The global PCIe connector market, including high-performance 8-pin variants critical for GPUs and power delivery in advanced computing systems, is witnessing robust expansion driven by rising demand in data centers, gaming hardware, and AI infrastructure. According to Grand View Research, the global board-to-board connector market—under which PCIe connectors fall—was valued at USD 11.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 7.3% from 2024 to 2030. This growth is fueled by increasing adoption of high-speed data transmission technologies and the proliferation of high-power graphics cards requiring reliable 8-pin PCIe power connectors. As system complexity increases, manufacturers specializing in durable, thermally efficient, and high-current PCIe 8-pin solutions are becoming strategically vital. Based on market presence, product quality, and innovation in materials and design, the following six manufacturers have emerged as leaders in supplying PCIe 8-pin connectors that meet the rigorous demands of modern computing.

Top 6 Pcie 8 Pin Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Specifications

Domain Est. 1996

Website: pcisig.com

Key Highlights: PCI-SIG specifications define standards driving the industry-wide compatibility of peripheral component interconnects….

#2 Can anyone explain how two 8

Domain Est. 1997

Website: forums.tomshardware.com

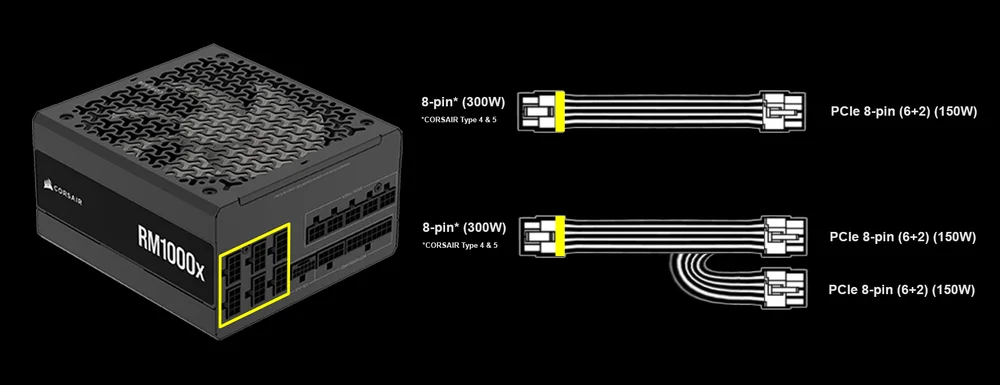

Key Highlights: If each port can provide roughly 150 watts, to get 600, the cable would need four (4) connectors on the PSU end and a 12VHRWR at the GPU end….

#3 Question about PCIe 8 pin cables

Domain Est. 2003

Website: overclock.net

Key Highlights: 1) Are all the black wires common ground? 2) What is this “Sense” wire? Are they the same as ground? 3) Are the 3 +12v wires rated the same……

#4 What are the part numbers for PCI

Domain Est. 2009

Website: electronics.stackexchange.com

Key Highlights: The 6-pin versions are: The 8-pin versions are: (*) The original part number was 45558-0002 part has been superseded by 45558-0003….

#5 Pro PCI

Domain Est. 2013

#6 PCIe Connectors

Domain Est. 2021

Website: amphenol-cs.com

Key Highlights: Amphenol has an array of Card Edge connectors supporting PCI Express Gen 3, Gen 4, Gen 5 and Gen 6 standards along with PCIe M.2 Connectors….

Expert Sourcing Insights for Pcie 8 Pin

H2: 2026 Market Trends for PCIe 8-Pin Connectors

As we approach 2026, the market for PCIe 8-pin power connectors—commonly used to deliver auxiliary power to high-performance graphics cards and other expansion cards—is undergoing significant transformation driven by evolving hardware requirements, shifting industry standards, and advancements in power delivery technologies.

-

Declining Relevance Due to Newer Standards

By 2026, the PCIe 8-pin connector is expected to experience reduced prominence due to the growing adoption of the 12V-1x Power Supply (12V-1x PSU) standard and the accompanying 12VHPWR (12-pin) connector introduced by NVIDIA and supported by the PCI-SIG. High-end GPUs such as the RTX 40 and upcoming RTX 50 series increasingly rely on the 12VHPWR connector, which consolidates power delivery into a single, more efficient interface. This transition reduces cable clutter and supports higher power budgets (up to 600W per connector), making the traditional 8-pin connector less suitable for flagship models. -

Legacy Support and Mid-Tier GPU Dependence

Despite the shift, PCIe 8-pin connectors will remain relevant in 2026 for mid-tier and budget GPUs, as well as in existing systems. Many GPUs in the RTX 4060/4070 class and AMD’s Radeon RX 7700/7800 series still utilize one or two 8-pin connectors. The large installed base of power supplies equipped with 8-pin outputs ensures continued demand for adapters and backward-compatible components. -

