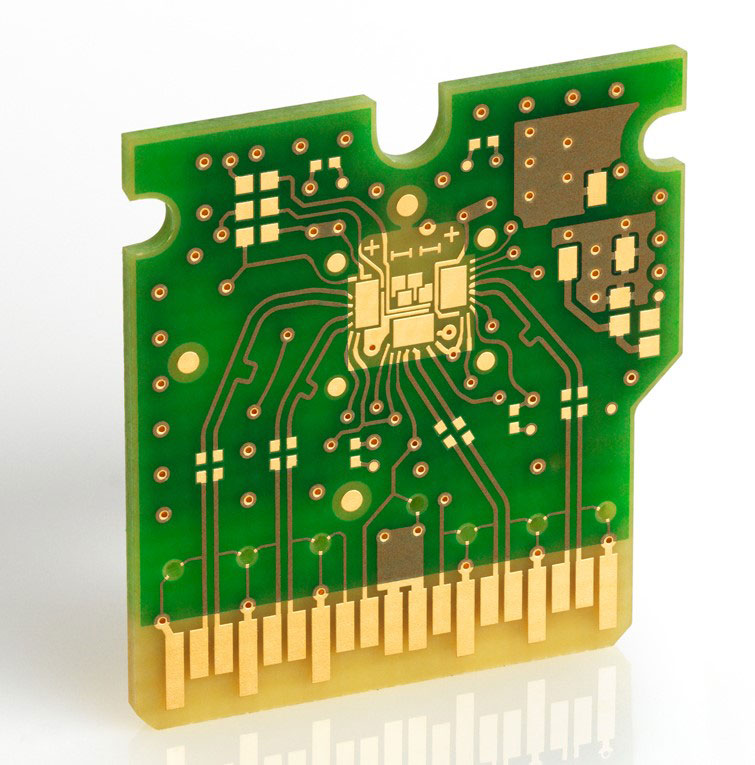

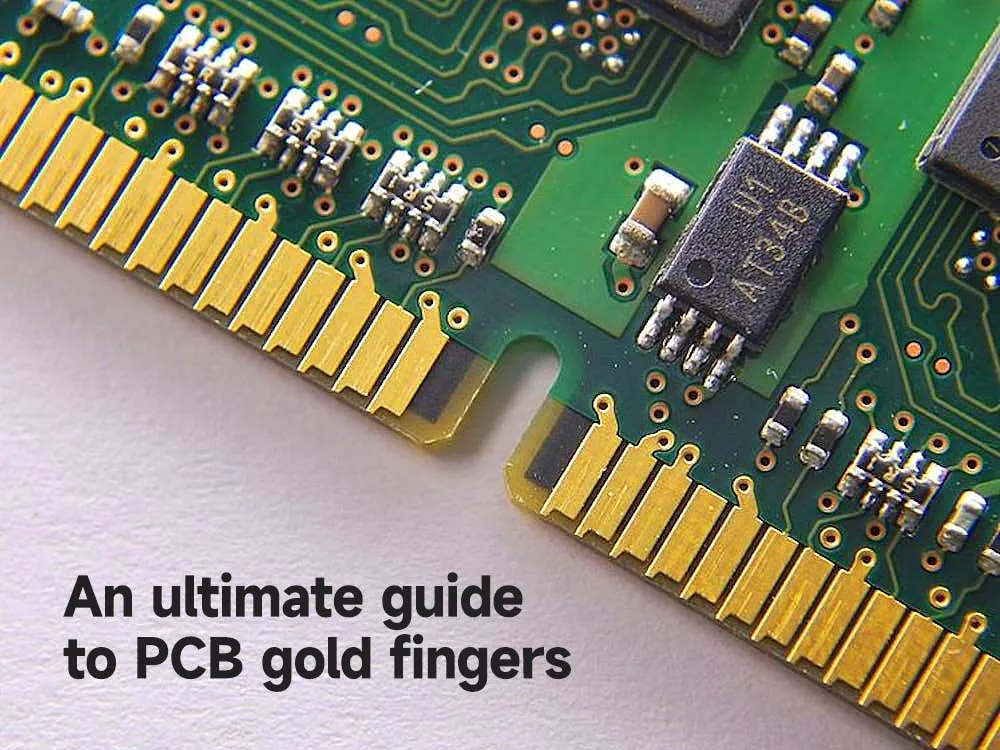

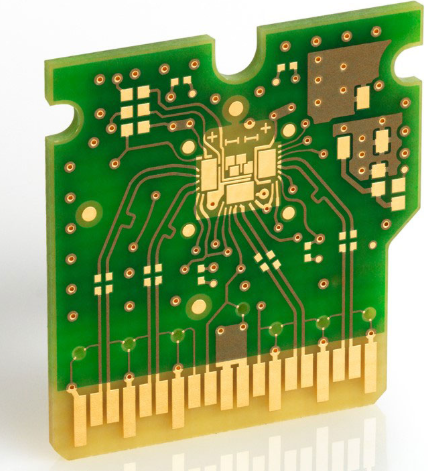

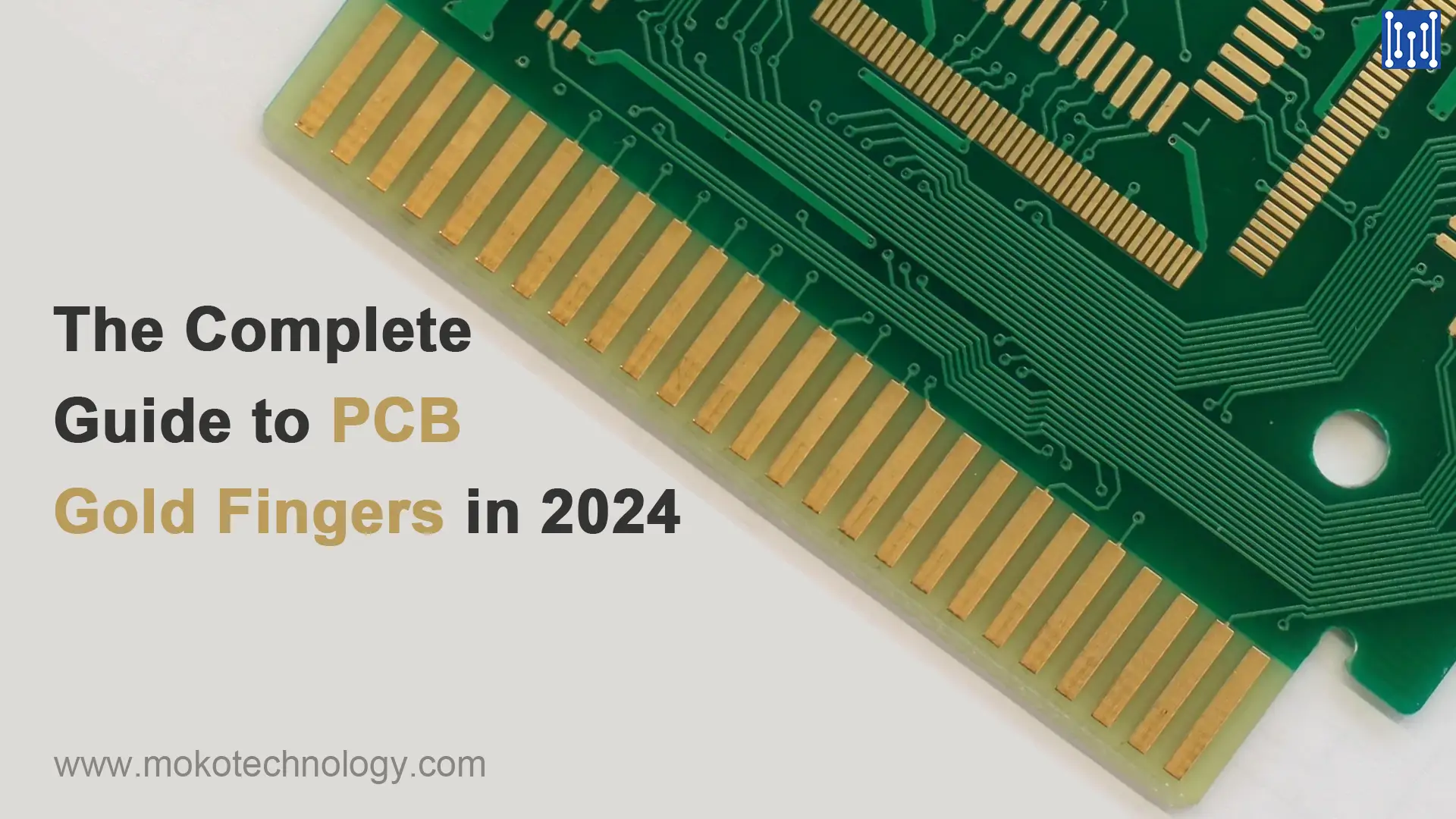

The global printed circuit board (PCB) market is experiencing robust growth, driven by rising demand in electronics, telecommunications, automotive, and industrial applications. According to Grand View Research, the global PCB market size was valued at USD 79.5 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030. A critical yet often overlooked component in high-performance PCBs is the gold finger—gold-plated connectors located along the edge of a board that enable reliable signal transmission between interconnected systems. As demand for high-speed, durable electronic interfaces grows—especially in servers, graphics cards, and medical devices—the need for precision-engineered gold fingers has intensified. This increasing technical demand, coupled with the broader PCB market expansion forecasted by industry analysts, has elevated the importance of specialized manufacturers capable of delivering consistent quality, precise plating thickness, and adherence to IPC standards. In this context, a select group of manufacturers has emerged as leaders in gold finger PCB production, combining advanced fabrication technologies with rigorous quality control. Below is a data-driven overview of the top 9 PCB gold finger manufacturers shaping the future of interconnect solutions.

