The global planer blades market is experiencing steady growth, driven by rising demand from woodworking, construction, and furniture manufacturing industries. According to Grand View Research, the global woodworking tools market, which includes planer blades, was valued at USD 8.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is fueled by increasing automation in wood processing, growing residential construction activities, and the need for precision cutting tools in industrial applications. As demand for high-performance and durable planer blades rises, manufacturers are investing in advanced materials such as tungsten carbide and innovative coating technologies to enhance blade longevity and efficiency. In this competitive landscape, a select group of leading manufacturers have emerged, combining technological innovation, global distribution, and consistent product quality to capture significant market share. Here’s a data-driven look at the top eight planer blades manufacturers shaping the industry’s future.

Top 8 Planer Blades Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Simonds International

Domain Est. 2003

Website: simondsint.com

Key Highlights: As the oldest cutting tool manufacturer in North America, Simonds International offers one of the broadest and most trusted lines of cutting tools….

#2 Planer and Jointer Knives

Domain Est. 2014

Website: powertecproducts.com

Key Highlights: Rating 4.4 (89) · Free delivery over $39POWERTEC High Speed Steel (HSS) Knives are made of premium High Speed Steel (HSS) with performance that meets or exceeds OEM product….

#3 Planer Blades & Accessories

Domain Est. 1995

Website: makitatools.com

Key Highlights: PLANER BLADES & ACCESSORIES. Below you will find options for replacement blades, guides and other accessories for your Makita cordless or corded handheld or ……

#4 Planer Blades

Domain Est. 1995

Website: kennametal.com

Key Highlights: Product Suggestions · Product Family suggestions · Chat Now · Call (833) 893-1514 · Message Sales….

#5 Freud Tools

Domain Est. 1999

Website: freudtools.com

Key Highlights: Official Website of Freud Tools. Learn about Freud’s line up of best in the world Saw Blades, Router Bits, Drilling & Boring, Cutterheads, Knives & Inserts, ……

#6 Dispozablade,easy,accurate,economical planer knives

Domain Est. 2002

Website: dispozablade.com

Key Highlights: An innovative line of planer knives and jointer blades that have completely replaced the troublesome, frustrating and imprecise task of changing knives….

#7 Planer Blades & Planer Knives

Domain Est. 2013

Website: sundicuttingtools.com

Key Highlights: SUNDI provides replacement planer blades and inserts for mainstream brands such as DeWalt, Ryobi, Delta, Porter Cable, Makita, Bosch, and Hitachi….

#8 Wood planer planer blades and knives

Domain Est. 2017

Website: pilanagroup.com

Key Highlights: Our replacement planer blades and planer blades for sale are designed to meet the highest standards of performance….

Expert Sourcing Insights for Planer Blades

H2: Projected Market Trends for Planer Blades in 2026

The global planer blade market is poised for steady growth and notable transformation by 2026, driven by advancements in materials, rising demand in key end-use industries, and evolving manufacturing technologies. Here’s an analysis of the major trends expected to shape the market in H2 2026:

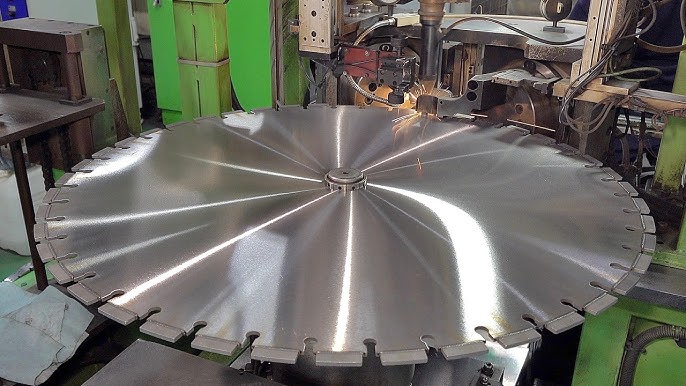

1. Increased Adoption of Advanced Materials

By H2 2026, high-performance materials such as CPM (Crucible Particle Metallurgy) tool steels, carbide-tipped blades, and nano-coated alloys will dominate premium segments. These materials offer superior wear resistance, extended blade life, and improved surface finish, particularly in industrial woodworking and metalworking applications. Demand will be fueled by cost-conscious manufacturers seeking to reduce downtime and replacement frequency.

