The global power tools market, driven by rising demand in construction, manufacturing, and woodworking industries, is experiencing steady growth—projected to expand at a CAGR of 4.8% from 2023 to 2030, according to Grand View Research. Within this landscape, planetary belt sanders have emerged as critical tools for high-efficiency surface finishing, offering superior material removal rates and consistent results. As industrial automation and precision machining gain traction, demand for advanced sanding solutions continues to climb. This increasing need, coupled with technological innovations in motor efficiency and dust extraction systems, has intensified competition among manufacturers. Based on market presence, product innovation, and global distribution, the following nine companies represent the leading planetary belt sander manufacturers shaping the future of surface preparation technology.

Top 9 Planetary Belt Sander Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Wood Wide Belt Sanders & Calibrating Machines

Domain Est. 1997

Website: scmgroup.com

Key Highlights: Calibrating sanding machines for furniture manufacturing and wood construction industries. Discover SCM Group technological units by DMC and Minimax….

#2 Northtech Machine

Domain Est. 2016

Website: northtechmachine.com

Key Highlights: It’s time to know Northtech, a supplier of industrial grade machinery of woodworking, including boring, sawing, dust collecting, profiling and more….

#3 Planetary sanding machine

Domain Est. 1999

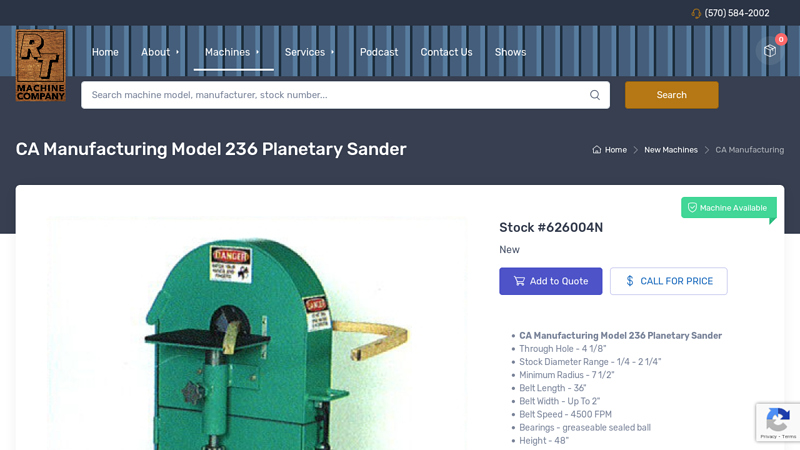

#4 New CA Manufacturing Model 236 Planetary Sander

Domain Est. 1999

Website: rtmachine.com

Key Highlights: CA Manufacturing Model 236 Planetary Sander · Through Hole – 4 1/8″ · Stock Diameter Range – 1/4 – 2 1/4″ · Minimum Radius – 7 1/2″ · Belt Length – 36″ · Belt Width ……

#5 Oliver Machinery

Domain Est. 2000

Website: olivermachinery.net

Key Highlights: Oliver Machinery creates woodworking machinery, tools & equipment like wood lathes, table saws, bandsaws, jointers, planers, sanders & wood shapers for ……

#6 Wide belt sander Maxx 6W 400

Domain Est. 2001

#7 Festool United States

Domain Est. 2004

Website: festoolusa.com

Key Highlights: Festool USA: German-engineered power tools and accessories for the toughest demands, such as plunge-cut saws, circular saws, jigsaws, cordless drills, ……

#8 Planetary Sander

Domain Est. 2015

Website: awmachineryllc.com

Key Highlights: Description. Sand chair bows, chair backs, chair posts, rocker rails, bed slats, table rims, etc. Consistent Finish Multiplies Productivity 2 Feeder Styles…

#9 Planetary grinding belt machine TP 80 and TP 80

Domain Est. 2015

Website: wloeser.com

Key Highlights: Planetary grinding belt machine TP 80 and TP 80-S. Pipe diameter 10 – 80 / 100 mm. Adjustable sanding belt resistance. Wet grinding device complete with ……

Expert Sourcing Insights for Planetary Belt Sander

H2: Projected Market Trends for Planetary Belt Sanders in 2026

The planetary belt sander market is poised for notable evolution by 2026, driven by advancements in industrial automation, growing demand for precision surface finishing, and the expansion of manufacturing sectors globally. These tools—known for combining orbital and belt sanding actions to deliver superior finish quality—are increasingly being adopted in high-precision applications across aerospace, automotive, metal fabrication, and woodworking industries.

