The global market for PEX (cross-linked polyethylene) plumbing components, including one-way valves, is experiencing steady growth driven by increasing demand for durable, corrosion-resistant, and cost-effective piping solutions in residential, commercial, and industrial construction. According to Grand View Research, the global PEX pipe market size was valued at USD 4.9 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.8% from 2023 to 2030. This growth is fueled by rising urbanization, infrastructure modernization, and favorable building codes promoting the use of flexible plumbing systems in regions like North America and Europe. With the surge in retrofitting projects and the adoption of radiant heating systems—where PEX piping and associated components like one-way (check) valves are essential—the need for reliable, high-performance valve manufacturers has never been greater. As the ecosystem evolves, eight key manufacturers have emerged as leaders in innovation, quality, and market reach, setting the benchmark in PEX one-way valve production.

Top 8 Pex One Way Valve Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Legend Valve

Domain Est. 1996

Website: legendvalve.com

Key Highlights: Legend provides high quality valves and fittings for plumbing, industrial, commercial and residential markets….

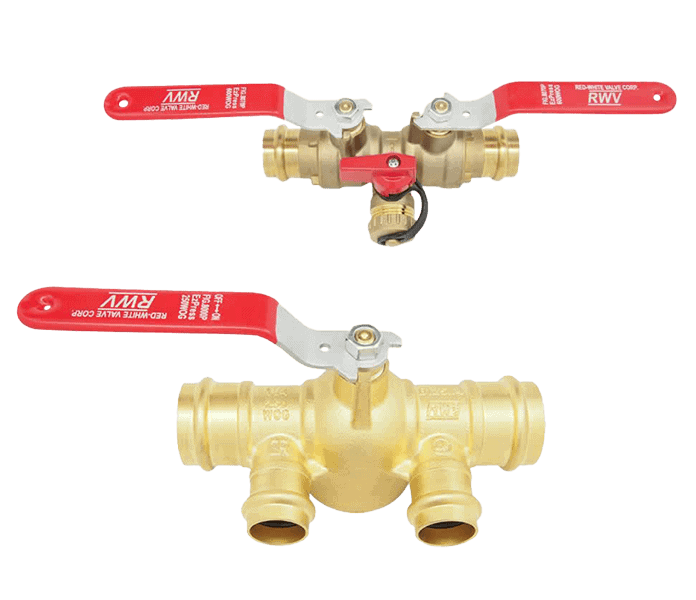

#2 RED-WHITE VALVE CORP.

Domain Est. 2008

Website: redwhitevalvecorp.com

Key Highlights: RED-WHITE VALVE CORP. manufactures a wide range of products using the finest Lead Free alloys available. All of our Lead Free valves are fully tested and ……

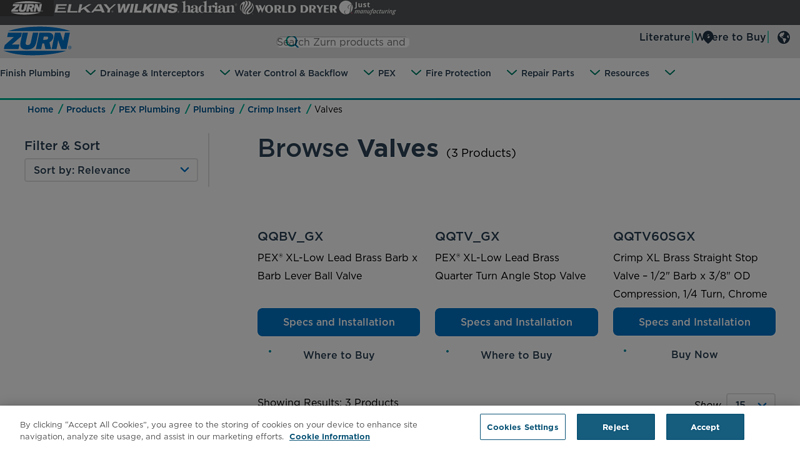

#3 Valves

Domain Est. 1995

Website: zurn.com

Key Highlights: Zurn manufactures a full line of Valves to be used with PEX Plumbing products. Discover the list of features and benefits….

