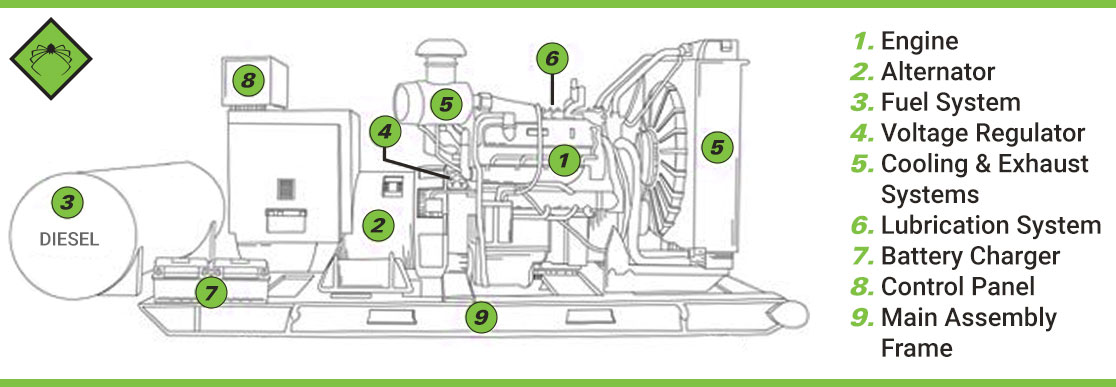

The global generator market is experiencing robust expansion, driven by increasing demand for reliable backup power across industrial, commercial, and residential sectors. According to Grand View Research, the global generator set market size was valued at USD 20.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.6% from 2024 to 2030. This growth is fueled by rising energy demands, frequent power outages in developing regions, and infrastructure development in emerging economies. As generator manufacturers scale production to meet this demand, the selection of high-performance, durable components becomes critical to maintaining efficiency, reliability, and compliance with evolving emissions standards. From engines and alternators to voltage regulators and cooling systems, the right parts not only enhance operational performance but also directly impact total cost of ownership and service life. In this context, identifying the top 10 essential parts for generator manufacturers is key to optimizing supply chain decisions, improving product quality, and staying competitive in a rapidly growing market.

Top 10 Parts For Generator Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Generator Parts & Transfer Switch Dealer

Domain Est. 1997

Website: energysystems.com

Key Highlights: Original Equipment Manufacturer (OEM) Parts. Energy Systems carries a broad range of branded parts for most generator makes and models, including Generac….

#2 PowerTech Parts

Domain Est. 2011

Website: powertechparts.com

Key Highlights: Your trusted source for genuine replacement parts and accessories, straight from the manufacturer. Ensure your PowerTech Generator runs at peak performance….

#3 Purchase Industrial Generator Parts

Domain Est. 1996

Website: americasgenerators.com

Key Highlights: Order generator parts from Americas Generators. Our generator parts for sale include electrical parts, regulators, alternators, and generator controllers….

#4 Generator Parts

Domain Est. 2004

Website: ereplacementparts.com

Key Highlights: 1–2 day deliveryShop for Generator parts today! Find genuine OEM replacement parts along with expert repair help, video tutorials, and same–day shipping on ……

#5 Genuine Cummins Parts

Domain Est. 1990

Website: parts.cummins.com

Key Highlights: https://parts.cummins.com is the Genuine online catalog for Holset®, Fleetguard®, Onan and Cummins parts….

#6 Portable Generator Parts and Accessories

Domain Est. 1995

Website: generac.com

Key Highlights: Boost your generator’s performance with genuine parts and accessories from Generac. Products are available to maximize convenience and simplify maintenance….

#7 Engine & Generator Parts for Sale

Domain Est. 1996

Website: ckpower.com

Key Highlights: Our inventory includes essential components such as oil filters, engine overhaul kits, cylinder head kits, remanufactured parts, and more….

