The global diesel engine market, which includes critical components for Deutz manufacturers, is projected to grow at a CAGR of 4.2% from 2023 to 2030, according to Grand View Research. With industrial machinery, agricultural equipment, and power generation sectors driving demand, the need for reliable and high-performance engine parts has never been greater. As Deutz AG remains a leading player in air- and liquid-cooled engine systems, sourcing the right components—backed by durability, OEM compatibility, and efficiency—is essential for maintaining uptime and performance. Based on industry data and supply chain analytics, the following four parts consistently emerge as the most critical and frequently replaced across Deutz-powered applications, shaping procurement strategies for maintenance teams and OEMs alike.

Top 4 Parts For Deutz Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 DEUTZ Genuine Parts and Fluids

Domain Est. 1996

Website: deutzusa.com

Key Highlights: DEUTZ Genuine Parts and Fluids have been designed and tested specifically for DEUTZ engines, in order to provide you with maximum performance and long engine ……

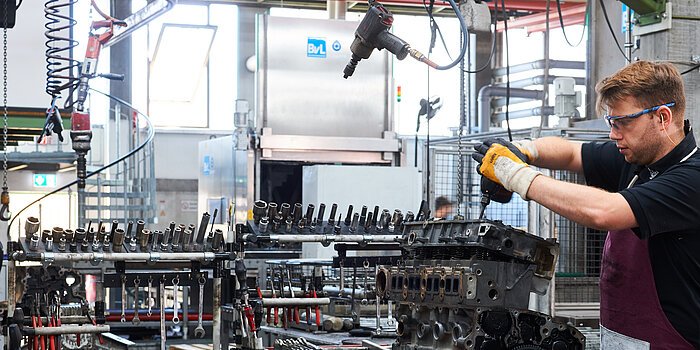

#2 DEUTZ Spare Parts: First choice

Domain Est. 1996

Website: deutz.com

Key Highlights: We offer you an extended warranty for five years or 5,000 operating hours for genuine DEUTZ spare parts and Xchange parts purchased from, and installed by, one ……

#3 Deutz Service Portal

Domain Est. 1996

Website: serviceportal.deutz.com

Key Highlights: Find and buy genuine DEUTZ Parts for your DEUTZ engine, benefit from our DEUTZ Lifetime Parts Warranty and access your engine´sdigital service ……

#4 Genuine DEUTZ Engine Parts Dealers & Service Centers USA

Domain Est. 2015

Website: deutzsupport.com

Key Highlights: Get genuine DEUTZ engine parts straight from the source. DEUTZ Support ensures you get the right parts and service, fast. Call us today….

Expert Sourcing Insights for Parts For Deutz

H2: 2026 Market Trends for Parts for Deutz

The market for parts for Deutz engines is poised for significant evolution by 2026, shaped by global industrial dynamics, technological advancements, regulatory shifts, and evolving customer demands. As Deutz AG remains a key player in the production of diesel and alternative-fuel engines for industrial, agricultural, and commercial applications, the aftermarket and OEM parts sector is expected to reflect broader trends in sustainability, digitalization, and supply chain resilience.

1. Growth Driven by Aftermarket Demand

By 2026, the aftermarket for Deutz engine parts is projected to expand steadily, fueled by the large installed base of Deutz-powered machinery in sectors such as construction, agriculture, material handling, and power generation. Aging equipment fleets, particularly in Europe and North America, will increase demand for replacement parts like fuel injectors, turbochargers, gaskets, and cooling system components. Independent service providers and third-party manufacturers will continue to capture market share, offering cost-effective alternatives to OEM parts.

2. Electrification and Alternative Fuels Impacting Part Requirements

Deutz’s strategic pivot toward emission-free technologies—including electric drives and hydrogen combustion engines—will begin influencing parts demand by 2026. While traditional internal combustion engine (ICE) components will remain in high demand, there will be a gradual shift toward parts related to hybrid systems, battery integration, thermal management, and hydrogen-compatible materials. This transition will require new supply chains and retooling for parts manufacturers, with opportunities emerging in electronic control units, power electronics, and sensors.

3. Regulatory Compliance and Emission Standards

Stringent global emissions regulations, such as EU Stage V and potential future standards, will continue to affect engine maintenance and part replacement cycles. Operators will seek high-efficiency, low-emission components, including advanced exhaust after-treatment systems (e.g., SCR modules, DPFs) and precision-engineered fuel systems compatible with cleaner fuels. Parts that enhance fuel efficiency and reduce downtime will gain competitive advantage in the marketplace.

