The global perfume and fragrance industry is experiencing robust growth, driven by rising consumer demand for luxury personal care products and increasing emphasis on self-expression through scent. According to Grand View Research, the global perfume market was valued at USD 47.6 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2030. This expansion is closely tied to the escalating need for innovative and aesthetically appealing packaging, particularly high-quality perfume bottles that enhance brand identity and shelf appeal. As a result, demand for leading perfume bottle manufacturer manufacturers has surged worldwide. These manufacturers play a pivotal role in combining craftsmanship, material innovation, and sustainable practices to meet the evolving needs of fragrance brands across mass, niche, and luxury segments. In this competitive landscape, identifying the top 10 manufacturers provides critical insight into industry leaders shaping the fusion of design, functionality, and scalability in fragrance packaging.

Top 10 Perfume Bottle Maker Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Perfume Bottles

Domain Est. 2012

Website: rockwoodglass.com

Key Highlights: Our complete range of perfume bottles, with over 500 private molds offers one of the largest choice worldwide….

#2 Private label perfume manufacturer

Domain Est. 2019

Website: privelabel.com

Key Highlights: Complete turnkey solution to start your own perfume line. USA based, we create natural fine fragrances with niche quality packaging and bottles….

#3 Perfume Bottles

Domain Est. 2019

Website: roetell.com

Key Highlights: Roetell has over 40 years of experience as a leading perfume bottle manufacturer, supplying medium and large wholesalers and international fragrance brands….

#4 PGP Glass Bottle and Glass Container Manufacturers

Domain Est. 2021

Website: pgpfirst.com

Key Highlights: Cosmetic and Perfumery We create customised as well as standard bottles for perfumery and cosmetics, like glass bottles for air fresheners, glass stoppers, ……

#5 Create your bottle

Domain Est. 1997

Website: coverpla.com

Key Highlights: Use the filters to quickly compose your bottle. Select your bottle All methods By pallet full in inventory All sizes 15ml 30ml 50ml 75ml 100ml All shapes…

#6 Ramon Clemente. Glassmaker & Glass Decoration Barcelona …

Domain Est. 1999

Website: rclemente.net

Key Highlights: Bottle design, mold construction, glass making and decoration. We produce as needed and serve the finished product. Perfume and Home….

#7 Glass Perfume Bottles & Vials

Domain Est. 2013

Website: stocksmetic.com

Key Highlights: $21.20 deliveryGlass perfume bottles and vials: elegant and durable. Available in multiple sizes, ideal for professional fragrance lines….

#8 Premium Glass Perfume Bottles

Domain Est. 2013

Website: calaso.com

Key Highlights: At Calaso, we offer an extensive range of premium glass packaging solutions designed for the fragrance industry, making them ideal for perfumes and colognes….

#9 Our group

Domain Est. 2016

Website: verescence.com

Key Highlights: Located in the heart of the Bresle Valley, the Verescence Mers-les-Bains site specializes in manufacturing glass bottles and jars for the luxury industry….

#10 Discover Custom Perfume Bottles by ABOLAND: Your Go

Domain Est. 2023

Website: gzaboland.com

Key Highlights: We manufacture high-end perfume bottle using premium quality raw materials to offer your brands the most stunning products….

Expert Sourcing Insights for Perfume Bottle Maker

H2: Emerging Market Trends for Perfume Bottle Makers in 2026

The global perfume bottle manufacturing industry is poised for significant transformation in 2026, driven by evolving consumer preferences, technological advancements, and sustainability imperatives. As demand for luxury and niche fragrances continues to rise, perfume bottle makers are adapting to new market dynamics to remain competitive and innovative. Below are key trends shaping the industry in 2026:

1. Sustainability as a Core Design Principle

Environmental concerns are reshaping packaging standards across industries, and perfume bottle manufacturing is no exception. By 2026, eco-conscious consumers are demanding recyclable, refillable, and biodegradable packaging. Leading brands are partnering with bottle makers to develop lightweight glass, use recycled materials, and reduce plastic components. Regulatory pressures in Europe and North America are also pushing companies to adopt circular economy models, with refillable perfume systems gaining traction—especially among premium and luxury brands.

2. Rise of Customization and Personalization

The growing desire for individuality in consumer products is fueling demand for personalized perfume bottles. In 2026, advanced digital printing, 3D printing, and laser engraving technologies enable cost-effective customization at scale. Perfume bottle makers are investing in agile production systems to offer bespoke shapes, colors, and finishes tailored to brand identities or even individual customers, particularly in the direct-to-consumer (DTC) fragrance segment.

3. Integration of Smart Packaging Technologies

Smart packaging is emerging as a differentiator in the luxury fragrance market. By 2026, perfume bottles with embedded NFC (Near Field Communication) chips or QR codes are becoming more common, allowing consumers to access product authenticity verification, ingredient transparency, usage tips, and brand storytelling via smartphones. This trend enhances customer engagement and combats counterfeiting, a persistent issue in the fragrance industry.