2. Growth in Automation and CNC Integration

As automated manufacturing and CNC planers become more widespread—especially in aerospace, automotive, and precision engineering—there will be a rising need for planer blades compatible with high-speed, high-precision operations. Blades designed for consistency, thermal stability, and digital tool monitoring integration will gain market share.

3. Expansion in Emerging Markets

Asia-Pacific, particularly India, Vietnam, and Indonesia, will see accelerated demand for planer blades due to infrastructure development, growth in furniture manufacturing, and government-backed industrialization programs. Localized production and distribution networks will expand to support this growth, reducing lead times and import dependency.

4. Sustainability and Circular Economy Initiatives

Environmental regulations and corporate sustainability goals will push manufacturers toward recyclable blade materials and reconditioning services. By H2 2026, remanufactured and re-sharpened planer blades are expected to capture a larger segment of the market, especially in Europe and North America, where lifecycle management is prioritized.

5. Digitalization and Predictive Maintenance

Smart tooling solutions, including IoT-enabled planer blades with embedded sensors, will begin entering the market. These will allow for real-time monitoring of blade wear, temperature, and performance, enabling predictive maintenance and optimizing operational efficiency in large-scale manufacturing environments.

6. Consolidation and Strategic Partnerships

Market consolidation is expected as major tooling companies acquire niche blade manufacturers to expand their product portfolios. Collaborations between blade producers and CNC machine OEMs will increase, offering integrated solutions that enhance compatibility and performance.

7. Impact of Raw Material Volatility

Fluctuations in the prices of tungsten, cobalt, and specialty steels may continue to affect production costs. However, by H2 2026, manufacturers are likely to have diversified supply chains and adopted alternative materials or coatings to mitigate risks, ensuring pricing stability in the mid-to-high-end segments.

Conclusion:

By the second half of 2026, the planer blade market will be characterized by innovation in materials and digital integration, strong regional growth in Asia-Pacific, and a growing emphasis on sustainability. Companies that invest in R&D, adopt smart manufacturing practices, and respond to regional demand dynamics will be best positioned to capture value in this evolving landscape.

Common Pitfalls When Sourcing Planer Blades: Quality and Intellectual Property Concerns

Sourcing planer blades involves more than just comparing prices—overlooking quality standards and intellectual property (IP) risks can lead to operational inefficiencies, legal exposure, and reputational damage. Below are key pitfalls to avoid.

