The global check valve market is experiencing robust growth, driven by increasing demand across critical industries such as oil & gas, water and wastewater treatment, power generation, and chemical processing. According to a report by Mordor Intelligence, the global check valve market was valued at USD 8.5 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of over 5.2% from 2024 to 2029. This expansion is underpinned by rising infrastructure investments, stricter regulatory standards for fluid control systems, and the need for energy-efficient and leak-proof solutions in industrial applications.

Within this growing market, pilot operated check valves (POCVs) have emerged as vital components for high-pressure hydraulic systems, offering precise control, reliability, and enhanced safety in challenging operating conditions. As automation and system efficiency become focal points across manufacturing and process industries, demand for advanced POCVs has surged. Based on industry analysis and market performance, the following eight manufacturers have distinguished themselves through innovation, product quality, global reach, and technological leadership in the pilot operated check valve segment.

Top 8 Pilot Operated Check Valve Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pilot Valves

Domain Est. 1995

Website: ph.parker.com

Key Highlights: Parker offers a large collection of pilot-operated (PO) check valves, which are check valves that can be opened by an external pilot pressure….

#2 Pilot Check Valve

Domain Est. 1995

Website: smcusa.com

Key Highlights: Pilot Check Valve. SMC pilot check valves permit flow in one direction and only allow reverse flow if supplied with an appropriate pilot signal….

#3 27 Series Pilot Operated Check Valves 2751A3901

Domain Est. 1996

Website: rosscontrols.com

Key Highlights: In stock27 Series Pilot Operated Check Valves 2751A3901 · Poppet construction for near zero leakage · Manual or remote trapped pressure release when pressure is removed ……

#4 PC – Pilot Check Valve

Domain Est. 1996

Website: brand-hyd.com

Key Highlights: The Brand, pilot check valve is precision built, dependable and low priced. In one direction oil opens a check valve and passes through the valve and into a ……

#5 Check Valves For Unique Customer Needs

Domain Est. 1996

Website: theleeco.com

Key Highlights: Lee Pilot-Operated Cheks are pressure piloted to open check valves available in diameters from 0.250 to 0.500 of an inch. When pressure is applied to the pilot ……

#6 Pilot operated check valves

Domain Est. 1997

Website: walvoil.com

Key Highlights: Check valves · Pilot operated check valves · Counterbalance valves · Self-leveling Valves. VUPSL. Single acting. VBPSL. Single acting. VRSE..A….

#7 Pilot-to-Close Check Valve, Port 1 to Port 2

Domain Est. 2009

Website: winnerhydraulics.com

Key Highlights: Pilot-to-close check valves with spring-biased design allow one-way flow and block reverse flow—ideal for reliable hydraulic flow control….

#8 PILOT OPERATED CHECK VALVES

Domain Est. 2022

Website: groupmarchesini.com

Key Highlights: A pilot-operated hydraulic check valve is a key component in hydraulic systems, designed to control the flow of fluid and block the movement of an actuator….