4. Growth of the Niche and Indie Fragrance Sector

The surge in independent and artisanal perfume brands is creating new opportunities for flexible, small-batch bottle manufacturers. These emerging fragrance houses often seek unique, avant-garde bottle designs that reflect their brand ethos. As a result, perfume bottle makers are shifting toward modular production lines and collaborative design services to support innovation and faster time-to-market for boutique clients.

5. Emphasis on Aesthetic Innovation and Material Diversity

Luxury aesthetics continue to dominate, with brands seeking bottles that double as collectible art objects. In 2026, manufacturers are experimenting with alternative materials such as ceramic, wood accents, and bio-based resins, alongside high-precision glass molding techniques. Geometric shapes, textured surfaces, and minimalist designs are trending, reflecting broader shifts in design philosophy toward elegance and functionality.

6. Regional Manufacturing and Supply Chain Resilience

Geopolitical uncertainties and post-pandemic supply chain disruptions have prompted brands to favor regional or nearshored production. Perfume bottle makers in Europe, North America, and Southeast Asia are investing in localized facilities to reduce lead times and transportation emissions. This shift supports faster response to market demands and strengthens client relationships through proximity and agility.

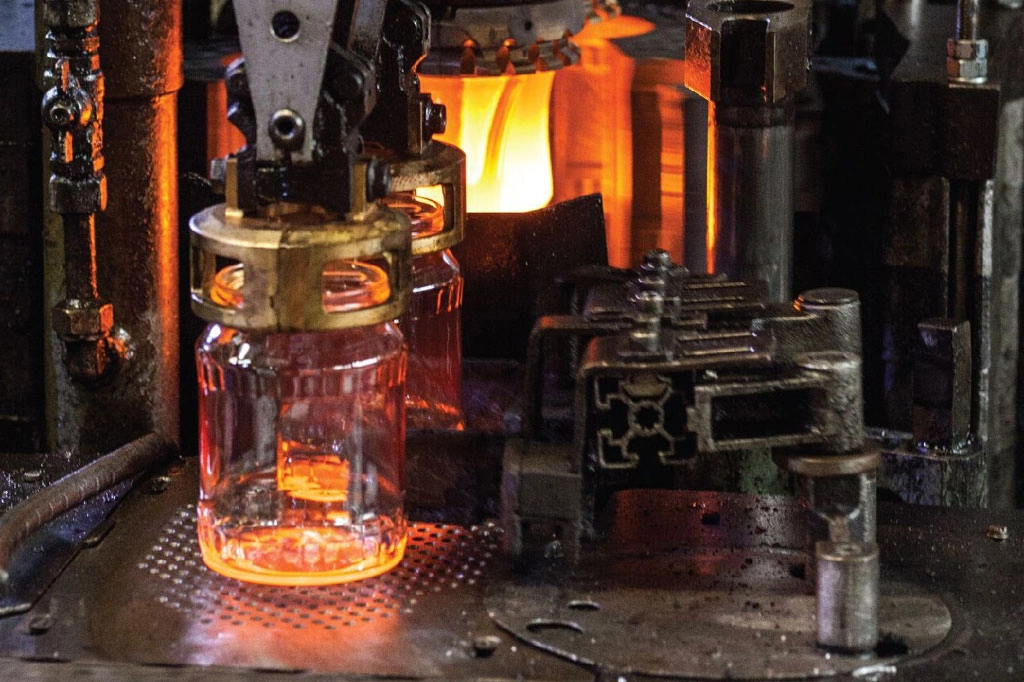

7. Digitalization and Industry 4.0 in Production

Automation, AI-driven quality control, and IoT-enabled machinery are transforming manufacturing efficiency. By 2026, leading perfume bottle makers leverage real-time data analytics to optimize production, reduce waste, and ensure consistency in high-precision molds. Digital twin technology allows for virtual prototyping, reducing development costs and accelerating innovation cycles.

Conclusion

The 2026 market landscape for perfume bottle makers is defined by sustainability, technological integration, and creative collaboration. Companies that embrace eco-design, digital tools, and flexible manufacturing will be best positioned to meet the demands of an increasingly sophisticated and environmentally aware consumer base. As the line between packaging and product experience blurs, perfume bottle makers are evolving from suppliers to strategic design partners in the fragrance ecosystem.

Common Pitfalls When Sourcing a Perfume Bottle Maker: Quality and Intellectual Property

Sourcing a perfume bottle manufacturer involves more than just finding the lowest price. Overlooking critical quality and intellectual property (IP) issues can lead to costly setbacks, damaged brand reputation, and legal disputes. Here are key pitfalls to avoid:

Quality-Related Pitfalls

Inconsistent Material Quality

Using substandard glass, plastic, or metal components can result in breakage, discoloration, or chemical interactions with the fragrance. Always verify material specifications (e.g., borosilicate glass for durability) and request material test reports (MTRs).

Poor Craftsmanship and Finishing

Imperfections such as uneven seams, misaligned caps, rough edges, or inconsistent spray mechanisms are common with inexperienced or low-cost manufacturers. Conduct pre-production samples and on-site quality audits to assess manufacturing precision.