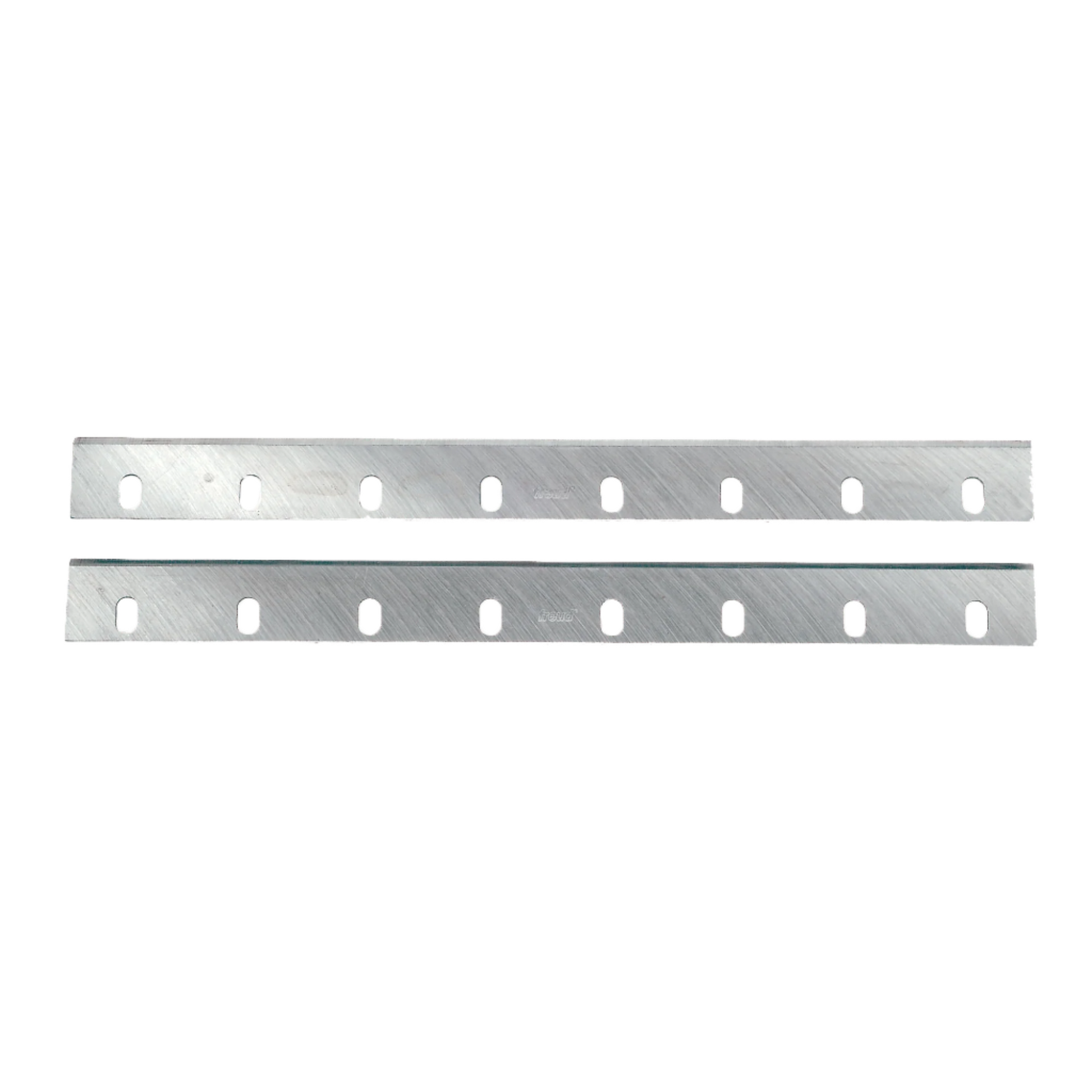

Inadequate Quality Control and Material Specifications

One of the most frequent issues when sourcing planer blades is receiving products that fail to meet required performance standards. Blades made from substandard steel or with imprecise heat treatment wear out quickly, cause poor surface finishes, and increase machine downtime. Buyers often assume specifications are standardized, but low-cost suppliers may use inferior alloys or skip critical manufacturing steps like proper tempering or edge grinding. Always verify material certifications (e.g., high-speed steel or tungsten carbide grades) and demand quality control documentation, such as hardness test reports and geometric tolerance checks.

Counterfeit or IP-Infringing Products

Many planer blades, especially those designed for specific OEM equipment, are protected by patents, trademarks, or design rights. Sourcing from unauthorized suppliers—particularly in regions with lax IP enforcement—risks acquiring counterfeit blades that mimic branded products. Using such blades may void equipment warranties and expose your company to legal liability for contributory infringement. Always confirm that suppliers have legitimate rights to manufacture and sell the blades, and avoid vendors offering “compatible” blades at suspiciously low prices without proper licensing disclosures.

Lack of Traceability and Certification

Reputable blade manufacturers provide batch traceability and compliance certifications (e.g., ISO 9001, RoHS). Without these, it’s difficult to investigate failures or ensure consistency across procurement cycles. Sourcing from suppliers who cannot provide lot numbers, material test reports, or quality assurance documentation increases the risk of inconsistent performance and complicates root-cause analysis during production issues.

Overlooking Precision Engineering and Tolerances

Planer blades require tight dimensional tolerances and precise edge geometry to function correctly. Poorly machined blades can cause vibration, uneven cutting, and premature wear. Generic or off-brand blades often lack the precision needed for high-speed or high-tolerance applications. Ensure suppliers adhere to documented engineering specifications and conduct sample testing before full-scale procurement.

Failure to Audit Suppliers and Manufacturing Processes

Relying solely on product samples without auditing the supplier’s production facility can be risky. Hidden issues such as outdated machinery, untrained personnel, or inconsistent process controls may not be evident from initial samples. Conducting on-site or third-party audits helps verify that quality systems are in place and capable of sustaining consistent output over time.

