The global market for precision cutting tools, including blades tailored for materials like Perspex (acrylic), is experiencing steady growth driven by rising demand in industries such as signage, architecture, automotive, and electronics. According to Grand View Research, the global industrial blades and cutting tools market was valued at USD 12.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by increasing automation in manufacturing and the need for high-precision cutting solutions capable of handling brittle, thermoplastic materials like Perspex without chipping or melting. As acrylic fabrication becomes more prevalent across design and industrial applications, the demand for specialized blades—engineered for smooth, burr-free cuts—has intensified. This has led to a surge in innovation among manufacturers producing diamond-tipped, carbide, and multi-toothed blades optimized for high-speed routers and CNC machines. In this competitive landscape, a select group of manufacturers has emerged as leaders, combining advanced materials science with precision engineering to deliver superior cutting performance. Based on market presence, product innovation, and technical capabilities, the following eight companies represent the forefront of Perspex cutting blade manufacturing worldwide.

Top 8 Perspex Cutting Blade Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial XTreme plexiglass and plastic circular saw blades

Domain Est. 2010

Website: cmtorangetools.com

Key Highlights: Looking for Industrial XTreme plexiglass and plastic circular saw blades 222.us? You will find them in the Industrial saw blades section of the CMT Orange …Missing: perspex manu…

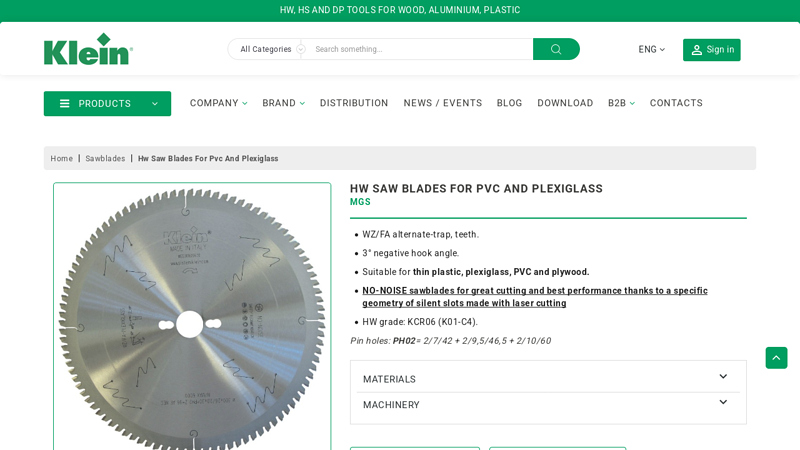

#2 hw saw blades for pvc and plexiglass

Domain Est. 1998

Website: sistemiklein.com

Key Highlights: Suitable for thin plastic, plexiglass, PVC and plywood. NO-NOISE sawblades for great cutting and best performance thanks to a specific geometry of silent slots …Missing: perspex…

#3 Tenryu Saw Mfg. Co., Ltd.

Domain Est. 2000

Website: tenryu-saw.com

Key Highlights: Tenryu Saw Mfg. Co., Ltd. Manufacturing, processing and sales of saws and blades, manufacturing, processing and sales of machinery and equipment for lumber, ……