-

Increased Demand in High-Precision Manufacturing

By 2026, industries requiring micron-level surface accuracy—particularly aerospace and medical device manufacturing—are expected to drive demand for planetary belt sanders. Their ability to minimize swirl marks and deliver consistent finishes makes them ideal for finishing turbine blades, prosthetics, and high-tolerance components. As global emphasis on product quality intensifies, manufacturers are investing in advanced sanding solutions that reduce rework and improve throughput. -

Integration with Smart Manufacturing and IoT

The rise of Industry 4.0 is influencing sander design. By 2026, a growing number of planetary belt sanders are expected to feature IoT connectivity, real-time performance monitoring, and predictive maintenance capabilities. Smart sanders equipped with sensors will provide feedback on belt wear, pressure distribution, and material removal rates, enabling operators to optimize performance and reduce downtime. -

Shift Toward Cordless and Portable Models

While traditionally used in fixed industrial setups, there is a rising trend toward compact, cordless planetary belt sanders for fieldwork and on-site finishing. Advancements in battery technology—particularly lithium-ion—are enabling longer runtimes and higher power outputs, making cordless models increasingly viable. This trend is particularly strong in construction, shipbuilding, and maintenance, repair, and operations (MRO) sectors. -

Sustainability and Dust Management Innovations

Environmental regulations and worker safety concerns are pushing manufacturers to develop sanders with integrated dust extraction and low-emission designs. By 2026, compliance with global standards such as OSHA and EU REACH will be a key differentiator. Planetary belt sanders with HEPA filtration systems and closed-loop dust collection are expected to gain market share, especially in regions with strict air quality norms. -

Regional Market Expansion

Asia-Pacific is projected to be the fastest-growing market for planetary belt sanders by 2026, fueled by booming industrialization in China, India, and Southeast Asia. Increased investments in automotive and electronics manufacturing, coupled with the adoption of automated production lines, will boost demand. Meanwhile, North America and Europe will see steady growth, primarily driven by equipment upgrades and retrofitting in legacy factories. -

Competitive Landscape and Innovation

Key players such as Bosch, Festool, Metabo, and Makita are expected to intensify R&D efforts to differentiate their offerings through ergonomic design, variable speed controls, and modular attachments. Private-label and regional manufacturers will also expand their presence, offering cost-effective alternatives and increasing market accessibility in emerging economies.

In conclusion, the planetary belt sander market in 2026 will be shaped by technological innovation, sustainability imperatives, and expanding industrial applications. Companies that invest in smart, efficient, and environmentally responsible solutions are likely to capture significant market share, especially in high-growth regions and precision-driven industries.

Common Pitfalls When Sourcing a Planetary Belt Sander (Quality & IP)

Sourcing a planetary belt sander—especially from overseas suppliers—can be fraught with challenges related to both product quality and intellectual property (IP) protection. Being aware of these pitfalls is crucial for making informed procurement decisions and avoiding costly setbacks.

Quality-Related Pitfalls

Inconsistent Build and Material Quality

Suppliers may use substandard materials (e.g., low-grade motors, plastic gears instead of metal, inferior sanding pads) to cut costs, leading to premature wear, overheating, or mechanical failure. Variability between production batches can further compromise reliability and performance.

Misleading Performance Claims

Some suppliers exaggerate technical specifications such as sanding speed, power output, or dust extraction efficiency. Without independent verification or third-party testing, buyers may receive a product that underperforms in real-world applications.

Poor Ergonomics and Safety Features

Low-cost models may lack essential safety mechanisms (e.g., overload protection, secure belt tracking) or have poorly designed handles and vibration dampening. This increases operator fatigue and accident risk, particularly in industrial settings.

Lack of Durability Under Load

While a sander may function during short test runs, it may fail under sustained or heavy-duty use. Components like bearings, motors, and planetary gear systems can degrade quickly without proper heat dissipation or quality control.

Inadequate After-Sales Support and Spare Parts

Many budget suppliers offer limited technical support, repair services, or availability of replacement parts. This can lead to extended downtime and higher total cost of ownership over time.

Intellectual Property (IP)-Related Pitfalls

Risk of IP Infringement

Sourcing from regions with lax IP enforcement increases the likelihood of purchasing a product that copies patented designs, technologies, or branding from established brands. This exposes the buyer to legal risks, including seizure of goods or lawsuits, especially in regulated markets like the EU or North America.

Unverified Supplier Authenticity

Suppliers may falsely claim to be original equipment manufacturers (OEMs) or authorized distributors. Without proper due diligence, companies may unknowingly source counterfeit or reverse-engineered tools, undermining brand integrity and warranty validity.

Lack of Design or Technology Ownership

Even when not outright infringing, some manufacturers use “inspired by” designs that closely mimic protected innovations. If your company rebrands or integrates the tool into a proprietary system, you could face claims of contributory infringement.

No IP Indemnification in Contracts

Many sourcing agreements, especially with low-cost suppliers, do not include clauses that protect the buyer from IP disputes. This leaves the purchaser liable for legal costs and damages if infringement is alleged.

