The septic tank market has experienced steady growth driven by rising sanitation needs, urbanization, and stricter environmental regulations. According to Grand View Research, the global septic tank market was valued at USD 7.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. A significant shift toward durable, lightweight, and corrosion-resistant materials has boosted demand for polyethylene (PE) septic tanks, particularly in residential and decentralized wastewater applications. This growth is further supported by increasing infrastructure development in emerging economies and government initiatives to improve rural sanitation. As the industry evolves, several manufacturers have emerged as leaders in innovation, product reliability, and market reach. Here, we profile the top 10 PE septic tank manufacturers shaping the future of decentralized wastewater solutions.

Top 10 Pe Septic Tank Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Septic Tank Overview

Domain Est. 1997 | Founded: 1980

Website: norwesco.com

Key Highlights: Septic Tank Overview. The world’s leading manufacturer of polyethylene tanks, Norwesco has been producing polyethylene septic tanks since 1980….

#2 Premier Plastics Tanks

Domain Est. 1997

Website: premierplastics.com

Key Highlights: Premier Plastics Inc. has over 20 years of experience manufacturing light weight, high strength, and corrosion free polyethylene plastic septic tanks, water ……

#3

Domain Est. 1998

Website: akindustries.com

Key Highlights: AK also manufactures a comprehensive line of polyethylene septic tanks, sump pits, basins, and plumbing accessories. Beyond our standard offerings, we ……

#4 Polyethylene Plastic Septic Tanks

Domain Est. 1997

Website: greertank.com

Key Highlights: Each of our septic tanks is made with High-Grade Polyethylene plastic that won’t rust or have issues when the temperatures rise and fall throughout the year….

#5 Ace Roto Mold

Domain Est. 1999

Website: denhartogindustries.com

Key Highlights: Ace Roto-Mold’s Septic/Cistern line leads the industry in strength and durability. Plastic Septic tanks are the future of wastewater management. Plastic Cistern ……

#6 Septic Tanks & Infiltrator Systems

Domain Est. 2000

Website: loomistank.com

Key Highlights: Get high-quality septic tanks & Infiltrator systems from Loomis Tanks. Pre-plumbed options available. Contact us for your wastewater solutions!…

#7 United Septic Tanks

Domain Est. 2006

Website: unitedseptictanks.com

Key Highlights: Polyethylene Septic Tank. As the name suggests, United Polyethylene Septic Tanks, are made of Polyethylene in a single moulding. Read More » ……

#8 Septic tanks

Domain Est. 2009

Website: premiertechaqua.com

Key Highlights: Count on our leak-proof septic tank solutions to give you the performance you need to protect your property and the environment for a lifetime….

#9 Plastic Septic Tank Products

Domain Est. 2015

Website: infiltratorwater.com

Key Highlights: Infiltrator’s plastic septic tanks are available in a full range of sizes and configurations to offer reliable, high-efficiency wastewater treatment with ……

#10 Polyethylene Septic Tanks

Domain Est. 2019

Website: oneclarion.com

Key Highlights: One Clarion Septic Tanks are crafted in the USA using the finest high-grade polyethylene, which forms the foundation for our unwavering product strength….

Expert Sourcing Insights for Pe Septic Tank

H2: Projected 2026 Market Trends for Polyethylene (PE) Septic Tanks

The global market for polyethylene (PE) septic tanks is expected to experience significant growth and transformation by 2026, driven by advancements in materials, environmental regulations, urbanization, and a rising demand for sustainable wastewater solutions. As governments and municipalities prioritize sanitation infrastructure—particularly in developing regions—PE septic tanks are emerging as a preferred alternative to traditional concrete and steel systems due to their durability, lightweight design, and corrosion resistance.

-

Increased Adoption in Rural and Off-Grid Areas

By 2026, PE septic tanks are projected to gain widespread adoption in rural and off-grid communities, especially in Asia-Pacific, Africa, and Latin America. Their ease of transportation and installation makes them ideal for remote locations with limited access to heavy construction equipment. Governments investing in rural sanitation programs are expected to increasingly specify PE tanks in public health initiatives. -

Sustainability and Environmental Regulations

Stricter environmental regulations regarding groundwater protection and wastewater treatment are pushing municipalities and homeowners toward leak-proof, high-performance systems. PE septic tanks, typically manufactured using high-density polyethylene (HDPE), offer superior resistance to cracking and leakage compared to concrete. This aligns with sustainability goals and reduces the risk of soil and water contamination, further boosting market demand. -

