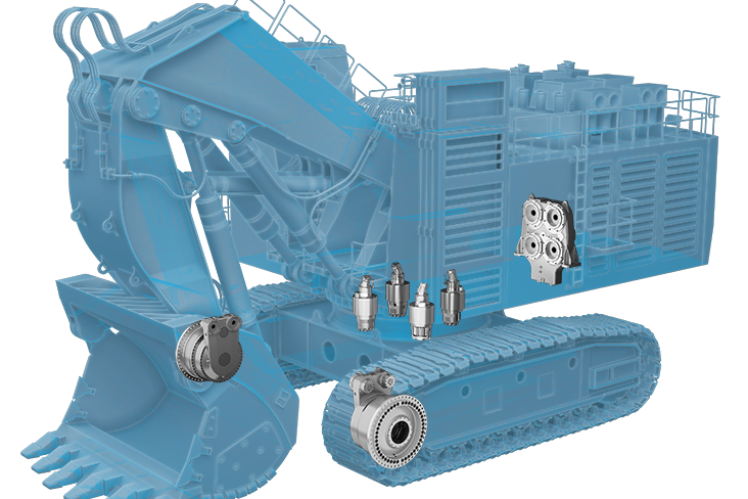

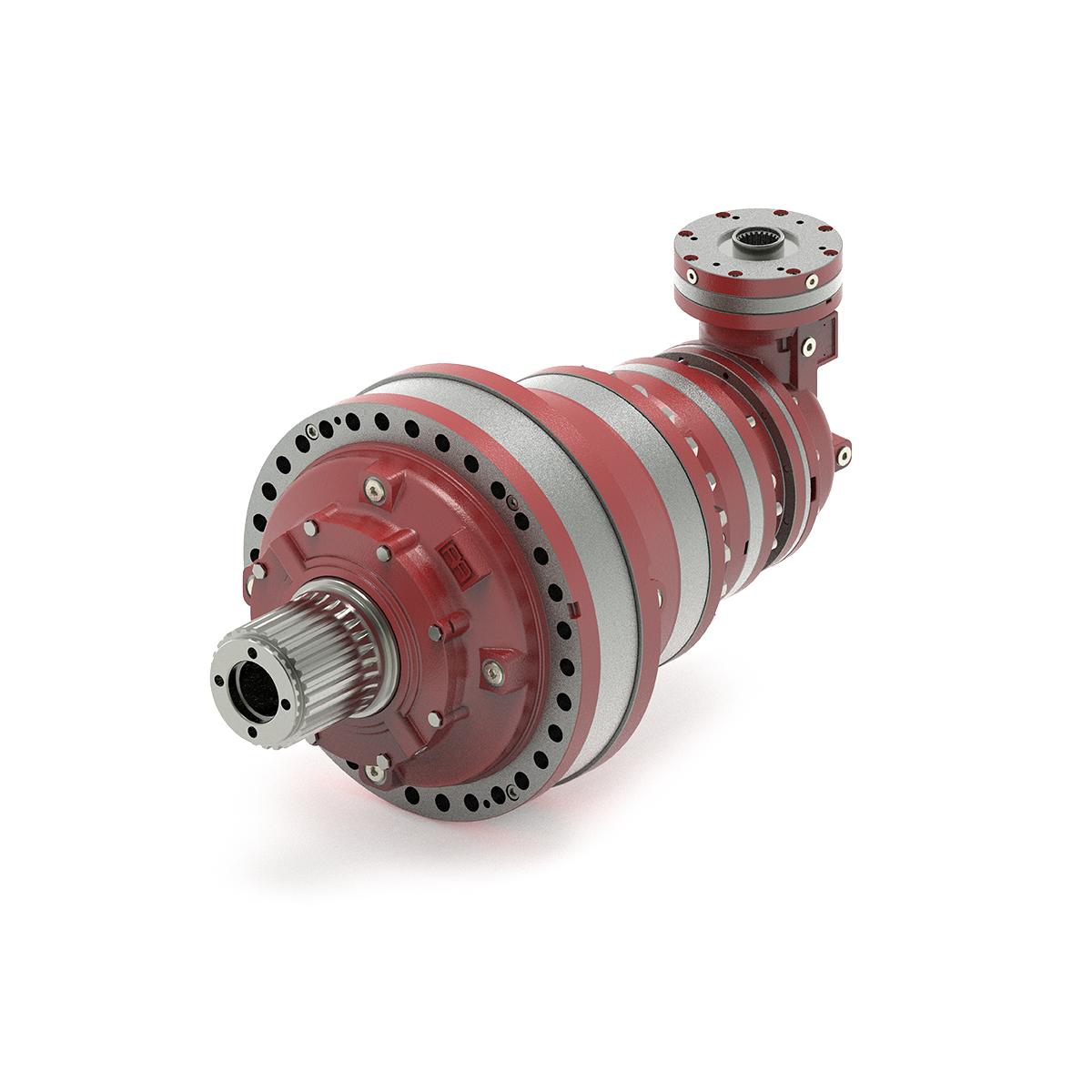

The global planetary gearbox market is experiencing robust growth, driven by increasing demand across industrial automation, renewable energy, and automotive sectors. According to a 2023 report by Mordor Intelligence, the market was valued at USD 26.8 billion in 2022 and is projected to reach USD 38.4 billion by 2028, growing at a CAGR of 6.1% during the forecast period. This expansion is fueled by the rising adoption of precision motion control systems, particularly in robotics and wind turbine applications, where planetary gearboxes offer superior torque density, efficiency, and compact design. Additionally, Grand View Research highlights the growing integration of these gearboxes in electric vehicles and aerospace systems as a key growth accelerator. As industry standards evolve and demand for high-performance transmission solutions intensifies, identifying the leading manufacturers becomes critical for engineers, procurement managers, and OEMs aiming to optimize system reliability and performance. The following list highlights the top 10 planetary gearbox manufacturers shaping the future of motion control through innovation, quality, and global reach.

Top 10 Planetary Gearbox Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 STOBER

Domain Est. 1996

Website: stober.com

Key Highlights: Right Angle Geared Motors. From helical gearboxes to planetary gearboxes, STOBER has geared motor options that fit your requirements….

