The global vacuum cleaner market is experiencing steady expansion, driven by increasing demand for high-efficiency cleaning solutions in both residential and commercial sectors. According to Grand View Research, the global vacuum cleaner market size was valued at USD 13.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is fueled by technological advancements, rising disposable incomes, and growing consumer awareness of hygiene and indoor air quality—factors that directly benefit beam vacuum manufacturers who serve built-in and whole-house cleaning systems. As demand for durable, high-performance components rises, identifying the top-performing parts has become critical for manufacturers aiming to maintain reliability, extend product lifespans, and stay competitive in a market increasingly shaped by innovation and efficiency standards.

Top 9 Parts For Beam Vacuum Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Experience the industry

Domain Est. 1996

Website: beamvac.com

Key Highlights: Warranties of up to 15 years on motors, electrical components and dirt receptacles. Ask a BEAM Dealer for warranty details….

#2 Owner’s Manuals

Domain Est. 1999

Website: beamstl.com

Key Highlights: Download the Owner’s Manual for the BEAM central vacuum system you own. BEAM Alliance Power Unit · BEAM Alliance LED Icon Chart ……

#3 Beam Products

Domain Est. 2000

Website: centralvacuumonline.com

Key Highlights: Free delivery over $60 · 30-day returns…

#4 Wall Inlets & Accessories for Beam Central Vacuum Systems

Domain Est. 2002

Website: thinkvacuums.com

Key Highlights: Our Inlets are fully compatible with your Beam Central Vacuum, and keep in mind that Central Vacuum Inlets come in different sizes, colors, and dimensions ……

#5 Beam Vacuum Parts

Domain Est. 2005

Website: ezvacuum.com

Key Highlights: Free delivery76 products · Beam Universal Telescopic Wand For Central Vacuums # 521165 · Beam Electrolux Eureka Central Vacuum Relay #305200 · Beam Electrolux Central Vacuum ……

#6 Parts & Accessories

Domain Est. 2008

Website: beamcentralsystems.com

Key Highlights: Beam Central Vacuum Parts & Accessories. A range of tools, brushes and service parts are available on our online store….

#7 Beam Central Vacuums, Parts & Accessories

Domain Est. 2008

Website: evacuumstore.com

Key Highlights: Free delivery over $50 · 30-day returns…

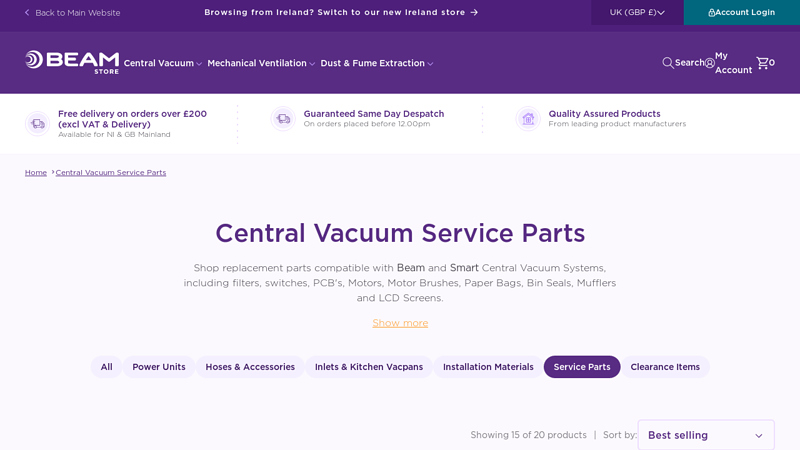

#8 Beam & Smart Central Vacuum Replacement Parts

Domain Est. 2008

Website: store.beamcentralsystems.com

Key Highlights: Shop replacement parts compatible with Beam & Smart Central Vacuum Systems, including filters, PCBs, Motors, Paper Bags, Bin Seals, Mufflers & LCD Screens….

#9 BEAM Attachments

Domain Est. 2011

Website: centralvacuumdirect.com

Key Highlights: Free delivery over $75 · 30-day returnsFind compatible attachments for your BEAM central vacuum here at CentralVacuumDirect.com….

Expert Sourcing Insights for Parts For Beam Vacuum

H2: 2026 Market Trends for Parts for Beam Vacuum

The global market for parts for beam vacuum systems is poised for significant evolution by 2026, driven by industrial automation, advancements in semiconductor manufacturing, and rising demand for high-precision vacuum technologies. Beam vacuum systems—critical in applications such as electron beam welding, lithography, and scientific research—require specialized, high-performance components that ensure reliability, efficiency, and minimal downtime. Several key trends are expected to shape the market landscape for these parts over the coming years:

-

Growth in Semiconductor and Electronics Manufacturing: As the semiconductor industry continues to expand, particularly with the proliferation of AI chips, 5G infrastructure, and advanced electronics, demand for beam vacuum systems in lithography and etching processes will rise. This will directly increase the need for replacement and high-precision parts such as vacuum chambers, electron guns, pumps, seals, and sensors.