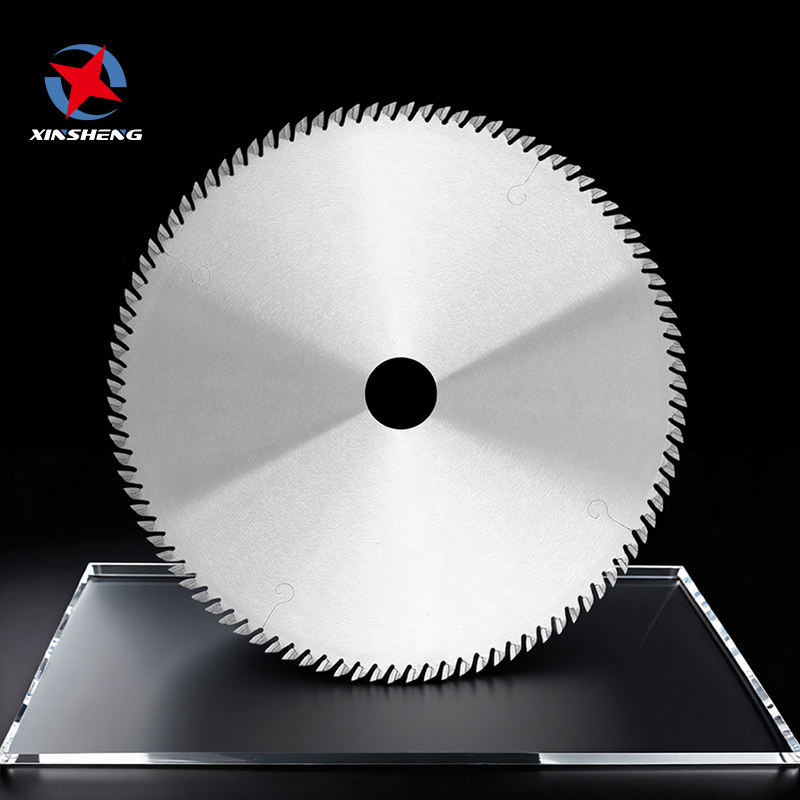

#4 Circular saw blades for Plexiglass

Domain Est. 2016

Website: fraisertools.com

Key Highlights: All our circular saw blades for plexiglass are made in Italy and have a carbide HM tipped tooth, ideal for cut-off discs and hand saws. The tooth is ideal for …Missing: perspex …

#5 Engineered Plastic Blades Saw Blade Cutting

Domain Est. 1996

Website: fletcher-terry.com

Key Highlights: Engineered Plastic Blades from Atlas Saw & Tool are made to cut a variety of plastics, including acrylic, phenolic, foam board and mechanical plastics….

#6 Craftics Saber Saw Blades

Domain Est. 1997

Website: professionalplastics.com

Key Highlights: Rating 5.0 (1) Designed to cut acrylic (plexiglass), polycarbonate (Lexan), and styrene so smoothly that edges can be polished. Blades are 3.75″ long. FEATURES AND BENEFITS of …..

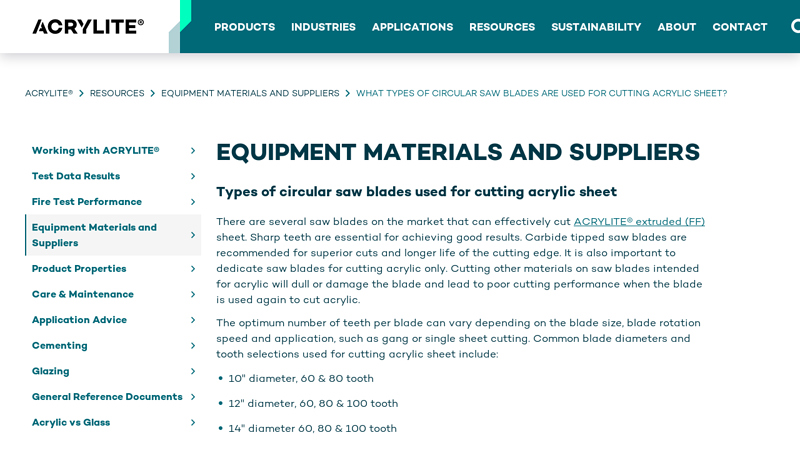

#7 What types of circular saw blades are used for cutting acrylic sheet?

Domain Est. 2017

Website: acrylite.co

Key Highlights: Carbide tipped saw blades are recommended for superior cuts and longer life of the cutting edge. It is also important to dedicate saw blades for cutting acrylic ……

#8 Cutting PLEXIGLAS

Website: plexiglas.de

Key Highlights: A saw blade specially ground for plastic is important to obtain cut edges that are as clean as possible. Further information on suitable saw blades is available ……

Expert Sourcing Insights for Perspex Cutting Blade

2026 Market Trends for Perspex Cutting Blade

The global market for Perspex (acrylic) cutting blades is expected to experience significant evolution by 2026, driven by advancements in manufacturing technologies, rising demand in key end-use industries, and a shift toward precision and automation. This analysis explores the key trends shaping the Perspex cutting blade market, focusing on technological innovation, regional growth, competitive dynamics, and sustainability.

Technological Advancements and Precision Engineering

By 2026, the development of high-precision cutting blades tailored specifically for Perspex will be a dominant trend. With increasing demand for clean, chip-free cuts in industries such as signage, architecture, and consumer electronics, manufacturers are investing in advanced blade materials like tungsten carbide, diamond-coated tips, and nano-layered coatings. These materials enhance blade durability and reduce friction, minimizing heat generation—a critical factor in avoiding melting or cracking of acrylic sheets during cutting.

