The global feed pellet machine market is experiencing robust expansion, driven by rising demand for efficient livestock feeding solutions and increasing commercialization in animal husbandry. According to Mordor Intelligence, the feed machinery market is projected to grow at a CAGR of over 5.8% from 2023 to 2028, fueled by advancements in automation and the growing need for high-capacity, energy-efficient equipment. As feed manufacturers scale operations to meet protein demand from expanding populations, pellet machines have become critical for ensuring feed uniformity, digestibility, and production throughput. With Grand View Research estimating the global animal feed market to surpass USD 600 billion by 2030, the pressure on manufacturers to invest in reliable, high-performance pelletizing systems has never been greater. In this evolving landscape, selecting the right pellet machine—balancing capacity, durability, energy efficiency, and maintenance requirements—is essential for staying competitive. The following list highlights the top 10 pellet machines tailored for feed manufacturers, evaluated based on technical specifications, output efficiency, user feedback, and suitability across varied production scales.

Top 10 Pellet Machine For Feed Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1

Domain Est. 2013

Website: gemco-energy.com

Key Highlights: Anyang GEMCO Energy Machinery Co., Ltd (a divison of ABC Machinery) is a leading manufacturer of renewable energy machinery which include pellet mill, pellet ……

#2 Pellet Mill & Pelleting Plant Manufacturer

Domain Est. 2012

Website: akahl.com

Key Highlights: PELLET MILL MANUFACTURER: Your expert in the field of flat die pellet mills for feed mills, wood pelleting plants, recycling plants and much more | AMANDUS…

#3 Pellet Mills

Domain Est. 2013

Website: onecpm.com

Key Highlights: From plastics to industrial products to commercial animal feed, this machine delivers rock-solid performance to meet your pelleting needs day after day….

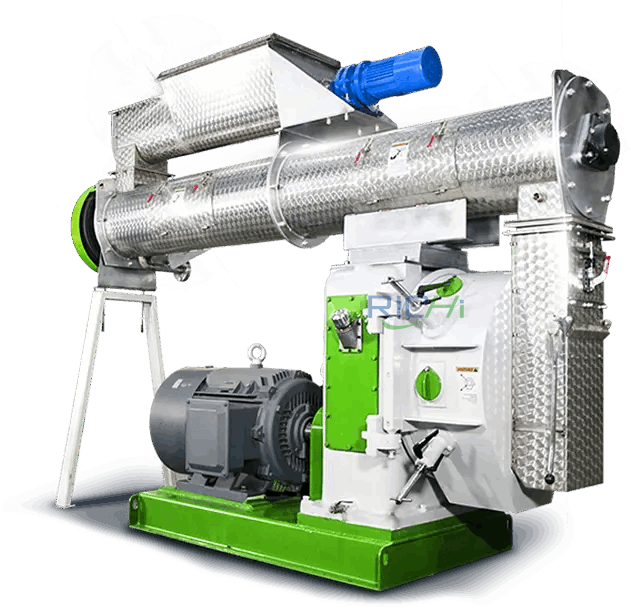

#4 Feed Pellet Mill Manufacturer. Expert In Animal Feed pelletizing …

Domain Est. 2013

Website: feed-pellet-mill.com

Key Highlights: Offer complete animal feed pellet production solutions from raw materials crushing, feed mixing, pelletizing, cooling, coating, packing, etc. Affordable Price….

#5 Pellet mills, animal feed

Domain Est. 1995

Website: andritz.com

Key Highlights: ANDRITZ Feed & Biofuel Technologies manufactures high-quality pellet mills that ensure highly efficient and reliable pellet feed production….

#6 Buskirk Engineering Pellet Mills

Domain Est. 2005

Website: buskirkeng.com

Key Highlights: The PM 1850 pellet mill is the heart of biomass reduction and material densification systems for agriculture, recycling, and manufacturing. Three-phase power ……

#7 Specialists In Feed Pellet Machines. Complete Animal Feed Pellet …

Domain Est. 2014

Website: feedpelletizer.com

Key Highlights: We offer a wide range of feed pellet machines to meet different production needs—from small-scale flat die pellet mills for farmers and small farms to large- ……

#8 USA Pellet Mill Pellet Mills & Extruders (Miami, FL)

Domain Est. 2018

Website: usapelletmill.com

Key Highlights: U.S.-based supplier of pellet mills & extruders for feed, biomass & pet food. Shipping globally from Miami. Request your quote today and boost production!…

#9 Animal Feed Pellet Machine

Domain Est. 2019

Website: en.famsun.com

Key Highlights: This versatile pellet mill ensures precise nutrition delivery and efficient pelletizing across different animal types. Designed with customizable configurations ……

#10 Feed Pellet Machine, Biomass Pellet Mill, Pellet Production Line

Domain Est. 2022

Website: richimanufacture.com

Key Highlights: Professional customized solutions for diverse animal feed production, enhancing livestock efficiency and feed quality to support modern animal husbandry….

