The industrial parts cleaning equipment market is undergoing rapid transformation, driven by increasing demand for precision cleaning in sectors such as automotive, aerospace, electronics, and medical devices. According to Grand View Research, the global industrial parts cleaning equipment market was valued at USD 9.6 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This expansion is fueled by stringent regulatory standards for contamination control, rising automation in manufacturing, and a growing emphasis on sustainability in cleaning processes. As industries prioritize operational efficiency and component reliability, the role of advanced cleaning technologies—such as aqueous cleaning systems, solvent-based degreasers, ultrasonic cleaners, and plasma treatment—has become increasingly critical. Against this backdrop, leading manufacturers are innovating to deliver high-performance, eco-friendly, and customizable solutions. The following list highlights the top 10 parts cleaning manufacturers shaping the future of industrial cleanliness, selected based on technological leadership, market reach, customer reviews, and contribution to sustainable manufacturing practices.

Top 10 Parts Cleaning Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Baron Blakeslee

Domain Est. 2009

Website: baronblakeslee.net

Key Highlights: We designed cleaning equipment for aerospace parts. · Baron Blakeslee designs and manufactures equipment specifically used to clean precision industrial parts….

#2 Environmental Products & Services

Domain Est. 1995

Website: safety-kleen.com

Key Highlights: Safety-Kleen is a leading provider of parts-cleaning services with a comprehensive selection of equipment, technology, solvents and chemistries….

#3 Services

Domain Est. 1995

Website: uct.com

Key Highlights: We are a global leader in ultra-high purity semiconductor chamber parts cleaning and coatings. We can improve your process performance and lower overall cost-of ……

#4 UCM Precision Cleaning

Domain Est. 1998

Website: ucm-ag.com

Key Highlights: UCM is manufacturer of ultrasonic precision parts cleaning machines. Its globally leading solutions help companies around the world in achieving highest ……

#5 Ransohoff: Industrial Parts Washers

Domain Est. 1999

Website: ransohoff.com

Key Highlights: Ransohoff offers a full range of energy efficient conveyor washers, from standard off the shelf LeanVeyor units to fully customized monorail cleaning systems….

#6 Cuda Cleaning Systems

Domain Est. 2001

Website: cudausa.com

Key Highlights: At Cuda Cleaning Systems, we are proud to offer quality automatic parts washers for cleaning parts in the auto, truck, agriculture and oil services industries….

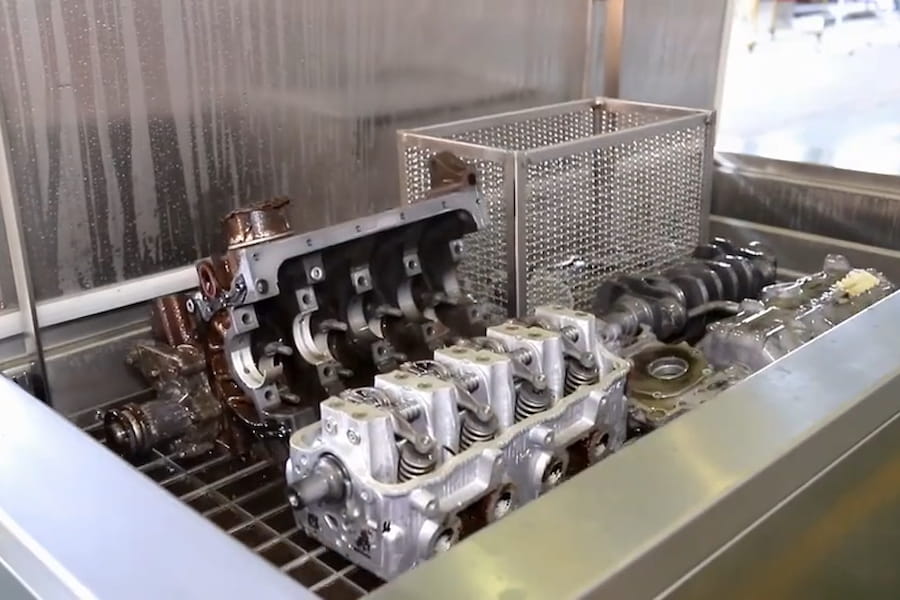

#7 Niagara Systems: Industrial Parts Washers

Domain Est. 2008

Website: niagarasystemsllc.com

Key Highlights: Niagara Systems provides industrial parts washers and heavy-duty parts cleaning machines. Our parts washer industrial machines can be customized to fit any ……

