The global plaster corner bead market is experiencing steady expansion, driven by rising construction activities and increasing demand for durable, aesthetically refined wall protection solutions. According to Grand View Research, the global drywall market—of which corner beads are a critical component—was valued at USD 43.5 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth trajectory underscores the escalating need for high-quality plaster accessories, including corner beads, in both residential and commercial construction. As the industry evolves, manufacturers are focusing on innovation, corrosion resistance, and ease of installation to meet stringent building standards and contractor demands. In this competitive landscape, a select group of manufacturers have emerged as leaders, combining scale, product diversity, and technological advancement to capture significant market share. The following analysis highlights the top 8 plaster corner bead manufacturers shaping the future of modern wall systems.

Top 8 Plaster Corner Bead Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Trim

Domain Est. 1996

Website: trim-tex.com

Key Highlights: Trim-Tex is the premier manufacturer of drywall beads & accessories. We coined the term “Drywall Art” and serve as a Design & Training Center….

#2 Widra® Corner Beads

Domain Est. 1993

Website: bekaert.com

Key Highlights: Use our corner beads for a wide range of plastering needs – from internal to external applications and specialized environments. Reinforcing internal corners?…

#3 Stucco, Veneer and Plaster Beads and Trims by Phillips Mfg

Domain Est. 1999

Website: phillipsmfg.com

Key Highlights: Phillips Manufacturing offers a broad range of the most popular stucco, veneer and plaster accessories including expanded metal corner beads, expansion joints, ……

#4 Beads and Trim at Capitol Materials

Domain Est. 2001

Website: capmat.com

Key Highlights: Joint treatment beads and trim help establish proper thickness of plaster assemblies, reinforce corners and angles, create junctions with other materials ……

#5 Corner Beads Galvanized Steel, Aluminum, PVC Perforated or …

Domain Est. 2008

Website: cornerbead.org

Key Highlights: Corner beads and trims are ideal building materials for plaster, render, stucco application in drywall construction of suspended ceilings, window and door frame ……

#6 About Us

Domain Est. 2010 | Founded: 1990

Website: corneranglebead.com

Key Highlights: Established in 1990 for the sales and export of plaster corner beads, we have concentrated on developing and manufacturing of a wide range of corner beads or ……

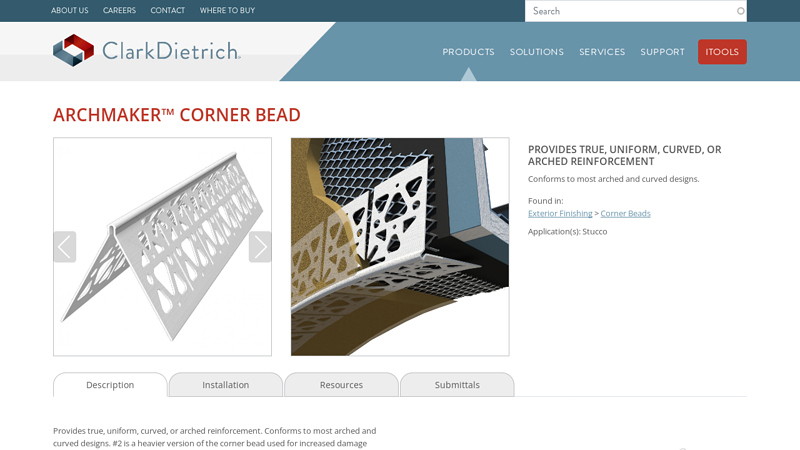

#7 Archmaker™ Corner Bead

Domain Est. 2011

Website: clarkdietrich.com

Key Highlights: Provides true, uniform, curved, or arched reinforcement. Conforms to most arched and curved designs. Found in: Exterior Finishing > Corner Beads….

#8 Inside corner bead for interior plaster

Website: www2.protektor.de

Key Highlights: Corner profile made of galvanised steel for inside corners and interior plaster of 8 mm and thicker. Specifications. Product areas, Internal plastering….

Expert Sourcing Insights for Plaster Corner Bead

H2: 2026 Market Trends for Plaster Corner Bead

The global plaster corner bead market is poised for steady growth through 2026, driven by rising construction activities, advancements in building materials, and a growing emphasis on durability and aesthetics in both residential and commercial infrastructure. As urbanization accelerates—particularly in emerging economies—and renovation projects increase in developed regions, demand for reliable finishing solutions like plaster corner bead is expected to rise significantly.

