The global fasteners market, driven by robust demand from automotive, aerospace, construction, and industrial manufacturing sectors, is projected to grow at a CAGR of 5.8% from 2023 to 2030, reaching an estimated value of USD 147.6 billion by 2030, according to Grand View Research. Within this expanding landscape, precision-engineered components like Peek (Polyetheretherketone) screws have gained critical importance due to their high strength-to-weight ratio, exceptional thermal stability, and resistance to chemical degradation. Peek screws are increasingly favored in high-performance applications across medical devices, semiconductor equipment, and aerospace systems. With the Asia Pacific region emerging as both a manufacturing hub and a key consumer market, the demand for high-quality Peek screw manufacturers has intensified. Based on production capabilities, material expertise, global reach, and industry certifications, the following eight manufacturers stand out as leaders in delivering reliable and innovative Peek screw solutions in a rapidly evolving marketplace.

Top 8 Peek Screws Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Peek Screws

Domain Est. 2024

Website: peekmaterials.com

Key Highlights: PEEK screws are superior kinds of industrial fasteners produced from poly ether ketone which is a brittle and powerful kind of polymer. Owing to these different ……

#2 PEEK SCREWS

Domain Est. 1997

Website: professionalplastics.com

Key Highlights: Rating 4.4 (3) PEEK Screws (PEEK SCREWS) High-Temperature, Corrosion-Resistant Plastic Screws are available through the Professional Plastics website….

#3 SPE-FT

Domain Est. 2000

Website: nbk1560.com

Key Highlights: PEEK hex socket head cap screws. PEEK is a thermoplastic super engineering plastic superior in physical and chemical properties. Excellent chemical resistance….

#4 ATEC Spine

Domain Est. 2008

Website: atecspine.com

Key Highlights: ATEC Spine is a solution-minded, problem-solving organization committed to providing outstanding patient outcomes….

#5 PEEK Fasteners – Bolts, Nuts & Screws

Domain Est. 2012

Website: extreme-bolt.com

Key Highlights: PEEK fasteners (chemically known as Polyetheretherketone) offer a unique combination of properties for some of the most extreme applications….

#6 PEEK Screws

Domain Est. 2012

Website: essentracomponents.com

Key Highlights: PEEK screws from Essentra Components deliver exceptional strength, heat resistance, and chemical stability for high-performance fastening applications….

#7 PEEK Screws: Standard and Custom

Domain Est. 2019

Website: peekchina.com

Key Highlights: PEEK Screws offer exceptional strength, chemical resistance, and high-temperature performance. Available in standard sizes or custom-made to your ……

#8 PEEK Screws

Domain Est. 2019

Website: junhuapeek.com

Key Highlights: PEEK screws offer exceptional high-temperature & chemical resistance for aerospace, automotive & electronics. Ensure reliable, long-life connections in ……

Expert Sourcing Insights for Peek Screws

H2: Market Trends for PEEK Screws in 2026

By 2026, the market for Polyetheretherketone (PEEK) screws is anticipated to experience significant growth and transformation, driven by advancements in material science, rising demand in medical and aerospace applications, and evolving regulatory landscapes. Here are the key trends shaping the PEEK screws market:

-

Increased Adoption in Spinal and Orthopedic Implants

PEEK screws are becoming the preferred alternative to traditional metal implants in spinal fusion and trauma fixation due to their biomechanical compatibility, radiolucency, and reduced stress shielding. By 2026, growing geriatric populations and rising incidences of spinal disorders are expected to drive demand, particularly in minimally invasive surgeries where imaging clarity is crucial. -

Advancements in Composite PEEK Materials

Enhanced versions of PEEK, such as carbon fiber-reinforced PEEK (CFR-PEEK) and bioactive surface-modified PEEK, are gaining traction. These composites offer improved strength, osseointegration, and antimicrobial properties, making them ideal for load-bearing applications. Manufacturers are investing heavily in R&D to optimize screw design and material performance. -

Growth in Aerospace and Automotive Applications

Beyond healthcare, PEEK screws are being increasingly adopted in high-performance industries. In aerospace, their high strength-to-weight ratio, thermal resistance, and corrosion resistance make them ideal for interior components and avionics. The push for lightweighting in electric vehicles is also creating new opportunities in automotive engineering. -

Regulatory Support and Standardization

Regulatory bodies such as the FDA and EMA are streamlining approvals for innovative PEEK-based medical devices. By 2026, clearer guidelines and international standards for biocompatibility and sterilization are expected to accelerate market entry and enhance product reliability. -

