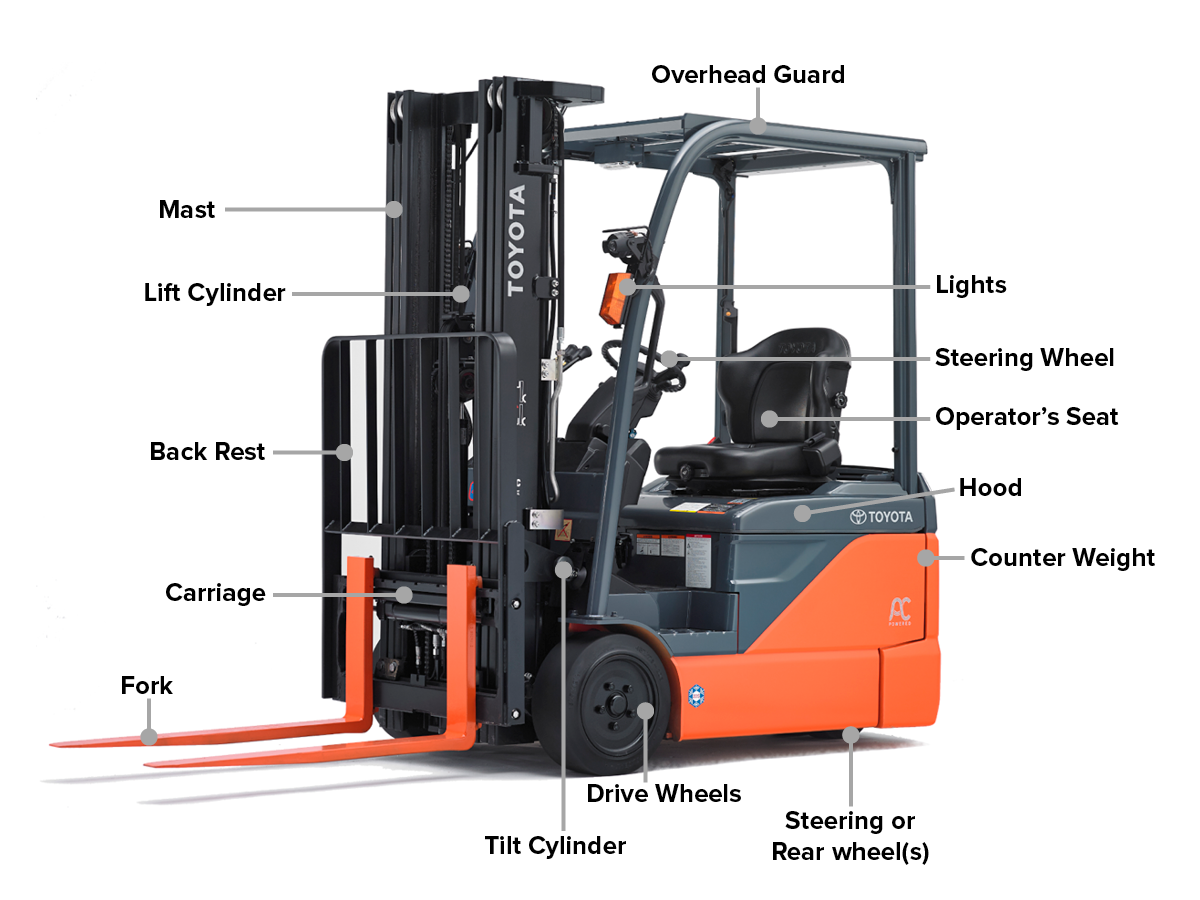

The global forklift market is experiencing steady expansion, driven by increasing demand for material handling equipment across warehouses, manufacturing, and logistics sectors. According to Grand View Research, the global forklift truck market size was valued at USD 76.4 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. This growth is fueled by rising automation in supply chains, expansion of e-commerce fulfillment centers, and a growing emphasis on operational efficiency in industrial environments. As manufacturers compete in this evolving landscape, understanding the core components that define high-performance forklifts becomes critical. From the power source to the mast assembly, each part plays a pivotal role in safety, reliability, and productivity. Here’s a breakdown of the top eight essential parts that leading forklift manufacturers prioritize to deliver durable, efficient, and technologically advanced material handling solutions.