#4 Uponor

Domain Est. 1996

Website: uponor.com

Key Highlights: Uponor offers durable PEX piping, fittings, and other products for plumbing, radiant heating and cooling. Learn why PEX is preferred by plumbers, ……

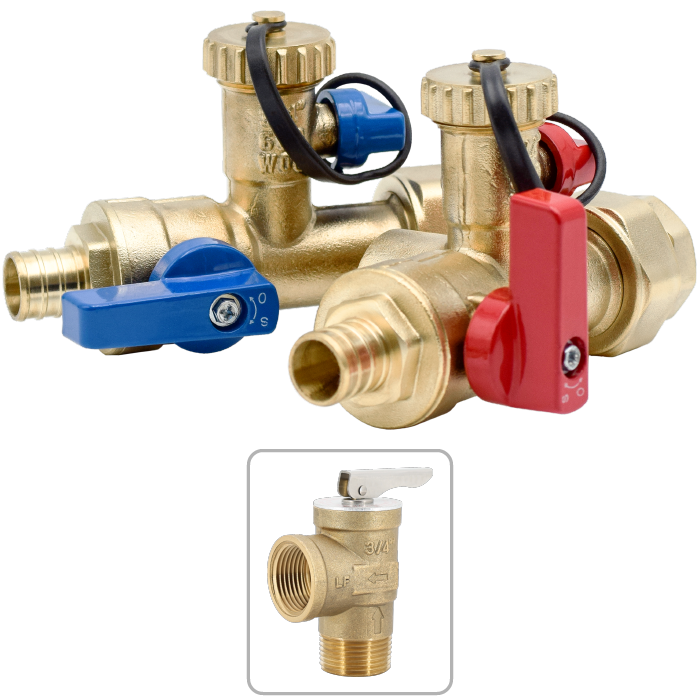

#5 Webstone

Domain Est. 1996

Website: nibco.com

Key Highlights: Webstone products include innovative designs of residential and commercial valves used in plumbing, hydronic, radiant, solar, and geothermal applications….

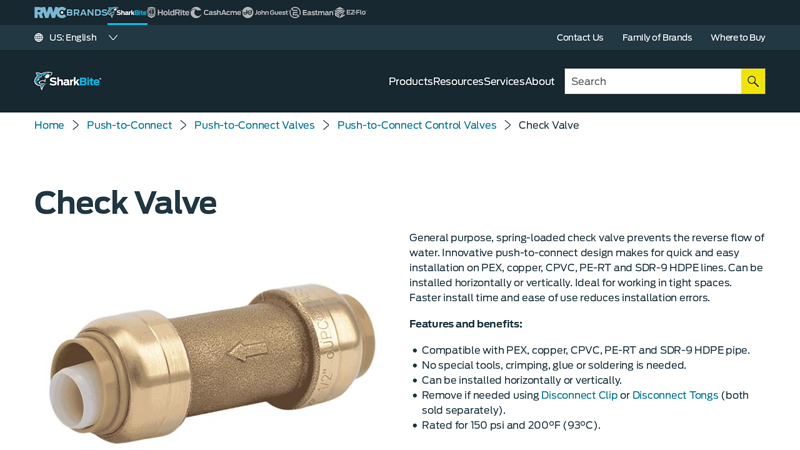

#6 Check Valve: Reverse Water Flow Protection

Domain Est. 2003

Website: sharkbite.com

Key Highlights: SharkBite Max check valves are designed to prevent the reverse flow of water, compatible with PEX, copper, CPVC, PE-RT or HDPE SDR-9 pipe….