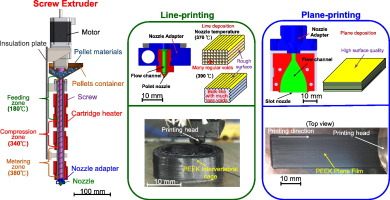

Sustainability and Manufacturing Efficiency

As sustainability becomes a boardroom priority, PEEK’s recyclability and durability are key selling points. Advances in additive manufacturing (3D printing) are enabling cost-effective, patient-specific PEEK screw production, reducing waste and lead times. -

Regional Market Expansion

While North America and Europe dominate the current market, Asia-Pacific is expected to witness the highest growth rate by 2026 due to expanding healthcare infrastructure, rising medical tourism, and increased investments in R&D from both public and private sectors.

In conclusion, the 2026 market for PEEK screws will be characterized by technological innovation, cross-industry applications, and strong demand in medical fields. Stakeholders who prioritize material enhancement, regulatory compliance, and scalable manufacturing will be best positioned to capitalize on these emerging opportunities.

Common Pitfalls When Sourcing PEEK Screws (Quality, IP)

Sourcing high-performance PEEK (Polyetheretherketone) screws, especially for critical applications in aerospace, medical, or semiconductor industries, presents unique challenges. Overlooking key aspects related to material quality and intellectual property (IP) can lead to product failure, regulatory non-compliance, or legal exposure. Below are common pitfalls to avoid:

Poor Material Quality and Traceability

One of the most significant risks when sourcing PEEK screws is receiving substandard or counterfeit material. PEEK’s performance hinges on precise polymer grade, molecular weight, and purity. Low-quality suppliers may use recycled PEEK, incorrect grades (e.g., unfilled instead of glass- or carbon-reinforced), or substitute with lower-cost polymers. Lack of material traceability—such as certificates of conformance (CoC), lot numbers, or manufacturer data—compromises quality assurance and regulatory compliance, particularly in FDA- or ISO-regulated environments.

Inadequate Manufacturing Process Control

PEEK screws require precision machining due to the material’s high strength and low thermal conductivity. Poor process control—such as improper tooling, incorrect cutting speeds, or inadequate annealing—can introduce internal stresses, dimensional inaccuracies, or surface defects. These flaws reduce mechanical performance and increase the risk of premature failure in service. Suppliers without certified quality management systems (e.g., ISO 13485, AS9100) are more likely to deliver inconsistent or non-conforming products.

Misrepresentation of Intellectual Property (IP) Rights

PEEK is a trademarked material originally developed by Victrex plc. While generic “PEEK-like” polymers exist, true PEEK must meet specific chemical and performance standards. Some suppliers may falsely claim their material is “Victrex PEEK” or fail to license the technology, infringing on IP rights. Using unlicensed PEEK can expose buyers to legal liability and void performance warranties. Always verify that the supplier is authorized to use the PEEK trademark and can provide proof of licensed material sourcing.

Lack of Regulatory and Industry Compliance

In regulated industries, PEEK components must comply with standards such as USP Class VI, ISO 10993 (for biocompatibility), or FAA/DO-160 (for aerospace). Sourcing screws without proper documentation—such as biocompatibility reports, flammability ratings, or sterilization compatibility—can delay product certification or lead to field failures. Assuming compliance without verified documentation is a common and costly mistake.

Insufficient Testing and Validation Data

Suppliers may provide optimistic performance claims without supporting test data. PEEK screws used in load-bearing or high-temperature environments require validation for tensile strength, creep resistance, chemical resistance, and long-term stability. Relying solely on datasheet values without access to batch-specific or application-relevant test results increases the risk of component failure under real-world conditions.

Overlooking Supply Chain Transparency

Complex supply chains can obscure the origin of raw materials and finished screws. Without transparency, it’s difficult to ensure ethical sourcing, avoid counterfeit parts, or respond to audits. Establishing direct relationships with reputable manufacturers and requiring full supply chain disclosure helps mitigate these risks and ensures accountability.

Avoiding these pitfalls requires due diligence: vetting suppliers thoroughly, demanding material certifications, verifying IP compliance, and insisting on traceability and testing documentation. Investing time upfront in supplier qualification protects product integrity, regulatory standing, and end-user safety.

