The pigeon hole rack market has experienced steady growth, driven by increasing demand for organized storage solutions across educational institutions, corporate offices, logistics centers, and government facilities. According to Grand View Research, the global storage and organization products market was valued at USD 34.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by rising urbanization, space optimization needs in commercial environments, and the expansion of postal and courier services. Mordor Intelligence reinforces this trend, noting a growing preference for modular and customizable storage systems in both public and private sectors. As demand for efficient document and parcel management intensifies, pigeon hole racks have become essential infrastructure—particularly in mailrooms and reception areas. With manufacturers increasingly focusing on durability, customization, and corrosion-resistant materials like powder-coated steel, the competitive landscape is evolving rapidly. Based on market presence, product innovation, and customer reach, the following nine manufacturers have emerged as leaders in the pigeon hole rack industry.

Top 9 Pigeon Hole Rack Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 China Standard Sized Pigeon Hole Rack Manufacturers Factory …

Domain Est. 2016 | Founded: 1993

Website: aplusmetal.com

Key Highlights: Founded in 1993, A-Plus is one of the most professional pigeon hole rack manufacturers and suppliers in China. Our factory offers high quality pigeon hole rack…

#2 Pigeon Hole Racks Manufacturer India

Domain Est. 2012

Website: sigmastorage.com

Key Highlights: Sigma Racks pigeon hole racking offers efficient storage for small to medium items. Customizable and durable, it optimizes organization in various ……

#3 Pigeon Hole Rack

Domain Est. 2017

Website: prksteel.com

Key Highlights: We offer a premium range of Pigeon Hole Rack designed for safe, efficient, and space-saving usage across various industrial applications. GET TODAY’S PRICE. Key ……

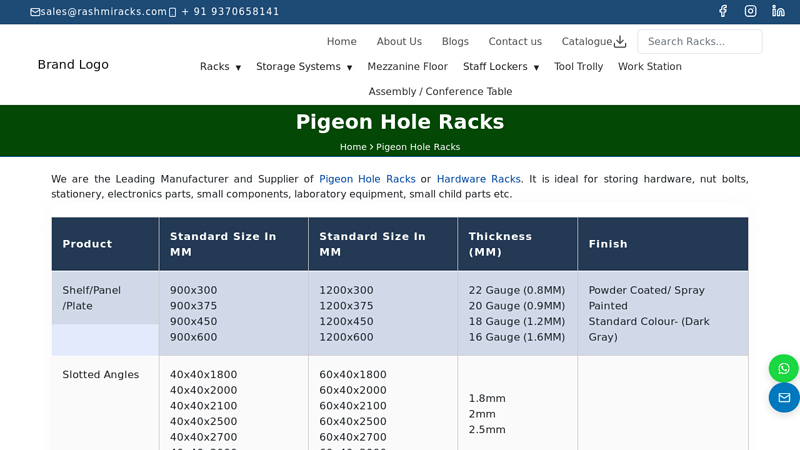

#4 Pigeon Hole Racks

Domain Est. 2020

Website: rashmiracks.com

Key Highlights: We are the Leading Manufacturer and Supplier of Pigeon Hole Racks or Hardware Racks. It is ideal for storing hardware, nut bolts, stationery, electronics parts….

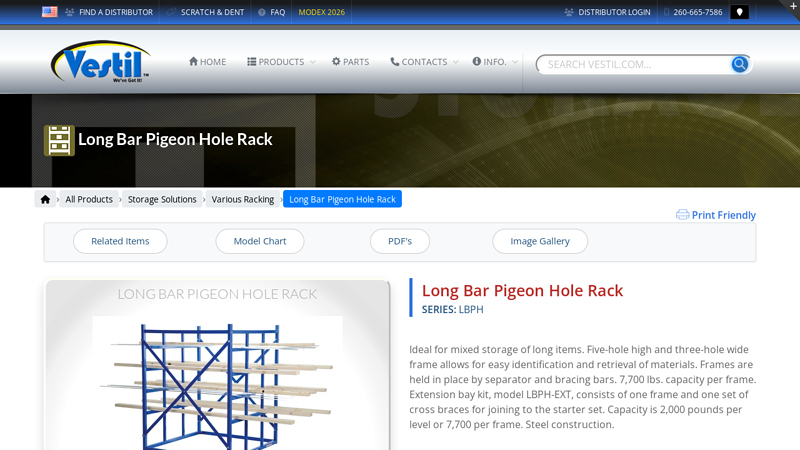

#5 Long Bar Pigeon Hole Rack

Domain Est. 1998

Website: vestil.com

Key Highlights: Ideal for mixed storage of long items. Five-hole high and three-hole wide frame allows for easy identification and retrieval of materials….