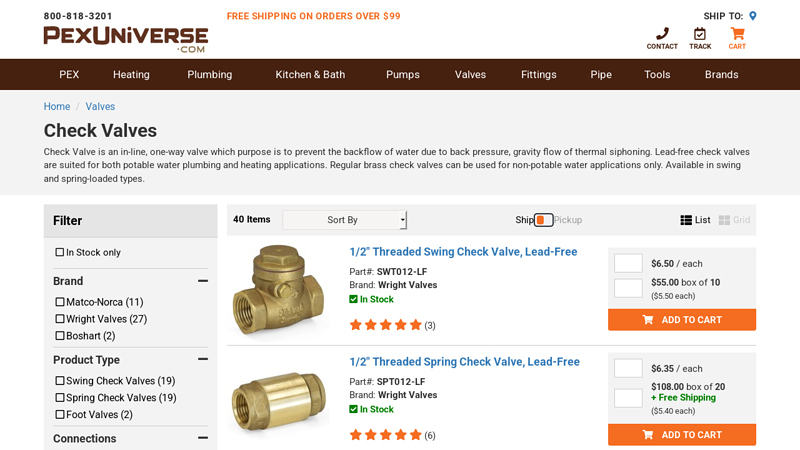

#7 Inline Check Valves

Domain Est. 2009

Website: pexuniverse.com

Key Highlights: Free delivery over $99Check Valve is an in-line, one-way valve which purpose is to prevent the backflow of water due to back pressure, gravity flow of thermal siphoning….

#8 PVC & ABS Backwater Valve Systems

Domain Est. 2009

Website: ipexna.com

Key Highlights: Available in ABS and PVC, IPEX Backwater Valves offer simple and effective protection against backflow of sewage and storm water into homes and businesses….

Expert Sourcing Insights for Pex One Way Valve

H2: 2026 Market Trends for Pex One-Way Valves

The global market for PEX (cross-linked polyethylene) one-way valves is poised for significant evolution by 2026, driven by advancements in plumbing technology, growing demand for energy-efficient building systems, and increased adoption of PEX piping in residential and commercial construction. These valves, designed to prevent backflow in PEX plumbing systems, are becoming increasingly integral to modern water distribution networks due to their reliability, corrosion resistance, and compatibility with flexible piping.

Key trends shaping the PEX one-way valve market in 2026 include:

-

Rising Adoption of PEX Plumbing Systems

The shift from traditional copper and PVC piping to PEX across North America, Europe, and parts of Asia-Pacific continues to accelerate. PEX offers superior freeze resistance, lower installation costs, and easier maneuverability around structures. This widespread adoption directly boosts demand for compatible components like one-way valves, particularly in new construction and retrofitting projects. -

Focus on Water Conservation and Building Codes

Regulatory bodies are increasingly mandating backflow prevention in plumbing systems to ensure water quality and safety. As green building standards such as LEED and WELL gain traction, the integration of one-way valves in PEX systems becomes essential to meet compliance. This regulatory push is expected to drive product innovation and market penetration by 2026. -

Technological Integration and Smart Plumbing

The emergence of smart home technologies is influencing valve design. By 2026, manufacturers are anticipated to introduce PEX one-way valves with integrated sensors or compatibility with building management systems (BMS), allowing for real-time monitoring of flow direction and leak detection. This trend supports predictive maintenance and enhances system efficiency. -

Growth in Residential and Multifamily Construction

Housing market recovery in key regions, especially the U.S. and Germany, along with increasing investments in multifamily and affordable housing, will expand the use of cost-effective PEX solutions. One-way valves are critical in recirculating hot water systems common in multifamily buildings, further stimulating demand. -

Regional Market Expansion

While North America remains the largest market due to mature PEX adoption, Europe and Asia-Pacific are expected to see the highest growth rates by 2026. Countries like India, Japan, and South Korea are modernizing infrastructure and embracing flexible plumbing solutions, creating new opportunities for PEX valve manufacturers. -

Sustainability and Material Innovation

Environmental concerns are pushing manufacturers to develop recyclable or bio-based PEX components. By 2026, expect to see one-way valves made with reduced carbon footprints and improved longevity, aligning with circular economy goals in construction.