Logistics & Compliance Guide for Peek Screws

This guide outlines the essential logistics and compliance considerations for the handling, transportation, storage, and regulatory adherence related to PEEK (Polyether Ether Ketone) screws used in medical, aerospace, and industrial applications.

Product Overview

PEEK screws are high-performance thermoplastic fasteners known for their excellent strength-to-weight ratio, chemical resistance, and biocompatibility. They are commonly used in implantable medical devices, aerospace assemblies, and high-temperature industrial environments.

Regulatory Compliance

Ensure all PEEK screws meet applicable regulatory standards depending on the region and application:

– Medical Devices (ISO 13485, FDA 21 CFR Part 820): Screws used in medical implants must comply with quality management systems and be manufactured in certified cleanrooms. Full traceability (lot/batch numbers, material certification) is required.

– Aerospace (AS9100, NADCAP): Components must adhere to strict quality and documentation standards. Material certifications (e.g., ASTM D6262) and non-destructive testing records must be maintained.

– REACH & RoHS Compliance: Confirm that PEEK material and any additives are free from restricted substances. Provide Declarations of Conformity upon request.

– Customs & Import Regulations: For international shipments, provide accurate HS codes (e.g., 3917.29 for plastic screws), Certificates of Origin, and Material Safety Data Sheets (MSDS) as needed.

Packaging & Labeling

- Use ESD-safe or anti-static packaging where applicable.

- Seal components in moisture-barrier bags if sensitivity to humidity is a concern.

- Label each package with:

- Part number and description

- Lot/batch number

- Quantity

- Manufacturing date

- Expiry date (if applicable)

- Regulatory markings (e.g., CE, USP Class VI for medical grades)

- Include compliance documentation (CoA, RoHS, REACH) with each shipment.

Storage Conditions

- Store in a clean, dry environment with controlled temperature (15–25°C) and humidity (<60% RH).

- Avoid direct sunlight and exposure to solvents or aggressive chemicals.

- Follow FIFO (First In, First Out) inventory practices.

- Shelf life for packaged PEEK screws is typically 2–5 years; refer to manufacturer specifications.

Transportation

- Use shock-resistant, tamper-evident packaging for transit.

- For medical or sterile screws, maintain sterile barrier integrity; validate shipping containers for sterility preservation.

- Ship via certified couriers with temperature monitoring if required.

- Comply with IATA/IMDG regulations if transporting hazardous materials (rare for PEEK, but relevant for cleaning agents or packaging gases).

Traceability & Documentation

- Maintain full traceability from raw material to finished screw.

- Retain records of:

- Material certifications (PEEK resin grade, e.g., Victrex 450G)

- Manufacturing process validation

- Inspection reports (dimensional, mechanical)

- Sterilization records (for medical use: EO, gamma, or e-beam)

- Provide customers with access to relevant compliance documentation upon request.

Handling & Use

- Train personnel in proper handling to avoid contamination (especially for medical-grade screws).

- Use cleanroom-compatible tools and gloves when necessary.

- Follow OEM installation guidelines to prevent over-torquing or damage.

Disposal & Environmental Responsibility

- PEEK is recyclable; follow local regulations for plastic waste separation.

- Do not incinerate without proper emission controls.

- Partner with certified waste management providers for end-of-life components.

Adherence to this guide ensures safe, compliant, and efficient management of PEEK screws across the supply chain. Always consult the manufacturer’s specifications and applicable regional regulations for application-specific requirements.

Conclusion for Sourcing PEEK Screws:

Sourcing PEEK (Polyether Ether Ketone) screws offers a high-performance alternative to traditional metal fasteners, particularly in industries requiring exceptional chemical resistance, high-temperature stability, electrical insulation, and biocompatibility—such as aerospace, medical devices, automotive, and semiconductor manufacturing. While PEEK screws typically come at a higher initial cost compared to metal counterparts, their long-term benefits—including reduced weight, corrosion resistance, and the elimination of secondary operations like coating or passivation—can lead to significant cost savings and improved product reliability.

When sourcing PEEK screws, it is essential to partner with reputable manufacturers or suppliers experienced in high-performance polymer machining to ensure tight tolerances, material consistency, and compliance with industry standards. Customization options, lead times, and volume scalability should also be evaluated based on application requirements.

In conclusion, sourcing PEEK screws is a strategic decision that supports innovation and performance in demanding environments. With careful supplier selection and a clear understanding of material properties, PEEK fasteners can enhance product durability, safety, and efficiency across a wide range of advanced applications.