-

Increased Focus on Aftermarket and Replacement Parts: With the high capital cost of beam vacuum systems, manufacturers are prioritizing maintenance and lifecycle extension. This trend is fueling demand for affordable, high-quality replacement parts from both OEMs and third-party suppliers. By 2026, the aftermarket segment is anticipated to capture a growing share of the parts market.

-

Technological Advancements and Miniaturization: Advancements in materials science—such as ceramic-metal composites and advanced coatings—are enabling the development of more durable and contamination-resistant parts. Additionally, as beam vacuum systems become more compact and efficient, demand for miniaturized, high-tolerance components will grow.

-

Regional Market Shifts: Asia-Pacific, particularly China, Japan, and South Korea, is expected to dominate the demand for beam vacuum parts due to heavy investments in semiconductor fabs and display manufacturing. Meanwhile, North America and Europe will maintain steady growth, driven by R&D in quantum technologies, aerospace, and nuclear fusion research.

-

Supply Chain Resilience and Localization: Post-pandemic disruptions have prompted manufacturers to reevaluate supply chains. By 2026, there will be a greater push toward regional sourcing and localized production of critical vacuum components to reduce lead times and mitigate geopolitical risks.

-

Adoption of Smart Components and Predictive Maintenance: Integration of IoT-enabled sensors into vacuum system parts allows for real-time monitoring of pressure, temperature, and wear. Predictive maintenance solutions will reduce unplanned downtime and optimize part replacement cycles, driving demand for intelligent components.

-

Sustainability and Energy Efficiency: Environmental regulations and corporate ESG goals are pushing demand for energy-efficient vacuum pumps and recyclable materials in part manufacturing. Companies offering eco-friendly or long-life components are likely to gain competitive advantage.

In conclusion, by 2026, the market for parts for beam vacuum systems will be characterized by innovation, regional diversification, and a strong aftermarket presence. Stakeholders who invest in advanced materials, digital integration, and localized supply chains will be best positioned to capitalize on these emerging opportunities.

Common Pitfalls Sourcing Parts for Beam Vacuum (Quality, IP)

When sourcing replacement or upgrade parts for beam vacuum systems—commonly used in semiconductor manufacturing, electron microscopy, and particle accelerators—organizations face significant challenges related to part quality and intellectual property (IP) protection. Failure to address these pitfalls can result in system downtime, compromised performance, legal exposure, and safety risks.

Poor Component Quality Leading to System Failure

One of the most prevalent risks is procuring substandard parts that fail to meet the stringent requirements of high-vacuum environments. Low-quality materials or imprecise manufacturing can lead to outgassing, leaks, or particulate contamination, which degrade vacuum integrity and damage sensitive equipment. For example, using non-UHV-grade stainless steel or improper sealing surfaces can introduce contaminants that compromise beam coherence and system performance. Additionally, counterfeit or reverse-engineered parts may appear functionally equivalent but lack the necessary certifications (e.g., ASTM, ISO) or traceability, increasing the likelihood of premature failure.

Intellectual Property Infringement and Legal Exposure

Sourcing generic or third-party alternatives without proper licensing exposes organizations to IP violations. Many beam vacuum components—such as specialized pumps, gauges, or chamber interfaces—are protected by patents, trade secrets, or proprietary designs. Unauthorized replication or use of such parts can result in legal action from original equipment manufacturers (OEMs), including cease-and-desist orders, financial penalties, or damage to corporate reputation. Furthermore, using non-OEM parts may void equipment warranties or service agreements, limiting support and increasing long-term costs.

Lack of Traceability and Compliance Documentation

High-reliability industries require full traceability of components, including material certifications (e.g., mill test reports), manufacturing records, and compliance with regulatory standards (e.g., ASME BPE, SEMI). Sourcing from unverified suppliers often results in missing or falsified documentation, making it difficult to validate part suitability or pass audits. This absence of traceability can derail quality assurance processes and regulatory compliance, especially in regulated environments like FDA- or ISO-certified facilities.

Supply Chain Vulnerabilities and Counterfeit Risk

Global sourcing increases exposure to counterfeit parts, especially when purchasing through secondary markets or unauthorized distributors. Fake components may mimic OEM packaging but use inferior materials or outdated designs. These parts often fail under operational stress, potentially causing catastrophic system failure. Moreover, inconsistent supply chains can lead to extended lead times or sudden discontinuation, disrupting maintenance schedules and production timelines.