#2 ZD Precision Gearboxes, Planetary Gear Reducers Manufacturers

Domain Est. 2019 | Founded: 2006

Website: zddriver.com

Key Highlights: Ningbo Zhongda Leader Intelligent Transmission Co., Ltd. is professional planetary gearbox manufacturers, established in 2006, we have more than 1500 employees, ……

#3 ZF Product Range Industrial Gearboxes

Domain Est. 1996

Website: zf.com

Key Highlights: ZF offers a complete range of planetary transmissions for a wide scope of applications and always perfectly matched to the intended purpose….

#4 Gearboxes, electric motors and inverters

Domain Est. 1996

Website: bonfiglioli.com

Key Highlights: Bonfiglioli distributes gearmotors, drive systems and planetary gearboxes to satisfy needs for industrial processes, automation, mobile and renewable ……

#5 Neugart

Domain Est. 1997

Website: neugart.com

Key Highlights: Discover the high-quality planetary and custom gearboxes from Neugart GmbH. As one of the leading gearbox manufacturers, we offer innovative drive solutions ……

#6 Reggiana Riduttori

Domain Est. 2000

Website: reggianariduttori.com

Key Highlights: Planetary Gearboxes – PLUS SERIES · Parallel and right angle shaft gearboxes … Reggiana Riduttori is a leading designer and manufacturer of gearboxes for the ……

#7 Products

Domain Est. 2001

Website: deltaww.com

Key Highlights: Home > · Products > · Industrial Automation > · Motion > · Planetary Gearbox >….