#6 Long Bar Pigeon Hole Rack

Domain Est. 1998

Website: materialflow.com

Key Highlights: In stock $364.78 deliveryEffortlessly store long items with the Vestil Long Bar Pigeon Hole Rack. 7700 lb. capacity per frame. Shop now at Material Flow for rugged steel storage….

#7 Pigeon Hole Rack In Salem

Domain Est. 2007

Website: mexstorage.com

Key Highlights: We provide a variety of Pigeon Hole Racks with an emphasis on providing top-notch solutions for your storage needs since they are made to maximize efficiency….

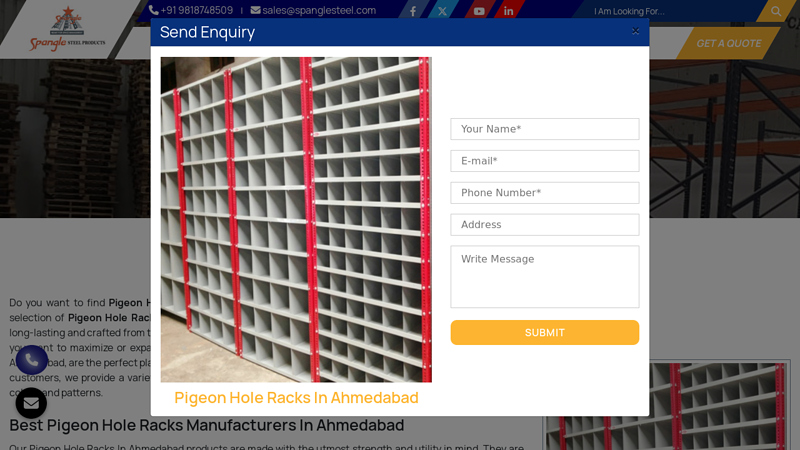

#8 Pigeon Hole Racks In Ahmedabad

Domain Est. 2012

Website: spanglesteel.in

Key Highlights: Our Pigeon Hole Racks In Ahmedabad products are made with the utmost strength and utility in mind. They are perfect for challenging and moist settings because ……

#9 1. Buy Pigeon Hole Racks

Domain Est. 2023

Website: ramanracks.com

Key Highlights: Pigeon Hole Rack Manufacturer, Raman Steel Industries offers high-quality, efficient shelving solutions for organized storage. Maximize space and efficiency ……

Expert Sourcing Insights for Pigeon Hole Rack

H2: Projected Market Trends for Pigeon Hole Racks in 2026

The global market for pigeon hole racks is expected to undergo notable transformation by 2026, driven by evolving workplace dynamics, digital integration, and rising demand in both corporate and educational sectors. Below is an analysis of key trends shaping the pigeon hole rack market in 2026:

1. Increased Adoption in Hybrid Work Environments

With hybrid and remote work models becoming standard post-pandemic, organizations are reimagining office layouts to support flexible work arrangements. Pigeon hole racks are being increasingly used to manage physical mail, packages, and internal communications for employees who work offsite part-time. These racks offer a secure, organized method for distributing items, making them essential in offices that maintain a blend of remote and in-person staff.

2. Integration with Smart Storage Solutions

By 2026, a growing number of pigeon hole racks are expected to incorporate smart technology, such as RFID tags, digital locks, and integration with internal communication platforms (e.g., Slack or Microsoft Teams). These “smart pigeon holes” can notify users via mobile apps when a new item is deposited, enhancing efficiency and security. This digital evolution caters to tech-forward organizations and logistics hubs seeking real-time tracking and access control.

3. Expansion in Educational and Healthcare Sectors

Schools, universities, and healthcare facilities are adopting pigeon hole racks for staff mail distribution, student assignment drop-offs, and internal document routing. In academic settings, racks are being customized with branding and durability to withstand high-traffic areas. In hospitals, they support internal logistics, such as distributing shift schedules or patient records (with appropriate privacy safeguards), contributing to operational efficiency.

