The global demand for fermented food products, including pickles, has driven significant growth in the food processing equipment sector, particularly for specialized storage and fermentation solutions like pickle barrels. According to Grand View Research, the global fermented food market size was valued at USD 647.2 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 5.7% from 2024 to 2030. This surge in demand is fueled by rising consumer awareness of gut health and clean-label products, prompting commercial producers to scale up production with reliable, food-grade fermentation systems. As a result, manufacturers of pickle barrels—ranging from traditional wooden casks to modern food-grade polymer tanks—are experiencing increased demand for hygienic, durable, and scalable solutions. In this competitive landscape, eight key manufacturers have emerged as leaders, combining innovation, material quality, and engineering precision to meet the evolving needs of artisanal and industrial pickle producers worldwide.

Top 8 Pickle Barrels Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Frequently Asked Questions

Domain Est. 1996

Website: mtolivepickles.com

Key Highlights: Get answers to your pickles questions. Check out our frequently asked questions (FAQs) to learn everything there is to know about Mt. Olive Pickle Company….

#2 Black Screw Top Pickle Barrels

Domain Est. 2009

Website: lexingtoncontainercompany.com

Key Highlights: These Screw Top Barrels are Very Thick. and Durable with Solid 1 Piece Lids. ; Pickle Barrels. come with. 2 piece lids. & screen ; Olive Barrels. come with. 2 ……

#3 Pickles & Sauerkraut

Domain Est. 2015

Website: kraftheinz.com

Key Highlights: Juicy, bold and always crunchy. Uncap a jar of Claussen today. Choose from classic kosher pickles, zesty dill pickles, hot gherkins, or even sauerkraut….

#4 Recipe Unlimited

Domain Est. 2017

Website: recipeunlimited.com

Key Highlights: Recipe Unlimited Corporation is Canada’s leading full service restaurant company. We are a nationally recognized franchisor of choice with 1200+ restaurants….

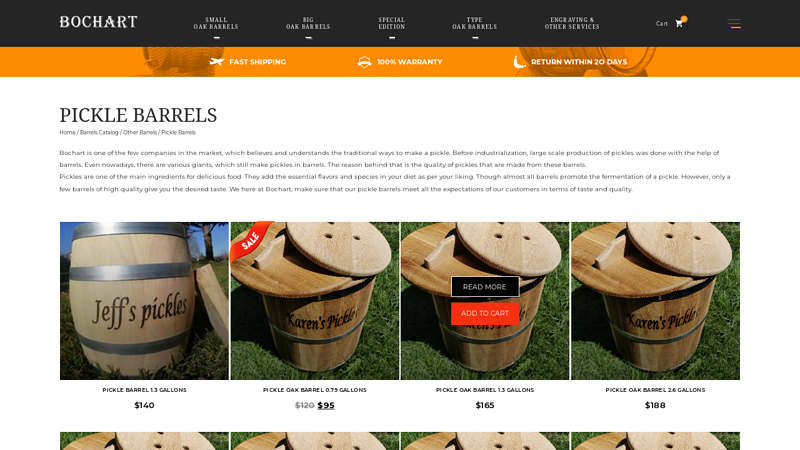

#5 Pickle Barrels — Bochart

Domain Est. 2019

#6 Pickle Barrels

Domain Est. 2021

#7 Pickle Barrel 20 L

Domain Est. 2022

Website: bonpos.cz

Key Highlights: Rating 4.5 (5) Pickle Barrel with a volume of 20 liters is ideal for salting a variety of foods – vegetables, mushrooms, meat, fish or berries. A container made of natural ……

#8 Bochart Barrels

Domain Est. 2023

Website: bochartbarrels.com

Key Highlights: Bochart, a distinguished purveyor of European Oak barrels, is committed to upholding the highest standards of craftsmanship and customer satisfaction….

Expert Sourcing Insights for Pickle Barrels

H2: Projected 2026 Market Trends for Pickle Barrels

As consumer preferences shift toward sustainability, artisanal products, and home food preservation, the market for pickle barrels is poised for notable evolution by 2026. Once primarily associated with commercial foodservice and traditional fermentation, pickle barrels—particularly wooden and eco-conscious models—are regaining popularity across multiple sectors, including residential, specialty food production, and experiential retail.