Adapters and Compatibility Solutions

The market for 8-pin to 12VHPWR adapters is expected to persist, though with greater scrutiny on safety and reliability following earlier issues (e.g., connector melting incidents in 2022–2023). By 2026, certified, over-molded, and monitoring-equipped adapters are likely to dominate, as consumers and OEMs prioritize stability. This creates a niche aftermarket for high-quality 8-pin-related accessories. -

Power Supply Evolution

Power supply manufacturers are increasingly phasing out native 8-pin PCIe cables in favor of 12VHPWR or modular systems with interchangeable connectors. However, many mid-range PSUs will still include 8-pin connectors to accommodate cost-sensitive builds and older GPU models, ensuring the connector’s presence in the market, albeit in a diminished role. -

Industrial and Embedded Applications

Beyond gaming and desktop computing, PCIe 8-pin connectors may find extended use in industrial PCs, workstations, and edge computing devices where high-power but non-flagship GPUs or accelerators are deployed. These sectors often prioritize stability and compatibility over cutting-edge interfaces, prolonging the lifecycle of 8-pin usage. -

Sustainability and E-Waste Considerations

As the industry moves toward newer standards, concerns about e-waste from obsolete cables and PSUs are rising. In 2026, we may see increased recycling initiatives and modularity in PSU designs to extend the usability of existing 8-pin infrastructure, reducing environmental impact.

Conclusion:

While the PCIe 8-pin connector is on a trajectory of gradual obsolescence in high-end consumer markets by 2026, it will remain a functional and necessary component in mid-range systems, legacy setups, and specialized applications. Its market presence will shift from primary power delivery to a transitional and supportive role, sustained by backward compatibility demands and ecosystem inertia.

H2: Common Pitfalls When Sourcing PCIe 8-Pin Connectors (Quality and IP Risks)

Sourcing PCIe 8-pin (also known as 6+2 pin) power connectors—commonly used to supply power to high-performance GPUs—can present several challenges, particularly concerning product quality and intellectual property (IP) compliance. Being aware of these pitfalls helps ensure reliable performance and legal safety in manufacturing or integration processes.

1. Poor Build Quality and Material Substitution

Many low-cost PCIe 8-pin connectors on the market use substandard materials such as inferior-grade plastics or copper alloys. These may not withstand high current loads (typically up to 150W per connector), increasing the risk of overheating, melting, or even fire hazards. Poor crimping or soldering techniques in counterfeit or knockoff cables also lead to intermittent connections and potential system damage.