4. Sustainable and Modular Designs

Environmental concerns are influencing product design, with manufacturers emphasizing recyclable materials (e.g., FSC-certified wood, recycled metal) and modular configurations. Modular pigeon hole racks allow for scalability and reconfiguration, appealing to businesses undergoing frequent spatial changes. This trend aligns with broader ESG (Environmental, Social, and Governance) goals adopted by enterprises globally.

5. Growth in E-Commerce and Last-Mile Delivery Hubs

As e-commerce continues to expand, pigeon hole racks are being repurposed in parcel management systems within office buildings, apartment complexes, and logistics centers. These racks serve as low-tech but effective solutions for organizing inbound and outbound deliveries, especially in urban areas with high package volume. Some models are now designed specifically for parcel handling, with larger compartments and tamper-evident features.

6. Regional Market Variations

While North America and Europe lead in smart and ergonomic pigeon hole rack adoption, the Asia-Pacific region is expected to witness the highest growth rate due to rapid urbanization, expanding corporate infrastructure, and increasing investments in office automation. Countries like India, Japan, and South Korea are integrating pigeon hole systems into government offices, educational institutions, and multinational corporations.

Conclusion

By 2026, the pigeon hole rack market will have evolved from a traditional office fixture into a strategic organizational tool, blending physical utility with digital intelligence. Driven by demands for efficiency, security, and sustainability, the market is poised for innovation and geographic expansion, ensuring continued relevance in both analog and digital workspaces.

Common Pitfalls When Sourcing Pigeon Hole Racks (Quality, IP)

-

Overlooking Material Quality and Durability

A frequent mistake is selecting pigeon hole racks made from low-grade materials such as particleboard or thin metal that warp, rust, or degrade quickly under daily use. This compromises both structural integrity and longevity, especially in high-traffic environments like offices or warehouses. -

Inadequate Assessment of Load Capacity

Buyers often fail to verify the weight capacity per compartment. Exceeding load limits can lead to sagging shelves or complete rack failure, posing safety risks and reducing operational efficiency. -

Ignoring IP (Intellectual Property) Risks

Sourcing from manufacturers without proper design rights or patents can expose businesses to legal issues, especially if the rack design is a protected innovation. Using counterfeit or copied designs may result in infringement claims, fines, or forced product recalls. -

Compromising on Finish and Corrosion Resistance

Poor surface treatments (e.g., substandard powder coating or lack of galvanization) make racks vulnerable to scratches, moisture, and corrosion—particularly problematic in humid or industrial settings where IP-rated durability is essential. -

Lack of Standardization and Dimensional Accuracy

Inconsistent sizing or poor manufacturing tolerances can lead to misalignment, inefficient space utilization, and difficulty integrating with existing storage systems, reducing overall functionality. -

Neglecting Supplier Verification and Certifications

Failing to audit suppliers for quality management systems (e.g., ISO 9001) or material certifications increases the risk of receiving subpar products. Unverified suppliers may also cut corners on IP compliance and quality control. -

Underestimating Environmental and Usage Conditions

Choosing a rack not suited for the intended environment—such as using non-IP-rated components in outdoor or dusty areas—leads to premature wear and failure. Ensure the rack meets appropriate Ingress Protection (IP) standards when exposed to water, dust, or chemicals. -

Focusing Solely on Upfront Cost

Prioritizing low price over total cost of ownership often results in frequent replacements and higher long-term expenses. Investing in higher-quality, IP-compliant racks reduces maintenance and downtime.

Logistics & Compliance Guide for Pigeon Hole Rack

Product Overview

The Pigeon Hole Rack is a modular storage solution designed for efficient organization in offices, warehouses, educational institutions, and retail environments. It typically features multiple compartments (or “pigeonholes”) arranged in a grid pattern, facilitating the sorting of mail, documents, packages, or small goods. This guide outlines logistics handling procedures and compliance considerations to ensure safe, efficient, and regulatory-compliant operations.

Dimensions & Weight Specifications

- Standard Unit Dimensions: Vary by model (e.g., 600mm W × 400mm D × 1800mm H)

- Weight (Empty): Typically 25–40 kg depending on material (steel, wood, or composite)

- Load Capacity per Compartment: 5–10 kg (verify model-specific ratings)

- Stacking Capability: Confirm manufacturer guidelines—some models are stackable, others require wall mounting

Ensure transport vehicles and storage areas accommodate these dimensions and weight loads.