#8 Generac, Onan, Kohler Generator Parts

Domain Est. 2006

Website: generator-parts.com

Key Highlights: Our site has all available Generac, Onan, and Kohler parts listed. Just enter the part number you are looking for in the search box located on every page of the ……

#9 Generator Magic

Domain Est. 2012

Website: generatormagic.com

Key Highlights: Free delivery over $50 · 30-day returns…

#10 Parts

Domain Est. 2016

Website: generacpowerproducts.com

Key Highlights: Free delivery over $100 30-day returns…

Expert Sourcing Insights for Parts For Generator

2026 Market Trends for Parts for Generator

The global market for generator parts is poised for significant transformation by 2026, driven by technological innovation, evolving energy demands, and heightened focus on resilience and sustainability. Here are the key trends shaping the industry:

Increasing Demand for Backup Power Solutions

Growing frequency and severity of extreme weather events, coupled with aging grid infrastructure in many regions, are accelerating investments in backup power systems. This directly translates to sustained demand for generator parts, particularly for maintenance, repair, and overhaul (MRO) activities. Hospitals, data centers, telecommunications, and industrial facilities are prioritizing power continuity, driving procurement of critical components like alternators, voltage regulators, and control panels.

Shift Toward Hybrid and Smart Generator Systems

The integration of renewable energy sources is推动 the development of hybrid generator systems that combine traditional diesel or natural gas engines with battery storage and solar/wind inputs. By 2026, demand will rise for intelligent parts compatible with these hybrid controls, including smart inverters, energy management modules, and IoT-enabled sensors. These components allow for optimized fuel usage, remote monitoring, and predictive maintenance, reducing operational costs and emissions.

Rise of Predictive Maintenance and IoT Integration

Generator manufacturers and end-users are increasingly adopting Internet of Things (IoT) technologies to monitor equipment health in real time. Parts equipped with embedded sensors—such as smart fuel injectors, temperature probes, and vibration detectors—will see strong growth. These components feed data into cloud-based platforms for predictive analytics, enabling proactive replacement of wear-prone parts like starter motors and air filters before failure occurs, minimizing downtime.

Focus on Emission Compliance and Alternative Fuels

Stricter environmental regulations, particularly in North America and Europe, are pushing demand for low-emission generator technologies. This trend favors parts designed for cleaner combustion, such as advanced exhaust after-treatment systems (e.g., diesel particulate filters and selective catalytic reduction components), high-efficiency turbochargers, and parts compatible with alternative fuels like biogas, hydrogen, and renewable natural gas (RNG). Suppliers investing in such components will gain a competitive edge.

Supply Chain Resilience and Localization

Ongoing geopolitical tensions and supply chain disruptions have prompted companies to reevaluate sourcing strategies. By 2026, there will be a noticeable shift toward regional manufacturing and localized inventory of critical generator parts, especially for defense, healthcare, and essential infrastructure. This trend supports the growth of regional distributors and aftermarket part manufacturers offering certified, cost-effective replacements.

Growth in Emerging Markets and Off-Grid Applications

Rapid urbanization and industrial expansion in Asia-Pacific, Africa, and Latin America are fueling demand for reliable power solutions. In areas with unreliable grids, generators serve as primary power sources, increasing the need for durable and affordable parts. Components such as engine blocks, cooling systems, and fuel systems designed for harsh environments and continuous operation will see robust demand in these regions.

Expansion of the Aftermarket and Remanufactured Parts

Cost-conscious consumers and businesses are increasingly turning to remanufactured or aftermarket generator parts as a sustainable and economical alternative to OEM components. By 2026, the aftermarket is expected to grow significantly, supported by improved quality standards and warranties. Key remanufactured parts include starters, alternators, and control modules, offering performance comparable to new parts at reduced cost and environmental impact.

Emphasis on Digital Platforms and E-Commerce

Digital transformation is reshaping how generator parts are sourced. Online marketplaces, B2B e-commerce platforms, and manufacturer-direct portals are becoming primary channels for procurement. Enhanced digital catalogs with 3D models, compatibility checkers, and real-time inventory tracking will improve customer experience and streamline supply chains, particularly for niche or obsolete parts.

In conclusion, the 2026 landscape for generator parts will be defined by intelligence, sustainability, and resilience. Companies that innovate in smart components, support alternative energy integration, and adapt to digital and regionalized supply models will be best positioned to capture growth in this dynamic market.

Common Pitfalls When Sourcing Parts for Generators: Quality and Intellectual Property Risks

Logistics & Compliance Guide for Parts for Generator

This guide outlines key logistics and compliance considerations when shipping, handling, and managing generator parts across supply chains. Adhering to these practices ensures timely delivery, regulatory compliance, and operational safety.