Inadequate Packaging and Shipping Protection

Fragile perfume bottles require secure, shock-absorbent packaging. Poor packaging leads to high breakage rates during transit. Ensure the manufacturer designs and tests packaging for durability under real shipping conditions.

Lack of Compliance with Regulatory Standards

Perfume bottles must meet regional safety and environmental regulations (e.g., REACH, FDA, CPNP). Failing to confirm compliance can result in rejected shipments or market access issues. Verify that the manufacturer adheres to relevant international standards.

Intellectual Property-Related Pitfalls

Unprotected Design Ownership

Many manufacturers claim partial rights to bottle designs developed in-house or based on your concepts. Always sign a clear IP assignment agreement stating that all designs, molds, and artwork belong exclusively to your brand.

Risk of Design Theft and Counterfeiting

Without proper legal safeguards, your unique bottle design could be replicated and sold to competitors. Choose manufacturers with a strong reputation for confidentiality and enforce strict non-disclosure agreements (NDAs).

Failure to Patent or Register Designs

Relying solely on manufacturer agreements without formally registering your design (e.g., via design patents or registered designs) leaves you vulnerable. Register IP in key markets before sharing detailed design files.

Shared or Reused Molds

Some factories reuse molds across clients, risking design leakage or quality inconsistencies. Demand exclusive use of molds and verify that they are properly stored and maintained under your control.

Avoiding these pitfalls requires due diligence, clear contracts, and proactive IP protection. Partnering with reputable, transparent manufacturers and investing in legal safeguards ensures your perfume brand maintains quality and exclusivity.

Logistics & Compliance Guide for Perfume Bottle Makers

Understanding International Shipping Requirements

Perfume bottle makers must comply with international shipping regulations due to the nature of their products. While the bottles themselves may not be hazardous, they are often shipped empty or pre-filled with alcohol-based liquids, which can be classified as dangerous goods. Familiarize yourself with the International Air Transport Association (IATA) Dangerous Goods Regulations and the International Maritime Dangerous Goods (IMDG) Code if shipping by air or sea. Ensure proper classification, packaging, labeling, and documentation—especially when exporting internationally.

Packaging and Labeling Standards

Use shock-resistant, tamper-evident packaging to prevent breakage during transit. Each shipment should include clear labels indicating contents, quantity, weight, and handling instructions (e.g., “Fragile,” “This Side Up”). If bottles contain residual alcohol or are pre-filled, they must be labeled according to hazardous materials standards, including UN numbers (e.g., UN1266 for perfume) and proper hazard class (typically Class 3 – Flammable Liquids). Include safety data sheets (SDS) with every shipment as required by law.

Import/Export Compliance

Verify compliance with destination country regulations, including customs documentation, tariffs, and product-specific restrictions. Register for an EORI (Economic Operators Registration and Identification) number in the EU or an IRS number in the U.S. if applicable. Ensure Harmonized System (HS) codes are correctly assigned—typically 7010.90 for glass perfume bottles or 3303.00 for filled perfume containers. Work with licensed customs brokers to avoid delays or penalties.

Environmental and Safety Regulations

Adhere to REACH (EU) and TSCA (U.S.) regulations concerning chemical substances used in bottle coatings or adhesives. Ensure volatile organic compound (VOC) emissions from production processes meet local environmental standards. Implement proper waste disposal procedures for glass, metal, and chemical byproducts. Comply with OSHA (U.S.) or equivalent workplace safety regulations to protect employees during manufacturing and packaging.

Intellectual Property and Brand Protection

Secure trademarks and design patents for unique bottle shapes and logos. When shipping to distributors or retailers, include authenticity markers or holograms to prevent counterfeiting. Maintain strict chain-of-custody documentation to protect against IP theft and ensure traceability across the supply chain.

Quality Assurance and Certifications

Obtain relevant certifications such as ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) to demonstrate compliance and reliability. Conduct regular audits of production and packaging processes. Provide certificates of conformance (COC) with bulk shipments to reassure clients of product consistency and regulatory adherence.

Carrier and Logistics Partner Selection

Choose freight carriers experienced in handling glass and hazardous materials. Confirm that partners are IATA-certified for dangerous goods if applicable. Use trackable, insured shipping methods and maintain contingency plans for delays or damages. Establish long-term contracts with reliable logistics providers to ensure consistent delivery times and cost efficiency.

In conclusion, sourcing a reliable perfume bottle maker requires careful evaluation of several key factors, including product quality, manufacturing capabilities, material options, design customization, minimum order quantities, pricing, and compliance with international standards. It is essential to partner with a supplier who not only meets aesthetic and functional requirements but also aligns with your brand’s values, sustainability goals, and long-term vision.

Conducting thorough due diligence—such as requesting samples, verifying certifications, reviewing client testimonials, and assessing communication efficiency—can significantly reduce risks and ensure a smooth production process. Whether sourcing locally or internationally, building a strong, transparent relationship with the manufacturer fosters collaboration, innovation, and timely delivery.

Ultimately, the right perfume bottle maker will act as a strategic partner in bringing your fragrance brand to life, enhancing your product’s appeal and contributing to overall market success.