Expert Sourcing Insights for Pilot Operated Check Valve

H2: 2026 Market Trends for Pilot Operated Check Valves

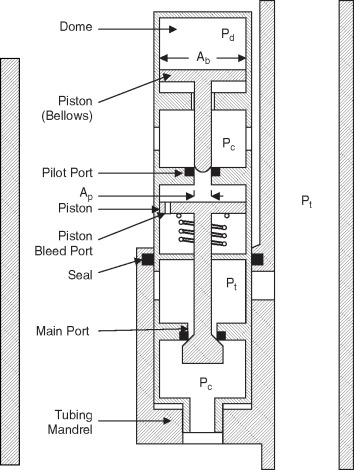

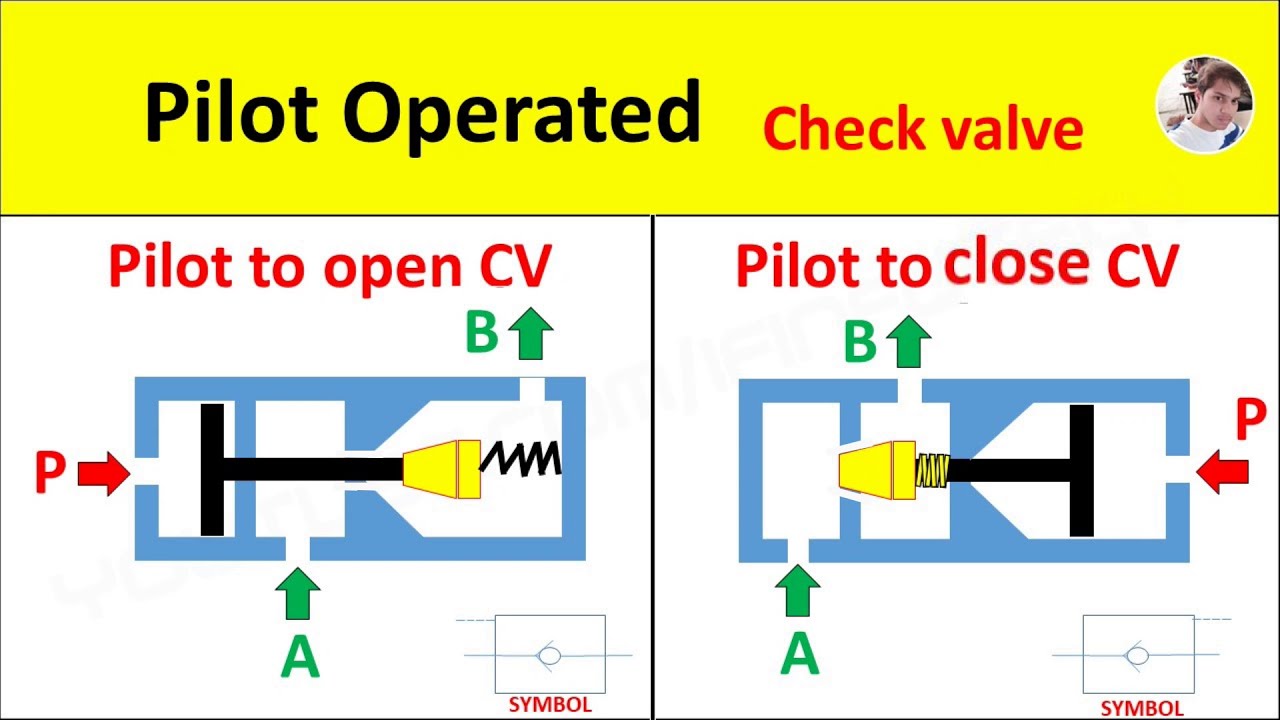

The global market for pilot operated check valves (POCVs) is poised for significant evolution by 2026, driven by technological advancements, expanding industrial automation, and increasing demand across key sectors such as oil & gas, water treatment, power generation, and chemical processing. These valves, known for their ability to prevent backflow and allow controlled flow reversal using pilot pressure, are becoming increasingly critical in high-pressure and high-reliability applications.

-

Growth in Industrial Automation and Process Optimization

By 2026, the integration of pilot operated check valves into automated control systems is expected to accelerate. Industries are prioritizing precision, safety, and efficiency, leading to higher adoption of smart POCVs equipped with sensors and digital communication capabilities (e.g., IoT-enabled valves). This trend supports predictive maintenance and real-time monitoring, reducing downtime and improving system reliability. -

Expansion in Oil & Gas and Energy Sectors

The oil & gas industry remains a dominant end-user of POCVs, particularly in upstream and midstream operations such as wellhead control, pipeline safety, and subsea systems. With renewed investments in both conventional and offshore energy projects—especially in regions like the Middle East, North America, and offshore Asia-Pacific—the demand for high-performance, fail-safe valves is projected to rise steadily through 2026. -

Rise in Renewable Energy Infrastructure

Emerging applications in geothermal and hydroelectric power generation are creating new opportunities for POCVs. These systems often require precise fluid control under variable pressure conditions, where pilot operated check valves offer superior performance compared to standard check valves. As renewable energy capacity expands globally, so too will the need for specialized fluid control components. -

Stringent Regulatory and Safety Standards

Increasing regulatory scrutiny on industrial safety and environmental protection is pushing industries to adopt valves that meet higher reliability and leak-tightness standards. POCVs, with their ability to ensure tight shutoff and controlled operation, are increasingly preferred in safety-critical applications. Compliance with standards such as API 570, ASME B16.34, and ISO 5208 will be a key market driver. -

Regional Market Dynamics

Asia-Pacific is expected to lead market growth by 2026, fueled by rapid industrialization, urbanization, and infrastructure development in countries like China, India, and South Korea. North America will see steady growth due to shale gas activities and aging infrastructure upgrades, while Europe focuses on sustainability and energy efficiency, promoting the adoption of advanced valve technologies. -

Technological Innovation and Material Advancements

Manufacturers are investing in advanced materials such as super duplex stainless steel, Inconel, and composite seals to enhance corrosion resistance and durability in aggressive environments. Additionally, compact and modular POCV designs are being introduced to meet space constraints and ease installation in modern plants. -

Supply Chain and Sustainability Considerations

By 2026, sustainability will play a growing role in procurement decisions. Companies are favoring suppliers that offer energy-efficient designs, recyclable materials, and transparent supply chains. Digital twins and simulation tools are also being used to optimize valve performance and reduce lifecycle costs.