Additionally, the integration of computer numerical control (CNC) machines and laser-guided systems is pushing the demand for blades compatible with automated systems. Blades designed for high-speed CNC routers and waterjet cutters are gaining popularity, enabling intricate designs and consistent output.

Growth in End-Use Industries

Several industries are driving the demand for Perspex cutting blades. The signage and display sector remains a major consumer, as businesses continue to adopt acrylic-based visual merchandising solutions. The architectural and interior design industries are also boosting demand, with acrylic used in lighting fixtures, partitions, and decorative elements.

Moreover, the automotive and aerospace sectors are increasingly incorporating lightweight acrylic components, necessitating specialized cutting tools. In healthcare, acrylic is used in medical devices and protective enclosures, further expanding the market for precision blades.

Regional Market Dynamics

Asia-Pacific is projected to be the fastest-growing region for Perspex cutting blades by 2026, led by China, India, and Southeast Asian countries. Rapid industrialization, urbanization, and infrastructure development are fueling demand for acrylic fabrication, especially in construction and advertising. North America and Europe will maintain steady growth, supported by technological adoption and stringent quality standards in manufacturing.

Emerging markets in Latin America and the Middle East are also expected to contribute to market expansion, as local fabrication industries modernize their equipment and processes.

Sustainability and Eco-Friendly Manufacturing

Environmental concerns are influencing blade manufacturing practices. By 2026, there will be a greater emphasis on sustainable production methods, including recyclable blade components and reduced energy consumption during manufacturing. Manufacturers are also exploring biodegradable coating materials and designing longer-lasting blades to reduce waste.

Regulatory pressures and corporate sustainability goals are pushing companies to adopt greener alternatives, which will impact the supply chain and product innovation in the Perspex cutting blade sector.

Competitive Landscape and Innovation

The market is becoming increasingly competitive, with key players focusing on product differentiation through R&D. Companies are launching blades with specialized tooth geometry, anti-static properties, and enhanced cooling features to improve performance on acrylic materials. Strategic partnerships with CNC machine manufacturers and distribution networks are also enabling faster market penetration.

In conclusion, the 2026 market for Perspex cutting blades will be defined by precision, automation, sustainability, and regional diversification. As industries demand higher quality and efficiency in acrylic fabrication, cutting blade manufacturers must innovate to stay competitive and meet evolving customer needs.

Common Pitfalls When Sourcing Perspex Cutting Blades (Quality and IP)

Sourcing the right blades for cutting Perspex (acrylic) is critical for achieving clean, chip-free results and maintaining tool longevity. However, several common pitfalls related to quality and intellectual property (IP) can lead to poor performance, increased costs, or legal risks.

Poor Blade Quality Leading to Substandard Cuts

Low-quality Perspex cutting blades often use inferior materials and imprecise manufacturing, resulting in rapid dulling, chipping, and rough edges. These blades may lack the appropriate tooth geometry (e.g., high tooth count, alternate top bevel grind) needed for clean acrylic cuts, leading to melted or cracked material. Always verify blade specifications and source from reputable manufacturers to ensure consistent performance.

Counterfeit or IP-Infringing Blades

Many high-performance Perspex blades are protected by intellectual property rights, including patents and trademarks. Sourcing from unauthorized suppliers increases the risk of purchasing counterfeit products that mimic well-known brands. These copies often fail to meet performance standards and may expose your business to legal liability for using or distributing infringing tools. Always confirm the authenticity of the supplier and request documentation to verify IP compliance.

Inadequate Coatings or Materials for Acrylic

Some blades marketed for Perspex cutting lack proper non-stick coatings (e.g., titanium nitride or specialized polymers) that prevent acrylic resin buildup. Without these, blades quickly gum up, increasing friction and heat, which can melt the Perspex. Ensure the blades are specifically designed for thermoplastics and feature appropriate coatings to maintain cutting efficiency and blade life.

Misrepresentation of Blade Specifications

Suppliers may exaggerate blade performance or mislabel specifications such as tooth count, blade diameter, or material composition. This can result in purchasing a blade unsuitable for precision Perspex work. Request detailed technical data sheets and, if possible, test samples before committing to bulk orders.

Ignoring Supplier Reliability and Traceability

Unverified suppliers, especially those offering unusually low prices, may lack quality control and traceability. This makes it difficult to address issues or recalls and increases the risk of receiving inconsistent batches. Opt for suppliers with verifiable manufacturing practices, quality certifications (e.g., ISO), and transparent supply chains to safeguard both quality and IP integrity.

