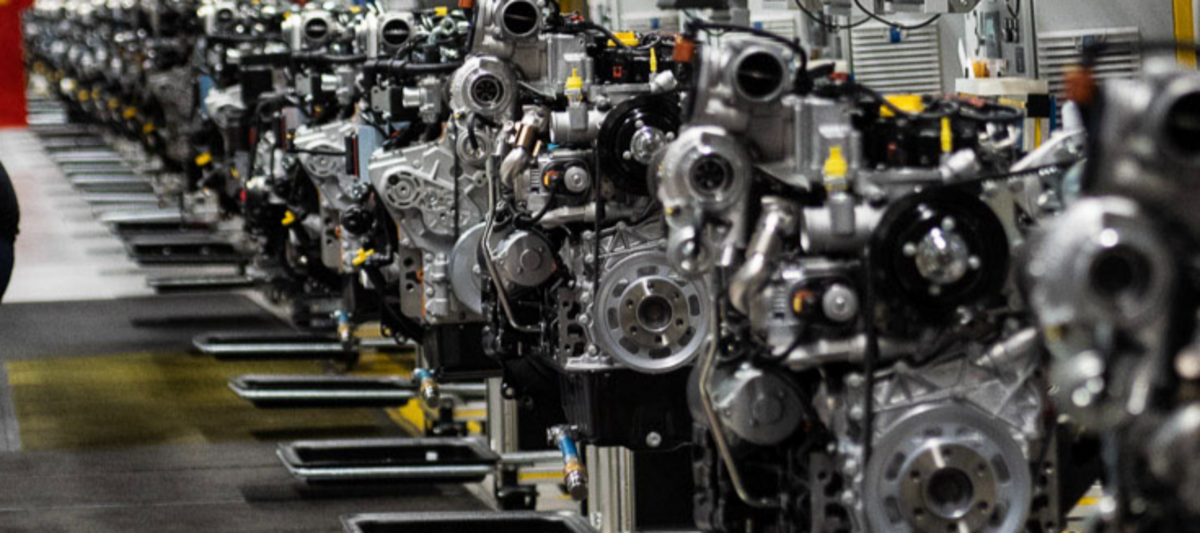

The global diesel engine market, which includes critical applications for Deutz engine manufacturers, is experiencing steady growth driven by increasing demand across construction, agricultural, and industrial sectors. According to Grand View Research, the global diesel engine market size was valued at USD 161.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This expansion underscores the rising need for reliable, high-performance engine components, particularly for established players like Deutz AG. As emission standards tighten and efficiency demands rise, manufacturers are prioritizing advanced parts that enhance durability, optimize fuel consumption, and ensure compliance. Against this backdrop, certain components have emerged as essential to maintaining competitive advantage and operational excellence in Deutz-powered equipment. The following four parts represent the most critical and frequently upgraded elements, supported by technical demand, service frequency, and OEM specifications within the Deutz engine ecosystem.

Top 4 Parts For Deutz Engine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 DEUTZ Genuine Parts and Fluids

Domain Est. 1996

Website: deutzusa.com

Key Highlights: DEUTZ Genuine Parts and Fluids have been designed and tested specifically for DEUTZ engines, in order to provide you with maximum performance and long engine ……

#2 DEUTZ Spare Parts: First choice

Domain Est. 1996

Website: deutz.com

Key Highlights: We offer you an extended warranty for five years or 5,000 operating hours for genuine DEUTZ spare parts and Xchange parts purchased from, and installed by, one ……

#3 Deutz Service Portal

Domain Est. 1996

Website: serviceportal.deutz.com

Key Highlights: Genuine DEUTZ parts have been designed and tested specifically for DEUTZ engines – to provide you with maximum performance and long engine life….

#4 Genuine DEUTZ Engine Parts Dealers & Service Centers USA

Domain Est. 2015

Website: deutzsupport.com

Key Highlights: Get genuine DEUTZ engine parts straight from the source. DEUTZ Support ensures you get the right parts and service, fast. Call us today….

Expert Sourcing Insights for Parts For Deutz Engine

H2: 2026 Market Trends for Parts for Deutz Engine

The market for parts for Deutz engines is poised for strategic evolution by 2026, shaped by technological innovation, regulatory shifts, and changing industry demands. As Deutz AG remains a key player in the production of diesel and alternative fuel engines for industrial, agricultural, and construction applications, the aftermarket parts sector is adapting to several emerging trends.

