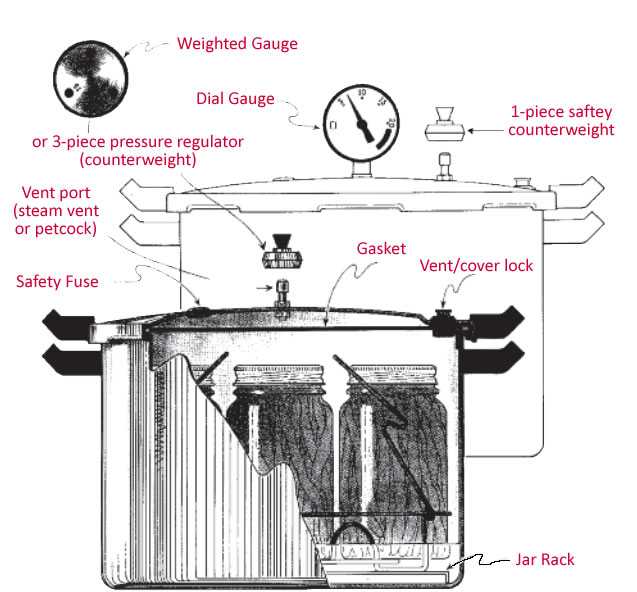

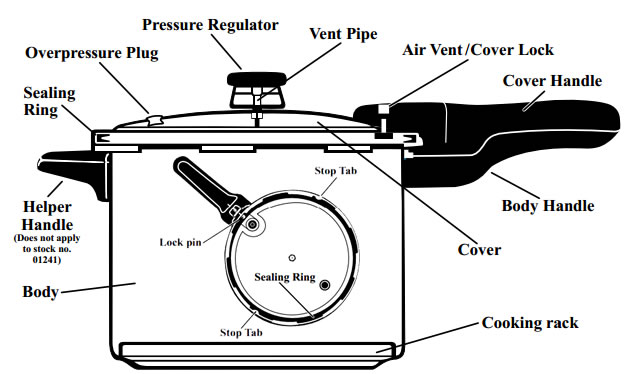

The pressure cooker market has experienced steady growth over the past decade, driven by increasing consumer demand for energy-efficient and time-saving kitchen appliances. According to a report by Grand View Research, the global pressure cooker market size was valued at USD 1.9 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This surge is fueled by rising urbanization, evolving lifestyles, and a growing interest in healthy, home-cooked meals prepared quickly. With North America and Asia Pacific leading in both production and adoption, innovation in design, safety, and multifunctionality has become paramount. As manufacturers integrate advanced materials and smart technology into their products, understanding the core components that define high-performance pressure cookers—such as lids, sealing rings, valves, and handles—becomes essential for both industry stakeholders and informed consumers. The following overview highlights the top eight critical parts that leading pressure cooker manufacturers prioritize to ensure safety, efficiency, and durability.

Top 8 Parts Of A Pressure Cooker Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Mirro Pressure Cooker Parts & Accessories

Domain Est. 1998

Website: goodmans.net

Key Highlights: 1–4 day delivery 45-day returnsGoodman’s carries a full line of Mirro pressure cooker parts, pressure cooker handles, canning press, canning jar openers, pressure cooker regulators…

#2 Official Cuisinart Pressure Cooker Parts

Domain Est. 1999

Website: partselect.com

Key Highlights: $12.99 deliveryShop for authentic Cuisinart Pressure Cooker parts today! Find genuine OEM replacement parts along with expert repair help, video tutorials, and same–day ……

#3 Parts and Accessories For 6

Domain Est. 1999

#4 Kuhn Rikon pressure cooker parts at PHG

Domain Est. 1999

#5 Pressure Cooker Outlet

Domain Est. 2000

Website: pressurecooker-outlet.com

Key Highlights: Pressure Cooker outlet offers a complete line of Pressure Cookers, Pressure Canners and Pressure Cooker/Canner Parts from Presto, Mirro, and All American….

#6 Replacement Pressure Cooker Parts for 12 Brands

Domain Est. 2000

Website: appliancefactoryparts.com

Key Highlights: Pressure Cooker Parts. Covers, Gaskets, Handles, Knobs, and more. Find Replacement Pressure Cooker Parts for 540 Models. Repair your Pressure Cooker today….

#7 All American Pressure Canners

Domain Est. 2006

Website: allamericancanner.com

Key Highlights: We carry the full line of All American Canners at everyday low prices. We also carry a full selection of All American Canner parts as well as All American ……

#8 Our Story

Domain Est. 2010

Website: pressurecookersparts.com

Key Highlights: Exclusive National distributors of Prestige, Manttra, Hawkins & Futura pressure cookers for over 20 years….