#8 Planetary Gearbox Manufacturer

Domain Est. 2003

Website: apexdynamicsusa.com

Key Highlights: Apex Dynamics is a worldwide name in planetary gearbox manufacturing with over 20 years of accumulated experience producing high-quality components….

#9 Sesame Motor Corp.

Domain Est. 2007

Website: sesamemotor.com

Key Highlights: A top brand of superior technology and reputation. Combined 35 years of professional motors and gearboxes manufacturing and sales experience….

#10 Planetary Gearboxes Manufacturer

Domain Est. 2023

Website: newstartgear.com

Key Highlights: Get reliable and precise planetary gearboxes from Newstart. Choose from our economic, high precision, and customizable gearbox solutions….

Expert Sourcing Insights for Planetary Gearbox

H2: 2026 Market Trends for Planetary Gearbox

The planetary gearbox market is poised for significant transformation by 2026, driven by technological advancements, increasing automation, and shifting industrial demands. As industries continue to prioritize efficiency, compactness, and reliability, planetary gearboxes—known for their high torque density and precision—are becoming critical components across multiple sectors. Below are the key market trends expected to shape the planetary gearbox landscape in 2026:

1. Rising Demand in Renewable Energy and Wind Turbines

The global push toward clean energy is expected to significantly boost demand for planetary gearboxes in wind turbine applications. By 2026, offshore and onshore wind farms will increasingly adopt multi-megawatt turbines that rely on planetary gearboxes for efficient power transmission. Innovations in gearbox durability and maintenance reduction will be crucial to support the longevity of wind energy infrastructure.

2. Growth in Electric and Hybrid Vehicles

The automotive sector, particularly electric and hybrid vehicle (EV/HEV) manufacturing, will be a major growth driver. Planetary gearboxes are essential in EV transmissions due to their compact design and ability to handle high torque. As EV adoption accelerates worldwide—supported by government regulations and consumer demand—gearbox manufacturers will focus on lightweight, high-efficiency designs tailored for electric drivetrains.

3. Expansion in Industrial Automation and Robotics

With Industry 4.0 gaining momentum, the integration of robotics and automated systems in manufacturing will increase the need for precise motion control. Planetary gearboxes are ideal for robotic joints, CNC machines, and automated assembly lines due to their backlash control and high accuracy. By 2026, demand will grow particularly in Asia-Pacific, where smart factory investments are accelerating.

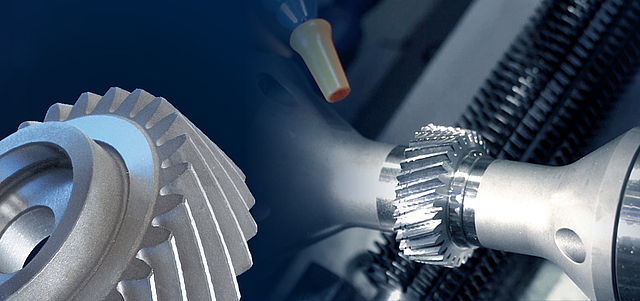

4. Advancements in Materials and Manufacturing

Innovations in materials—such as high-strength alloys, composites, and surface treatments—will enhance gearbox performance, reduce weight, and extend service life. Additive manufacturing (3D printing) and precision machining techniques will also enable more customized and efficient designs, reducing production lead times and costs.

5. Increased Focus on Predictive Maintenance and Smart Gearboxes

The integration of IoT sensors and condition monitoring systems into planetary gearboxes will become standard by 2026. These “smart” gearboxes will allow for real-time performance tracking, predictive maintenance, and reduced downtime—especially valuable in critical applications like aerospace and heavy machinery.

6. Regional Market Shifts

Asia-Pacific will remain the largest and fastest-growing market due to industrialization in China, India, and Southeast Asia. Europe and North America will see steady growth driven by automation, green energy, and automotive electrification. Meanwhile, emerging markets in Latin America and the Middle East will begin to adopt advanced gearbox solutions as infrastructure projects expand.