Top 8 Parts Of A Fork Truck Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 CLARK Wholesale Forklift Truck Parts & Supplies Online

Domain Est. 1996

Website: clarkmhc.com

Key Highlights: CLARK Parts simplifies the forklift maintenance process by providing a full line of the highest quality OEM and aftermarket parts available on the market….

#2 fpe

Domain Est. 2020

Website: fpe-store.com

Key Highlights: Free delivery over $475Through our online store, we’re able to offer a wide range of OEM and aftermarket parts from all major brands, including Nissan forklift parts, Toyota forkli…

#3 Cascade Corporation: Forklift Parts

Domain Est. 1995

Website: cascorp.com

Key Highlights: Cascade offers versatile attachments, forks, masts and related technologies to improve productivity throughout the supply chain….

#4 Genuine Toyota Forklift Parts & Accessories

Domain Est. 1996

Website: toyotaforklift.com

Key Highlights: Toyota Genuine Forklift Parts & Accessories go through Toyota’s quality control system to ensure strict quality. Our parts keep you at optimum performance….

#5 Forklift Parts & Accessories

Domain Est. 1997

Website: tvh.com

Key Highlights: TVH is the biggest supplier of forklift parts and accessories worldwide. We supply parts and accessories for all makes, including the hard-to-find ones….

#6 Forklift Parts Finder

Domain Est. 2011

Website: lsforklifts.com

Key Highlights: Trust LS Forklifts, The leading supplier of new and used forklift Truck Parts, Find your parts easy using our Online Forklift Parts Finder Search….

#7 Material Handling Equipment

Domain Est. 2013

Website: arrowmhp.com

Key Highlights: Arrow Material Handling Products, Forklift Forks & Skid Steer Attachments – Loader, Tractor and other Construction Equipment Attachments….

#8 Intella Parts

Domain Est. 2021

Website: intellaparts.com

Key Highlights: Get quality, low-priced aftermarket forklift parts from popular brands like Hyster, Yale, Toyota, Cat, & many more. Fast shipping and quality assured….

Expert Sourcing Insights for Parts Of A Fork Truck

2026 Market Trends for Parts of a Forklift Truck

Growing Demand for Electric Forklift Components

In 2026, the market for electric forklift components is projected to experience significant growth due to increased focus on sustainability and warehouse electrification. Key parts such as electric motors, battery systems (especially lithium-ion), and regenerative braking systems are witnessing rising demand. Manufacturers are investing heavily in improving battery longevity and charging efficiency, making electric forklifts more viable for long-shift operations. This shift is driven by stricter emissions regulations in urban logistics centers and the total cost of ownership (TCO) advantages of electric models over internal combustion (IC) engines.

Advancements in Smart and Connected Forklift Systems

The integration of IoT (Internet of Things) and telematics into forklifts is transforming how components are monitored and maintained. By 2026, smart sensors embedded in critical parts—such as steering systems, hydraulic pumps, and load backrests—enable real-time diagnostics, predictive maintenance, and fleet management. Fleet operators are increasingly adopting connected forklifts to reduce downtime and extend the lifespan of parts. Cloud-based platforms analyze performance data from these components, allowing for proactive servicing and optimized part replacement cycles.

