The global demand for precision testing equipment in electronics manufacturing has surged in recent years, driven by the rapid expansion of semiconductor production, consumer electronics, and automotive electronics. According to Mordor Intelligence, the global semiconductor testing equipment market was valued at USD 4.8 billion in 2023 and is projected to grow at a CAGR of approximately 7.2% from 2024 to 2029. Pin testers—critical for ensuring the electrical connectivity and reliability of integrated circuits and PCBs—are a cornerstone of this ecosystem. As quality control becomes increasingly stringent across high-stakes industries, manufacturers are prioritizing advanced pin testing solutions that offer higher accuracy, faster throughput, and seamless integration with automated production lines. This growing imperative has led to increased innovation and competition among pin tester manufacturers worldwide. Based on market presence, technological advancement, global reach, and customer reviews, the following list highlights the top 10 pin tester manufacturers shaping the future of electronic test and measurement.

Top 10 Pin Tester Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pomona Electronics

Domain Est. 1998

Website: pomonaelectronics.com

Key Highlights: Leading manufacturer of test and measurement accessories for professionals worldwide….

#2 Probe Manufacturer Produces Test Probe Pin and PCB Probe

Domain Est. 2003 | Founded: 1996

Website: m.cpm-probes.com.tw

Key Highlights: Chunglai CPM is a probe manufacturer, established in 1996, makes efforts in research and development of test probe pin and PCB probe….

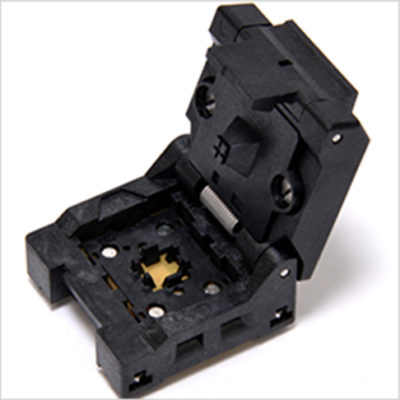

#3 IC Test Socket Manufacturer

Domain Est. 2013

Website: pin-jet.com

Key Highlights: Our company specializes in manufacturing professional semiconductor testing equipment components including ic test sockets, pins, production fixtures, ……

#4 New website online

Website: chushing-tw.com

Key Highlights: Pin Shin’s new website will be officially launched! With a more friendly function design and simpler interface, you can more easily search and find the ……

#5 Coda Systems

Domain Est. 1996

Website: coda-systems.co.uk

Key Highlights: Coda Systems are leading stockists and distributors of spring contact test probes, test jigs, specialist test products and spring loaded connectors….

#6

Domain Est. 1997

Website: dmctools.com

Key Highlights: For 75 years, DMC® has manufactured tooling for mission-critical electrical systems in aerospace and defense, rail, marine, and several other industries….

#7 King Pin Tester

Domain Est. 1998

Website: kingtester.com

Key Highlights: Test anywhere on your part with the King Pin hand-held Brinell tester. The King Pin Tester® provide an economical, fast and accurate means of testing….

#8 Homepage – LEENO

Domain Est. 2000

Website: leeno.com

Key Highlights: LEENO has proven test solutions for cloud or network server devices which typically require high speed, high pin-count and high power testing. Automotive. LEENO ……

#9 Pintester

Domain Est. 2015

Website: atv-systems.com

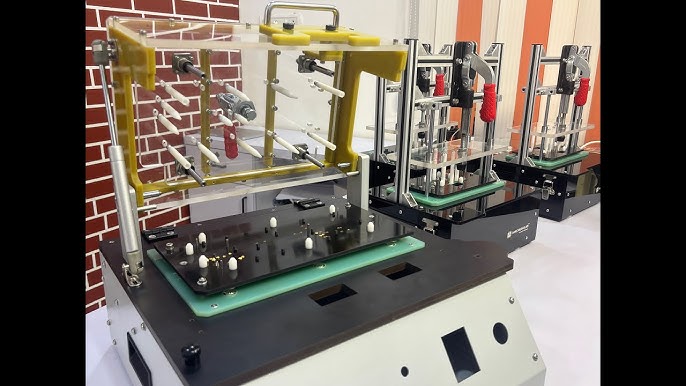

Key Highlights: The Pintester is a complete test environment which has been specially developed for use in the semiconductor industry….