-

Increasing Demand for Emission-Compliant Components

With the enforcement of stringent global emissions standards—such as EU Stage V and potential updates toward Stage VI—the demand for emission control parts (e.g., diesel particulate filters, selective catalytic reduction systems, and exhaust gas recirculation components) will grow. Aftermarket suppliers are focusing on producing high-quality, compliant parts that meet OEM specifications while offering cost advantages. -

Growth in Alternative Fuel Engine Parts

Deutz’s investment in hydrogen-powered and natural gas engines is accelerating. By 2026, the market is expected to see a rise in demand for specialized parts tailored to these alternative fuel systems, including hydrogen injectors, reinforced cylinder heads, and modified fuel delivery systems. This shift will drive innovation among parts manufacturers and increase the need for technician training in handling new technologies. -

Expansion of Remanufactured and Recycled Parts Market

Sustainability initiatives and cost-efficiency demands are boosting the remanufactured parts segment. In 2026, remanufactured Deutz engine components—such as turbochargers, fuel pumps, and starters—are expected to capture a larger market share, especially in developing regions. These parts offer up to 40% cost savings compared to new OEM parts while maintaining reliability, supported by improved quality control processes. -

Digitalization and Predictive Maintenance Integration

The integration of IoT-enabled sensors and telematics in industrial machinery is transforming maintenance practices. By 2026, smart parts and digital service platforms will allow real-time monitoring of engine health, predicting failure points and optimizing part replacement schedules. This trend will increase demand for compatible sensors and data-connected components within the Deutz ecosystem. -

Regional Market Shifts and Supply Chain Localization

Emerging markets in Asia-Pacific, Africa, and Latin America will drive demand for Deutz engine parts due to rising infrastructure development and mechanization in agriculture. To reduce lead times and logistics costs, suppliers are increasingly localizing production and distribution networks. This localization trend supports faster access to parts and strengthens regional service capabilities. -

Counterfeit Parts Challenge and Brand Protection

As demand grows, so does the risk of counterfeit parts. OEMs and authorized distributors are expected to intensify anti-counterfeiting efforts in 2026 using blockchain-based tracking, QR codes, and digital part authentication. Customers will increasingly prioritize certified parts to ensure engine longevity and compliance.

Conclusion

By 2026, the market for Deutz engine parts will be characterized by innovation, sustainability, and digital integration. Stakeholders who adapt to emission regulations, embrace alternative fuels, and leverage digital tools will gain a competitive edge. The aftermarket sector must balance cost-efficiency with quality assurance to meet the evolving needs of global industries relying on Deutz-powered equipment.

Common Pitfalls Sourcing Parts for Deutz Engine (Quality, IP)

1. Counterfeit or Substandard Components

One of the most significant risks when sourcing Deutz engine parts is encountering counterfeit or low-quality imitations. These parts may appear identical to genuine components but often fail prematurely due to inferior materials and manufacturing processes. Using such parts can lead to engine damage, increased downtime, and higher long-term repair costs.

2. Lack of Intellectual Property (IP) Compliance

Many aftermarket parts infringe on Deutz’s intellectual property, including trademarks, designs, and technical specifications. Sourcing non-OEM parts that violate IP rights not only exposes buyers to legal risks but may also compromise engine performance and warranty coverage.

3. Inadequate Certification and Testing

Genuine Deutz parts undergo rigorous testing and meet strict quality standards. However, third-party suppliers may not provide equivalent certifications (e.g., ISO, CE, or OEM approval). Without proper documentation, it’s difficult to verify part reliability and compliance with safety regulations.

4. Inconsistent Part Fit and Functionality

Even if a part looks similar, dimensional inaccuracies or material differences in non-genuine components can result in improper fitment or suboptimal performance. This can cause operational inefficiencies, increased wear on adjacent components, and potential engine failure.

5. Unreliable Supply Chain and Traceability

Sourcing parts from unauthorized distributors or unclear supply chains increases the risk of receiving outdated, refurbished, or stolen components. Lack of traceability makes it difficult to ensure authenticity and complicates warranty claims.

6. Voided Manufacturer Warranty

Using non-genuine or IP-infringing parts may void the engine’s warranty. Deutz and authorized service providers often require OEM parts to maintain warranty coverage, and using unapproved components can lead to denied service claims.

7. Hidden Costs from Downtime and Repairs

While non-OEM parts may offer short-term cost savings, the long-term expenses due to frequent failures, unplanned downtime, and secondary damage can far exceed the initial price difference. Investing in genuine, IP-compliant parts reduces total cost of ownership.

8. Insufficient Technical Support and Documentation

Genuine Deutz parts come with comprehensive technical documentation and access to manufacturer support. Aftermarket suppliers may lack detailed installation guides, performance data, or responsive customer service, leading to incorrect installation or troubleshooting challenges.

To mitigate these risks, always purchase Deutz engine parts through authorized dealers or certified suppliers, verify part numbers against official catalogs, and confirm compliance with OEM specifications and IP rights.

Logistics & Compliance Guide for Parts for Deutz Engine

Overview

This guide outlines the key logistics and compliance considerations when sourcing, shipping, and handling replacement parts for Deutz engines. Adhering to these procedures ensures timely delivery, regulatory compliance, and product integrity across international and domestic supply chains.

