The global plasma cutting equipment market is experiencing steady expansion, driven by increasing demand for precision cutting solutions in metal fabrication, automotive, and construction industries. According to a report by Mordor Intelligence, the plasma cutting machine market was valued at USD 1.85 billion in 2023 and is projected to grow at a CAGR of over 4.5% through 2029. This growth is fueled by advancements in portable and compact plasma cutting technologies, as well as rising adoption among small and medium-sized enterprises (SMEs) seeking cost-effective and energy-efficient alternatives to traditional cutting methods. As the demand for lightweight, high-precision tools continues to rise, a new wave of small manufacturers is emerging—offering innovative, niche solutions that challenge established players. These compact plasma cutters are increasingly favored for their ease of use, mobility, and integration with CNC systems, making them essential in both industrial and workshop environments. In this evolving landscape, identifying top small manufacturers becomes crucial for businesses prioritizing performance and scalability without compromising on quality.

Top 10 Plasma Cutter Small Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 The Perfect CNC Plasma Cutter for Small Manufacturers

Domain Est. 2001

Website: bend-tech.com

Key Highlights: Bend-Tech’s CNC plasma cutting technology is versatile and designed to help manufacturers large and small improve their operations and do the work of multiple ……

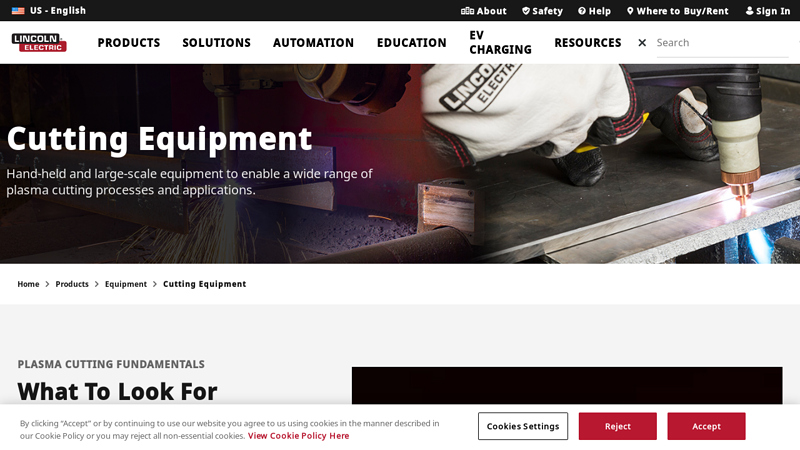

#2 Cutting Equipment

Domain Est. 1996

Website: lincolnelectric.com

Key Highlights: Lincoln Electric offers a complete CNC plasma table package for Educators, Small Business & Industrial Manufacturing. Let our selector tool guide you to the CNC ……

#3 Cutting Systems

Domain Est. 1998

Website: cuttingsystems.com

Key Highlights: Cutting Systems engineers CNC plasma tables, industrial plasma cutters, and oxyfuel cutting machines built for heavy production environments….

#4 Machitech

Domain Est. 2014

Website: machitech.com

Key Highlights: Leading Manufacturer of custom CNC Plasma Tables. For over 15 years, we have offered fully customizable CNC Plasma Cutting Systems of the highest quality….

#5 Langmuir Systems

Domain Est. 2017

Website: langmuirsystems.com

Key Highlights: Engineered to increase your manufacturing output, the CrossFire XR is a high performance industrial CNC Plasma table with 4×8′ cutting envelope, heavy-duty ……

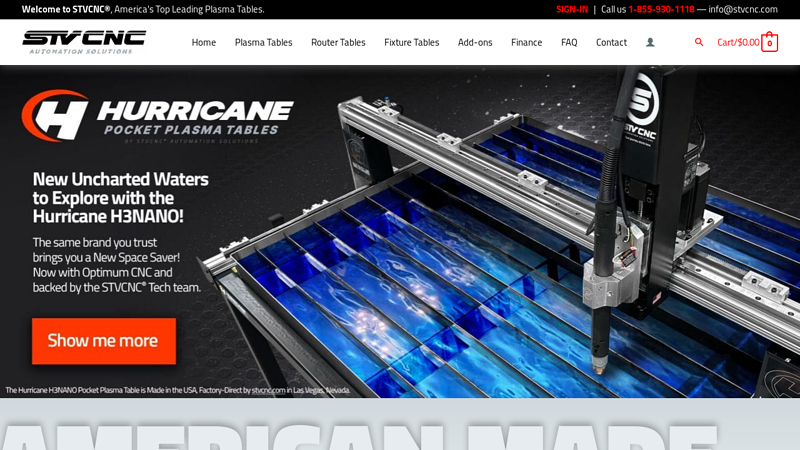

#6 Factory

Domain Est. 2018

Website: stvcnc.com

Key Highlights: Bring manufacturing back home with STV CNC Plasma Cutting Table. Factory-direct reliability & pricing guaranteed….