#10 Calibrated Pin Static Tester

Domain Est. 2015

Website: store.ametekstc.com

Key Highlights: In stock $5 deliveryThe Calibrated Pin Static Tester is specifically designed to measure static electricity levels accurately and reliably. Ideal for use in electronics ……

Expert Sourcing Insights for Pin Tester

H2: 2026 Market Trends for Pin Testers

The Pin Tester market in 2026 is poised for transformation driven by advancements in semiconductor packaging, rising demand for miniaturization, and the integration of intelligent testing methodologies. Here are the key trends shaping the sector:

1. Rise of Advanced Packaging Driving Tester Complexity

As the semiconductor industry shifts toward heterogeneous integration (e.g., chiplets, 2.5D/3D packaging), Pin Testers must adapt to handle increasingly complex interconnects and finer pitch configurations. In 2026, demand will grow for high-density, high-precision testers capable of validating thousands of microbumps and through-silicon vias (TSVs), particularly in AI, HPC, and automotive applications.

2. Integration of AI and Machine Learning

By 2026, AI-powered diagnostics and predictive maintenance will become standard in Pin Testing systems. Machine learning algorithms will analyze test data in real-time to identify failure patterns, reduce false positives, and optimize test time. This shift will improve yield rates and lower overall cost-of-test, especially in high-volume manufacturing environments.

3. Demand for Faster Test Throughput

With escalating production volumes—particularly in consumer electronics and IoT—there will be strong pressure to increase test throughput. Future Pin Testers will leverage parallel testing architectures, faster signal switching, and advanced contactor technologies (e.g., vertical probe cards) to meet cycle time demands without sacrificing accuracy.

4. Miniaturization and Contact Force Optimization

As devices shrink, so do test contact points. In 2026, Pin Testers will incorporate ultra-fine probes with lower contact forces to prevent pad damage on delicate wafers and packages. MEMS-based probes and self-cleaning contact technologies will gain traction to maintain reliability and extend probe card life.

5. Increased Adoption in Automotive and Power Electronics

Stringent reliability requirements in automotive (e.g., ISO 26262) and power semiconductor sectors will drive demand for robust, high-reliability Pin Testing. Testers supporting high-current and high-temperature operation will see increased deployment for IGBTs, SiC, and GaN devices used in EVs and renewable energy systems.

6. Focus on Sustainability and Total Cost of Ownership (TCO)

Manufacturers will prioritize energy-efficient testers and systems with longer lifespans and modular designs for easy upgrades. Reducing probe card wear and test time directly impacts sustainability and TCO—key decision factors in 2026 procurement strategies.

7. Regional Production Shifts and Supply Chain Resilience

With semiconductor manufacturing expanding in North America, Europe, and Southeast Asia, Pin Tester suppliers will localize support and service networks. This trend supports reduced downtime and faster deployment, aligning with global supply chain resilience initiatives.

Conclusion

By 2026, the Pin Tester market will evolve beyond simple electrical verification to become an intelligent, high-speed, and precision-critical component of semiconductor manufacturing. Success will depend on innovation in probe technology, data analytics integration, and alignment with advanced packaging roadmaps—positioning leading vendors at the forefront of next-generation electronics validation.

Common Pitfalls When Sourcing Pin Testers (Quality, IP)

Sourcing pin testers—critical tools used in semiconductor and electronics manufacturing for electrical testing—requires careful evaluation to avoid compromising product quality, reliability, and intellectual property (IP). Overlooking key factors can lead to production delays, increased costs, and security risks. Below are common pitfalls to watch for, particularly in the areas of quality and IP protection.

Poor Manufacturing Quality and Reliability

One of the most frequent issues is procuring pin testers with substandard build quality. Low-cost suppliers may cut corners on materials, calibration, or assembly processes, resulting in inconsistent performance, frequent downtime, or shortened equipment lifespan. Poorly manufactured testers can introduce measurement inaccuracies that affect yield rates and product reliability. Always verify the supplier’s quality certifications (e.g., ISO 9001), request third-party test reports, and, if possible, conduct on-site factory audits.

Lack of Traceability and Calibration Documentation

Reputable pin testers must come with full traceability and calibration certificates compliant with international standards (e.g., NIST). Sourcing from vendors who cannot provide detailed documentation increases the risk of using non-compliant or inaccurate equipment. This can lead to failed audits, rejected batches, or compliance issues in regulated industries. Ensure calibration procedures are repeatable and supported by documented evidence.

Inadequate Protection of Intellectual Property (IP)

Pin testers often interface directly with proprietary designs, test programs, and sensitive device data. A major pitfall is sourcing from suppliers with weak cybersecurity measures or unclear IP ownership agreements. This exposes your organization to risks such as unauthorized access to test algorithms, reverse engineering of your products, or data leakage. Always review the supplier’s data protection policies, firmware security protocols, and contractual terms regarding IP rights before procurement.

Use of Counterfeit or Refurbished Components

Some vendors may supply pin testers containing counterfeit or unqualified replacement parts, especially in the probe card or signal routing modules. These components can degrade performance and lead to intermittent failures. Verify component authenticity through lot tracing and supplier qualification processes. Be cautious of offers that seem too good to be true—extremely low prices may indicate the use of non-OEM or recycled parts.