Technological Advancements and Smart Integration

The integration of smart monitoring technologies into PE septic systems is expected to rise by 2026. IoT-enabled sensors for monitoring tank levels, effluent quality, and pump performance will become more common, particularly in developed markets. These innovations enhance maintenance efficiency, reduce operational costs, and prolong system lifespan—making PE tanks more attractive to environmentally conscious consumers and service providers. -

Growth in Prefabricated and Modular Solutions

The construction industry’s shift toward prefabricated and modular infrastructure supports the growth of factory-built PE septic tanks. These systems offer faster installation, consistent quality control, and reduced on-site labor costs. As urban development accelerates, especially in emerging economies, demand for ready-to-install wastewater solutions will favor PE-based products. -

Competitive Landscape and Regional Expansion

Major manufacturers are expected to expand production capacity and R&D investments in PE septic technology. North America and Europe will remain key markets due to aging infrastructure and regulatory compliance needs, while the Asia-Pacific region will witness the highest growth rate, driven by rapid urbanization and sanitation improvement programs. -

Challenges and Market Barriers

Despite growth prospects, the market may face challenges such as fluctuating raw material prices (particularly for petroleum-based polyethylene) and competition from alternative materials like fiberglass. Additionally, awareness and acceptance in traditional markets still favor concrete, requiring continued education and demonstration of long-term cost benefits.

In conclusion, the 2026 market outlook for PE septic tanks is positive, with strong growth potential fueled by environmental concerns, technological innovation, and global sanitation needs. Stakeholders who invest in sustainable manufacturing, smart features, and market education are likely to capture significant market share in the evolving wastewater management landscape.

H2: Common Pitfalls When Sourcing PE Septic Tanks (Quality and Intellectual Property)

Sourcing polyethylene (PE) septic tanks can be cost-effective and efficient, but buyers often encounter several pitfalls related to quality assurance and intellectual property (IP) concerns. Being aware of these challenges helps mitigate risks and ensures long-term performance and compliance.

1. Inconsistent Material Quality

One of the most frequent issues is variability in the quality of polyethylene used. Low-grade or recycled PE may compromise structural integrity, chemical resistance, and lifespan. Buyers must verify material specifications such as density (HDPE vs. LDPE), melt flow index, and UV stabilization to ensure durability in underground and wastewater environments.

2. Lack of Compliance with Industry Standards

Many suppliers fail to adhere to recognized standards (e.g., NSF/ANSI 460, EN 12566, or ASTM C1707). Non-compliant tanks may not pass local regulatory inspections or perform reliably under load and environmental stress. Always request third-party certification documents before procurement.

3. Poor Manufacturing Processes

Inadequate rotational molding or improper welding techniques can lead to weak seams, uneven wall thickness, and premature cracking. Inspecting manufacturing facilities or requesting production samples can help assess process reliability.

4. Insufficient Structural Design and Load Rating

Some sourced tanks are not engineered for the required soil and traffic loads. Tanks with inadequate wall thickness or poor ribbing design may collapse under backfill or vehicular traffic. Ensure technical drawings include load testing data and engineering validation.

5. Intellectual Property Infringement

Copying patented tank designs—such as specific baffle configurations, inlet/outlet fittings, or internal treatment chambers—poses serious IP risks. Sourcing from manufacturers that replicate branded systems (e.g., Aerobic Treatment Units with proprietary features) can lead to legal liability. Always confirm that the design is either licensed or independently developed.

6. Inadequate Documentation and Traceability

Missing or falsified documentation—such as material test reports, manufacturing dates, or serial numbers—hinders traceability and warranty claims. Insist on complete technical dossiers and batch-specific quality records.

7. Unverified Supplier Credentials

Dealing with unverified suppliers, especially through online marketplaces, increases the risk of counterfeit products or misrepresentation. Conduct due diligence: verify business licenses, visit facilities, and seek customer references.

8. Short-Term Cost vs. Long-Term Value

Opting for the lowest price often results in higher lifecycle costs due to failures, replacements, or environmental violations. Prioritize total cost of ownership, including installation, maintenance, and expected service life (typically 30–50 years for quality PE tanks).

By addressing these pitfalls proactively—focusing on material quality, compliance, design legitimacy, and supplier credibility—procurement professionals can ensure reliable, legal, and cost-effective sourcing of PE septic tanks.