In conclusion, the 2026 market landscape for pilot operated check valves will be shaped by digitalization, regulatory demands, and sector-specific growth—especially in energy and infrastructure. Companies that innovate in smart valve technology, sustainability, and global service support are likely to gain a competitive edge in this evolving market.

Common Pitfalls When Sourcing Pilot Operated Check Valves (Quality & IP)

Sourcing Pilot Operated Check Valves (POCVs) requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these areas can lead to performance issues, safety hazards, legal disputes, and increased lifecycle costs. Below are key pitfalls to avoid:

Quality-Related Pitfalls

-

Insufficient Material Certification and Traceability

Accepting valves without proper material test reports (MTRs) or traceability documentation risks receiving substandard materials. This can lead to premature failure, especially in corrosive or high-pressure environments. Always require full material compliance with standards (e.g., ASTM, NACE) and ensure lot traceability. -

Inadequate Testing and Certification

Some suppliers may provide valves without full factory acceptance testing (FAT), such as shell and seat leakage tests, pilot function validation, or pressure cycling. Ensure valves are tested per recognized standards (e.g., API 598, ISO 5208) and that test records are provided. -

Poor Sealing Performance Under Real Conditions

POCVs may perform well in lab settings but fail in actual service due to backpressure fluctuations or contamination. Verify that the valve is rated for the specific system dynamics and includes features like dirt-tolerant pilot mechanisms. -

Counterfeit or Replica Components

Low-cost suppliers may offer counterfeit valves that mimic reputable brands but lack engineering integrity. These often fail under pressure or temperature extremes. Source from authorized distributors or directly from OEMs with verifiable supply chains. -

Missing or Inaccurate Documentation

Incomplete operation manuals, incorrect dimensional drawings, or missing installation guidelines can lead to improper installation and operational failures. Insist on comprehensive, accurate technical documentation.

Intellectual Property (IP)-Related Pitfalls

-

Unauthorized Manufacturing or Reverse Engineering

Some suppliers produce POCVs by reverse-engineering patented designs. Using such valves exposes end-users to legal liability, especially in regulated industries. Always verify that the valve design does not infringe on existing patents (e.g., check USPTO or EPO databases). -

Lack of Licensing Agreements

Certain POCV technologies are protected by licensing agreements. Sourcing from manufacturers without proper licensing can result in enforcement actions or forced equipment shutdowns. Confirm the supplier holds valid rights to produce and sell the design. -

Generic Labels Masking IP Violations

Suppliers may market copies under generic names but mimic patented features (e.g., specific pilot chamber geometry or poppet design). Conduct due diligence to ensure design originality or proper licensing. -

Inadequate Warranty and Liability Coverage

Suppliers using unlicensed designs often offer limited warranties and disclaim IP infringement liability. This leaves the buyer exposed to third-party claims. Ensure contracts include IP indemnification clauses. -

OEM vs. “Equivalent” Confusion

Assuming “equivalent” valves are legal substitutes can be risky. True equivalents require licensing or design-around engineering. Always confirm whether the alternative is a licensed product or a legally distinct design.

Mitigation Strategies

- Source from Reputable Manufacturers: Prioritize suppliers with established certifications (e.g., ISO 9001, API Q1).

- Perform Supplier Audits: Evaluate manufacturing facilities and quality control processes.

- Verify IP Status: Conduct IP due diligence, especially for critical or high-volume applications.

- Include IP Clauses in Contracts: Require suppliers to warrant non-infringement and assume liability.

- Consult Engineering and Legal Experts: Involve both technical and legal teams during procurement.

By addressing these quality and IP pitfalls proactively, organizations can ensure reliable valve performance, regulatory compliance, and protection against legal and operational risks.

Logistics & Compliance Guide for Pilot Operated Check Valve

Product Overview

Pilot Operated Check Valves (POCVs) are specialized industrial valves designed to allow fluid flow in one direction while preventing backflow through the use of a pilot control mechanism. These valves are commonly used in high-pressure systems, oil & gas, chemical processing, power generation, and water treatment applications where reliable, leak-tight shutoff and precise control are critical. Due to their operational complexity and integration into safety-critical systems, POCVs are subject to stringent logistics and compliance requirements.

Handling and Storage

- Packaging: POCVs must be shipped in protective, manufacturer-approved packaging to prevent damage to internal components, seals, and pilot lines. Valves should be secured with end caps or blind flanges to protect bore surfaces.

- Orientation: Store and transport in the position recommended by the manufacturer (typically upright) to avoid internal component misalignment or seal damage.

- Environment: Store in a clean, dry, temperature-controlled environment (typically 5°C to 40°C). Avoid exposure to moisture, dust, corrosive atmospheres, or direct sunlight.