Insufficient After-Sales Support and Spare Parts Availability

Even high-quality pin testers require maintenance and occasional part replacements. Sourcing from suppliers without reliable technical support or spare parts inventory can result in extended downtimes. Evaluate the vendor’s service network, response times, and availability of trained engineers before making a purchase decision.

Non-Compliance with Industry Standards

Pin testers must meet specific industry standards for electrical safety, EMI/EMC, and interface compatibility. Sourcing non-compliant equipment can lead to integration issues, safety hazards, or regulatory non-conformance. Confirm that the equipment meets relevant standards such as IEC, SEMI, or JEDEC, depending on your application.

Avoiding these pitfalls requires due diligence, clear vendor evaluation criteria, and a focus on long-term reliability and security—not just initial cost. Prioritize suppliers with proven track records, strong quality systems, and transparent IP protection practices.

Logistics & Compliance Guide for Pin Tester

This guide outlines the key logistics and compliance considerations for the use, transport, handling, and maintenance of Pin Testers—devices commonly used in electronic manufacturing, quality assurance, and PCB (Printed Circuit Board) testing environments.

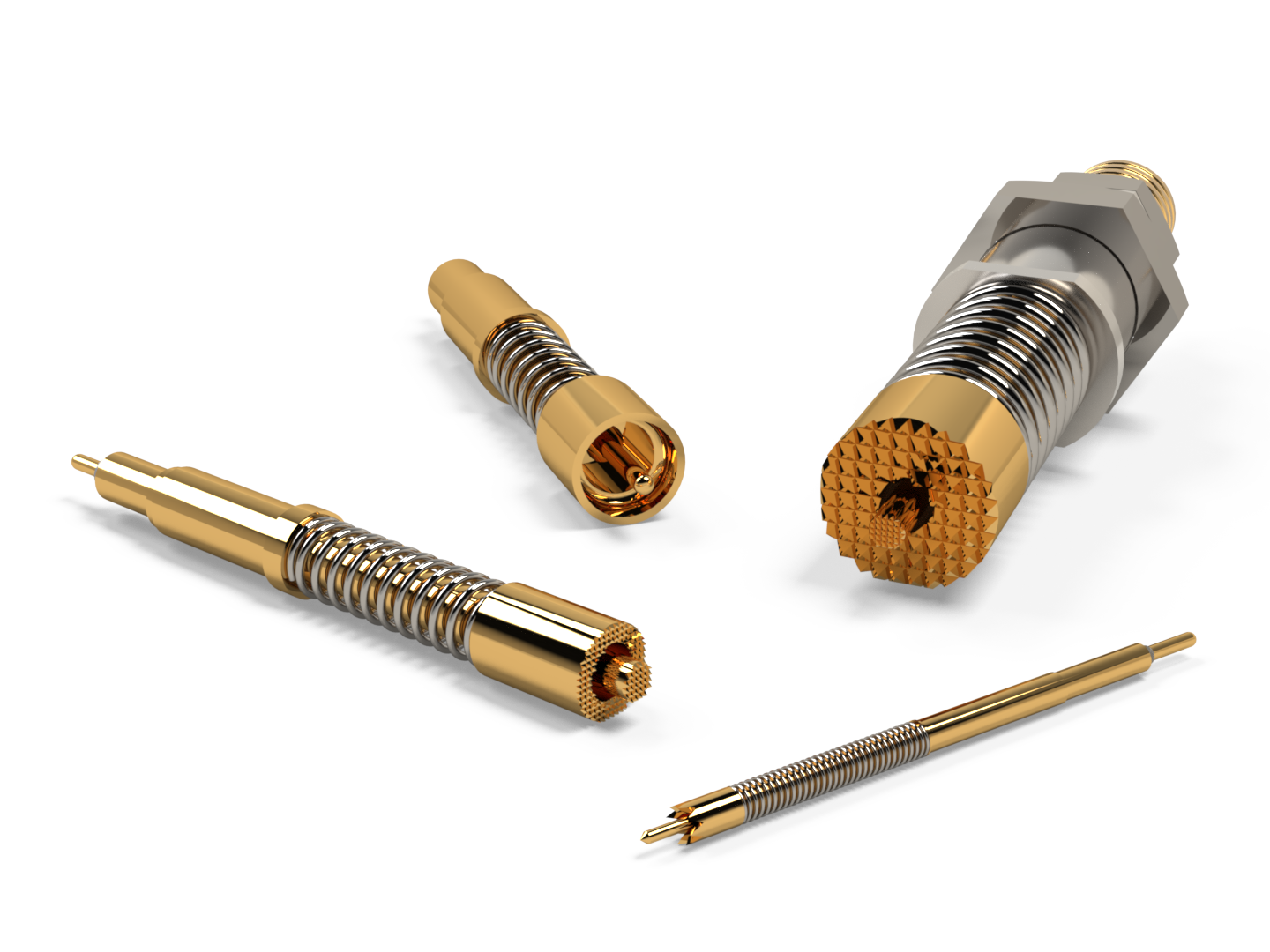

Device Overview

A Pin Tester, also known as a bed-of-nails tester, is a fixture-based tool used to verify the electrical functionality of printed circuit boards. It makes contact with multiple test points simultaneously using spring-loaded pins to detect faults such as opens, shorts, or component failures.