In conclusion, the 2026 outlook for PEX one-way valves is highly favorable, supported by infrastructural modernization, regulatory developments, and technological innovation. Companies that invest in R&D, comply with international standards, and expand into emerging markets are likely to gain a competitive edge in this growing niche of the fluid control industry.

Common Pitfalls When Sourcing Pex One-Way Valves (Quality and IP)

Sourcing PEX one-way valves—critical components in plumbing and radiant heating systems—requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these aspects can lead to system failures, compliance issues, and legal risks. Below are the most common pitfalls to avoid.

1. Compromising on Material Quality

One of the most frequent mistakes is selecting valves made from substandard materials. Low-quality PEX or brass components may degrade quickly under temperature and pressure fluctuations, leading to leaks or valve failure. Look for valves compliant with ASTM F1807 or ASTM F2159 standards and ensure the materials are rated for potable water use.

2. Ignoring Pressure and Temperature Ratings

Not all PEX check valves are created equal. Sourcing a valve without verifying its pressure (PSI) and temperature (°F/°C) ratings for the intended application can result in premature failure. Always match the valve’s specifications to your system’s operating conditions, especially in hydronic heating or high-rise buildings.

3. Overlooking Third-Party Certifications

Failing to verify third-party certifications such as NSF/ANSI 61 (for drinking water safety) or CSA B125.1 can lead to non-compliant installations. Reputable suppliers provide documentation; always request test reports or certification listings before procurement.

4. Falling for Counterfeit or Knock-Off Products

The market is flooded with imitation valves that mimic well-known brands. These knock-offs often lack proper engineering, durability, and safety testing. Be cautious of unusually low prices and ambiguous supplier origins. Stick to authorized distributors and verify product authenticity through batch numbers or manufacturer databases.

5. Neglecting Intellectual Property (IP) Risks

Sourcing valves that infringe on patented designs or trademarks exposes buyers and contractors to legal liability. Some manufacturers replicate patented valve mechanisms (e.g., spring-loaded designs or specific flow geometries) without licensing. Always confirm that the product does not violate existing IP rights—review patent databases or request IP indemnification from suppliers.

6. Inadequate Supply Chain Transparency

Lack of visibility into the manufacturing origin and supply chain increases risks related to quality control and ethical sourcing. Suppliers unwilling to disclose factory information or audit trails may be sourcing from unregulated facilities with inconsistent quality standards.

7. Poor Valve Design Leading to Flow Restriction

Some low-cost PEX check valves feature suboptimal internal geometry, causing unnecessary flow resistance or water hammer. Ensure the valve design supports smooth, full-flow operation and is suitable for the pipe size being used (e.g., ½”, ¾”).

8. Skipping Field Testing and Sample Evaluation

Procuring large quantities without testing a sample unit in real-world conditions can result in system-wide issues. Always evaluate performance, ease of installation, and durability with a pilot batch before full-scale deployment.

By addressing these pitfalls proactively, buyers can ensure reliable performance, regulatory compliance, and protection from legal and operational risks when sourcing PEX one-way valves.

Logistics & Compliance Guide for Pex One Way Valve

This guide outlines the essential logistics and compliance considerations for the handling, transportation, storage, and regulatory adherence of Pex One Way Valves. Proper procedures ensure product integrity, safety, and conformity with international and regional standards.

Product Overview and Specifications

The Pex One Way Valve is designed for use in plumbing and heating systems utilizing PEX (cross-linked polyethylene) piping. It allows fluid flow in one direction only, preventing backflow and protecting system components. Key specifications include material composition (typically brass, stainless steel, or engineered thermoplastics), temperature and pressure ratings, connection types (e.g., crimp, clamp, or push-fit), and applicable standards (e.g., ASTM, NSF, ISO).