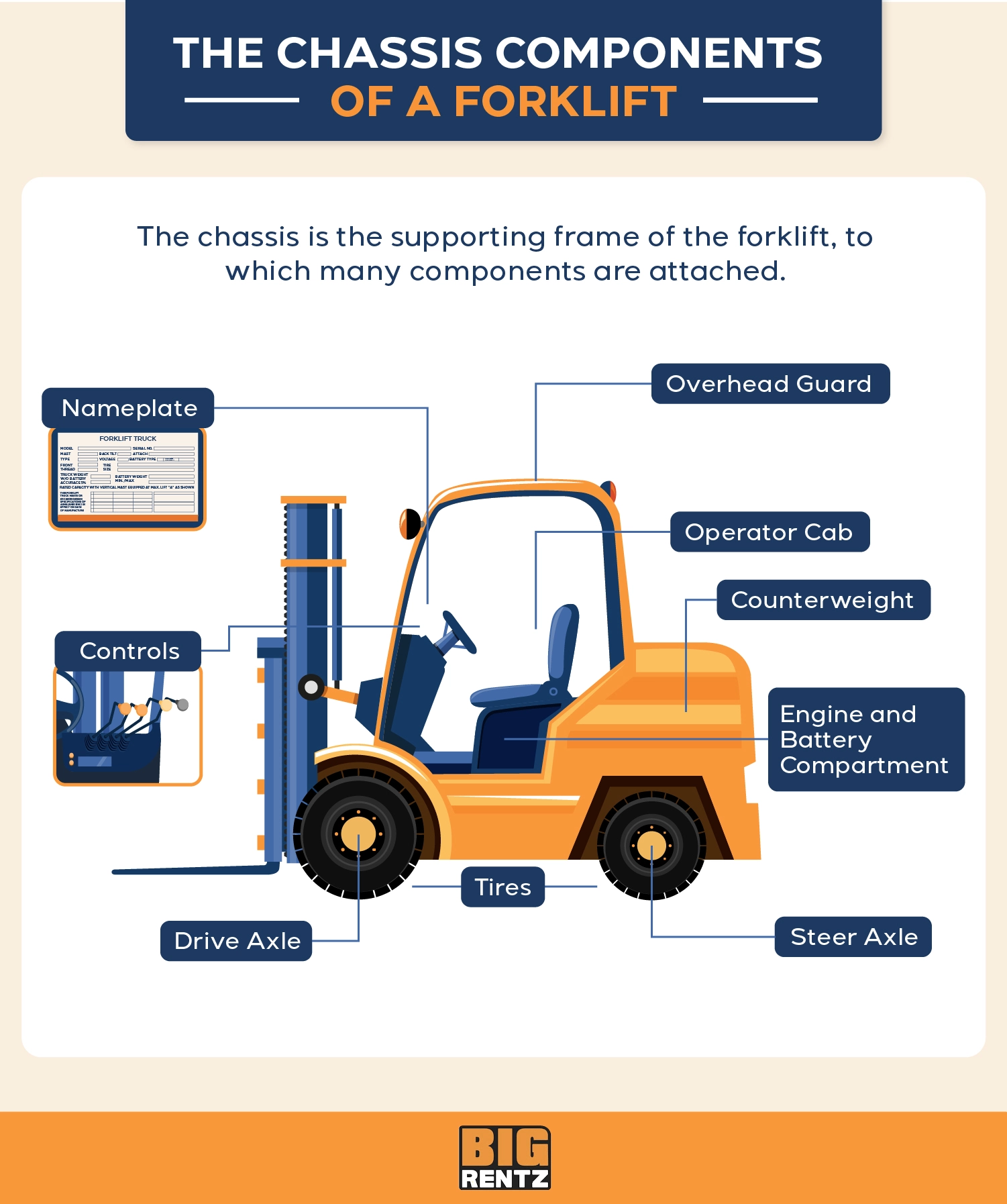

Rising Focus on Safety and Ergonomic Component Design

Safety regulations and workforce well-being are shaping the design of key forklift components. In 2026, parts such as operator cabins, seat belts, overhead guards, and control panels are being redesigned with enhanced ergonomics and safety features. Advanced seat suspensions, anti-slip pedals, and intuitive control levers are becoming standard. Additionally, collision avoidance systems—integrated into the mast and overhead guard structures—are gaining traction, reducing accident rates and insurance costs. Regulatory bodies in North America and Europe are expected to enforce stricter safety standards, further boosting demand for compliant components.

Increasing Aftermarket for Replacement and Upgraded Parts

The aftermarket for forklift parts is expanding rapidly, fueled by aging fleets and cost-conscious businesses seeking to extend equipment life. In 2026, there is strong demand for replacement masts, tires, hydraulic cylinders, and drive axles. Third-party manufacturers are offering high-quality, competitively priced components, challenging OEM dominance. Additionally, retrofit kits that upgrade older IC forklifts with electric drivetrains or smart technology are gaining popularity, creating a hybrid parts ecosystem.

Supply Chain Resilience and Localization of Component Manufacturing

Global supply chain disruptions have prompted forklift part manufacturers to localize production. By 2026, companies are shifting toward regional manufacturing hubs for components like transmissions, forks, and hydraulic systems to reduce lead times and mitigate geopolitical risks. This trend supports faster delivery, customization, and reduced logistics costs. Investment in automation and additive manufacturing (3D printing) is also enabling on-demand production of low-volume or obsolete parts, improving serviceability.

Conclusion

The 2026 market for forklift truck parts is being reshaped by electrification, digitalization, safety regulations, and supply chain innovation. Companies that adapt to these trends—by developing smarter, safer, and more sustainable components—will gain a competitive edge in a rapidly evolving industrial landscape.