Inadequate Technical Support and Integration Issues

Non-OEM parts may lack technical documentation or compatibility support, leading to improper installation or integration. Without access to OEM engineering data or calibration specifications, users risk misalignment, incorrect tolerances, or incompatible interfaces. This can result in reduced system efficiency, increased maintenance, or the need for costly retrofits.

To mitigate these risks, organizations should prioritize sourcing from authorized distributors, verify supplier credentials, demand full documentation, and conduct thorough quality inspections. Engaging in formal IP licensing agreements when using third-party parts can also protect against legal exposure while ensuring performance and reliability.

Logistics & Compliance Guide for Parts for Beam Vacuum

This guide outlines the essential logistics and compliance considerations for the handling, transportation, and regulatory adherence of replacement and spare parts used in Beam Vacuum systems. Adhering to these guidelines ensures efficient supply chain operations, regulatory compliance, and product integrity.

Supply Chain Management

Establish a reliable network of suppliers, distributors, and logistics partners familiar with industrial vacuum components. Implement vendor qualification processes to ensure part authenticity, quality, and compliance with technical specifications. Maintain accurate inventory records using an integrated inventory management system to prevent stockouts and overstocking of critical parts.

Packaging and Labeling Requirements

All parts must be packaged to prevent damage during transit, using anti-static materials where applicable, particularly for electronic components. Each package must include clear labeling with part number, description, serial number (if applicable), batch/lot number, country of origin, and handling instructions (e.g., “Fragile,” “Do Not Invert”). Labels must comply with international shipping standards and include barcodes or QR codes for traceability.

International Shipping and Import/Export Compliance

Ensure compliance with international trade regulations, including accurate Harmonized System (HS) codes, commercial invoices, packing lists, and certificates of origin. Screen all shipments against export control lists (e.g., EAR, ITAR) and obtain necessary export licenses when required. Verify import regulations in destination countries, including customs duties, import permits, and conformity assessments (e.g., CE, UKCA, RoHS, REACH).

Regulatory and Environmental Compliance

Parts must meet relevant environmental and safety directives, including:

– RoHS (Restriction of Hazardous Substances) – for electrical and electronic components.

– REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) – for material content disclosure.

– WEEE (Waste Electrical and Electronic Equipment) – ensure proper end-of-life handling information is available.

Maintain Declarations of Conformity (DoC) and technical documentation for all regulated parts.

Transportation and Carrier Selection

Use certified carriers experienced in handling industrial equipment parts. Choose shipping modes (air, sea, ground) based on urgency, cost, and part sensitivity. Ensure temperature-sensitive or fragile components are transported under controlled conditions. Require carriers to provide real-time tracking and proof of delivery.

Quality Assurance and Traceability

Implement a traceability system that logs part movement from supplier to end customer. Conduct regular quality audits of received parts and maintain records of inspections, non-conformance reports, and corrective actions. Use serialized tracking for high-value or safety-critical components.

Documentation and Record Retention

Maintain comprehensive records including:

– Bills of lading

– Customs documentation

– Certificates of compliance

– Quality inspection reports

– Supplier agreements

Retain all documents for a minimum of seven years or as required by local and international regulations.

Returns and Reverse Logistics

Establish a clear process for handling defective or incorrect part returns, including Return Material Authorization (RMA) procedures. Ensure returned parts are inspected, logged, and dispositioned in compliance with environmental regulations. Manage refurbishment, recycling, or disposal according to WEEE and local waste management laws.

Training and Compliance Oversight

Provide regular training for logistics and procurement staff on compliance requirements, packaging standards, and documentation procedures. Appoint a compliance officer to monitor changes in international trade laws and ensure ongoing adherence across the supply chain.

Conclusion for Sourcing Parts for Beam Vacuum Systems

Sourcing components for beam vacuum systems requires a strategic approach that balances technical specifications, quality assurance, supplier reliability, and cost-effectiveness. Given the critical role these systems play in applications such as particle accelerators, electron microscopy, and semiconductor manufacturing, the integrity of each component—ranging from vacuum chambers and pumps to seals, valves, and gauges—is paramount.

A successful sourcing strategy involves identifying suppliers with proven experience in ultra-high vacuum (UHV) environments, materials compatible with stringent cleanliness and outgassing standards (e.g., 316L stainless steel, copper gaskets), and certifications such as ISO 9001 or AS9100 where applicable. Close collaboration with engineering teams ensures components meet performance requirements, including leak-tightness, thermal stability, and compatibility with beamline integration.

Furthermore, lead times, scalability, and after-sales support should be evaluated to support project timelines and long-term maintenance. When possible, standardizing components across systems enhances interchangeability and reduces logistical complexity.

In conclusion, effective sourcing of beam vacuum parts hinges on a meticulous evaluation of technical needs, supplier capabilities, and lifecycle considerations. By prioritizing quality, compatibility, and reliability, organizations can ensure the robust performance and longevity of their vacuum beamline systems.