Classification and Documentation

Proper classification of generator parts is essential for regulatory compliance and smooth customs clearance. Determine the Harmonized System (HS) code for each part, such as alternators (HS 8501), control panels (HS 8537), or fuel systems (HS 8413). Maintain accurate commercial invoices, packing lists, and certificates of origin. For international shipments, ensure compliance with Incoterms® (e.g., FOB, CIF) to clarify responsibilities between buyer and seller.

Packaging and Handling Requirements

Generator parts vary in size, weight, and sensitivity. Use robust packaging to protect components from moisture, shock, and corrosion. Seal electrical parts in anti-static or moisture-resistant materials. Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”) and include part numbers, serial numbers, and safety warnings. Use secure crating for heavy components like engine blocks or stators to prevent damage during transit.

Transportation and Shipping Modes

Select the appropriate transportation mode based on part size, urgency, and destination. Small parts can be shipped via air freight for speed; large or heavy components may require ocean or road freight. Coordinate with carriers experienced in industrial equipment logistics. Ensure temperature control if shipping sensitive electronics. Track shipments in real time and maintain communication with logistics partners to manage delays.

Import/Export Regulations

Comply with export control regulations such as the U.S. Export Administration Regulations (EAR) or EU Dual-Use Regulation, especially if parts have potential military applications. Obtain necessary export licenses where required. Verify import restrictions, duties, and taxes in the destination country. Some generator components may be subject to environmental or energy efficiency standards (e.g., EPA, CE marking), requiring conformity assessments before entry.

Environmental and Safety Compliance

Adhere to environmental regulations for parts containing hazardous materials, such as lead-acid batteries or oil-lubricated components. Follow proper disposal and recycling protocols in line with directives like RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment). Ensure packaging materials are recyclable and minimize waste. Comply with OSHA (or local equivalent) guidelines for safe warehouse handling and storage.

Customs Clearance and Duties

Prepare accurate documentation to facilitate customs clearance. Include detailed descriptions, values, country of origin, and applicable certifications. Use Authorized Economic Operator (AEO) status if available to expedite processing. Monitor changes in trade agreements or tariffs that may impact duty rates. Leverage bonded warehouses or free trade zones when storing parts temporarily to defer duty payments.

Inventory and Traceability Management

Maintain a robust inventory system to track generator parts from receipt to delivery. Use barcode or RFID tagging for real-time visibility and traceability. Record batch/lot numbers, manufacturing dates, and warranty information. Implement first-in, first-out (FIFO) practices for parts with shelf-life limitations. Regular audits help ensure inventory accuracy and compliance with quality standards (e.g., ISO 9001).

Supplier and Vendor Compliance

Verify that suppliers adhere to international standards and ethical sourcing practices. Conduct compliance audits for environmental, labor, and quality management systems. Ensure vendor contracts include clauses on delivery timelines, quality assurance, and liability for non-compliant shipments. Maintain a qualified supplier list and monitor performance metrics regularly.

Risk Mitigation and Contingency Planning

Identify potential supply chain risks such as geopolitical issues, natural disasters, or port congestion. Diversify suppliers and transportation routes where possible. Maintain safety stock for critical generator components to avoid operational downtime. Develop a contingency plan for recall situations, including procedures for reverse logistics and regulatory reporting.

Training and Regulatory Updates

Provide regular training for logistics and procurement teams on compliance requirements, handling procedures, and emergency response. Subscribe to regulatory updates from agencies such as U.S. Customs and Border Protection (CBP), European Commission, or local authorities. Stay informed about changes in sanctions, trade policies, or environmental standards affecting generator part distribution.

In conclusion, sourcing parts for a generator requires careful consideration of factors such as compatibility, quality, availability, and cost. It is essential to identify the generator’s make, model, and serial number to ensure precise part matching. Opting for OEM (Original Equipment Manufacturer) parts guarantees reliability and performance, while reputable aftermarket alternatives can offer cost savings without compromising durability. Establishing relationships with trusted suppliers, verifying certifications, and reviewing warranties contribute to long-term operational efficiency and reduced downtime. Additionally, maintaining an inventory of critical spare parts and leveraging digital sourcing tools can streamline maintenance and enhance generator uptime. A strategic and well-informed sourcing approach ultimately ensures optimal generator performance, safety, and longevity.