Common Pitfalls Sourcing Parts Of A Fork Truck (Quality, IP)

When sourcing parts for a forklift (also known as a fork truck), businesses often face challenges related to quality assurance and intellectual property (IP) concerns. Avoiding these common pitfalls is crucial for ensuring operational safety, regulatory compliance, and long-term cost-efficiency.

Poor Quality Components

One of the most frequent issues when sourcing forklift parts is receiving substandard components. Low-quality parts—such as worn hydraulic cylinders, weak forks, or faulty brake systems—can lead to equipment failure, workplace accidents, and increased downtime. These parts may come from suppliers offering lower prices but compromising on materials, manufacturing precision, or testing standards. Using such parts not only risks safety but also increases total cost of ownership due to frequent replacements and repairs.

Counterfeit or Non-OEM Parts with IP Violations

Another major pitfall is the unintentional procurement of counterfeit or imitation parts that infringe on intellectual property rights. Many third-party manufacturers produce look-alike components branded with logos or part numbers that mimic original equipment manufacturer (OEM) designs. While marketed as compatible, these may violate trademarks or patents. Sourcing such parts exposes companies to legal risks, including fines, import seizures, or liability in case of failure. Additionally, counterfeit parts often lack proper certification and traceability, making compliance with industry standards difficult.

Lack of Certification and Compliance

Forklift parts must meet specific safety and performance standards (e.g., ANSI, OSHA, ISO). Sourcing components without proper certifications—such as CE marking or ISO 9001—can result in non-compliance during audits or inspections. This is especially risky with critical parts like load backrests, overhead guards, or lifting chains, where failure could lead to serious injury or regulatory penalties.

Inadequate Supplier Verification

Many organizations fail to perform due diligence on suppliers, particularly when sourcing from international or online marketplaces. Without verifying a supplier’s reputation, manufacturing capabilities, or quality control processes, buyers risk receiving inconsistent or defective parts. This is compounded when communication barriers or lack of transparency prevent effective post-purchase support or warranty claims.

Ignoring Compatibility and Specifications

Even if a part appears identical, slight differences in dimensions, load capacity, or mounting configuration can render it incompatible. Sourcing parts without cross-referencing serial numbers, model specifications, or technical drawings may lead to improper fit or performance issues. This pitfall is especially common when replacing forks, mast components, or hydraulic fittings.

Conclusion

To avoid these pitfalls, businesses should prioritize certified suppliers, verify part authenticity, insist on documentation (such as material test reports and compliance certificates), and consult OEM guidelines when possible. Investing time in due diligence reduces risks related to quality, safety, and IP, ensuring reliable and legally sound forklift operations.

Logistics & Compliance Guide for Parts of a Fork Truck

Understanding the logistics and compliance requirements for forklift parts is essential for safe operation, regulatory adherence, and efficient supply chain management. Below is a comprehensive guide covering key components, transportation considerations, and compliance standards.