Exposure of Customization or Proprietary Requirements

Sharing detailed technical specs or custom feature requests with unvetted suppliers can lead to IP leakage. There’s a risk the supplier could replicate or sell your design to competitors if proper NDAs and IP agreements are not in place.

Mitigation Strategies

To avoid these pitfalls, conduct thorough supplier audits, request product samples for independent testing, verify IP compliance through patent searches, and use contracts with strong IP indemnification clauses. Partnering with reputable manufacturers and leveraging legal counsel during the sourcing process can significantly reduce both quality and IP risks.

Logistics & Compliance Guide for Planetary Belt Sander

This guide outlines the essential logistics and compliance considerations for the safe, legal, and efficient handling, transportation, and use of a Planetary Belt Sander across various markets.

Product Classification & Regulatory Identification

Identify the specific model and technical specifications (voltage, power rating, dimensions, weight) to determine correct classification under international trade and safety systems. The Planetary Belt Sander typically falls under HS Code 8467.21 (Machines for grinding, polishing or other machining of metal, of non-metallic mineral substances) in most countries. Ensure product labels include accurate voltage, frequency, IP rating (if applicable), and manufacturer details.

Packaging & Shipping Requirements

Package the sander securely using robust materials to prevent damage during transit. Include anti-vibration cushioning and secure internal bracing. Use standardized cartons marked with handling symbols (e.g., “Fragile,” “This Side Up”). Confirm compliance with ISTA 3A or similar distribution testing standards for export shipments. Include all necessary accessories, user manuals, and safety documentation within the package.

Import/Export Documentation

Prepare essential documentation for international movement, including commercial invoice, packing list, bill of lading/air waybill, and certificate of origin. Depending on destination, an Export Control Classification Number (ECCN) may be required. Verify if the product contains restricted substances (e.g., under EU RoHS) and provide a Declaration of Conformity or equivalent.

Safety & Electromagnetic Compliance

Ensure the sander complies with relevant safety standards prior to market entry. In the European Union, it must meet the requirements of the Machinery Directive (2006/42/EC) and Low Voltage Directive (2014/35/EU), and carry the CE marking. In the United States, compliance with OSHA and ANSI B7.1 (safety requirements for portable power tools) is required. For electromagnetic compatibility, meet FCC Part 15 (USA) and EMC Directive 2014/30/EU (EU).

Environmental & Chemical Regulations

Confirm that the sander and its components adhere to environmental regulations restricting hazardous substances. Comply with EU RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), and similar standards in other regions (e.g., China RoHS). Properly declare any substances of very high concern (SVHCs) and ensure recyclability per WEEE (Waste Electrical and Electronic Equipment) Directive requirements in applicable markets.

Labeling & User Documentation

All units must feature clear, permanent labeling including manufacturer name, model number, electrical ratings, serial number, and safety warnings. User manuals must be provided in the official language(s) of the destination country, detailing safe operation, maintenance procedures, and compliance information. Include pictograms per ISO 3864 for hazard communication.

Customs Clearance & Duties

Work with a licensed customs broker to ensure accurate tariff classification and valuation. Be prepared to pay applicable import duties, VAT, or GST based on the destination country. Maintain records of all compliance certifications to facilitate smooth customs clearance and potential audits.

Post-Market Surveillance & Recalls

Establish a system to monitor field performance and customer feedback. In the event of safety defects or non-compliance, follow jurisdiction-specific recall protocols (e.g., RAPEX in the EU, CPSC reporting in the U.S.). Maintain traceability through batch/serial number records for effective product recalls if necessary.

Storage & Handling at Destination

Store units in a dry, temperature-controlled environment, away from dust and moisture. Stack cartons according to manufacturer guidelines to prevent crushing. Train warehouse personnel on proper handling to avoid damage to the motor or abrasive components prior to distribution.

Conclusion: Sourcing a Planetary Belt Sander

In conclusion, sourcing a planetary belt sander requires a strategic evaluation of quality, performance, cost, and long-term reliability. These specialized tools offer superior surface finishing capabilities, especially for precision and large-scale applications, due to their orbital sanding action and reduced swirl marks. When selecting a supplier or manufacturer, factors such as build quality, motor power, dust extraction efficiency, ease of maintenance, and availability of spare parts must be carefully assessed.

Sourcing from reputable manufacturers—whether domestic or international—ensures compliance with safety and performance standards, while also providing access to technical support and warranties. Additionally, considering total cost of ownership, including energy consumption and consumable costs, contributes to a more sustainable and economical investment.

Ultimately, the right planetary belt sander sourced from a reliable supplier will enhance productivity, improve finish quality, and deliver long-term value across industrial, woodworking, or metalworking operations. A well-informed sourcing decision today supports operational excellence and performance consistency tomorrow.