Top 9 Pcb Gold Finger Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 30µ” PCB Gold Finger

Domain Est. 2010

Website: us.transcend-info.com

Key Highlights: Gold fingers are the gold-plated connectors at the edge of printed circuit boards (PCBs). Shaped like a finger, they serve as connectors that connect the PCB to ……

#2 Your Reliable PCB Gold Finger Manufacturer in China

Domain Est. 2020

Website: pcbmay.com

Key Highlights: PCBMay is a professional PCB gold finger manufacturer in China. We can offer different gold thickness with gold finger to be 50u”. Over 12 years PCB gold ……

#3 Sierra Circuits

Domain Est. 1997

Website: protoexpress.com

Key Highlights: Sierra Circuits can manufacture your PCB and have it expedited to you within 24 hours. Full turnkey boards, with assembly and components in as fast as 5 days….

#4 PCB Gold Fingers: All You Need to Know

Domain Est. 2005

Website: pcbpower.com

Key Highlights: Gold fingers are gold-plated connections found at PCB margins; between PCBs and connectors. These fingers operate as contact points, thereby enabling seamless ……

#5 PCB Gold Fingers

Domain Est. 2015

Website: alteraflex.com

Key Highlights: Gold Fingers are the gold plated narrow connectors found on the edge of printed circuit boards to enable connections between multiple boards….

#6 Gold Fingers

Domain Est. 2016

Website: nextpcb.com