Logistics & Compliance Guide for Perspex Cutting Blade

Product Classification and HS Code

The Perspex cutting blade is typically classified under Harmonized System (HS) Code 8208.10 or 8208.90, depending on the specific design and material composition. These codes cover cutting blades for machine tools. Accurate classification is essential for customs clearance, tariff application, and import/export compliance. Confirm the exact HS code with local customs authorities or a licensed customs broker based on the product specifications.

Export Controls and Restrictions

Perspex cutting blades are generally not subject to stringent export controls such as those imposed by ITAR (International Traffic in Arms Regulations) or dual-use regulations (e.g., EU Dual-Use Regulation or U.S. EAR). However, exporters must verify that the blades do not incorporate controlled materials or technologies. Always conduct a screening against denied party lists and ensure compliance with destination country-specific restrictions.

Packaging and Shipping Requirements

Package blades securely to prevent damage and ensure safety during transit. Use rigid, tamper-evident packaging with protective sheathing or guards over the cutting edge. Clearly label packages with handling instructions such as “Sharp Edges,” “Fragile,” and “This Side Up.” Use UN-certified packaging if shipping by air, especially when blades are part of a larger industrial shipment.

Labeling and Marking Compliance

Each blade or its packaging must bear necessary markings, including:

– Product name and model number

– Manufacturer or supplier name and address

– CE marking (if applicable for EU markets)

– Safety warnings indicating sharp edges

– Material composition (e.g., tungsten carbide, high-speed steel)

Ensure labeling complies with the target market’s regulatory standards, such as UKCA for the United Kingdom or equivalent regional requirements.

Safety and Regulatory Standards

Perspex cutting blades must comply with relevant safety and performance standards in the destination market. For the European Economic Area (EEA), compliance with the Machinery Directive (2006/42/EC) and provision of a Declaration of Conformity (DoC) may be required if the blade is sold as part of machinery. In the U.S., adherence to OSHA and ANSI standards for industrial tools is recommended to ensure workplace safety.

Import Duties and Taxes

Import duties vary by country and are determined by the HS code, country of origin, and trade agreements. Importers must account for applicable VAT, GST, or sales tax upon entry. Utilize preferential trade agreements (e.g., USMCA, RCEP) where applicable to reduce or eliminate duty rates, provided origin criteria are met.

Documentation Requirements

Ensure all shipments include:

– Commercial invoice (with detailed product description, value, and HS code)

– Packing list

– Bill of lading or air waybill

– Certificate of Origin (if claiming preferential tariff treatment)

– Export declaration (where required by the exporting country)

Maintain records for a minimum of five years for audit and compliance purposes.

Environmental and Disposal Compliance

Blades made from materials such as tungsten carbide or coated steels may be subject to environmental regulations upon disposal. Comply with waste electrical and electronic equipment (WEEE) directives or local hazardous waste rules if applicable. Provide end-of-life guidance to customers on proper recycling or disposal methods.

Country-Specific Considerations

- European Union: CE marking and compliance with REACH (chemical safety) may apply.

- United States: No federal product certification required, but state-level regulations (e.g., California Prop 65) may apply if hazardous substances are present.

- Australia/New Zealand: Adhere to AS/NZS standards for industrial safety.

Always verify local requirements before shipping.

Risk Management and Insurance

Insure shipments against loss, damage, and theft. Given the sharp nature of the product, ensure liability coverage includes potential injury claims related to improper handling. Implement quality control checks pre-shipment to minimize returns and compliance issues.

Conclusion on Sourcing Perspex Cutting Blades

In conclusion, sourcing the right blade for cutting Perspex (acrylic) is essential to achieve clean, smooth, and chip-free results. After evaluating various blade types, materials, and specifications, it is evident that high-quality carbide-tipped blades with a high tooth count (typically 60 to 80 teeth) and a triple-chip grind or alternate top bevel (ATB) design are most effective for precision cutting. Additionally, blades specifically designed for non-ferrous materials or plastics minimize friction and heat buildup, preventing melting or cracking of the Perspex.

When sourcing, it is important to consider blade diameter, arbor size, and compatibility with your cutting equipment (such as table saws, circular saws, or CNC routers). Reputable suppliers and manufacturers that offer reliable product specifications, customer support, and consistent quality should be prioritized. While cost is a factor, investing in a premium-grade blade ultimately reduces waste, enhances finish quality, and increases tool longevity.

In summary, selecting the appropriate Perspex cutting blade—based on material-specific design, sharpness, and tool compatibility—ensures optimal performance and professional results in both industrial and workshop environments.