Expert Sourcing Insights for Pellet Machine For Feed

2026 Market Trends for Pellet Machines for Feed

Sustainable Feed Production Driving Adoption

By 2026, the global demand for sustainable and efficient animal feed solutions will significantly influence the pellet machine for feed market. Increasing awareness of environmental impact and resource optimization in livestock and aquaculture sectors will drive investment in advanced pelleting technologies. Pellet machines enhance feed digestibility, reduce waste, and improve handling efficiency, aligning with circular economy principles. This focus on sustainability will encourage adoption in both developed and emerging markets, particularly where feed conversion ratios directly impact profitability and ecological footprints.

Technological Integration and Automation

Pellet machine manufacturers will increasingly integrate smart technologies by 2026, including IoT sensors, real-time monitoring systems, and automated control panels. These advancements will enable predictive maintenance, energy optimization, and consistent pellet quality, reducing operational downtime and labor costs. Data-driven insights from connected machines will allow feed producers to fine-tune formulations and improve batch consistency, meeting stringent quality standards required by commercial farms and export markets.

Growth in Alternative and Specialty Feed Ingredients

The rising use of non-conventional feedstocks—such as insect protein, algae, agricultural by-products, and food waste—will necessitate pellet machines capable of handling diverse raw materials. By 2026, demand will grow for versatile machines with adjustable die specifications, temperature controls, and pre-conditioning systems to accommodate variable moisture and fiber content. This shift supports cost reduction and innovation in feed formulations, especially in response to fluctuating grain prices and supply chain concerns.

Expansion in Emerging Economies

Emerging markets in Southeast Asia, Africa, and Latin America will see accelerated adoption of feed pellet machines by 2026, driven by expanding livestock populations and government initiatives to modernize agriculture. Small and medium-scale feed producers will benefit from modular and semi-automatic pellet systems that offer affordability and ease of use. Localized manufacturing and after-sales support will be critical success factors for equipment suppliers targeting these high-growth regions.

Regulatory and Quality Standards Influence

Stricter feed safety and traceability regulations worldwide will push producers toward standardized pelleting processes. By 2026, pellet machines with hygienic designs, clean-in-place (CIP) features, and compliance with international standards (e.g., ISO, GMP) will gain preference. This trend will be particularly evident in the aquaculture and pet food segments, where product consistency and contamination control are paramount.

Common Pitfalls When Sourcing Pellet Machines for Feed (Quality and Intellectual Property)

Sourcing a pellet machine for feed production involves careful consideration of both equipment quality and intellectual property (IP) aspects. Overlooking these factors can lead to operational inefficiencies, legal risks, and financial losses. Below are some common pitfalls to avoid:

1. Prioritizing Low Cost Over Quality

One of the most frequent mistakes is selecting a pellet machine based solely on price. Cheap machines often use substandard materials and components, leading to frequent breakdowns, higher maintenance costs, and reduced pellet quality. Look for machines with durable dies, robust motors, and reliable build quality—even if they come at a higher upfront cost.

2. Ignoring Machine Specifications and Feed Compatibility

Not all pellet machines are suitable for every type of feed material. Some are designed for coarse grains, while others work better with high-fiber or high-moisture ingredients. Failing to match the machine’s specifications with your feed formulation can result in poor pellet durability, low throughput, and increased energy consumption.

3. Overlooking After-Sales Support and Spare Parts Availability

A lack of local technical support or inaccessible spare parts can halt production for days or weeks. Choose suppliers who offer comprehensive after-sales service, maintenance training, and easy access to replacement parts—especially critical components like dies and rollers.

4. Assuming All Suppliers Own Their Technology (IP Risks)

Many manufacturers, particularly in competitive markets, may use designs or technologies protected by intellectual property rights without proper licensing. Purchasing such machines could expose your business to legal liability, especially if the machine is imported or used commercially in IP-sensitive regions. Always verify that the supplier owns the design or has legitimate licensing rights.

5. Failing to Verify Certifications and Compliance

Reputable pellet machines should meet international standards such as CE, ISO, or other regional safety and quality certifications. Machines without proper certification may not comply with safety regulations or environmental standards, risking operational shutdowns or fines.

6. Not Requesting Performance Data or Customer References

Avoid making purchasing decisions without reviewing real-world performance data. Request test reports, production capacity metrics, and energy consumption figures. Additionally, speak with existing customers to assess long-term reliability and support quality.

7. Underestimating the Importance of Die and Roller Quality

The die and roller are critical wear parts that directly affect pellet quality and machine longevity. Low-quality dies wear out quickly and produce inconsistent pellets. Ensure the machine uses hardened alloy steel dies with proper heat treatment and precise hole geometry.