Key Highlights: Gold fingers are the gold-plated columns seen along the connecting edges of printed circuit boards (PCBs)….

#7 Gold Fingers PCB

Domain Est. 2019

Website: ymspcb.com

Key Highlights: Gold Fingers PCB is the gold-plated terminal of the side card connector. Usually, the Fingers are made of flash Gold (hard Gold) and the thickness of Gold is ……

#8 Flex PCB Gold Finger

Domain Est. 2023

Website: flexplusfpc.com

Key Highlights: The gold finger of the flex PCB is a part of the flexible printed circuit board. It forms a gold conductive layer on the PCB through a special process….

#9 Guide to PCB Gold Fingers

Domain Est. 2011

Website: mclpcb.com

Key Highlights: In our comprehensive guide, explore the gold finger PCB plating process. Learn about PCB gold fingers and the importance of gold finger plating for PCBs….

Expert Sourcing Insights for Pcb Gold Finger

H2: 2026 Market Trends for PCB Gold Finger

The global market for PCB (Printed Circuit Board) gold fingers is poised for significant transformation by 2026, driven by advancements in electronics, rising demand for high-performance computing, and the proliferation of next-generation communication technologies. Gold fingers—gold-plated connectors located along the edge of PCBs—play a critical role in ensuring reliable electrical connections between circuit boards and other components or systems. Below is an analysis of the key trends expected to shape the PCB gold finger market through 2026.