#8 Ecoclean Ecoclean industrial parts cleaning machines

Domain Est. 2016

Website: ecoclean-group.net

Key Highlights: The SBS Ecoclean Group supplies innovative machines for industrial parts cleaning and surface treatment applications, helping customers to achieve highest ……

#9 CRC SmartWasher Products

Domain Est. 1996

Website: crcindustries.com

Key Highlights: Clean parts safely with CRC SmartWasher eco-friendly cleaning systems. Non-toxic parts washers, bioremediation fluids & safe cleaning solutions….

#10 Parts Cleaning in Manufacturing

Domain Est. 1997

Website: pfonline.com

Key Highlights: Process cleaning includes aqueous cleaning, ultrasonic cleaning, vapor degreasing, solvent cleaning, pretreatments and drying….

Expert Sourcing Insights for Parts Cleaning

2026 Market Trends for Parts Cleaning: Key Developments and Projections

Rising Demand for Sustainable and Eco-Friendly Cleaning Solutions

By 2026, environmental regulations and corporate sustainability goals will significantly drive innovation in the parts cleaning industry. There will be a strong shift toward biodegradable cleaning agents, water-based solvents, and closed-loop recycling systems to reduce hazardous waste and VOC (volatile organic compound) emissions. Governments in North America and Europe are expected to enforce stricter environmental standards, pushing manufacturers to adopt green alternatives. This trend will accelerate investment in non-halogenated solvents and aqueous cleaning technologies, with companies prioritizing certifications like ISO 14001 to remain competitive.

Increased Adoption of Automation and Industry 4.0 Integration

The integration of smart manufacturing technologies will reshape parts cleaning processes by 2026. Automated cleaning systems—such as robotic parts washers and IoT-enabled monitoring—will become standard in high-volume production environments, particularly in automotive and aerospace sectors. Real-time data analytics, predictive maintenance, and remote system diagnostics will improve cleaning efficiency, reduce downtime, and ensure consistent quality. Cloud-connected cleaning machines will allow for centralized control across global facilities, enhancing traceability and compliance with quality standards like IATF 16949.

Growth in Demand from Electric Vehicle (EV) and Renewable Energy Sectors

The rapid expansion of the electric vehicle market will create new opportunities in parts cleaning. By 2026, specialized cleaning solutions will be required for EV components such as battery casings, power electronics, and electric motors, which demand ultra-clean surfaces free of contaminants that could compromise performance or safety. Similarly, the renewable energy sector—especially wind turbine and solar panel manufacturing—will drive demand for precision cleaning systems capable of handling large or sensitive parts. These applications will favor non-corrosive, residue-free cleaning methods.

Advancements in Solvent and Aqueous Technology

Technological improvements in both solvent-based and aqueous cleaning systems will continue to evolve by 2026. While aqueous systems will dominate due to environmental benefits, next-generation solvents—such as hydrofluoroolefins (HFOs) and engineered alcohols—will gain traction in applications requiring fast drying and high solvency. Innovations in surfactant chemistry and ultrasonic enhancement will improve the performance of water-based systems, narrowing the performance gap with traditional solvents. Additionally, modular and compact cleaning units will support flexible manufacturing setups.

Regional Shifts and Supply Chain Localization

Geopolitical factors and supply chain resilience concerns will influence parts cleaning market dynamics. By 2026, there will be a noticeable shift toward regionalized production, particularly in North America and Southeast Asia, to reduce dependency on global logistics. This localization trend will boost demand for localized cleaning equipment manufacturing and after-sales service networks. Emerging markets in India, Vietnam, and Mexico will see increased adoption of mid-tier cleaning systems, driven by industrial expansion and foreign direct investment.