Packaging and Labeling Requirements

Pex One Way Valves must be packaged in moisture-resistant, shock-absorbent materials to prevent damage during transit. Individual units or bulk packs should be sealed and placed in labeled cartons. Labels must include product name, model number, batch/lot number, quantity, manufacturer details, country of origin, and handling symbols (e.g., “Fragile,” “This Way Up”). Compliance with GHS labeling may be required if associated with chemical exposure risks during installation.

Storage Conditions

Valves should be stored in a dry, temperature-controlled environment with temperatures between 40°F (5°C) and 100°F (38°C). Avoid prolonged exposure to direct sunlight, UV radiation, or extreme humidity, which may degrade polymer components. Store horizontally on pallets, away from chemicals, solvents, and corrosive materials. Ensure warehouse practices follow FIFO (First In, First Out) inventory management.

Transportation Guidelines

Use enclosed, climate-controlled vehicles for long-distance or international shipping to prevent exposure to moisture and temperature extremes. Secure loads to prevent shifting during transit. For air freight, comply with IATA Dangerous Goods Regulations if applicable (typically not required for inert plumbing components). For sea freight, follow IMDG Code guidelines and protect cargo from saltwater exposure. Use pallets and shrink wrap to stabilize unit loads.

Import/Export Compliance

Verify compliance with destination country regulations before shipment. Key documentation includes commercial invoice, packing list, bill of lading/air waybill, and certificate of origin. The Pex One Way Valve may require conformity assessment under local plumbing codes (e.g., UPC in the U.S., WRAS in the UK, DVGW in Germany). Ensure products meet CE marking requirements for EU markets and NSF/ANSI 61 certification for potable water applications where applicable.

Regulatory and Certification Standards

Pex One Way Valves used in potable water systems must comply with health and safety standards such as NSF/ANSI 61 (Drinking Water System Components) and NSF/ANSI 372 (Lead Content). In Europe, compliance with EN 13949 (plumbing valves) and the Construction Products Regulation (CPR) may apply. Maintain up-to-date test reports and certification documentation for audit purposes. Confirm RoHS and REACH compliance for shipments to the EU.

Quality Control and Traceability

Implement a traceability system linking each valve batch to manufacturing records, inspection reports, and test certifications. Conduct periodic quality audits of production and packaging processes. Retain documentation for a minimum of 10 years to support warranty claims and regulatory inquiries. Use serialized labeling where required for high-risk applications.

Environmental and Disposal Considerations

Dispose of packaging materials in accordance with local recycling regulations. While Pex One Way Valves are not classified as hazardous waste, end-of-life units should be handled according to municipal e-waste or metal/plastic recycling programs. Manufacturers should comply with WEEE directives in applicable regions and provide take-back options if mandated.

Incident Reporting and Recalls

Establish a clear protocol for reporting defects, non-conformances, or safety incidents related to the valves. In the event of a product recall, notify relevant regulatory bodies (e.g., CPSC in the U.S., RAPEX in the EU) and coordinate with distributors to remove affected batches from the supply chain. Maintain a recall communication plan and customer notification system.

Conclusion for Sourcing PEX One-Way Valve:

After evaluating various suppliers, product specifications, cost considerations, and performance requirements, sourcing a PEX one-way (check) valve should prioritize reliability, compatibility with existing PEX plumbing systems, and compliance with relevant industry standards (such as ASTM and NSF/ANSI 61). Key factors in the final decision include durability, ease of installation (e.g., crimp vs. expansion system compatibility), resistance to scaling or jamming, and long-term leak prevention.

Based on the assessment, it is recommended to source PEX one-way valves from reputable manufacturers with proven track records in plumbing components—such as Watts, Viega, or Uponor—to ensure quality and system integrity. Additionally, consolidating supply through distributors offering bulk pricing and technical support can enhance cost-efficiency and reduce lead times.

In summary, a strategic sourcing approach focusing on quality, compatibility, and supplier reliability will ensure optimal performance of PEX one-way valves in residential, commercial, or radiant heating applications, minimizing maintenance issues and supporting long-term system efficiency.