1. Surge in 5G and Telecommunications Infrastructure

The global rollout of 5G networks is one of the most influential drivers for the PCB gold finger market. 5G base stations, routers, and high-speed data transmission equipment require PCBs with superior signal integrity, thermal stability, and durability—all qualities enhanced by gold finger plating. As telecom infrastructure expands, especially in Asia-Pacific and North America, demand for high-reliability PCBs with gold fingers will grow steadily.

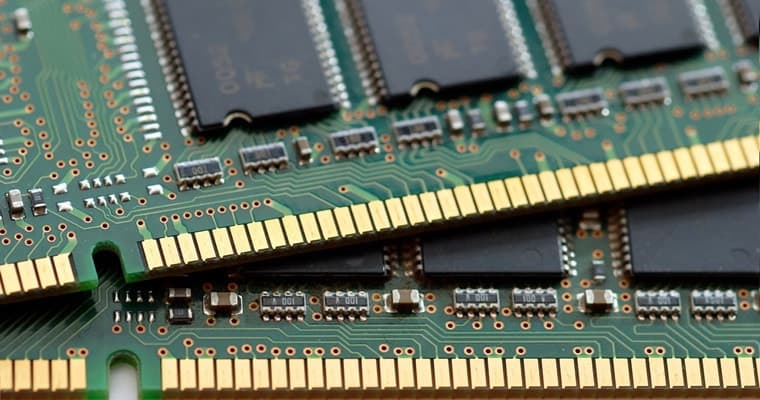

2. Growth in High-Performance Computing (HPC) and Data Centers

Data centers and HPC systems rely heavily on edge connectors for server-to-server and server-to-switch communications. With the rise of artificial intelligence (AI), cloud computing, and big data analytics, these systems are pushing the limits of speed and connectivity. Gold fingers, with their excellent conductivity and resistance to oxidation, are essential in motherboards and expansion cards (e.g., GPUs, PCIe cards). This trend will sustain demand through 2026.

3. Expansion in Automotive Electronics and EVs

The automotive industry is undergoing rapid electrification and digitalization. Advanced driver-assistance systems (ADAS), infotainment systems, and electric vehicle (EV) control units increasingly utilize PCBs with gold fingers for reliable interconnectivity in harsh environments. As EV production grows globally, the need for durable and corrosion-resistant connectors will further boost the gold finger market.

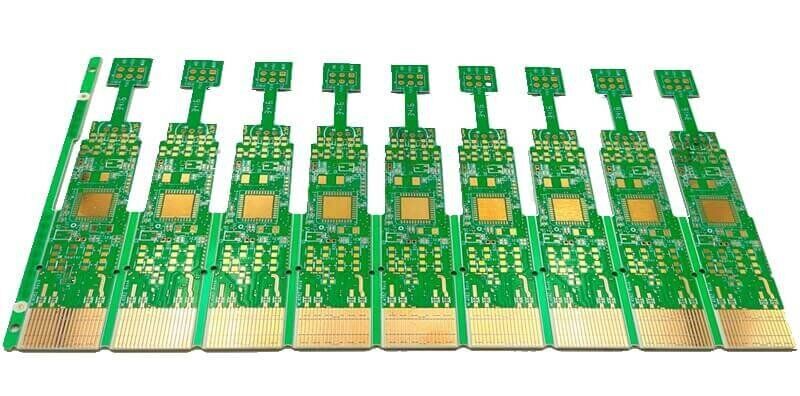

4. Miniaturization and High-Density Interconnect (HDI) PCBs

As consumer electronics become smaller and more powerful, PCBs are trending toward higher density and miniaturization. Gold fingers are being adapted for use in compact HDI boards, requiring tighter tolerances and precise plating techniques. Manufacturers are investing in advanced electroplating processes to meet these evolving specifications without compromising reliability.

5. Sustainability and RoHS Compliance Pressures

Environmental regulations such as RoHS and REACH are prompting PCB manufacturers to optimize gold usage and explore alternative materials or plating methods (e.g., immersion gold, edge-selective plating). While gold remains irreplaceable for high-wear applications, efforts to reduce gold thickness and improve recycling will influence production strategies by 2026.