- Lifting and Moving: Use appropriate lifting equipment. Never lift by the pilot tubing, actuator, or control lines. Follow OEM lifting points and weight guidelines.

Transportation Requirements

- Domestic & International Shipping: Comply with IATA (air), IMDG (sea), and ADR (road) regulations if transporting hazardous materials (e.g., residual fluids).

- Documentation: Include packing list, bill of lading, commercial invoice, and material test reports (MTRs). For international shipments, provide a certificate of origin and HS code (typically 8481.80 or 8481.90).

- Hazardous Materials: If the valve contains residual process media, classify and declare according to GHS and transport regulations. Clean and purge valves before shipment if required.

Regulatory Compliance

- Pressure Equipment Directive (PED 2014/68/EU): POCVs used in the European market must comply with PED. CE marking is required, along with a Declaration of Conformity. Classification depends on fluid group, pressure, and volume (typically Category II–IV).

- ASME B16.34 & Section VIII, Division 1: In North America, valves must meet ASME construction standards. Code stamping (e.g., “U” stamp) may be required for pressure-retaining components.

- API Standards: Relevant standards include API 598 (valve testing), API 6D (pipeline valves), and API 600 (gate valves). Compliance ensures interoperability and performance in oil & gas applications.

- ATEX Directive 2014/34/EU: If used in explosive atmospheres, POCVs must be certified for specific zones (e.g., Zone 1/21). Equipment Group II, Category 2G/2D may apply.

- NORSOK & ISO Standards: For offshore and international projects, compliance with NORSOK Z-013, ISO 5208 (leakage classification), and ISO 15848 (emission testing) may be required.

Certification and Documentation

- Material Test Reports (MTRs): Provide traceability for all wetted and pressure-containing parts (e.g., ASTM A216 WCB, A351 CF8M).

- Pressure Test Certificates: Include hydrostatic and pneumatic test results per API 598 or ISO 5208.

- NDE Reports: Non-destructive examination (e.g., RT, PT, UT) documentation for critical welds and castings.

- Traceability: Maintain full traceability of components (heat numbers, serial numbers) throughout the supply chain.

Installation and Pre-Commissioning

- Pre-Installation Inspection: Verify no shipping damage, presence of all components (pilot lines, filters, solenoid valves), and correct valve orientation.

- Cleaning and Flushing: Ensure upstream piping is clean and free of debris before installation to protect pilot mechanisms.

- Compliance Verification: Confirm that installed POCV meets project specifications, piping and instrumentation diagrams (P&IDs), and local jurisdictional requirements.

Import/Export Considerations

- Customs Classification: Use accurate HTS codes (e.g., 8481.80.50 for check valves in the U.S.). Tariff rates vary by country and material.

- Export Controls: Check if POCVs fall under dual-use regulations (e.g., EU Dual-Use Regulation 2021/821, U.S. EAR). High-pressure or cryogenic variants may require export licenses.

- Sanctions Compliance: Screen end-users and destinations against OFAC, EU, and UN sanctions lists.

Maintenance and Lifecycle Compliance

- Inspection Intervals: Follow manufacturer-recommended maintenance schedules. Periodic inspection of pilot mechanism, seals, and control lines is essential.

- Emission Standards: Comply with fugitive emission regulations (e.g., TA-Luft, EPA Method 21). Re-certify per ISO 15848 if required.

- Decommissioning & Disposal: Follow environmental regulations (e.g., WEEE, RoHS) for end-of-life disposal. Recycle materials where possible.

Summary

Pilot Operated Check Valves require careful attention throughout their lifecycle—from manufacturing and shipping to installation and maintenance. Adhering to international standards, maintaining full documentation, and ensuring proper handling are critical to regulatory compliance, operational safety, and project success. Always consult the valve manufacturer’s technical and compliance documentation for application-specific requirements.

Conclusion for Sourcing Pilot Operated Check Valve:

After a thorough evaluation of technical requirements, supplier capabilities, cost considerations, and reliability, sourcing pilot operated check valves from qualified suppliers is a strategic decision that supports system safety, operational efficiency, and long-term performance. These valves are essential for preventing backflow and maintaining load stability in hydraulic systems, particularly in demanding industrial and mobile applications.

The selected suppliers offer valves that meet relevant industry standards (such as ISO, ANSI, or DIN), provide reliable pilot operation, and deliver consistent performance under varying pressure conditions. Additionally, lead times, technical support, and after-sales service were key factors in the decision-making process, ensuring minimal downtime and ease of integration.

In conclusion, sourcing pilot operated check valves from reputable manufacturers not only ensures product quality and system reliability but also contributes to overall cost-effectiveness through reduced maintenance and improved operational safety. Continued monitoring of supplier performance and periodic reviews will further optimize the sourcing strategy moving forward.