Expert Sourcing Insights for Parts Of A Pressure Cooker

H2: 2026 Market Trends for Parts of a Pressure Cooker

As the global kitchen appliance market evolves, the demand for replacement and upgraded parts of pressure cookers is expected to grow significantly by 2026. Driven by rising consumer interest in energy-efficient cooking, smart kitchen technology, and sustainability, the market for pressure cooker components is undergoing transformation. Below are key trends shaping the market for individual pressure cooker parts in 2026:

-

Increased Demand for Replacement Seals and Gaskets

Silicone sealing rings and rubber gaskets remain the most frequently replaced components due to wear and tear. In 2026, manufacturers are focusing on durable, odor-resistant, and dishwasher-safe materials. Consumers are increasingly purchasing multiple gaskets (in different colors) to avoid cross-contamination between food types, boosting aftermarket sales. -

Growth in Smart Lid Components

With the proliferation of smart pressure cookers (e.g., multi-cookers with Wi-Fi and app connectivity), lids equipped with pressure sensors, microprocessors, and safety valves are becoming high-value replacement items. The 2026 market will see modular smart lids that can be upgraded independently, promoting a circular economy and reducing e-waste. -

Standardization and Interchangeability

A major trend in 2026 is the push toward standardized parts across brands and models, especially for popular multi-cooker platforms. This allows third-party manufacturers to produce compatible components, increasing competition and lowering prices while improving accessibility for consumers. -

Sustainability and Recyclable Materials

Environmental concerns are driving the use of recyclable metals (e.g., 18/10 stainless steel) and BPA-free, food-grade plastics in pressure cooker parts. By 2026, leading brands are expected to offer take-back programs for worn parts, supporting repairability and reducing appliance turnover. -

Expansion of E-Commerce and Aftermarket Sales

Online marketplaces and brand-specific websites are becoming primary channels for purchasing individual parts. In 2026, augmented reality (AR) tools will help consumers identify the correct part using smartphone scans, reducing return rates and improving user experience. -

Rising DIY and Repair Culture

Empowered by online tutorials and repair communities, consumers are increasingly repairing rather than replacing pressure cookers. This cultural shift supports the market for affordable, high-quality replacement parts such as handles, steam release valves, and inner pots. -

Regional Market Diversification

Emerging markets in Asia-Pacific and Latin America are witnessing increased pressure cooker usage due to energy costs and cooking traditions. This drives demand for localized spare parts distribution networks and region-specific designs (e.g., higher pressure tolerance for high-altitude areas).

In summary, by 2026, the market for pressure cooker parts is becoming more dynamic, sustainable, and consumer-centric. Innovation in materials, digital integration, and circular economy practices will define the future of this niche but essential segment within the broader kitchen appliance industry.

Common Pitfalls When Sourcing Parts of a Pressure Cooker (Quality and IP)

Sourcing replacement or OEM parts for pressure cookers involves several potential pitfalls, especially concerning product quality and intellectual property (IP) rights. Understanding these risks is essential for manufacturers, distributors, and retailers to ensure compliance, product safety, and long-term business sustainability.

Poor Quality Control in Manufacturing

One of the most frequent issues when sourcing pressure cooker parts—such as lids, gaskets, pressure valves, or locking mechanisms—is inconsistent quality. Many suppliers, particularly in low-cost manufacturing regions, may lack rigorous quality assurance processes. This can result in:

- Substandard materials (e.g., non-food-grade silicone in gaskets)

- Inaccurate tolerances affecting seal integrity

- Premature wear or failure under pressure

Using such components increases the risk of safety hazards, including pressure leaks or explosions, which can lead to product recalls and legal liabilities.

Lack of Compliance with Safety Standards

Pressure cookers are safety-critical appliances, and their components must adhere to international standards such as ISO, UL, or CE. However, some suppliers may provide parts that are not independently tested or certified. Sourcing non-compliant parts can expose businesses to:

- Regulatory penalties

- Rejection at customs

- Voided insurance in case of accidents

Always verify that parts meet region-specific safety and material standards before procurement.

Intellectual Property Infringement

Sourcing generic or imitation parts can inadvertently violate intellectual property rights. Many established brands (e.g., Instant Pot, Fissler, or Presto) hold patents, trademarks, or design rights on specific components such as:

- Unique sealing mechanisms

- Proprietary lid designs

- Brand-specific valve systems

Purchasing or distributing parts that replicate these protected designs—even as “compatible” replacements—can lead to:

- Cease-and-desist letters

- Legal action for patent or trademark infringement

- Seizure of goods by customs authorities

Inadequate Supplier Verification

Relying on unverified suppliers from online marketplaces (e.g., Alibaba, Made-in-China) increases exposure to counterfeit or misrepresented parts. Red flags include:

- Unwillingness to provide material certifications

- Vague or missing product specifications

- No traceability or batch numbering

Conduct thorough due diligence, including factory audits and sample testing, to validate supplier credibility.

Inconsistent Part Compatibility

Even when parts appear identical, minor differences in design or dimensions can affect performance and safety. Issues include:

- Misalignment of locking mechanisms

- Incompatible pressure release systems

- Gaskets that don’t fit specific models

Always test sourced parts with actual pressure cooker units before mass procurement to ensure proper fit and function.

Conclusion

To avoid these pitfalls, businesses should prioritize certified suppliers, demand full compliance documentation, and conduct regular quality audits. Additionally, consult legal experts to ensure that replacement parts do not infringe on existing IP rights. Proper sourcing safeguards both consumer safety and brand reputation.