6. Regional Manufacturing Shifts

Asia-Pacific, particularly China, Taiwan, and South Korea, will continue to dominate PCB production and gold finger manufacturing due to established supply chains and advanced fabrication capabilities. However, regional tensions and supply chain diversification efforts may lead to increased PCB production in India, Vietnam, and Mexico, affecting gold finger plating services and material sourcing.

7. Advancements in Plating Technology

Innovations in selective plating, automation, and quality control are enhancing the precision and consistency of gold finger fabrication. Laser-assisted plating and AI-driven inspection systems are expected to become more common, improving yield rates and reducing defects—crucial for high-reliability applications in aerospace, defense, and medical devices.

Conclusion

By 2026, the PCB gold finger market will be shaped by technological advancements, regulatory demands, and growing application across high-growth sectors. While challenges such as material cost and environmental compliance persist, ongoing innovation and expanding end-use markets will ensure steady growth. Stakeholders must focus on precision manufacturing, supply chain resilience, and sustainable practices to capitalize on emerging opportunities in this niche but vital segment of the electronics industry.

Common Pitfalls When Sourcing PCB Gold Finger (Quality, IP)

Poor Gold Plating Quality

One of the most frequent issues when sourcing PCBs with gold fingers is substandard gold plating. Gold fingers require hard gold plating (typically 2–50 microinches) to ensure durability and reliable electrical contact. However, some manufacturers may use thinner or softer gold layers to cut costs, leading to premature wear, corrosion, or poor conductivity. Inconsistent plating thickness across the fingers can also result in unreliable connections, especially in high-insertion-cycle applications.

Lack of Adherence to IPC Standards

Many suppliers fail to comply with IPC-4761 and IPC-6012 standards for gold finger design and plating. These standards define specifications for via tenting, plating thickness, beveling, and edge clearance. Non-compliance increases the risk of electrical failures, short circuits, or mechanical damage during mating. Buyers should verify that manufacturers follow IPC guidelines and request documentation or test reports to confirm conformance.

Inadequate Beveling and Edge Definition

Gold fingers often require precise beveling (typically 30°–45°) to facilitate smooth insertion into connectors. Poorly executed or omitted beveling can cause physical damage to mating connectors or difficulty during assembly. Additionally, imprecise routing or edge definition may result in misalignment or mechanical stress, affecting long-term reliability.

Contamination or Poor Surface Finish

Contamination from solder mask, flux residues, or oxidation on gold fingers severely impacts performance. Residual contamination can lead to poor signal integrity and intermittent connections. Proper handling, packaging, and storage are essential to avoid surface contamination. Some low-cost suppliers may skip cleaning processes or use improper handling procedures, compromising the finish quality.

Intellectual Property (IP) Risks

Sourcing PCBs from untrusted manufacturers—especially in regions with weak IP enforcement—exposes companies to significant IP theft risks. Sharing PCB designs with third-party fabricators without proper legal safeguards (e.g., NDAs, IP clauses in contracts) can result in unauthorized duplication, reverse engineering, or sale of design data to competitors. Always vet suppliers for IP protection policies and consider using trusted manufacturing partners with verifiable compliance records.

Inconsistent Quality Control and Testing

Many suppliers lack rigorous quality assurance processes, such as flying probe testing, X-ray inspection, or micro-section analysis for gold thickness. Without consistent testing, defects may go undetected until final assembly or field use. Request certifications (e.g., ISO 9001) and regular QC reports to ensure consistent production quality.

Conclusion

To avoid these pitfalls, buyers should work with reputable PCB manufacturers, require compliance with IPC standards, enforce strict quality controls, and protect intellectual property through legal and technical safeguards. Due diligence during supplier selection is critical for reliable, high-performance gold finger PCBs.

Logistics & Compliance Guide for PCB Gold Finger

Overview of PCB Gold Fingers

PCB gold fingers are edge connectors plated with a thin layer of gold to ensure reliable electrical connections between printed circuit boards (PCBs) and other components or systems. Due to their precision and material composition, special attention must be paid to logistics, handling, and regulatory compliance throughout the supply chain.