#7 Hypertherm

Domain Est. 1995

Website: hypertherm.com

Key Highlights: Hypertherm Powermax® is the world’s most versatile family of portable plasma cutters, delivering maximum productivity and unmatched reliability. With the ……

#8 HD CNC Plasma Cutter Tables by Piranha

Domain Est. 1999

Website: piranhafab.com

Key Highlights: CNC Plasma Tables by Piranha Are Affordable And Reliable. Plasma Cutter Tables In Sizes 4×4, 4×8, and 5×10 With 45 Amp to 300 Amp Hypertherm Plasma Cutters….

#9 Kinetic

Domain Est. 2000

Website: kineticusa.com

Key Highlights: We’re a productivity company. Our innovative large format laser cutting systems, plasma cutting machines and combination cutting, drilling and milling machines ……

#10 Plasma Cutting Systems

Domain Est. 2017

Website: us.messer-cutting.com

Key Highlights: We have perfected machinery for straight and bevel plasma cutting to ensure the quality, reliability, and efficiency of your cutting process….

Expert Sourcing Insights for Plasma Cutter Small

H2: 2026 Market Trends for Small Plasma Cutters – Precision, Portability, and Smart Integration Drive Growth

The global market for small plasma cutters is poised for significant transformation by 2026, driven by technological advancements, shifting industrial demands, and the rise of skilled trades. While facing economic headwinds, the sector is expected to experience robust growth, characterized by several key H2 (second-half) trends shaping its trajectory.

1. Dominance of Inverter Technology & Enhanced Portability:

By 2026, lightweight, high-efficiency inverter-based plasma cutters will solidify their position as the dominant design for small units. Manufacturers will prioritize extreme portability without sacrificing cutting power, targeting mobile fabricators, HVAC technicians, and automotive repair shops. Expect widespread adoption of compact designs weighing under 20 lbs (9 kg) with integrated handles and rugged casings, enabling true job-site mobility. Air-cooled systems will remain prevalent, further reducing complexity and weight.

2. Smart Features and IoT Integration:

Small plasma cutters will increasingly incorporate “smart” functionalities. By H2 2026, integration with mobile apps for remote monitoring, performance diagnostics, consumable tracking (nozzles, electrodes), and firmware updates will become standard in mid-to-high-end models. Bluetooth and Wi-Fi connectivity will allow technicians to optimize settings, receive maintenance alerts, and access digital manuals, improving uptime and reducing operational costs. Predictive maintenance based on usage data will emerge as a key differentiator.

3. Focus on User-Friendly Operation and Safety:

Ease of use will be paramount. Anticipate simplified control interfaces, intuitive digital displays showing critical parameters (amperage, gas pressure, duty cycle), and “plug-and-play” setups requiring minimal training. Enhanced safety features will be critical, including improved arc-start technologies (like HF start or contact start alternatives) to reduce electromagnetic interference (EMI), automatic gas pre/post-flow controls, and robust thermal protection. Designs will emphasize ergonomic handling and reduced noise levels.

4. Expansion in Niche and High-Precision Applications:

Beyond traditional metal fabrication, small plasma cutters will gain traction in specialized sectors. The growing demand for intricate work in art, sculpture, signage, and architectural detailing will drive demand for models offering finer arc control, lower amperage options (down to 20-30A), and superior cut quality on thinner materials (<1/4″). Integration with CNC routers and cutting tables using smaller plasma heads will expand, enabling precise automated cutting for small workshops and prototyping.

5. Sustainability and Consumable Efficiency:

Environmental and cost concerns will push innovation in consumable life and energy efficiency. Manufacturers will develop longer-lasting nozzle/electrode designs and optimize gas usage (especially with the rise of alternative gases like compressed air in specific applications). Energy-efficient inverter designs will reduce power consumption, appealing to eco-conscious users and reducing operating costs. Recycling programs for spent consumables may become more common.