-

Growth in Artisanal and Fermented Foods

The continued expansion of the fermented foods market—driven by consumer interest in gut health, probiotics, and functional foods—is a key driver for pickle barrel demand. By 2026, the global fermented foods market is projected to exceed $700 billion, with fermented vegetables like pickles playing a significant role. Artisanal producers and small-batch fermenters are increasingly adopting traditional wooden pickle barrels to differentiate their products and appeal to premium markets. -

Sustainability and Eco-Friendly Materials

Environmental concerns are shaping purchasing decisions. Consumers and businesses alike are favoring reusable, biodegradable, and non-plastic storage solutions. Wooden pickle barrels, especially those made from sustainably sourced oak or cedar, align with zero-waste and circular economy trends. This shift is expected to boost demand for high-quality, handcrafted barrels over plastic or metal alternatives. -

Home Fermentation Movement

The DIY food movement continues to grow, with more households embracing home fermentation for health, cost savings, and culinary creativity. In 2026, online tutorials, fermentation kits, and specialty retailers are likely to include pickle barrels as core components of home fermentation setups. Expect increased demand for smaller, user-friendly barrels designed for residential use. -

Commercial and Hospitality Sector Adoption

Restaurants, farm-to-table establishments, and craft food halls are incorporating visible fermentation stations—often featuring pickle barrels—as part of their branding and customer experience. By 2026, the use of pickle barrels in commercial kitchens for both function and aesthetic appeal is expected to rise, especially in niche markets like sourdough bakeries, kombucha bars, and specialty delis. -

Regional Market Expansion

While North America and Western Europe lead in fermented food innovation, emerging markets in Asia-Pacific and Latin America are beginning to adopt Western-style fermented vegetables and fermentation tools. By 2026, export opportunities for pickle barrels—especially heritage or customized designs—are anticipated to grow, supported by e-commerce platforms and global logistics. -

Innovation and Hybrid Designs

Manufacturers are responding to market demands with hybrid pickle barrels that combine traditional wood with modern food-safe linings or modular components for easier cleaning and maintenance. These innovations are expected to broaden the appeal of pickle barrels beyond purists, making them accessible to a wider consumer base.

Conclusion:

By 2026, the pickle barrel market will likely transition from a niche, industrial tool to a symbol of sustainable living, artisanal craftsmanship, and holistic wellness. With rising interest in fermentation and eco-conscious consumption, pickle barrels are set to experience renewed relevance across both home and commercial applications, supported by innovation and global market expansion.

Common Pitfalls When Sourcing Pickle Barrels (Quality and Intellectual Property)

Sourcing pickle barrels, especially for commercial or branded food production, involves more than just finding a supplier. Overlooking key quality and intellectual property (IP) concerns can lead to product spoilage, legal disputes, and reputational damage. Below are common pitfalls to avoid.

Poor Material Quality and Construction

One of the most frequent issues is selecting barrels made from substandard materials. Pickle barrels must resist acidity, moisture, and long-term fermentation without leaching harmful substances. Barrels made from low-grade wood, improper sealants, or non-food-grade plastics can compromise food safety, alter flavor, or lead to premature barrel failure.

Lack of Food-Grade Certification

Not all barrels are suitable for food storage. Sourcing barrels without proper food-grade certifications (such as FDA compliance or NSF approval) risks contamination. Non-certified barrels may contain chemicals or glues that are unsafe for direct food contact, violating health regulations and endangering consumers.

Inadequate Sealing and Leakage Risks

Poorly sealed barrels can leak brine, leading to product loss, mess, and potential microbial contamination. Barrels with inconsistent stave alignment or weak hoops are prone to warping or splitting, especially under pressure from fermentation gases. This undermines both product quality and operational efficiency.

Misunderstanding Barrel Origin and IP Rights

When sourcing branded or uniquely designed pickle barrels (e.g., those with proprietary shapes, logos, or patented features), failing to verify intellectual property rights can lead to legal exposure. Using barrels that incorporate patented designs or trademarked elements without authorization may result in infringement claims, especially if the barrels are visible in packaging or marketing.

Sourcing from Unverified Suppliers

Engaging with suppliers lacking transparency about manufacturing processes or material sourcing increases risk. Unverified vendors may offer counterfeit or imitation barrels that mimic reputable brands. These not only lack performance guarantees but may also violate IP laws, exposing the buyer to liability.

Overlooking Custom Design IP Ownership

If you commission custom-designed pickle barrels, failing to secure written agreements on IP ownership is a critical oversight. Without clear contracts, the supplier may retain rights to the design, limiting your ability to reproduce, modify, or protect the barrel design in the future.

