of modernizing funeral practices. Government initiatives promoting hygienic and affordable disposal methods may further stimulate growth in these regions. -

Regulatory and Industry Standards

By 2026, stricter environmental regulations—particularly around emissions from crematoria—are expected to influence material choices. Plastic caskets compliant with ISO and CEN standards for safe combustion and low toxic emissions will gain preference. Certification and transparency in material sourcing will become key differentiators for manufacturers.

Conclusion

The plastic casket market in 2026 will be shaped by affordability, sustainability, and changing death care practices. As cremation becomes the dominant disposition method and eco-consciousness grows, plastic caskets—especially those made from recyclable or biodegradable polymers—are poised to capture a larger share of the global funeral products market. Companies that innovate responsibly and align with regulatory and consumer trends will be best positioned for growth.

Common Pitfalls When Sourcing Plastic Caskets: Quality and Intellectual Property Issues

Sourcing plastic caskets—often used for temporary interment, repatriation, or eco-friendly burials—can present unique challenges, particularly concerning product quality and intellectual property (IP) risks. Buyers, distributors, and funeral service providers must be vigilant to avoid common pitfalls that can lead to legal complications, reputational damage, or customer dissatisfaction.

Quality-Related Pitfalls

Substandard Materials and Construction

One of the most frequent issues in plastic casket sourcing is the use of low-grade polymers, such as recycled or brittle plastics, which compromise structural integrity. Poorly manufactured caskets may crack under minimal stress or degrade quickly when exposed to environmental conditions, posing dignity and safety concerns during transportation or storage.

Inconsistent Manufacturing Standards

Suppliers, especially those in regions with lax regulatory oversight, may lack standardized production processes. This inconsistency can result in variations in dimensions, color, finish, or sealing mechanisms—critical flaws when caskets must meet specific funeral or transportation requirements.

Inadequate Sealing and Leak Prevention

Plastic caskets used in transport or temporary holding must be hermetically sealed. Poorly designed or manufactured models may fail to prevent leakage, leading to health hazards and regulatory non-compliance, particularly in international repatriation cases governed by IATA and WHO guidelines.

Misleading Product Claims

Some suppliers exaggerate product durability, biodegradability, or compliance certifications (e.g., ISO, CE). Without independent verification, buyers risk purchasing caskets that do not perform as advertised, potentially violating environmental regulations or ethical promises made to clients.

Intellectual Property (IP) Risks

Infringement of Patented Designs

The design and engineering of plastic caskets—especially those with unique locking mechanisms, ergonomic features, or modular components—may be protected by patents. Sourcing generic or “look-alike” products from third-party manufacturers can inadvertently infringe on existing IP, exposing the buyer or distributor to legal action, product seizures, or costly litigation.

Unauthorized Use of Trademarks and Branding

Some suppliers may replicate branding elements, logos, or packaging associated with well-known casket brands. Distributing such products—even unknowingly—can result in trademark infringement claims, damaging business relationships and consumer trust.

Lack of IP Due Diligence in Supplier Contracts

Many sourcing agreements fail to include clear clauses transferring IP rights or confirming that the supplier owns or has licensed all designs used. Without proper contractual safeguards, buyers may face liability or lose the right to continue selling the product in key markets.

Grey Market and Counterfeit Goods

Plastic caskets sourced through unauthorized channels may be counterfeit or diverted from legitimate distribution networks. These products often lack quality controls and may carry fake certifications, increasing both legal and operational risks.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Conduct rigorous supplier audits and request material certifications.

– Obtain third-party testing for structural and sealing performance.

– Verify all IP rights and require indemnification clauses in contracts.

– Work with legal counsel to assess patent landscapes in target markets.

– Prioritize transparent, traceable supply chains with documented compliance.

By proactively addressing quality and IP concerns, stakeholders can ensure reliable, ethical, and legally sound sourcing of plastic caskets.