Product Classification and Harmonized System (HS) Codes

Accurately classify Deutz engine parts using the Harmonized System (HS) coding structure to ensure proper customs clearance and tariff application. Common classifications include:

– 8409.91: Parts and accessories for internal combustion piston engines (e.g., cylinder heads, pistons, crankshafts)

– 8413.30: Fuel injection pumps and injectors

– 8414.90: Turbochargers and superchargers

– 8511.50: Ignition equipment (for gas-powered Deutz engines)

Consult local customs authorities or a licensed customs broker to confirm the correct HS code based on part function and material.

Import/Export Regulations

Deutz engine parts may be subject to import/export controls depending on destination country and part type. Key compliance areas include:

– Export Licenses: Required for certain high-performance or dual-use components (e.g., advanced fuel systems) under national security or technology transfer regulations (e.g., EAR in the U.S.).

– Trade Sanctions: Ensure destination countries are not under international sanctions (e.g., OFAC, EU embargoes).

– Certificate of Origin: Required by many countries to determine duty rates under free trade agreements (e.g., EUR.1 for EU trade).

– Import Permits: Some countries require approval for automotive or industrial engine components.

Packaging and Labeling Requirements

Proper packaging and labeling ensure parts arrive undamaged and meet regulatory standards:

– Use anti-corrosion packaging (VCI paper, desiccants) for metal components.

– Label each package with:

– Part number and description

– Quantity

– Net/Gross weight

– HS code

– Country of origin

– Handling symbols (e.g., “Fragile,” “Do Not Stack”)

– Include bilingual labeling where required (e.g., English and local language).

Shipping and Transportation

Select appropriate logistics modes based on urgency, cost, and part sensitivity:

– Air Freight: Recommended for high-value or urgent parts; provides faster delivery and better tracking.

– Ocean Freight: Cost-effective for bulk shipments; requires proper container sealing and moisture protection.

– Ground Transport: Suitable for regional distribution; ensure temperature and shock protection for sensitive components.

Use carriers experienced in handling automotive or industrial spare parts.

Customs Documentation

Ensure all required documents accompany each shipment:

– Commercial Invoice (with detailed part descriptions and values)

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Export Declaration (e.g., EEI via AES in the U.S.)

– Any applicable test reports or conformity certificates

Incomplete or inaccurate documentation can lead to customs delays, fines, or seizure.

Regulatory Compliance and Certifications

Deutz parts must meet relevant technical and safety standards:

– CE Marking: Required for parts sold in the European Economic Area (EEA), indicating compliance with health, safety, and environmental standards.

– E-Mark Certification: For vehicle components subject to UNECE regulations (e.g., lighting, emission systems).

– RoHS/REACH Compliance: Ensure parts are free from restricted hazardous substances (especially for electrical components).

Verify with Deutz or authorized distributors whether parts are OEM (Original Equipment Manufacturer) or aftermarket, as certification requirements may differ.

Warranty and Traceability

Maintain traceability of parts through:

– Batch/serial number tracking

– Proper storage conditions (temperature, humidity)

– FIFO (First In, First Out) inventory practices

Ensure compliance with Deutz’s warranty policies, especially for remanufactured or rebuilt components.

Environmental and End-of-Life Compliance

Adhere to environmental regulations for handling and disposal:

– WEEE Directive (EU): Applies to electrical and electronic engine components.

– Battery and Oil Handling: If shipping parts with residual fluids, comply with IATA/IMDG regulations for hazardous materials.

– Proper recycling and disposal procedures for packaging and obsolete parts.

Conclusion

Effective logistics and compliance management for Deutz engine parts reduces risks, avoids delays, and ensures customer satisfaction. Partner with experienced freight forwarders, maintain accurate documentation, and stay updated on international trade regulations to support smooth operations.

Conclusion for Sourcing Parts for Deutz Engine:

Sourcing parts for a Deutz engine requires careful consideration of quality, authenticity, availability, and cost-effectiveness. Original Equipment Manufacturer (OEM) parts are highly recommended to ensure compatibility, reliability, and long-term performance, despite their higher initial cost. However, in certain cases where budget constraints exist, high-quality aftermarket alternatives from reputable suppliers can provide a viable solution, provided they meet industry specifications and standards.

Establishing relationships with authorized Deutz distributors or certified suppliers ensures access to genuine components, proper technical support, and warranty coverage. Additionally, maintaining accurate records of part numbers, engine models, and service history helps streamline the procurement process and prevents errors.

In conclusion, a strategic approach—balancing cost, quality, and supplier reliability—is essential when sourcing Deutz engine parts. Prioritizing genuine parts and trusted supply channels ultimately contributes to optimal engine performance, reduced downtime, and extended equipment lifespan.