Logistics & Compliance Guide for Parts of a Pressure Cooker

Pressure cooker components—such as lids, gaskets, valves, sealing rings, handles, and pressure regulators—are subject to various logistics and compliance requirements depending on the manufacturing origin, destination markets, and materials used. This guide outlines key logistics considerations and regulatory compliance standards relevant to the transportation, import/export, and sale of pressure cooker parts.

Product Classification and Harmonized System (HS) Codes

Each component of a pressure cooker must be accurately classified under the Harmonized System (HS) for customs purposes. Typical classifications may include:

- HS 7323.93 – Table, kitchen or other household articles of iron or steel; parts thereof (e.g., metal lids or handles)

- HS 8481.80 – Valves for machinery, appliances, or equipment (e.g., pressure release valves)

- HS 4016.93 – Other articles of vulcanized rubber (non-hardened), such as sealing rings or gaskets

Accurate HS code assignment is essential for determining import duties, trade agreements, and compliance with destination country regulations.

Regulatory Compliance Requirements

United States – Consumer Product Safety Commission (CPSC)

- All pressure cooker replacement parts must comply with the Federal Hazardous Substances Act (FHSA) and general safety standards under the Consumer Product Safety Act (CPSA).

- Silicone and rubber gaskets must be food-grade and labeled accordingly.

- Pressure-regulating components must meet performance standards to prevent explosion or steam burn risks.

European Union – CE Marking and REACH

- Parts must comply with the General Product Safety Directive (GPSD) 2001/95/EC.

- CE marking is required for components that could impact safety (e.g., pressure valves, locking mechanisms).

- REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) compliance is mandatory for all materials, particularly rubber and plastic parts, to ensure no restricted substances (e.g., phthalates, heavy metals) are present.

United Kingdom – UKCA Marking

- Post-Brexit, pressure cooker parts sold in Great Britain require UKCA marking, aligning with UK-specific regulations derived from EU standards.

- Northern Ireland continues to follow EU CE marking rules under the Northern Ireland Protocol.

Canada – Health Canada & CSA Standards

- Replacement parts must meet Consumer Product Safety Directorate (CPSD) guidelines.

- Rubber and silicone components must comply with food contact material regulations under the Food and Drugs Act.

- Certification to CSA B51 (Boiler, Pressure Vessel, and Pressure Piping Code) may be required for safety-critical parts.

Australia and New Zealand – AS/NZS Standards

- Compliance with AS/NZS 2077:2019 (Pressure cookers and pressure canners) is recommended.

- Importers must ensure parts do not present a risk under the Australian Consumer Law (ACL).

Packaging and Labeling Requirements

- All replacement parts must be clearly labeled with:

- Part name or number

- Material composition (e.g., “Food-grade silicone”)

- Manufacturer or supplier name and contact

- Country of origin

- Compatibility (e.g., “Fits Model X”)

- Packaging must protect parts from damage during transit and comply with destination country labeling laws (e.g., bilingual labeling in Canada).

Logistics and Transportation Considerations

Mode of Transport

- Air freight: Suitable for high-value or urgent shipments; requires proper classification if shipping rubber or chemical-based materials.

- Ocean freight: Cost-effective for bulk shipments; containers must be secured against moisture, especially for metal components vulnerable to corrosion.

Incoterms

- Use appropriate Incoterms (e.g., FOB, CIF, DDP) to define responsibilities for shipping, insurance, and customs clearance.

- DDP (Delivered Duty Paid) is preferred for direct-to-consumer shipments to ensure compliance with local import laws.

Warehousing and Inventory Management

- Store rubber and silicone parts away from direct sunlight and ozone sources to prevent degradation.

- Implement FIFO (First In, First Out) inventory practices to avoid material aging.

Import Documentation

Essential documents for international shipment include:

– Commercial invoice

– Packing list

– Bill of lading or air waybill

– Certificate of Origin (may be required for preferential tariff treatment)

– Test reports or compliance certificates (e.g., FDA, REACH, CE)

– Import license (if required by destination country)

Environmental and Sustainability Compliance

- Ensure recyclability of packaging materials in compliance with EU Packaging Waste Directive or California’s SB 20.

- Monitor evolving regulations on Extended Producer Responsibility (EPR) in Europe and Canada, which may apply to spare parts programs.

Conclusion

Shipping and selling individual parts of a pressure cooker involves careful attention to material safety, regulatory standards, and international trade compliance. By adhering to classification rules, regional safety requirements, and proper logistics protocols, businesses can ensure smooth distribution while minimizing compliance risks. Always consult with legal and customs experts when entering new markets.

In conclusion, sourcing parts for a pressure cooker requires careful consideration of compatibility, quality, and safety standards. It is essential to identify the specific make and model of the pressure cooker to ensure that replacement parts—such as sealing rings, pressure weights, valves, and lid handles—are exact matches. Opting for genuine manufacturer parts or reliable aftermarket alternatives from reputable suppliers helps maintain the appliance’s performance and safety. Additionally, verifying certifications and reading customer reviews can further ensure durability and proper function. Properly sourced parts not only extend the lifespan of the pressure cooker but also safeguard against potential hazards, ensuring efficient and safe cooking over time.