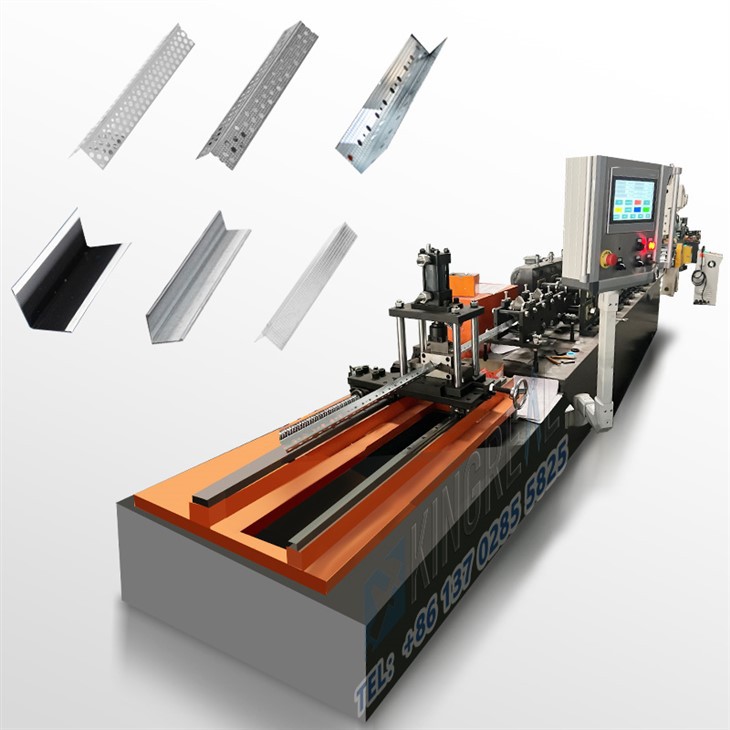

One of the key drivers shaping the 2026 market landscape is the increasing adoption of lightweight and corrosion-resistant materials. Manufacturers are shifting toward galvanized steel, fiberglass, and plastic-based corner beads that offer enhanced longevity and moisture resistance. These innovations align with the construction industry’s broader move toward sustainable and low-maintenance building practices, especially in high-humidity environments and green-certified buildings.

Another notable trend is the integration of corner bead systems with prefabricated and modular construction techniques. As off-site construction gains traction for its efficiency and cost-effectiveness, pre-finished corner bead solutions that streamline on-site installation are becoming more prevalent. This shift is expected to boost demand for standardized, easy-to-install corner bead products compatible with drywall and plasterboard systems.

Regionally, Asia-Pacific is anticipated to lead market growth, supported by rapid urban development in countries like India, China, and Vietnam. Government investments in affordable housing and infrastructure projects are creating robust demand for construction materials, including finishing products like plaster corner beads. Meanwhile, North America and Europe will continue to see moderate but stable growth, fueled by residential remodeling and stringent building codes that emphasize structural integrity and fire resistance.

Additionally, digitalization in construction planning—such as the use of BIM (Building Information Modeling)—is enabling more precise material estimation and waste reduction. This trend supports optimized use of corner beads, reducing over-ordering and improving project efficiency.

In summary, by 2026, the plaster corner bead market will be characterized by material innovation, integration with modern construction methods, and strong regional growth, particularly in developing markets. Stakeholders who invest in product differentiation, sustainability, and compatibility with evolving building technologies are likely to capture significant market share.

Common Pitfalls When Sourcing Plaster Corner Bead (Quality, IP)

Sourcing plaster corner bead may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to project delays, cost overruns, and legal risks. Here are common pitfalls to avoid:

1. Prioritizing Cost Over Quality

Choosing the cheapest option often results in substandard materials. Low-quality corner beads may feature inconsistent gauge thickness, poor galvanization, or weak flanges, leading to cracking, rust, or poor adhesion during or after installation.

2. Ignoring Material Specifications

Failing to verify compliance with industry standards (e.g., ASTM C1063 for lath and accessories) can result in unsuitable products. Ensure the corner bead meets required dimensions, coating weight (e.g., G90 galvanization), and material type (e.g., galvanized steel, PVC, or fiberglass).

3. Overlooking Corrosion Resistance

In damp or high-humidity environments, using non-corrosion-resistant corner beads—especially in exterior or wet-area applications—can lead to rust and joint failure. Always specify appropriate coatings (e.g., aluminized steel or PVC-coated) where needed.

4. Assuming All Corner Beads Are Interchangeable

Different types (e.g., paper-faced, vinyl-coated, self-furring, bullnose) serve distinct purposes. Using the wrong type can compromise durability and finish quality. Confirm compatibility with the plaster system and substrate.

5. Failing to Verify Intellectual Property Compliance

Some corner bead designs, especially innovative profiles or composite materials, are protected by patents or trademarks. Sourcing counterfeit or IP-infringing products can expose contractors and developers to legal action, supply chain disruptions, and reputational damage.