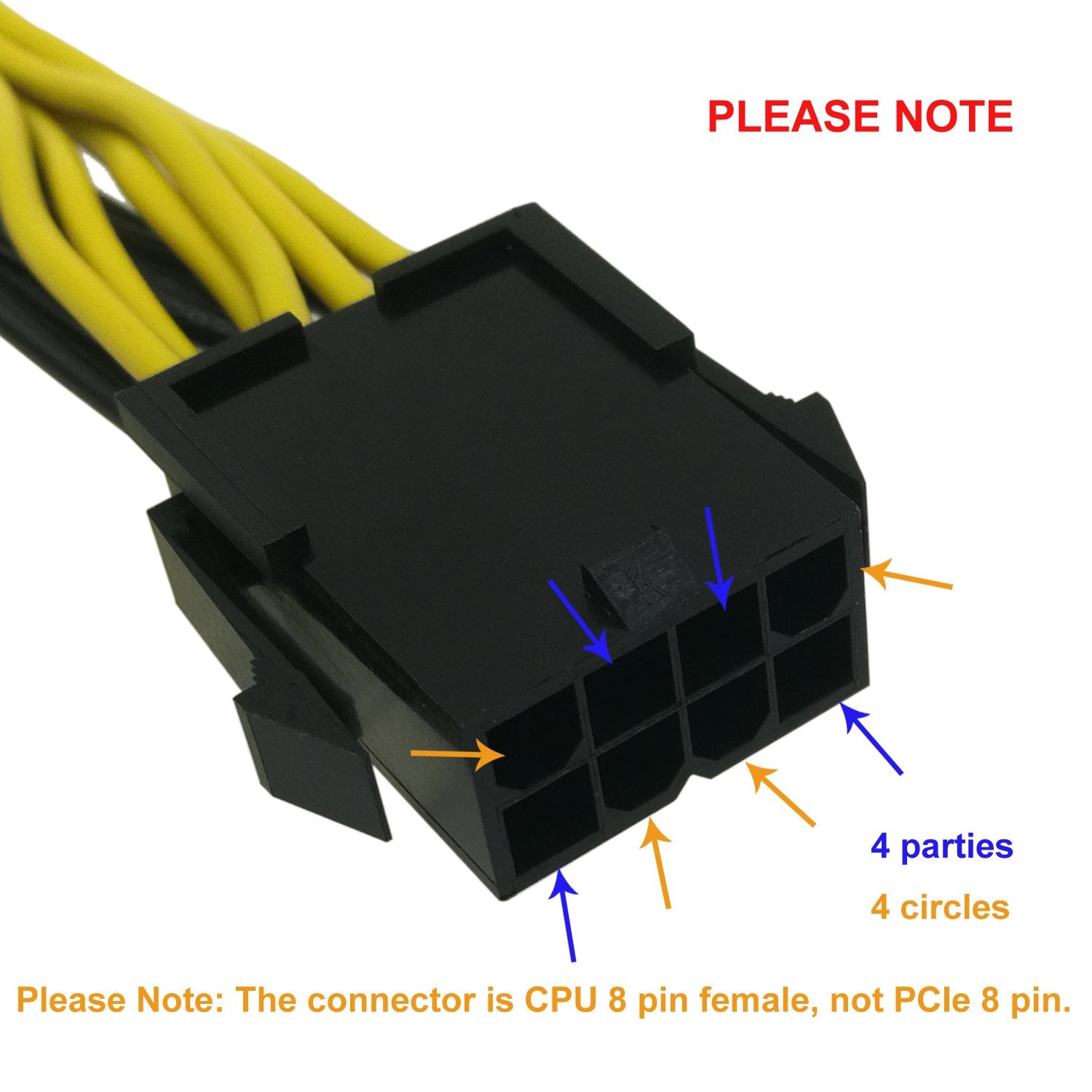

2. Inaccurate Pin Configuration and Miswiring

Some counterfeit or poorly designed cables feature incorrect pinouts, such as reversed or misrouted power and ground wires. This can cause catastrophic damage to GPUs or power supplies. Always verify that the connector adheres to PCI-SIG specifications for proper 12V, ground, and sense pin placement.

3. Lack of Over-Molding and Strain Relief

Low-quality connectors often lack adequate over-molding and strain relief, making them prone to physical damage from repeated plugging/unplugging or cable tugging. This results in broken solder joints or loosened terminals, compromising long-term reliability.

4. Counterfeit Components and IP Infringement

Many PCIe 8-pin connectors on third-party marketplaces (e.g., certain online electronics suppliers) are counterfeit versions of original Molex or TE Connectivity designs. These clones may infringe on patented designs and trademarks, exposing buyers to intellectual property (IP) liability, especially in commercial or OEM applications. Using non-licensed copies can also void warranties or compliance certifications.

5. Non-Compliance with Safety and Industry Standards

Reputable PCIe connectors comply with safety standards such as UL, CE, and RoHS. Counterfeit or low-quality versions often lack proper certification, failing to meet flammability, electrical safety, or environmental requirements. This poses risks in both consumer and enterprise deployments.

6. Inadequate Current Rating and Derating Issues

Some connectors are marketed as PCIe 8-pin but are not rated for sustained high-current loads. Always confirm the current rating per pin (typically 8A max per 12V pin) and consider derating under high-temperature conditions. Under-spec’d connectors can overheat under load, especially in densely packed systems.

7. Supply Chain Transparency and Traceability

Sourcing from unverified distributors increases the risk of receiving recycled, remarked, or out-of-spec components. Lack of traceability makes it difficult to address failures or recalls, particularly in regulated industries.

Best Practices to Avoid Pitfalls

– Source connectors from authorized distributors or directly from reputable manufacturers (e.g., Molex, TE Connectivity, Amphenol).

– Request compliance documentation (UL, RoHS, spec sheets).

– Perform incoming quality inspections and electrical testing.

– Verify IP rights when integrating into commercial products—avoid using patented designs without proper licensing.

– Use cables and connectors clearly labeled with manufacturer marks and certifications.

By addressing these common pitfalls, businesses and integrators can ensure the reliability, safety, and legal compliance of their power delivery systems.

PCIe 8-Pin Connector: Logistics & Compliance Guide

Overview of PCIe 8-Pin Connectors

The PCIe 8-pin connector (also known as 6+2 pin) is a power delivery standard used in computer hardware, primarily to supply additional power to high-performance graphics cards and other expansion cards. It delivers up to 150 watts of additional power (75W from the PCIe slot + 75W via the 8-pin connector). Proper logistics handling and compliance with international standards are essential due to electrical safety, environmental, and regulatory concerns.

Regulatory & Safety Compliance

PCIe 8-pin cables and power supplies must comply with a range of international safety and electromagnetic compatibility (EMC) standards. Key certifications include:

– UL (Underwriters Laboratories) / cUL (Canada): Required for electrical safety in North America.