Regulatory Compliance

Pin Testers must comply with relevant international and regional regulations to ensure safety, environmental protection, and operational integrity.

Electrical Safety Standards

- Comply with IEC 61010-1: Safety requirements for electrical equipment for measurement, control, and laboratory use.

- Ensure grounding and insulation meet local electrical codes (e.g., NEC in the U.S., BS 7671 in the UK).

- Use only power supplies and connectors certified by recognized bodies (e.g., UL, CE, CSA).

Electromagnetic Compatibility (EMC)

- The device must meet EMC directives such as:

- EU EMC Directive 2014/30/EU

- FCC Part 15 (U.S.) for electromagnetic emissions

- Shielding and grounding must prevent interference with nearby equipment.

Environmental Compliance

- Adhere to RoHS (Restriction of Hazardous Substances) for components within the tester.

- Comply with WEEE (Waste Electrical and Electronic Equipment) for end-of-life disposal planning.

- Use packaging and materials that meet REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) requirements.

Shipping and Handling

Proper logistics practices are essential to prevent damage during transit and ensure operational readiness upon delivery.

Packaging Requirements

- Secure the Pin Tester in anti-static, shock-absorbent packaging.

- Use rigid outer containers with cushioning (e.g., foam inserts) to protect connectors and pins.

- Include desiccant packs if shipping to humid climates to prevent corrosion.

Transportation

- Label packages with “Fragile,” “This Side Up,” and “Electrostatic Sensitive Device” warnings.

- Use carriers experienced in handling precision electronic equipment.

- For international shipments, ensure compliance with IATA/ICAO regulations if air freight is used.

Import/Export Documentation

- Prepare commercial invoices, packing lists, and certificates of origin.

- Verify export control classifications (e.g., ECCN under the U.S. Commerce Control List).

- Obtain necessary permits for cross-border movement of electronic test equipment, especially if containing embedded software.

Installation and Operational Compliance

Ensure safe and compliant setup and use in the workplace.

Facility Requirements

- Install in a clean, dry, temperature-controlled environment (typically 15–35°C, 30–70% RH non-condensing).

- Provide stable power supply with surge protection.

- Ensure adequate ventilation and space for maintenance access.

Calibration and Maintenance

- Follow manufacturer-recommended calibration schedules (typically annually).

- Maintain calibration records for ISO 9001 or IATF 16949 compliance.

- Document all maintenance activities, including pin replacement and alignment checks.

Operator Safety and Training

- Train personnel on proper handling, electrical safety, and emergency shutdown procedures.

- Provide ESD (electrostatic discharge) protection: wrist straps, grounded workstations, and ESD-safe flooring.

- Restrict access to authorized, trained personnel only.

Data Security and Software Compliance

Many Pin Testers include onboard software or connect to host systems for test data logging.

Software Licensing

- Ensure all software is properly licensed and up to date.

- Comply with software export controls (e.g., EAR for U.S.-origin technology).

Data Management

- Secure test data in compliance with GDPR, CCPA, or other applicable data privacy regulations if personal or sensitive data is processed.

- Implement access controls and audit logs for test result databases.

End-of-Life Management

Dispose of or recycle Pin Testers responsibly.

Decommissioning

- Back up and securely erase any stored test data.

- Remove sensitive components (e.g., memory modules) before disposal.

Recycling and Disposal

- Partner with certified e-waste recyclers compliant with R2 or e-Stewards standards.

- Follow WEEE protocols for proper material recovery.

Summary

Adhering to this logistics and compliance guide ensures the safe, legal, and efficient operation of Pin Testers across their lifecycle—from shipment and installation to maintenance and disposal. Regular audits and staff training are recommended to maintain compliance with evolving standards.

Conclusion:

After a thorough evaluation of available options, it is recommended to source a high-precision, automated pin tester that aligns with our production requirements, offering reliability, scalability, and long-term cost efficiency. The selected pin tester should support a wide range of connector types, integrate seamlessly with existing testing systems, and provide accurate, repeatable results to ensure product quality and performance. Supplier credibility, service support, and ease of maintenance were key deciding factors. Ultimately, investing in a robust pin tester will enhance testing efficiency, reduce failure rates in the field, and support consistent delivery of high-quality electronic assemblies.