6. Not Requesting Samples or Product Data

Skipping product evaluation increases the risk of receiving non-conforming materials. Request physical samples, technical data sheets, and test reports to verify performance claims before bulk ordering.

7. Relying on Unverified Suppliers

Procuring from unknown or unverified vendors increases the likelihood of receiving counterfeit or off-spec products. Work with reputable suppliers who provide traceability, certifications, and warranties.

8. Neglecting Lead Times and Availability

Corner bead shortages or long lead times can stall projects. Confirm availability and delivery schedules early, especially for specialty or patented products with limited manufacturers.

By addressing these pitfalls proactively, specifiers and contractors can ensure they source durable, compliant, and legally sound plaster corner bead that supports high-quality finishes and long-term performance.

Logistics & Compliance Guide for Plaster Corner Bead

Product Overview

Plaster corner bead is a reinforcement material used in drywall and plastering applications to provide clean, durable edges on internal and external wall corners. Typically made from galvanized steel, aluminum, or PVC, it enhances structural integrity and surface finish while minimizing cracking and damage.

Packaging and Handling

- Packaging Type: Corner beads are commonly bundled in plastic-wrapped packs or cardboard boxes, secured on wooden pallets for shipping.

- Handling Instructions:

- Use mechanical lifting equipment (e.g., forklifts) when moving full pallets.

- Avoid dragging or dropping bundles to prevent deformation.

- Store in a dry, covered area to prevent moisture exposure, especially for galvanized steel variants.

- Stacking Limits: Do not exceed the manufacturer’s recommended stacking height to avoid compression damage.

Transportation Requirements

- Mode of Transport: Suitable for road, sea, and air freight.

- Loading Guidelines:

- Secure loads with straps or shrink wrap to prevent shifting.

- Protect from direct rain or snow during transit.

- Maintain upright positioning to avoid bending.

- Temperature & Humidity: No extreme temperature requirements, but prolonged exposure to high humidity may affect metal types if packaging is compromised.

Storage Conditions

- Environment: Store indoors in a dry, well-ventilated area.

- Shelf Life: Indefinite if stored properly; inspect periodically for signs of corrosion (metal types) or warping (PVC).

- Separation: Keep separate from chemicals, solvents, or abrasive materials that could degrade the product.

Regulatory Compliance

- Material Safety Data Sheets (MSDS/SDS): Available upon request; contains handling, storage, and safety information.

- REACH & RoHS Compliance:

- Metal corner beads (steel/aluminum) are generally REACH and RoHS compliant.

- Confirm with supplier for PVC variants containing possible restricted additives.

- Construction Product Regulation (CPR) – EU: May require CE marking if sold in the European Union; verify classification for fire performance and durability.

- OSHA & Building Codes (USA): Complies with standard construction safety practices; must be installed per local building codes (e.g., IBC).

Import/Export Documentation

- HS Code Example: 7326.20 (Other articles of iron or steel) or 3918.10 (Plastic beadings) – verify based on material.

- Required Documents:

- Commercial Invoice

- Packing List

- Bill of Lading/Air Waybill

- Certificate of Origin (if applicable)

- SDS for customs clearance (especially for air freight)

- Customs Considerations: Declare accurate weight, material composition, and intended use to avoid delays.

Sustainability & Disposal

- Recyclability:

- Steel and aluminum corner beads are 100% recyclable.

- PVC variants may be recyclable depending on local facilities.

- Waste Disposal: Follow local construction waste regulations. Do not incinerate PVC products without proper emission controls.

Quality Assurance & Certifications

- Standards Compliance:

- ASTM C840: Standard for gypsum board installation (references use of corner bead).

- EN 1396 (for aluminum) or EN 10327 (for coated steel) – if applicable.

- Inspection Upon Delivery: Check for bent edges, corrosion, or packaging damage. Report discrepancies immediately.

Supplier & Support Information

- Maintain documentation from the manufacturer, including:

- Product data sheets

- Installation guidelines

- Warranty and technical support contacts

- Report compliance or quality issues promptly to the supplier for resolution.

Note: Always confirm specifications and requirements with your specific supplier and local regulatory authorities prior to shipment and installation.

In conclusion, sourcing plaster corner bead requires careful consideration of material quality, durability, compatibility with plaster systems, and project-specific requirements such as internal vs. external applications. Evaluating suppliers based on reliability, cost-effectiveness, and compliance with industry standards ensures consistent performance and long-term integrity of plastered corners. By prioritizing reputable manufacturers and selecting the appropriate type—such as PVC, galvanized steel, or paper-faced metal—builders and contractors can achieve clean, durable edges that enhance both the aesthetic and structural quality of the finished work. Effective sourcing ultimately contributes to efficient installation, reduced waste, and superior end results in plastering projects.