Avoiding these pitfalls requires due diligence, clear specifications, and partnerships with reputable suppliers who prioritize both quality and legal compliance.

Logistics & Compliance Guide for Planer Blades

Overview

Planer blades are precision cutting tools used in woodworking and industrial machinery to shape and smooth materials. Due to their sharp nature and potential classification under various regulatory frameworks, proper logistics and compliance practices are essential for safe handling, transport, and legal distribution.

Classification & Regulatory Considerations

Planer blades may be classified under specific commodity codes depending on material composition (e.g., high-speed steel, carbide-tipped), intended use, and form. Common HS (Harmonized System) codes include:

– 8208.10: Cutting blades for machine tools for working wood

– 8208.40: Parts and accessories of planers for wood

Always verify the correct HS code with local customs authorities to avoid misclassification, duties, or shipment delays.

Some jurisdictions may regulate sharp industrial tools under safety or trade control laws. Confirm compliance with regional import/export restrictions, especially for blades made from strategic materials (e.g., tungsten carbide).

Packaging & Handling Requirements

- Protective Packaging: Blades must be individually wrapped or secured in rigid packaging to prevent damage and reduce injury risk. Use edge protectors, foam inserts, or plastic sleeves.

- Labeling: Clearly mark packages with “Sharp Edges,” “Fragile,” and “Handle with Care.” Include product identification, batch numbers, and safety warnings.

- Stackability & Weight Distribution: Ensure outer cartons are strong enough for stacking and clearly indicate gross weight and orientation (e.g., “This Side Up”).

Transportation & Shipping

- Domestic Shipments: Comply with carrier-specific regulations for sharp objects. Most major carriers (e.g., FedEx, UPS) allow planer blades if properly packaged and labeled.

- International Shipments:

- Include a commercial invoice detailing description, quantity, value, HS code, country of origin, and end-use.

- Provide a packing list and bill of lading/air waybill.

- Verify export controls (e.g., EAR in the U.S.) if blades contain controlled materials or are destined for sanctioned regions.

- Air Freight: Subject to IATA Dangerous Goods Regulations if sharp objects are not adequately protected. While planer blades are typically not classified as dangerous goods, proper containment is required to pass security screening.

Safety & Compliance Standards

- OSHA (U.S.) / HSE (UK): Ensure workplace handling complies with occupational safety standards for sharp tools. Provide training on safe storage and use.

- REACH & RoHS (EU): If blades contain certain metals or coatings, verify compliance with chemical and hazardous substance regulations.

- Product Liability: Maintain quality control documentation and traceability for defect tracking and recall preparedness.

Import/Export Documentation

Required documents typically include:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin (if claiming preferential tariffs)

– Export License (if applicable based on destination or material)

Storage & Inventory Management

Store planer blades in dry, secure areas to prevent corrosion and unauthorized access. Use first-in, first-out (FIFO) inventory practices to ensure freshness and reduce obsolescence.

Disposal & Environmental Compliance

Dispose of worn or damaged blades as industrial metal waste. Follow local environmental regulations for scrap metal recycling—do not discard in general waste due to injury risk and material recovery requirements.

Summary

Proper logistics and compliance for planer blades involve accurate classification, secure packaging, adherence to transportation rules, and documentation integrity. Staying informed about regional regulations and maintaining safety standards ensures smooth operations and legal compliance across the supply chain.

Conclusion for Sourcing Planer Blades

In conclusion, sourcing high-quality planer blades is essential to ensuring optimal performance, precision, and longevity in woodworking and manufacturing operations. A well-structured sourcing strategy should prioritize blade material (such as high-speed steel or carbide-tipped), dimensional accuracy, heat resistance, and edge durability to maintain consistent cut quality and reduce downtime. Evaluating suppliers based on reputation, quality certifications, cost-effectiveness, and reliability ensures a steady supply of blades that meet both operational demands and budget constraints. Additionally, considering sustainability and the availability of blade sharpening or recycling services can further enhance cost-efficiency and environmental responsibility. By implementing a strategic and informed sourcing approach, businesses can achieve improved productivity, reduced maintenance costs, and superior finished products.