7. Sustainability and Energy Efficiency Regulations

Stricter global energy efficiency standards will compel industries to adopt high-efficiency gearboxes. Manufacturers will respond by optimizing gear designs, improving lubrication systems, and minimizing energy losses—aligning with ESG (Environmental, Social, and Governance) goals.

In conclusion, the planetary gearbox market in 2026 will be shaped by digitalization, sustainability, and sector-specific innovations. Companies that invest in R&D, embrace smart technologies, and align with global energy transitions will be best positioned to capitalize on these evolving trends.

Common Pitfalls Sourcing Planetary Gearboxes (Quality, IP)

Sourcing planetary gearboxes requires careful evaluation to ensure performance, longevity, and legal compliance. Overlooking key factors can lead to system failures, increased downtime, and intellectual property (IP) risks. Below are critical pitfalls to avoid:

Quality-Related Pitfalls

Inadequate Material and Heat Treatment Verification

Many suppliers quote high-torque capabilities but use substandard materials or improper heat treatment processes. Without third-party certifications or material test reports (MTRs), gear hardness and core toughness may not meet required standards, leading to premature pitting, wear, or tooth breakage under load.

Poor Manufacturing Tolerances and Gear Finishing

Precision planetary gearboxes rely on tight tolerances and fine surface finishes to minimize backlash and noise. Sourcing from manufacturers without advanced CNC gear grinding or honing capabilities often results in inconsistent performance, higher vibration, and reduced efficiency, especially in high-precision applications.

Insufficient Testing and Quality Control Documentation

Some suppliers provide minimal or falsified test reports. Lack of documented performance testing—such as load testing, backlash measurement, and noise/vibration analysis—makes it difficult to verify claimed specifications. Absence of ISO 9001 certification or in-house QC labs is a red flag.

Overstated Performance Specifications

Be cautious of gearboxes advertised with torque, efficiency, or service life values that significantly exceed industry norms. These claims may be based on ideal lab conditions without real-world cycling, temperature, or contamination factors. Always request application-specific validation data.

Misalignment of Lubrication and Sealing Standards

Inappropriate lubricant type, viscosity, or inadequate sealing (e.g., low IP ratings) can cause contamination ingress or lubricant leakage, especially in harsh environments. Verify that seals and lubricants are suitable for the intended operating conditions, including temperature and exposure to dust or moisture.

Intellectual Property (IP) and Compliance Pitfalls

Sourcing Counterfeit or IP-Infringing Designs

Some low-cost suppliers replicate patented gearbox designs from reputable brands without authorization. Using such components exposes your company to legal liability, product recalls, and reputational damage. Always verify the originality of design and request proof of IP ownership or licensing agreements.

Lack of Traceability and Documentation

Gearboxes without proper serial numbers, batch traceability, or technical documentation hinder warranty claims and failure analysis. In regulated industries (e.g., medical, aerospace), missing documentation can result in non-compliance with quality standards such as ISO 13485 or AS9100.

Unclear Warranty and Support Terms

Ambiguous or restrictive warranty terms—especially regarding wear items like seals and bearings—can lead to unexpected costs. Ensure the supplier provides clear service life expectations, replacement part availability, and technical support.

Failure to Address Export Controls and Regulatory Compliance

Certain high-precision or high-torque gearboxes may be subject to export controls (e.g., ITAR, EAR). Sourcing from regions with weak IP enforcement or unclear compliance frameworks can lead to shipment delays or legal complications, particularly for defense or aerospace applications.

By proactively addressing these pitfalls—through supplier audits, technical validation, and IP due diligence—buyers can ensure reliable, compliant, and high-performance planetary gearbox integration.

Logistics & Compliance Guide for Planetary Gearbox

Overview

Planetary gearboxes are precision mechanical components used across industries such as robotics, aerospace, automotive, and renewable energy. Ensuring safe, efficient logistics and full regulatory compliance is critical due to their technical complexity, value, and international trade implications.

Packaging & Handling

Proper packaging and handling are essential to prevent damage during transportation.