6. Competitive Landscape and Pricing Pressure:

The market will remain competitive, with established players (Hypertherm, Lincoln Electric, Miller) facing increasing pressure from agile Asian manufacturers offering capable, lower-cost alternatives. This competition will drive innovation but also put downward pressure on prices, particularly in the entry-level segment. Differentiation will increasingly come from reliability, brand reputation, after-sales support, and advanced features rather than just price.

7. Impact of Economic and Industrial Factors:

The 2026 outlook is contingent on broader economic health. A sustained recovery in construction, manufacturing, and DIY sectors will boost demand. Conversely, economic slowdowns or reduced industrial investment could dampen growth. The ongoing demand for skilled tradespeople and the rise of small fabrication businesses (makerspaces, micro-factories) will provide a resilient foundation for the small plasma cutter market.

Conclusion:

By H2 2026, the small plasma cutter market will be defined by smarter, lighter, and more user-friendly tools. Success will hinge on manufacturers’ ability to deliver reliable, portable systems with integrated digital features, cater to precision and niche applications, and offer value through efficiency and support. The convergence of portability, intelligence, and precision will empower a new generation of users, solidifying the small plasma cutter’s role as an indispensable tool across diverse industries.

H2: Common Pitfalls When Sourcing Small Plasma Cutters (Quality and IP Rating Issues)

Sourcing small plasma cutters—especially for industrial, fabrication, or field repair applications—requires careful attention to quality and Ingress Protection (IP) ratings. Overlooking these factors can result in equipment failure, safety hazards, and increased long-term costs. Below are the most common pitfalls to avoid:

1. Compromising on Build Quality for Lower Cost

- Pitfall: Choosing cheaper models from unknown manufacturers to save money.

- Risk: Poor internal components (e.g., substandard inverters, cooling systems) lead to frequent breakdowns, inconsistent arc performance, and short service life.

- Solution: Source from reputable brands with proven track records. Look for certifications like CE, UL, or ISO 9001 as indicators of quality control.

2. Ignoring IP Rating for Intended Environment

- Pitfall: Selecting a plasma cutter with insufficient IP protection for the operating environment.

- Risk: Units with low IP ratings (e.g., IP21 or no rating) are vulnerable to dust, moisture, and debris—common in workshops or outdoor job sites—leading to internal corrosion and electrical failure.

- Solution: Match IP rating to environment:

- IP23: Protection against dripping water and tools—suitable for indoor, dry areas.

- IP44 or higher: Resists splashing water and dust—ideal for harsh environments or outdoor use.

- IP54/IP65: Optimal for mobile or construction sites with exposure to rain, dirt, and vibration.

3. Overestimating Portability at the Expense of Durability

- Pitfall: Prioritizing lightweight, compact designs without assessing structural integrity.

- Risk: Lightweight units may use thin housings and weak cooling systems, reducing reliability under continuous use.

- Solution: Balance portability with rugged design. Look for impact-resistant casings, robust handles, and adequate thermal protection.

4. Inadequate Duty Cycle for Application Needs

- Pitfall: Assuming all small plasma cutters can handle prolonged cutting tasks.

- Risk: Low duty cycle (e.g., 20% at 30A) causes overheating and shutdowns during extended operations.

- Solution: Match duty cycle to workload. For frequent or long cuts, choose models with ≥60% duty cycle at required amperage.

5. Lack of After-Sales Support and Spare Parts Availability

- Pitfall: Sourcing from suppliers without service networks or parts inventory.

- Risk: Downtime increases due to difficulty repairing units or replacing consumables (nozzles, electrodes, shields).

- Solution: Verify local support, warranty terms, and availability of consumables before purchase.

6. Misunderstanding Cutting Capacity vs. Advertised Specs

- Pitfall: Relying solely on maximum cut thickness claims.

- Risk: Advertised cuts may be for mild steel under ideal conditions; actual performance on rusted or painted metal may be significantly lower.

- Solution: Evaluate “clean cut” thickness (typically 60–70% of max) and test under real-world conditions.

7. Neglecting Input Power Compatibility

- Pitfall: Assuming small plasma cutters work on any power source.

- Risk: Units requiring 230V single-phase may not operate on standard 120V outlets, limiting usability in remote or mobile applications.