4. Digitalization and Predictive Maintenance

The integration of IoT and telematics in Deutz-powered equipment will grow by 2026, enabling predictive maintenance and remote diagnostics. This shift will increase demand for smart parts with embedded sensors and connectivity features. Additionally, digital platforms for parts ordering, inventory management, and compatibility verification (e.g., AI-driven part matching) will become standard, improving supply chain efficiency and customer experience.

5. Supply Chain Localization and Resilience

Ongoing geopolitical uncertainties and past disruptions have prompted a strategic shift toward regionalization. By 2026, Deutz and its partners are expected to strengthen localized production and distribution networks, particularly in Europe, North America, and parts of Asia. This will reduce lead times and enhance availability of critical parts, especially during peak operational seasons in agriculture and construction.

6. Sustainability and Circular Economy Initiatives

Environmental concerns will drive demand for remanufactured and recycled Deutz engine parts. By 2026, remanufactured components—such as starters, alternators, and pumps—are expected to gain market share due to their lower cost and reduced environmental impact. Deutz’s own reman programs, along with third-party specialists, will benefit from improved logistics and quality certification processes.

Conclusion

The 2026 market for Deutz engine parts will be characterized by a balanced transition: strong ongoing demand for traditional ICE components alongside emerging opportunities in electrification, digital integration, and sustainable practices. Stakeholders who adapt to these trends—by investing in technology, expanding service capabilities, and embracing circular economy models—will be best positioned for growth in this evolving landscape.

Common Pitfalls Sourcing Parts for Deutz Engines

Sourcing parts for Deutz engines—especially for industrial, agricultural, or power generation applications—can be challenging. While cost and availability are primary concerns, overlooking quality and intellectual property (IP) issues can lead to serious operational, legal, and financial consequences. Below are two major pitfalls to avoid when procuring Deutz engine components.

Quality Concerns with Aftermarket or Imitation Parts

One of the most significant risks when sourcing Deutz parts is compromising on quality. Many suppliers offer “compatible” or “universal” parts at lower prices, but these often fail to meet the rigorous engineering standards required for Deutz engines. Common quality-related issues include:

- Material Deficiencies: Substandard alloys or inferior casting processes can lead to premature wear, cracking, or catastrophic failure under high-load or high-temperature conditions.

- Inconsistent Tolerances: Non-OEM parts may not adhere to precise dimensional specifications, leading to poor fitment, leaks, or reduced engine efficiency.

- Lack of Testing and Certification: Genuine Deutz parts undergo extensive testing for durability, emissions compliance, and performance. Counterfeit or low-quality alternatives often skip these validations.

- Shorter Lifespan and Increased Downtime: Poor-quality parts may require more frequent replacements, increasing maintenance costs and operational downtime.

Using non-certified components can void warranties and may not comply with regional emissions or safety regulations, especially in EU and North American markets.

Intellectual Property (IP) and Counterfeit Risks

Another critical pitfall is inadvertently sourcing counterfeit or IP-infringing parts. Deutz holds patents, trademarks, and design rights on many of its engine components. When sourcing from third-party suppliers—especially in markets with weak IP enforcement—buyers risk:

- Purchasing Counterfeit Goods: Fake parts may bear Deutz logos or part numbers without authorization. These are often manufactured without quality control and can damage the engine or pose safety hazards.

- Legal and Reputational Exposure: Distributing or installing counterfeit parts may expose businesses to legal liability, including claims of trademark infringement or breach of contract.

- Supply Chain Vulnerability: Unverified suppliers may lack traceability, making it difficult to verify authenticity or recall defective components.

- Support and Warranty Issues: Deutz and authorized service providers may refuse to support engines that contain counterfeit or non-approved parts.

To mitigate IP risks, always purchase from authorized Deutz distributors or certified resellers, verify part authenticity through official channels, and maintain proper documentation of procurement.

In summary, prioritizing genuine, high-quality Deutz parts not only ensures engine reliability and longevity but also protects your business from legal and operational risks associated with substandard or counterfeit components.

Logistics & Compliance Guide for Parts for Deutz

This guide outlines key logistics and compliance considerations when handling, shipping, and distributing spare parts for Deutz engines. Adherence to these guidelines ensures efficient operations, regulatory compliance, and customer satisfaction.