– Use custom-fitted, shock-absorbent packaging with internal supports to secure moving parts.

– Apply anti-corrosion protection such as VCI (Vapor Corrosion Inhibitor) paper or coating, especially for long-term storage or maritime shipping.

– Clearly label packages with “Fragile,” “Do Not Invert,” and “This Side Up” indicators.

– Secure gearboxes on pallets using stretch wrap or strapping; avoid stacking heavy items on top.

– Handle with care using appropriate lifting equipment—never lift by shafts or flanges.

Transportation Requirements

Select transportation modes based on urgency, destination, and environmental controls.

– For international shipments, use air freight for high-value or time-sensitive gearboxes.

– Sea freight is cost-effective for bulk shipments but requires enhanced moisture and salt protection.

– Use climate-controlled containers if transporting through extreme temperatures or humid regions.

– Ensure temperature and humidity limits (typically -20°C to +60°C and <85% RH) are respected during transit.

Import/Export Regulations

Planetary gearboxes may be subject to international trade controls.

– Verify Harmonized System (HS) code; commonly 8483.40 (gear boxes and gear-reducing sets).

– Confirm export control classification (e.g., EAR99 under U.S. EAR) or potential ITAR/EAR restrictions if used in defense applications.

– Prepare commercial invoice, packing list, bill of lading/air waybill, and certificate of origin.

– Check for import duties, VAT, and local customs requirements in the destination country.

Product Compliance & Certifications

Ensure gearboxes meet relevant technical and safety standards.

– CE marking required for sale in the European Economic Area (per Machinery Directive 2006/42/EC).

– UL or CSA certification may be required for North American markets.

– ISO 9001 quality management compliance enhances credibility.

– Provide technical documentation including user manuals, safety instructions, and conformity declarations.

Environmental & Safety Compliance

Adhere to environmental regulations throughout the supply chain.

– Comply with RoHS (Restriction of Hazardous Substances) and REACH (EU chemical regulations) if applicable.

– Manage packaging waste per local regulations (e.g., EU Packaging Waste Directive).

– Follow OSHA (USA) or equivalent workplace safety guidelines during handling and storage.

Documentation & Traceability

Maintain accurate records for compliance and after-sales support.

– Assign unique serial numbers or batch codes to each unit for traceability.

– Retain shipping documents, compliance certificates, and test reports for minimum 5–10 years.

– Provide end-users with operation manuals, maintenance schedules, and warranty information.

Returns & Reverse Logistics

Establish clear procedures for defective or non-conforming units.

– Define return authorization (RMA) process with inspection and testing protocols.

– Use original or equivalent protective packaging for returns.

– Comply with destination country’s import rules for returned goods (e.g., temporary importation under ATA Carnet).

Conclusion

Effective logistics and compliance management for planetary gearboxes ensures product integrity, regulatory adherence, and customer satisfaction. Proactive planning, detailed documentation, and adherence to international standards are essential for smooth global operations.

Conclusion for Sourcing Planetary Gearboxes

Sourcing planetary gearboxes requires a strategic approach that balances performance requirements, cost-efficiency, reliability, and supplier capabilities. These gearboxes are critical components in various industries—such as robotics, automation, renewable energy, and heavy machinery—due to their high torque density, compact design, and efficient power transmission. When selecting a supplier, it is essential to evaluate technical expertise, manufacturing quality (including certifications like ISO 9001), customization capabilities, lead times, and after-sales support.

Furthermore, considering long-term factors such as total cost of ownership, maintenance needs, and compatibility with existing systems ensures a sustainable and reliable integration. Global sourcing offers competitive pricing and innovative solutions but must be balanced with supply chain resilience and quality control measures. By conducting thorough due diligence, engaging in supplier collaboration, and aligning specifications with application demands, organizations can secure planetary gearboxes that enhance system performance and operational efficiency. Ultimately, the right sourcing strategy contributes significantly to the success and competitiveness of industrial and mechanical systems.