Packaging & Handling Instructions

- Packaging: Shipped flat-packed in recyclable cardboard with protective corner guards. Components include panels, shelves, fasteners, and assembly hardware.

- Handling: Use two-person lift for assembled units. Avoid dragging; use hand trucks or pallet jacks for floor movement.

- Storage Precautions: Store in dry, indoor conditions. Avoid exposure to moisture, extreme temperatures, or direct sunlight to prevent warping or corrosion.

- Assembly: Follow included instructions. Use appropriate tools; do not overtighten fasteners.

Transportation Guidelines

- Inbound Logistics:

- Palletized shipments with stretch-wrapping recommended.

- Maximum stack height: 2–3 layers per pallet (verify with supplier).

- Secure load with straps during transit.

- Last-Mile Delivery:

- Notify recipients in advance for large deliveries.

- Curbside delivery standard; white-glove service available if specified.

- International Shipping:

- Compliant with ISPM 15 for wooden components (if applicable).

- Provide commercial invoice, packing list, and HS code (e.g., 9403.60 for metal storage furniture).

Regulatory & Safety Compliance

- Fire Safety:

- Material must meet local fire codes (e.g., ASTM E84 Class B for flammability if used in commercial buildings).

- Avoid placement in fire exits or blocking emergency pathways.

- Structural Safety:

- Anchor to wall if installed in seismic zones (per IBC standards).

- Do not exceed maximum load per compartment.

- Accessibility (ADA Compliance):

- Ensure bottom compartments are no lower than 9 inches from the floor and top compartments no higher than 48 inches for ADA-compliant installations.

- Electrical Clearance: Maintain minimum 30 cm clearance from electrical panels or outlets.

Environmental & Sustainability Compliance

- Materials:

- Steel models: Recyclable; check for REACH and RoHS compliance (EU).

- Wood models: Sourced from FSC-certified forests where applicable.

- End-of-Life Disposal:

- Separate materials for recycling.

- Follow local WEEE or waste management regulations for metal and composite parts.

- Carbon Footprint: Optimize delivery routes and consolidate shipments to reduce emissions.

Import/Export Requirements

- Documentation:

- Bill of Lading, Commercial Invoice, Packing List, Certificate of Origin.

- Test reports (e.g., for heavy metals if entering EU or California).

- Customs Classification:

- HS Code: 9403.60 (Other furniture and parts, of iron or steel) or 9403.40 (of wood), depending on material.

- Duties & Tariffs: Check local tariff schedules; some regions offer preferential rates under trade agreements (e.g., USMCA, RCEP).

Installation & Workplace Compliance

- Workplace Safety (OSHA/Local Regulations):

- Ensure stable placement to prevent tipping.

- Maintain clear walkways (minimum 80 cm width).

- Labeling: Clearly label compartments to avoid mis-sorting in mailrooms or logistics hubs.

- Maintenance: Inspect regularly for loose fittings, rust, or structural wear. Replace damaged parts promptly.

Warranty & Support

- Standard Warranty: 1–5 years on materials and workmanship (varies by supplier).

- Claim Process: Register product online; provide proof of purchase and photos of defect.

- Customer Support: Contact logistics team for delivery issues; technical support for assembly or compliance queries.

Summary

Proper logistics handling and regulatory compliance ensure the safe and efficient use of Pigeon Hole Racks across diverse environments. Adherence to packaging, transportation, safety, and environmental standards minimizes risks and supports sustainable operations. Always consult the manufacturer’s specifications and local regulations before installation and use.

Conclusion for Sourcing Pigeon Hole Rack:

After evaluating various suppliers, materials, pricing, durability, and customization options, it is evident that sourcing pigeon hole racks requires a balanced approach between quality, functionality, and cost-effectiveness. The ideal supplier should offer sturdy construction—preferably using durable materials such as wood, metal, or high-grade plastic—combined with a modular design that allows for easy installation and scalability. Additionally, factors such as lead time, after-sales service, and adherence to specifications play a crucial role in ensuring seamless integration into the intended environment, whether for office mail organization, educational institutions, or retail settings.

Considering long-term value over initial cost, it is recommended to partner with a reliable vendor who provides product customization, competitive pricing, and consistent quality control. Finalizing the sourcing decision should include sample testing, supplier verification, and clear communication of delivery and installation requirements. Ultimately, a well-sourced pigeon hole rack enhances organizational efficiency and contributes to a professional, clutter-free workspace.