Order Processing & Inventory Management

Ensure accurate and timely order fulfillment by maintaining an up-to-date inventory system integrated with Deutz’s official parts catalog. Use standardized part numbering and descriptions to prevent errors. Conduct regular cycle counts and audits to maintain inventory accuracy. Prioritize stock rotation (FIFO – First In, First Out) to minimize obsolescence, especially for rubber components and fluids.

Packaging & Labeling Standards

All Deutz parts must be packaged to prevent damage during transit. Use protective materials such as foam inserts, corrugated boxes, and moisture barriers where necessary. Labels must include:

– Deutz part number and description

– Serial or batch number (if applicable)

– Quantity

– Country of origin

– Handling instructions (e.g., “Fragile,” “This Side Up”)

– Compliance markings (e.g., CE, RoHS, REACH)

Shipping & Transportation

Partner with reliable carriers experienced in handling industrial spare parts. Use tracked and insured shipping methods for all consignments. For international shipments, ensure compliance with Incoterms (e.g., EXW, FCA, DAP) as agreed with the customer. Maintain proper documentation, including commercial invoices, packing lists, and certificates of origin.

Customs Compliance

Prepare accurate customs documentation to avoid delays. For exports, classify parts using the correct HS (Harmonized System) codes. Ensure compliance with export control regulations, especially for dual-use items. Verify sanctions lists and obtain necessary export licenses when required. For imports, confirm tariff classifications and duty rates in the destination country.

Regulatory & Environmental Compliance

Adhere to regional and international regulations, including:

– REACH & RoHS (EU): Ensure parts are free from restricted substances.

– WEEE Directive: Comply with waste electrical and electronic equipment guidelines where applicable.

– Battery Regulations: Follow proper handling and disposal protocols for starter batteries.

– Chemical Handling: Comply with SDS (Safety Data Sheet) requirements for oils, coolants, and adhesives.

Product Authenticity & Anti-Counterfeiting

Distribute only genuine Deutz parts sourced through authorized channels. Implement traceability systems to track parts from receipt to delivery. Report suspected counterfeit parts to Deutz immediately. Use holograms, tamper-evident seals, or unique serial numbers on high-value components.

Returns & Warranty Handling

Establish a clear returns policy aligned with Deutz warranty terms. Inspect returned parts for damage, usage, and authenticity. Document all warranty claims and coordinate with Deutz for authorization and reimbursement. Maintain records for audit purposes.

Documentation & Record Keeping

Retain all logistics and compliance records for a minimum of 7 years. This includes:

– Purchase and sales invoices

– Shipping manifests

– Customs documentation

– Certificates of conformity

– Warranty claim records

– SDS for hazardous materials

Training & Compliance Oversight

Provide regular training for staff on logistics procedures, safety standards, and regulatory updates. Appoint a compliance officer to monitor changes in international trade laws and ensure ongoing adherence. Conduct internal audits to verify compliance with this guide.

By following this Logistics & Compliance Guide, distributors and service partners can ensure reliable, legal, and efficient handling of Parts for Deutz, supporting operational excellence and customer trust.

Conclusion: Sourcing Parts for Deutz Engines

Sourcing parts for Deutz engines requires a strategic approach that balances quality, reliability, cost, and availability. As a leading manufacturer of diesel and natural gas engines, Deutz equipment is widely used across industrial, agricultural, and power generation sectors, making access to genuine and compatible components essential for maintaining performance and longevity.

The most reliable option for sourcing parts is through authorized Deutz dealers and OEM suppliers, which ensure authenticity, proper fit, and compliance with manufacturer specifications. These channels often provide technical support and warranties, reducing downtime and costly repairs. However, OEM parts typically come at a higher price point.

Alternatively, high-quality aftermarket parts from reputable suppliers can offer cost-effective solutions without significantly compromising performance. When selecting aftermarket options, it is crucial to verify specifications, certifications, and supplier credibility to avoid compatibility issues or premature failures.

Additionally, digital platforms and global supply networks have improved access to both new and remanufactured Deutz components, increasing convenience and competitive pricing. Nevertheless, thorough vetting of suppliers remains essential to avoid counterfeit products.

In conclusion, effective sourcing of Deutz parts involves a balanced mix of OEM reliability and aftermarket cost-efficiency, supported by due diligence in supplier selection. Establishing long-term relationships with trusted vendors, maintaining an inventory of critical spares, and staying informed about part availability contribute to optimized maintenance operations and enhanced equipment uptime. Ultimately, proper sourcing directly supports the efficient, safe, and sustainable operation of Deutz-powered machinery.