Material and Environmental Compliance

Gold fingers involve the use of precious metals and plating chemicals, requiring adherence to environmental and material regulations. Key compliance standards include:

– RoHS (Restriction of Hazardous Substances): Ensure the PCB and gold plating process comply with EU RoHS directives, restricting substances like lead, mercury, and cadmium.

– REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): Confirm that all chemicals used in gold plating are registered and compliant.

– Conflict Minerals (Dodd-Frank Act Section 1502): Provide documentation verifying that gold is sourced from conflict-free regions, particularly in the Democratic Republic of Congo (DRC) and adjoining countries.

Packaging and Handling Requirements

Proper packaging is critical to prevent physical and chemical damage to gold fingers:

– Use anti-static packaging materials (e.g., static shielding bags) to prevent electrostatic discharge (ESD) damage.

– Separate individual PCBs with non-abrasive, non-conductive spacers to avoid scratching the gold surface.

– Clearly label packages with “Fragile,” “ESD Sensitive,” and “Handle with Care” warnings.

– Avoid direct contact with bare hands; use ESD-safe gloves during handling to prevent oxidation from skin oils.

Transportation and Storage Conditions

Maintain strict environmental controls during shipping and storage:

– Store PCBs in a dry, temperature-controlled environment (15–25°C, 30–60% RH) to prevent moisture absorption and oxidation.

– Use desiccant packs and moisture barrier bags (MBBs) when storing or shipping over long distances.

– Avoid exposure to corrosive atmospheres, sulfur compounds, or high humidity during transit.

– Ensure containers are sealed and protected against vibration and mechanical shocks.

Import/Export Documentation and Regulations

International shipments of PCBs with gold fingers may be subject to customs and trade regulations:

– Provide accurate Harmonized System (HS) codes (e.g., 8534.00 for printed circuits).

– Declare gold content if required by destination country; some nations have precious metal reporting requirements.

– Comply with export control regulations such as the U.S. Export Administration Regulations (EAR), especially if the PCBs are used in military or dual-use applications.

– Retain certificates of compliance (RoHS, REACH, conflict minerals) for audit purposes.

Quality Assurance and Traceability

Implement robust quality and traceability practices:

– Maintain batch records linking gold plating processes, material sources, and inspection results.

– Conduct periodic inspections using optical microscopy and adhesion testing to verify gold layer integrity.

– Use serialized labeling or barcodes to track PCBs throughout logistics and distribution.

Disposal and Recycling Considerations

Due to the presence of gold and other metals, end-of-life PCBs must be handled responsibly:

– Follow WEEE (Waste Electrical and Electronic Equipment) directives for collection and recycling in the EU.

– Partner with certified e-waste recyclers capable of recovering gold and other materials.

– Avoid landfill disposal; ensure compliance with local hazardous waste regulations.

Conclusion

Managing the logistics and compliance of PCB gold fingers requires attention to material sourcing, environmental regulations, packaging integrity, and documentation. By adhering to international standards and implementing best practices in handling and transport, manufacturers and distributors can ensure product reliability and regulatory compliance across global markets.

Conclusion on Sourcing PCB Gold Fingers:

Sourcing PCBs with gold fingers requires careful consideration of quality, specifications, and supplier reliability. Gold fingers are critical for ensuring durable and reliable edge connections, especially in applications demanding frequent insertion and removal, such as connectors in computer peripherals, industrial equipment, and telecommunications hardware. To achieve optimal performance and longevity, it is essential to work with reputable PCB manufacturers that adhere to industry standards (e.g., IPC-4552 for ENIG and gold plating) and offer precise control over plating thickness, beveling, and surface finish.

Key factors in sourcing include the purity and thickness of the gold plating (typically hard gold between 2–50 microinches), proper ramping and beveling angles, and compliance with design specifications. Additionally, clear communication with suppliers regarding environmental durability, testing requirements (such as insertion cycle testing), and certifications (like RoHS and UL) is crucial.

In conclusion, successfully sourcing PCBs with gold fingers hinges on balancing cost, quality, and technical expertise. Selecting a qualified manufacturer with proven experience in gold finger processing ensures reliable electrical performance, mechanical durability, and long-term product success in demanding applications.