- Solution: Confirm voltage and amperage requirements match available power sources. Consider dual-voltage models for flexibility.

Conclusion:

To avoid costly mistakes, prioritize verified quality, appropriate IP protection, and realistic performance metrics when sourcing small plasma cutters. Investing in a well-rated, durable unit from a trusted supplier ensures reliability, safety, and lower total cost of ownership.

Logistics & Compliance Guide for Plasma Cutter (Small, H₂-Powered)

Version 1.0 | Intended for Small Industrial and Workshop Use

1. Introduction

This guide outlines the logistics, safety, and regulatory compliance considerations for the import, transport, storage, use, and maintenance of a small hydrogen (H₂)-powered plasma cutter. These systems utilize hydrogen gas (often generated on-site via electrolysis) as the plasma medium instead of compressed air or inert gases. Due to the flammable nature of hydrogen, strict compliance with safety and transportation regulations is essential.

2. Product Overview

- Equipment Type: Small-scale plasma cutter (e.g., handheld or bench-top)

- Plasma Gas: Hydrogen (H₂), typically generated via water electrolysis (PEM or alkaline)

- Power Input: 110V–240V AC, 50/60 Hz

- Hydrogen Source: On-demand generation (no high-pressure H₂ storage in many models)

- Output Capacity: Suitable for cutting metals up to 15–25 mm thickness

- Typical Applications: Metal fabrication, automotive repair, DIY workshops

3. Logistics Considerations

3.1 Shipping & Transportation

⚠️ Hydrogen is a Class 2.1 Flammable Gas (UN 1049) under international transport regulations.

- If the unit contains no hydrogen at shipment (most small units generate H₂ on-demand and contain no stored gas):

- May be shipped as non-hazardous if certified and verified.

-

Label: “Non-spillable battery” (if applicable) and standard electrical equipment warnings.

-

If hydrogen storage is involved (e.g., pressurized canisters or metal hydrides):

- Must comply with:

- ADR (Europe – Road)

- IMDG Code (Sea)

- IATA DGR (Air)

- 49 CFR (USA – DOT)

- Use UN-certified cylinders, proper packaging, and hazardous materials documentation.

- Shipments require:

- Hazard Class 2.1 label

- Proper shipping name: “Hydrogen, compressed” (UN 1049)

- Safety Data Sheet (SDS) provided

- Shipper’s Declaration for Dangerous Goods (if applicable)

✅ Recommendation: Procure models with on-demand hydrogen generation only to avoid transport classification as hazardous.

3.2 Import/Export Compliance

- HS Codes (Example – verify locally):

- 8515.21 – Plasma-arc cutting machines

- 8413.60 – Electrolytic hydrogen generators (if separate)

- Regulatory Approvals Required:

- CE Marking (EU) – Machinery Directive, ATEX (if used in explosive atmospheres)

- FCC (USA) – Electromagnetic interference

- CSA/UL (North America) – Electrical safety

-

Pressure Equipment Directive (PED) – If H₂ is stored under pressure in EU

-

Customs Documentation:

- Commercial invoice

- Packing list

- Certificate of Conformity (CE, UL, etc.)

- SDS (if H₂ generator or stored gas included)

- Import permits (if required by country)

4. Storage & Handling

4.1 On-Site Storage

- Electrolyte (if used): Store KOH or NaOH solutions in chemical storage cabinets, away from acids.

- Water Supply: Use deionized or distilled water for electrolysis to prevent scaling.

- Ventilation: Ensure adequate room ventilation (≥4 air changes/hour). Hydrogen is lighter than air and rises; high-point ventilation recommended.

- No Open Flames or Sparks: Prohibit smoking, welding, or electrical work nearby.

- Storage Location: Dry, temperature-controlled (5–40°C), away from direct sunlight.

4.2 Hydrogen Safety

- Leak Detection: Install H₂ gas detectors (alarm set at 1% LEL).

- Ventilation: Use passive vents near ceiling or active exhaust systems.

- Static Control: Ground all equipment; use anti-static flooring in workshop.

- Fire Extinguishers: Class C (electrical/flammable gas) extinguishers nearby.