– CE Marking (EU): Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area. Includes compliance with the Low Voltage Directive (LVD) and EMC Directive.

– RoHS (Restriction of Hazardous Substances): Restricts the use of specific hazardous materials (e.g., lead, mercury, cadmium) in electrical and electronic equipment. Applies in the EU, UK, China, and other regions.

– REACH (Registration, Evaluation, Authorization and Restriction of Chemicals): Requires disclosure of Substances of Very High Concern (SVHC) in products sold in the EU.

– FCC Part 15 (USA): Governs electromagnetic interference (EMI) emissions for digital devices. Class B is typically required for consumer electronics.

– KC Mark (South Korea): Mandatory safety certification for electrical products.

– PSE Mark (Japan): Required for electrical products under the Japanese Electrical Appliance and Material Safety Law.

Manufacturers and distributors must maintain technical documentation and issue Declarations of Conformity (DoC) for each applicable regulation.

Packaging & Labeling Requirements

Proper packaging and labeling ensure product safety, regulatory compliance, and ease of logistics:

– Labeling: Include manufacturer name, model number, voltage/current ratings (e.g., 12V, 8A per connector), compliance marks (UL, CE, RoHS), and country of origin.

– Packaging: Use anti-static bags for individual cables or connectors to prevent electrostatic discharge (ESD) damage. Bulk packaging must be durable to prevent crushing or abrasion during shipping.

– Multilingual Labels: For international distribution, include safety warnings and instructions in local languages (e.g., English, German, French, Spanish, Japanese).

– Hazard Symbols: If applicable, include symbols for electrical hazards or environmental disposal (e.g., WEEE symbol for electronic waste).

Transportation & Logistics

PCIe 8-pin connectors are generally low-risk for transport but must be handled in accordance with broader electronic component logistics:

– Storage Conditions: Store in dry, temperature-controlled environments (typically 10°C to 30°C). Avoid exposure to moisture, dust, or corrosive atmospheres.

– Shipping Classification: Not classified as hazardous goods under IATA, IMDG, or ADR, unless combined with batteries or other regulated components.

– ESD Protection: Use static-dissipative packaging and handling procedures throughout the supply chain.

– Inventory Management: Track lot numbers and production dates for traceability, especially to support RoHS and REACH compliance.

Environmental & End-of-Life Compliance

- WEEE (Waste Electrical and Electronic Equipment Directive): In the EU, producers must finance the collection and recycling of electronic waste. Products must be labeled with the crossed-out wheeled bin symbol.

- Battery Directive (if applicable): Does not typically apply to PCIe cables unless integrated with backup batteries.

- Recycling: Encourage proper recycling through take-back programs or certified e-waste handlers.

Import/Export Documentation

For international trade, ensure the following documents are prepared:

– Commercial Invoice (with Harmonized System (HS) Code: Typically 8544.42 or 8473.30 for cable assemblies or computer parts)

– Packing List

– Certificate of Origin (may be required for preferential tariffs under trade agreements)

– RoHS and REACH Compliance Declarations

– Safety Certificates (e.g., UL, CE test reports)

Best Practices for Distributors & Resellers

- Verify supplier compliance documentation before distribution.

- Train staff on ESD-safe handling procedures.

- Maintain records of compliance for audits (minimum 5–10 years depending on jurisdiction).

- Monitor regulatory updates (e.g., new RoHS exemptions, changes to WEEE categories).

By adhering to these logistics and compliance guidelines, businesses can ensure the safe, legal, and environmentally responsible distribution of PCIe 8-pin connectors worldwide.

Conclusion for Sourcing PCIe 8-Pin Connectors:

Sourcing PCIe 8-pin power connectors requires careful consideration of compatibility, quality, and safety to ensure reliable operation of high-performance components such as graphics cards. It is essential to obtain connectors from reputable manufacturers or suppliers that comply with industry standards (e.g., PCI-SIG specifications) to prevent issues like overheating, voltage instability, or permanent hardware damage. Key factors to evaluate include pin configuration (both 8-pin and 6+2-pin variants), current rating (typically rated for 150W), cable gauge (preferably 16AWG or lower), and proper insulation and retention mechanisms.

When sourcing, prioritize original power supplies with native 8-pin PCIe outputs or high-quality extension cables from trusted brands—avoiding cheap, uncertified adapters that may pose fire hazards. Additionally, verify system compatibility, particularly with newer standards like PCIe 5.0 and the 12VHPWR connector, to future-proof builds. In summary, sourcing the right PCIe 8-pin solution involves balancing performance needs with safety and reliability, ensuring stable power delivery for demanding GPU workloads.