Emphasis on Health, Safety, and Regulatory Compliance

Workplace safety and regulatory compliance will remain top priorities. By 2026, stricter occupational exposure limits (OELs) for cleaning chemicals will be enforced globally, leading to greater use of enclosed systems and personal protective equipment (PPE). Manufacturers will increasingly adopt cleaning solutions with low toxicity and minimal odor to improve worker safety. Regulatory bodies such as REACH (EU) and OSHA (US) will continue to shape product formulations and operational protocols, influencing global market access and competitiveness.

Common Pitfalls in Sourcing Parts Cleaning (Quality, IP)

Sourcing parts cleaning services or equipment involves critical considerations around both quality assurance and intellectual property (IP) protection. Overlooking these aspects can lead to significant operational, legal, and reputational risks. Below are key pitfalls to avoid:

Quality-Related Pitfalls

Inadequate Cleaning Specifications and Validation

One of the most frequent issues is failing to define clear, measurable cleaning standards upfront. Without detailed specifications—such as acceptable levels of contaminants (e.g., oils, particulates, residues)—it becomes difficult to assess whether the cleaning process meets functional or regulatory requirements. Additionally, lack of validation protocols (e.g., cleanliness testing via gravimetric analysis, ionic contamination testing) means no objective proof that cleaning is effective, increasing the risk of product failure.

Unverified Supplier Capabilities and Processes

Choosing a supplier based solely on cost or proximity without auditing their equipment, methodology, or quality control systems can lead to inconsistent results. Different cleaning techniques (ultrasonic, aqueous, solvent-based, plasma) are suited to different materials and contamination types. Using an inappropriate method can damage parts or leave residues, impacting performance in downstream processes like coating, welding, or assembly.

Lack of Traceability and Documentation

Effective parts cleaning requires full process traceability—knowing what was cleaned, when, how, and by whom. Suppliers that do not provide batch records, process parameters, or certificates of cleanliness make it difficult to troubleshoot contamination issues or meet quality standards such as ISO 9001 or AS9100. This absence of documentation can derail audits or root cause analyses.

Intellectual Property-Related Pitfalls

Insufficient IP Protection Agreements

Parts being cleaned may incorporate proprietary designs, materials, or technologies. Failing to establish strong non-disclosure agreements (NDAs) and confidentiality clauses before engaging a cleaning provider exposes your IP to unauthorized use, reverse engineering, or disclosure. This is especially critical in high-tech, aerospace, or medical device industries.

Inadequate Control Over Access and Handling

Entrusting complex or sensitive components to a third party increases exposure to IP theft or accidental disclosure. Without strict access controls, secure handling procedures, and defined data protection policies (including digital records and photographs), there’s a risk that competitors or unauthorized personnel could gain insights into your product design or manufacturing process.

Ambiguous Ownership of Process Innovations

In some cases, the cleaning provider may develop or optimize a cleaning method specific to your parts. If the contract does not clearly define ownership of such process improvements or know-how, disputes may arise over who controls or can reuse that IP. This can limit your flexibility and create dependency on a single supplier.

Mitigation Strategies

To avoid these pitfalls, establish detailed cleaning specifications, conduct thorough supplier audits, require full documentation and validation, and implement robust legal protections for IP. Regular performance reviews and on-site assessments can further ensure ongoing compliance with both quality and confidentiality requirements.

Logistics & Compliance Guide for Parts Cleaning

Proper logistics and compliance management are essential for safe, efficient, and legally sound parts cleaning operations. This guide outlines key considerations to ensure regulatory adherence, environmental protection, worker safety, and supply chain integrity.

Regulatory Compliance

Adherence to local, national, and international regulations is mandatory. Key regulatory frameworks include:

-

Environmental Protection Regulations

Comply with guidelines from agencies such as the U.S. Environmental Protection Agency (EPA) or equivalent bodies (e.g., ECHA in the EU). Ensure proper handling, storage, and disposal of cleaning solvents, especially hazardous substances like chlorinated or petroleum-based solvents. -

Hazard Communication (HazCom)

Maintain Safety Data Sheets (SDS) for all cleaning agents and ensure they are accessible to all personnel. Label all containers clearly with chemical names, hazards, and handling instructions in accordance with OSHA HazCom Standard (29 CFR 1910.1200) or GHS standards. -

Waste Management and Disposal

Used cleaning solutions and contaminated materials (rags, filters, sludge) may be classified as hazardous waste. Follow RCRA (Resource Conservation and Recovery Act) or local waste disposal regulations. Use licensed waste disposal vendors and maintain records of waste manifests. -

Air Quality and Emissions Control

Volatile organic compounds (VOCs) released during parts cleaning may be regulated under Clean Air Act regulations. Employ vapor recovery systems, closed-loop cleaning units, or low-VOC alternatives to minimize emissions.