Assuming All “Oak” Barrels Are Equal

Not all oak barrels are created equal—species (e.g., white oak vs. red oak), seasoning methods, and toasting levels affect flavor and durability. Sourcing without understanding these nuances can result in barrels that impart undesirable tastes or fail to meet performance expectations.

Ignoring Sustainability and Chain-of-Custody Documentation

For brands emphasizing sustainability, sourcing barrels without proper forestry certifications (e.g., FSC) can undermine environmental claims. Additionally, lack of documentation in the supply chain may raise red flags during audits or when verifying compliance with import regulations.

Avoiding these pitfalls requires due diligence in vetting suppliers, insisting on certifications, and securing clear IP agreements—especially when custom or branded elements are involved.

Logistics & Compliance Guide for Pickle Barrels

Overview

Transporting and storing pickle barrels involves unique logistical and compliance considerations due to the nature of the product—brined cucumbers in large containers. This guide outlines best practices for safe handling, transportation, storage, and regulatory compliance.

Container Specifications

Pickle barrels are typically made of food-grade plastic (HDPE) or oak and range from 55 to 110 gallons. Ensure barrels are:

– Certified for food contact (FDA compliant in the U.S.)

– Free from cracks, leaks, or contamination

– Properly sealed with tamper-evident lids

– Labeled with contents, batch number, production date, and allergen information

Handling & Storage

- Store barrels upright in a cool, dry, and well-ventilated area (ideally 32–50°F / 0–10°C)

- Avoid direct sunlight and extreme temperatures to prevent fermentation or spoilage

- Stack no more than two high unless designed for multi-tier stacking

- Use appropriate equipment (e.g., pallet jacks, barrel movers) to prevent injury or damage

- Maintain a first-in, first-out (FIFO) inventory system

Transportation Requirements

- Secure barrels on pallets using straps or shrink wrap to prevent shifting

- Use refrigerated (reefer) trucks for long-haul transport to maintain temperature control

- Ensure vehicles are clean and sanitized before loading

- Minimize vibration and rough handling to avoid leaks or structural damage

- Transport documentation must include bill of lading, temperature logs (if applicable), and safety data (if brine contains regulated chemicals)

Regulatory Compliance

- Comply with FDA Food Safety Modernization Act (FSMA) requirements for safe food transportation

- Follow Good Manufacturing Practices (GMPs) and Hazard Analysis Critical Control Point (HACCP) protocols

- Adhere to local, state, and federal labeling regulations (e.g., FDA, USDA, CFIA in Canada)

- Maintain records of supplier certifications, inspections, and batch traceability for at least 2 years

Import/Export Considerations

- Ensure barrels meet destination country’s food safety standards (e.g., EU EFSA, Health Canada)

- Provide accurate Harmonized System (HS) codes (e.g., 2001.10 for preserved cucumbers)

- Include phytosanitary certificates if required

- Comply with customs documentation and tariffs

Safety & Environmental Precautions

- Train personnel in safe handling and emergency response (e.g., brine spills)

- Use proper PPE (gloves, safety goggles) when opening or transferring contents

- Dispose of damaged barrels or waste brine in accordance with local environmental regulations

- Recycle or repurpose barrels where possible using certified waste management services

Quality Assurance

- Conduct routine visual and microbial inspections

- Monitor pH and salt concentration of brine to ensure product safety

- Perform leak tests before shipment

- Maintain audit trails for all compliance and quality control activities

Emergency Procedures

- In case of spill: contain brine, neutralize if necessary, clean with approved sanitizers, and report per local regulations

- In case of contamination: quarantine affected barrels, investigate root cause, and notify relevant authorities if required

Adhering to this guide ensures the safe, legal, and efficient movement of pickle barrels across the supply chain while protecting product integrity and consumer safety.

In conclusion, sourcing pickle barrels requires careful consideration of material quality, supplier reliability, cost-effectiveness, and compliance with food safety standards. Whether opting for traditional wooden barrels or modern food-grade plastic containers, it is essential to prioritize durability, sanitation, and proper storage conditions to maintain product integrity. Building relationships with reputable suppliers, evaluating long-term needs, and considering sustainability can further enhance the efficiency and quality of the sourcing process. By taking a strategic and informed approach, businesses can ensure a consistent supply of suitable pickle barrels that support both operational success and product excellence.