5. Operational Compliance & Safety

5.1 Safety Standards

- NFPA 51A – Standard for Acetylene Charging Plants (relevant for gas handling)

- NFPA 2 – Hydrogen Technologies Code (USA)

- ISO 16852 – Flame arresters – Performance requirements

- OSHA 29 CFR 1910 – General Industry Standards (USA)

- ATEX Directive 2014/34/EU – Equipment in explosive atmospheres (EU)

5.2 Personal Protective Equipment (PPE)

- Flame-resistant clothing

- Welding helmet with appropriate shade

- Heat-resistant gloves

- Safety glasses (under helmet)

- Hearing protection

- Closed-toe safety shoes

5.3 Operational Best Practices

- Pre-Use Checks:

- Inspect hoses, fittings, and electrodes

- Confirm water level and electrolyte concentration

-

Test emergency stop and ventilation

-

Startup/Shutdown:

- Purge system before ignition

- Follow manufacturer’s startup sequence

-

Shut down and vent after use

-

Hydrogen Monitoring:

- Monitor for leaks with soap solution or H₂ detector

- Never operate in confined spaces without ventilation

6. Maintenance & Servicing

- Routine Maintenance:

- Clean electrodes and nozzles weekly

- Replace consumables per manufacturer schedule

- Check water/electrolyte levels daily

-

Inspect hoses and seals monthly

-

Electrolyzer Care:

- Descale regularly (if hard water is used)

-

Replace membrane (PEM) every 1–3 years

-

Calibration:

- Gas flow sensors and pressure regulators annually

- Safety alarms and detectors quarterly

7. Environmental & Waste Compliance

- Used Electrolyte:

- KOH/NaOH solutions are corrosive – dispose as hazardous waste per local regulations.

-

Neutralize before disposal if permitted.

-

Metal Fumes:

- Use fume extraction systems (LEV – Local Exhaust Ventilation)

-

Comply with OSHA PEL or EU WEL for metal fumes (e.g., Cr, Mn, Ni)

-

End-of-Life Equipment:

- Recycle per WEEE (EU) or EPA (USA) standards

- Remove batteries and electronics for proper disposal

8. Training & Documentation

- Mandatory Training:

- Hydrogen safety

- Plasma cutting procedures

-

Emergency response (leak, fire, injury)

-

Required Documentation:

- Equipment manual

- Risk Assessment (COSHH, DSEAR, or equivalent)

- Standard Operating Procedures (SOP)

- Maintenance logs

- SDS for all chemicals used

9. Emergency Procedures

| Scenario | Response |

|——–|———|

| H₂ Leak | Evacuate area, shut off system, ventilate, do not operate electrical switches |

| Fire | Use Class C extinguisher; do not use water on electrical components |

| Electrical Shock | Cut power, use non-conductive rescue tool, administer first aid |

| Chemical Splash | Flush with water for 15+ minutes; seek medical help |

10. Summary of Key Compliance Points

| Requirement | Standard/Regulation |

|———–|———————|

| Transport (no stored H₂) | Non-hazardous if no pressurized gas |

| Transport (stored H₂) | IATA/IMDG/ADR, UN 1049 |

| Electrical Safety | CE, UL, CSA |

| Workshop Safety | NFPA 2, OSHA 1910, ATEX |

| Emissions Control | Local air quality regulations |

| Waste Disposal | EPA, RCRA, or local hazardous waste rules |

11. Manufacturer & Support Contacts

- Include manufacturer’s technical support, service centers, and emergency hotline in your facility documentation.

Appendices

- Appendix A: Sample Risk Assessment Template

- Appendix B: Hydrogen Safety Data Sheet (SDS) Excerpt

- Appendix C: Checklist for H₂ Plasma Cutter Installation

📘 Disclaimer: This guide is for informational purposes. Always consult local regulations and the equipment manufacturer for site-specific requirements.

Prepared by: [Your Company/Department]

Date: [Insert Date]

Review Cycle: Annual

In conclusion, sourcing a small plasma cutter requires careful consideration of your specific cutting needs, budget, and intended applications. By evaluating factors such as cutting capacity, duty cycle, portability, power requirements, and brand reliability, you can identify a model that offers the best balance of performance and value. Whether for hobbyist projects, automotive repairs, or light industrial use, a small plasma cutter provides precision, speed, and versatility in metal cutting tasks. Exploring reputable suppliers, comparing features, and reading user reviews will further ensure a smart investment. Ultimately, choosing the right small plasma cutter enhances efficiency and productivity while supporting high-quality results in any metalworking environment.