Logistics & Compliance Guide for PE Septic Tanks

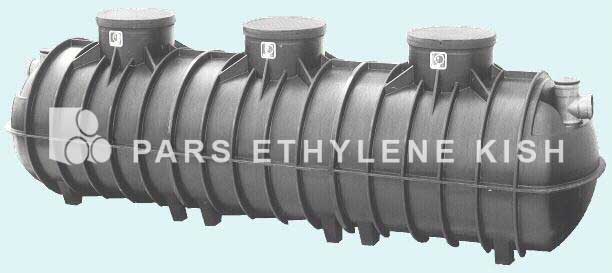

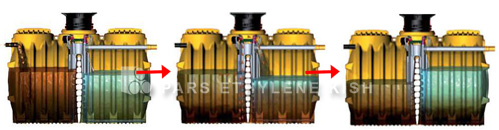

Overview of PE Septic Tanks

Polyethylene (PE) septic tanks are prefabricated wastewater treatment units made from high-density polyethylene (HDPE). They offer advantages such as lightweight construction, corrosion resistance, ease of transport, and long service life. Proper logistics planning and compliance with local, national, and environmental regulations are essential for their successful installation and operation.

Transportation and Handling

Ensure all PE septic tanks are transported on flatbed trucks with adequate support to prevent deformation. Secure tanks using nylon straps—not chains or metal cables—to avoid damaging the polyethylene shell. Avoid dragging or dropping the tank during offloading. Use lifting equipment with slings or spreader bars attached to designated lifting points only. Never lift by manholes or inlet/outlet pipes.

Storage Requirements

Store PE septic tanks on a flat, level surface free of sharp objects or debris. Stack no more than two tanks high, placing wooden dunnage between layers to prevent point loading and deformation. Protect tanks from direct sunlight when stored for extended periods; cover with UV-resistant tarps if needed. Keep tanks away from high traffic areas and potential impact sources.

Site Preparation & Delivery Access

Verify that the delivery route and onsite access can accommodate the size and weight of the delivery vehicle and crane (if required). Prepare the installation site by clearing vegetation, removing obstructions, and ensuring a stable working platform. Excavation must comply with local soil and safety codes, including trench shoring when necessary. Confirm that the delivery schedule aligns with excavation completion to minimize on-site storage time.

Regulatory Compliance

PE septic tanks must meet national and local environmental and building standards. In the U.S., tanks should comply with NSF/ANSI Standard 46 for onsite residential wastewater treatment systems. In the EU, adherence to EN 12566-1 is required. Confirm that the tank design, capacity, and materials meet local health department and environmental agency regulations. Obtain all necessary permits prior to delivery and installation.

Installation Compliance

Installation must follow manufacturer specifications and local code requirements. Ensure the tank is level (±1° tolerance), backfilled in stages with approved granular material, and compacted properly to prevent shifting or floating. All inlet, outlet, and ventilation piping must be correctly aligned and sealed. Conduct a water tightness test post-installation as required by jurisdictional standards.

Inspection and Documentation

Schedule mandatory inspections with local authorities before backfilling and upon system completion. Maintain detailed records including delivery notes, installation logs, inspection reports, compliance certificates (e.g., NSF, CE), and as-built drawings. Submit documentation to relevant regulatory bodies as part of the permitting process.

Environmental & Safety Considerations

Prevent soil and groundwater contamination by avoiding tank damage during handling and installation. Follow spill prevention protocols and ensure all workers wear appropriate PPE. Do not install tanks in flood-prone areas or environmentally sensitive zones without additional engineering controls and approvals.

Post-Installation Compliance

Register the septic system with the local health or environmental authority if required. Provide the end user with operation and maintenance guidelines. Schedule periodic pumping and inspections in accordance with local regulations—typically every 3–5 years—to ensure continued compliance and system longevity.

Conclusion

Successful deployment of PE septic tanks requires coordinated logistics and strict adherence to compliance standards. By following this guide, contractors and installers can ensure safe delivery, proper installation, and long-term regulatory compliance of polyethylene septic systems. Always consult local authorities and the manufacturer for project-specific requirements.

Conclusion for Sourcing PE Septic Tanks

Sourcing polyethylene (PE) septic tanks presents a viable, cost-effective, and sustainable solution for both residential and commercial wastewater management needs. Their lightweight design, corrosion resistance, ease of transportation, and quick installation significantly reduce labor and maintenance costs compared to traditional concrete tanks. Additionally, PE tanks offer excellent durability and long service life when properly manufactured and installed.

When sourcing PE septic tanks, it is crucial to partner with reputable manufacturers and suppliers who comply with relevant industry standards (such as EN 12566 or ASTM) and provide certified, high-quality products. Evaluating factors such as tank capacity, site requirements, environmental conditions, and regulatory compliance ensures optimal performance and longevity.

In conclusion, PE septic tanks are a modern, efficient alternative to conventional systems, offering long-term value and environmental benefits. With careful supplier selection and adherence to installation best practices, sourcing PE septic tanks supports sustainable infrastructure development and reliable wastewater treatment solutions.