Worker Safety and Health

Protecting personnel is paramount in parts cleaning operations.

-

Personal Protective Equipment (PPE)

Require appropriate PPE including chemical-resistant gloves, safety goggles, face shields, and respiratory protection when handling hazardous solvents or working in poorly ventilated areas. -

Ventilation and Exposure Limits

Ensure adequate ventilation in cleaning areas. Monitor exposure to airborne contaminants and adhere to permissible exposure limits (PELs) set by OSHA or TLVs (Threshold Limit Values) from ACGIH. -

Training and Procedures

Provide regular training on safe handling of chemicals, emergency response, and proper use of cleaning equipment. Document standard operating procedures (SOPs) and review them periodically.

Equipment and Facility Requirements

Optimize setup to support compliance and efficiency.

-

Containment and Spill Prevention

Use spill containment pallets, secondary containment systems, and drip trays. Install emergency eyewash stations and safety showers within accessible distances. -

Cleaning Equipment Maintenance

Regularly inspect and maintain parts washers, filters, pumps, and recovery systems to prevent leaks, breakdowns, and inefficiencies. Follow manufacturer maintenance schedules. -

Segregation of Processes

Separate parts cleaning operations from other production areas to minimize cross-contamination and exposure risks.

Supply Chain and Material Handling

Ensure responsible sourcing and handling of cleaning materials.

-

Solvent Procurement

Source cleaning agents from reputable suppliers with full regulatory documentation. Prioritize biodegradable, non-toxic, or aqueous-based cleaners where feasible. -

Storage Practices

Store flammable and hazardous cleaning agents in approved, well-ventilated cabinets away from ignition sources. Segregate incompatible chemicals to prevent dangerous reactions. -

Transportation Compliance

When transporting cleaning agents or waste off-site, comply with DOT (Department of Transportation) or ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road) regulations for labeling, packaging, and documentation.

Monitoring, Auditing, and Recordkeeping

Maintain documentation to demonstrate compliance and support continuous improvement.

-

Compliance Audits

Conduct regular internal audits to verify adherence to environmental, safety, and operational standards. -

Record Retention

Keep records of SDS, training logs, waste disposal manifests, inspection reports, and regulatory permits for the required duration (typically 3–5 years). -

Incident Reporting

Establish procedures for reporting spills, exposures, or equipment failures. Investigate incidents promptly and implement corrective actions.

Sustainability and Continuous Improvement

Adopt best practices to reduce environmental impact and operational costs.

-

Solvent Recycling and Reuse

Implement on-site distillation or filtration systems to extend the life of cleaning solutions and reduce waste. -

Green Cleaning Alternatives

Evaluate and transition to environmentally preferable cleaning technologies such as aqueous cleaners, ultrasonic systems, or CO₂ blasting. -

Energy Efficiency

Optimize cleaning cycles and equipment settings to reduce energy and water consumption.

By following this logistics and compliance guide, organizations can ensure safe, efficient, and legally compliant parts cleaning operations while minimizing environmental impact and protecting workforce health.

Conclusion for Sourcing Parts Cleaning:

In conclusion, effective sourcing of parts cleaning solutions is essential to maintaining product quality, ensuring process efficiency, and complying with environmental and safety regulations. By carefully evaluating factors such as cleaning method (aqueous, solvent-based, ultrasonic, etc.), equipment capabilities, chemical compatibility, cost-efficiency, and sustainability, organizations can identify the most suitable cleaning solutions for their specific applications. Strategic sourcing should also consider supplier reliability, technical support, and long-term partnership potential. Ultimately, a well-structured sourcing approach not only enhances operational performance but also contributes to cost savings, regulatory compliance, and improved environmental stewardship across the manufacturing and maintenance lifecycle.