Logistics & Compliance Guide for Plastic Caskets

Product Classification and Regulatory Overview

Plastic caskets are classified as funeral merchandise and are subject to specific federal, state, and international regulations. In the United States, they fall under the jurisdiction of the Federal Trade Commission (FTC) Funeral Rule, which governs consumer protections, pricing disclosures, and product descriptions. Compliance with environmental regulations such as REACH (EU) and TSCA (U.S.) is required due to chemical composition and potential hazardous materials.

Material and Manufacturing Compliance

Ensure all plastic materials used (e.g., polypropylene, polyethylene) meet FDA or equivalent standards for non-toxicity and environmental safety. Manufacturers must provide documentation verifying that additives, flame retardants, and colorants comply with RoHS, REACH, and Proposition 65 (California) where applicable. Certificates of Conformity (CoC) should be maintained for every production batch.

Packaging and Handling Requirements

Plastic caskets must be securely packaged to prevent damage during transit. Use moisture-resistant wrapping and rigid external cartons with internal bracing. Clearly label packages with “Fragile,” “This Side Up,” and “Funeral Product – Handle with Care.” Avoid overstacking during storage and transport to prevent deformation.

Domestic Transportation Regulations

When shipping within the U.S., comply with Department of Transportation (DOT) regulations for ground transport. No special hazardous materials designation is typically required unless the casket contains non-compliant chemical treatments. Coordinate with carriers experienced in funeral product logistics to ensure timely and respectful handling.

International Shipping Considerations

Exporting plastic caskets requires adherence to destination country regulations. Key requirements may include:

– ISPM 15 compliance for wooden pallets (if used)

– Customs documentation with accurate HS Code classification (e.g., 9705.00.00 for funeral articles)

– Import permits or certifications (e.g., CE marking for EU, Health Ministry approval for certain countries)

– Language-specific labeling and user instructions

FTC Funeral Rule Compliance

Sellers must provide consumers with:

– A General Price List (GPL) detailing the plastic casket price and alternatives

– Written disclosure affirming the right to purchase an alternative container for direct cremation

– Clear information that caskets are not required for cremation

Ensure all marketing materials avoid misleading claims about environmental benefits unless substantiated.

Environmental and Disposal Regulations

Plastic caskets may be subject to landfill regulations or crematory acceptance policies. Confirm compatibility with local crematorium emissions standards. Provide end-of-life guidance to funeral homes regarding recyclability or disposal options, especially in regions with plastic waste restrictions.

Documentation and Recordkeeping

Maintain records for a minimum of three years, including:

– Product compliance certifications

– Safety Data Sheets (SDS) for materials used

– Shipping manifests and customs filings

– FTC GPL distribution logs

Proper documentation supports audits and ensures regulatory accountability.

Quality Assurance and Recalls

Implement a quality control process for structural integrity, latch mechanisms, and finish durability. Establish a recall protocol in case of safety defects or non-compliance. Register with the FTC and relevant authorities to report and manage product recalls efficiently.

Conclusion for Sourcing Plastic Caskets

In conclusion, sourcing plastic caskets presents a viable, cost-effective, and environmentally conscious option for funeral service providers, healthcare institutions, and event planners requiring temporary or transport caskets. The lightweight nature of plastic caskets facilitates easier handling and shipping, reducing logistical costs and increasing operational efficiency. Additionally, their durability and hygienic properties make them ideal for medical transport, repatriation, and emergency preparedness scenarios.

With growing demand for sustainable and affordable alternatives to traditional wood or metal caskets, plastic models—particularly those made from recyclable or biodegradable materials—offer an eco-friendly solution without compromising dignity or functionality. Careful consideration of supplier reliability, product quality, compliance with international standards (such as WHO or IATA regulations), and end-of-life disposal options is essential to ensure responsible sourcing.

Ultimately, plastic caskets serve a critical role in modern mortuary and disaster management practices. By partnering with reputable manufacturers and adopting sustainable sourcing practices, organizations can meet practical needs while upholding respect, safety, and environmental responsibility.