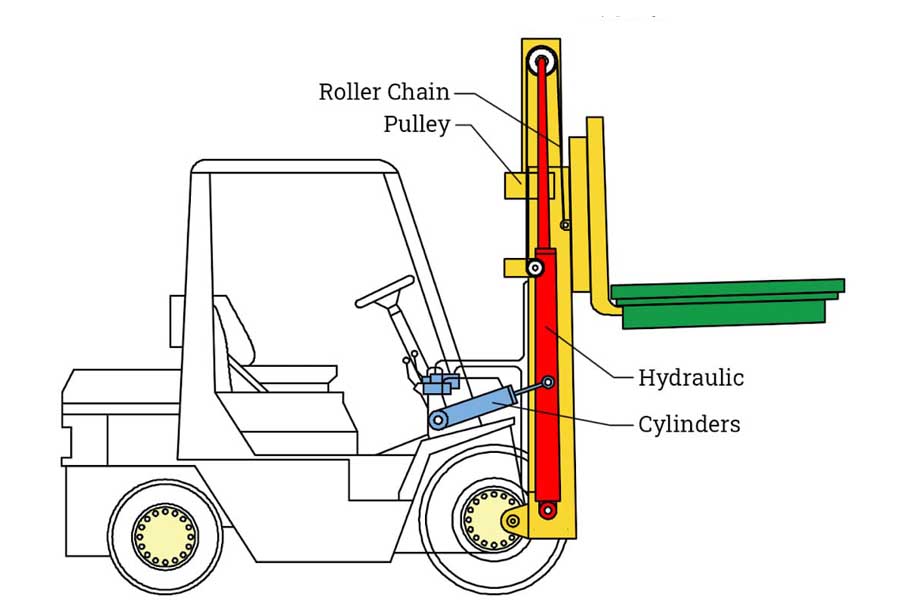

Forklift Mast & Hydraulic System

The mast and hydraulic system are critical for lifting and lowering loads. Logistics considerations include the size and weight of mast assemblies and hydraulic cylinders, which may require specialized packaging and handling. Ensure compliance with OSHA 29 CFR 1910.178, which mandates regular inspection and maintenance of lifting mechanisms. When transporting, secure components to prevent damage and label with handling instructions (e.g., “Fragile – Hydraulic Components”).

Forks & Carriage Assembly

Forks and carriage parts must meet ANSI/ITSDF B56.1 safety standards for material strength and load capacity. During logistics, use protective covers to prevent bending or corrosion. Forks are often made of high-tensile steel and must be clearly marked with rated capacity and manufacturer information. Verify compliance with local regulations when importing/exporting, as some regions require certification marks (e.g., CE in Europe).

Power Source Components (Battery, Fuel System, Motor)

Logistics for batteries (especially lead-acid) must comply with IATA/IMDG regulations for hazardous materials due to sulfuric acid content. Use UN-certified packaging and proper labeling (Class 8 Corrosive). Electric motors and controllers should be packed in anti-static materials. For internal combustion forklifts, fuel tanks must be drained and purged before shipping to meet DOT and ADR safety standards. Always include Material Safety Data Sheets (MSDS/SDS) with shipments.

Tires & Wheels

Pneumatic and solid cushion tires require different handling. Pneumatic tires should be shipped deflated to reduce volume and prevent rupture. Ensure tires comply with regional standards (e.g., E-Mark in EU). Record tire specifications (size, load index, speed rating) for traceability. Store in cool, dry areas away from UV exposure to maintain integrity during transit and storage.

Control Systems & Electrical Components

Sensors, wiring harnesses, and operator controls are sensitive to moisture and vibration. Use moisture-resistant packaging and shock-absorbing materials. Comply with electromagnetic compatibility (EMC) directives (e.g., EU Directive 2014/30/EU) for electronic parts. Include compliance documentation with each shipment, especially for OEM replacements. Label with ESD (Electrostatic Discharge) protection symbols where applicable.

Safety & Warning Devices

Horns, backup alarms, warning lights, and load backrests must meet ANSI/ITSDF B56.1 and OSHA requirements. Confirm all safety devices are operational upon receipt. Ship with original compliance tags and manufacturer certification. Maintain records to support workplace safety audits and prevent non-compliant installations.

Compliance Documentation & Recordkeeping

Maintain a digital and physical log of all parts, including:

– Manufacturer name and part number

– Compliance certifications (CE, ANSI, ISO)

– Date of receipt and installation

– Inspection and maintenance records

This supports traceability, recalls, and regulatory audits. Ensure all suppliers provide certified documentation, especially for critical safety components.

Import/Export & Customs Compliance

When shipping internationally, classify parts using the correct HS codes (e.g., 8427.90 for forklift parts). Complete customs declarations accurately, including country of origin and value. Comply with REACH (EU), RoHS (electronics), and TSCA (US) for chemical content. Use licensed freight forwarders familiar with industrial equipment regulations.

Storage & Inventory Management

Store parts in a clean, dry, and organized environment. Use FIFO (First In, First Out) for perishable items like seals and hoses. Segregate hazardous materials (e.g., batteries, fluids) in approved storage cabinets. Conduct periodic inventory audits to ensure compliance with safety stock and obsolescence policies.

By adhering to logistics best practices and regulatory standards, businesses can ensure the safe, legal, and efficient handling of forklift parts throughout their lifecycle.

In conclusion, sourcing parts for a forklift requires a strategic approach that balances cost, quality, availability, and compatibility. Whether opting for original equipment manufacturer (OEM) parts or aftermarket alternatives, it is essential to evaluate suppliers based on their reputation, certifications, and after-sales support. Proper identification of required components, adherence to safety standards, and consideration of lead times and warranty terms all contribute to maintaining optimal forklift performance and minimizing downtime. By establishing reliable supply chains and maintaining strong vendor relationships, businesses can ensure efficient operations, extend equipment lifespan, and enhance overall productivity in material handling environments.