8. Neglecting Energy Efficiency and Automation Features

Older or basic models may lack energy-saving features or automated controls, leading to higher operating costs and labor requirements. Modern pellet machines with variable frequency drives (VFDs), moisture sensors, and automated lubrication systems can significantly improve efficiency and consistency.

By being aware of these common pitfalls—especially those related to quality assurance and intellectual property—buyers can make informed decisions that support long-term productivity and compliance in their feed production operations.

Logistics & Compliance Guide for Pellet Machine For Feed

Overview

Transporting and deploying a pellet machine for feed involves navigating a range of logistical and regulatory requirements. This guide outlines key considerations to ensure smooth international or domestic shipment, customs clearance, installation, and legal compliance.

Equipment Classification & HS Code

Identify the correct Harmonized System (HS) code for customs purposes. Pellet machines for feed typically fall under:

– HS Code: 8436.80 – “Machinery for cleaning, sorting, or grading seed, grain, or dried leguminous vegetables; machinery used in animal feeding operations.”

Confirm the exact classification with local customs authorities, as variations exist by country.

Export Documentation

Prepare the following documents for international shipments:

– Commercial Invoice

– Packing List

– Bill of Lading (B/L) or Air Waybill (AWB)

– Certificate of Origin

– Export License (if required by exporting country)

– Technical Specifications and User Manual (translated if necessary)

Import Regulations

Check the importing country’s regulations, including:

– Import duties and taxes

– Product conformity and certification requirements (e.g., CE, UL, ISO)

– Restrictions on agricultural machinery or electrical equipment

– Environmental and emissions standards

Safety & Compliance Certifications

Ensure the pellet machine meets safety and quality standards:

– CE Marking (for EU markets)

– UL/CSA Certification (for North America)

– ISO 9001 (Quality Management)

– Local electrical and mechanical safety standards (e.g., CCC in China, PSE in Japan)

Packaging & Shipping Requirements

Use robust, weather-resistant packaging to protect the machine:

– Wooden crates with fumigation treatment (ISPM 15 compliant for international wood packaging)

– Waterproof wrapping and rust protection

– Secure anchoring to prevent movement during transit

– Labeling with handling instructions (e.g., “Fragile,” “This Side Up”)

Transportation Modes

Choose the appropriate shipping method based on size, weight, and urgency:

– Sea Freight (FCL/LCL): Most cost-effective for large, heavy machines

– Air Freight: Faster but expensive; suitable for urgent or smaller components

– Road/Rail: For domestic or regional transport; requires route planning for oversized loads

Customs Clearance

Facilitate smooth customs entry by:

– Providing accurate product description and valuation

– Pre-paying duties or arranging a customs broker

– Submitting required conformity certificates

– Ensuring all labels and manuals are in the local language (if required)

Installation & Site Compliance

Upon arrival, ensure the installation site complies with:

– Local electrical codes (voltage, grounding, circuit protection)

– Factory safety standards (machine guarding, emergency stops)

– Noise and dust emission regulations

– Zoning laws for agricultural or industrial use

After-Sales & Warranty Compliance

Maintain compliance post-delivery by:

– Registering the product with relevant authorities (if required)

– Providing local customer support and spare parts

– Honoring warranty terms in accordance with national consumer protection laws

– Offering training on safe operation and maintenance

Environmental & Disposal Regulations

Adhere to environmental laws regarding:

– Waste generated during operation (e.g., dust, unused biomass)

– End-of-life disposal or recycling of the machine

– Noise and energy efficiency standards

Conclusion

Successfully managing the logistics and compliance of a feed pellet machine requires careful planning, accurate documentation, and adherence to international and local regulations. Partnering with experienced freight forwarders, customs brokers, and local compliance experts can significantly reduce delays and ensure legal operation.

Conclusion: Sourcing a Pellet Machine for Feed Production

Sourcing the right pellet machine for feed production is a critical decision that impacts the efficiency, quality, and scalability of your operations. After evaluating various factors such as production capacity, pellet quality, raw material compatibility, energy efficiency, durability, and after-sales support, it becomes evident that selecting a machine aligned with your specific needs is essential.

Investing in a reliable and well-engineered pellet machine not only ensures consistent output of high-quality animal feed but also contributes to long-term cost savings and operational sustainability. It is advisable to source from reputable manufacturers with proven track records, certifications, and strong technical support networks. Additionally, considering automation features and future expansion needs can provide scalability and a competitive advantage.

Ultimately, a thorough evaluation process—incorporating site visits, product testing, and vendor assessments—will lead to an informed decision. By prioritizing quality, efficiency, and long-term reliability, businesses can establish a robust feed production system capable of meeting current demands and adapting to future challenges in the agricultural and livestock sectors.