The global stretch wrap and packaging materials market has experienced steady growth, driven by expanding logistics, warehousing, and e-commerce sectors. According to Grand View Research, the global stretch film market was valued at USD 10.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This upward trajectory is fueled by increasing demand for efficient load stabilization solutions in supply chains, with pallet net wrap emerging as a sustainable and high-performance alternative to traditional stretch film. As industries prioritize durability, ease of application, and reduced material usage, manufacturers specializing in pallet net wrap are scaling innovation and production capacity. In this evolving landscape, we spotlight the top nine pallet net wrap manufacturers leveraging advanced materials, automation, and global distribution networks to lead the market and meet rising demand across retail, agriculture, and manufacturing sectors.

Top 9 Pallet Net Wrap Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Leading Bale Netwrap Producer » Standard Pallet net wrap

Domain Est. 2020

Website: cpsagro.com

Key Highlights: We are CPS, leading bale net wrap manufacturer, focusing on quality of product. Our bale net works globally in all weather conditions….

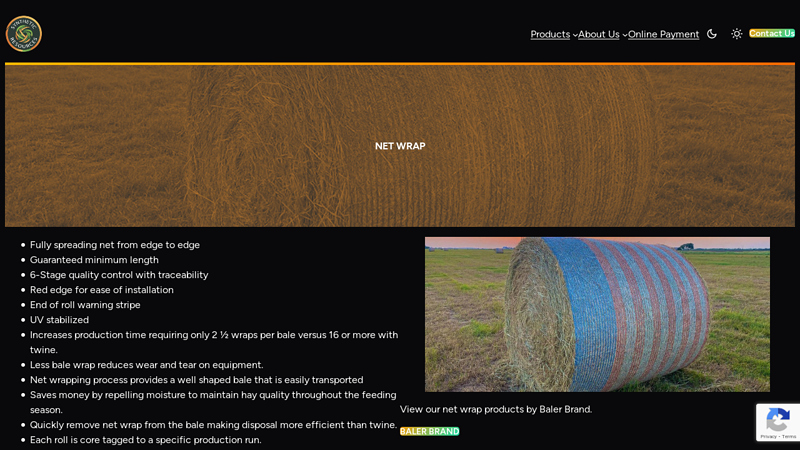

#2 Net Wrap

Domain Est. 2002

Website: syntheticresources.com

Key Highlights: Fully spreading net from edge to edge · Guaranteed minimum length · 6-Stage quality control with traceability · Red edge for ease of installation · End of roll ……

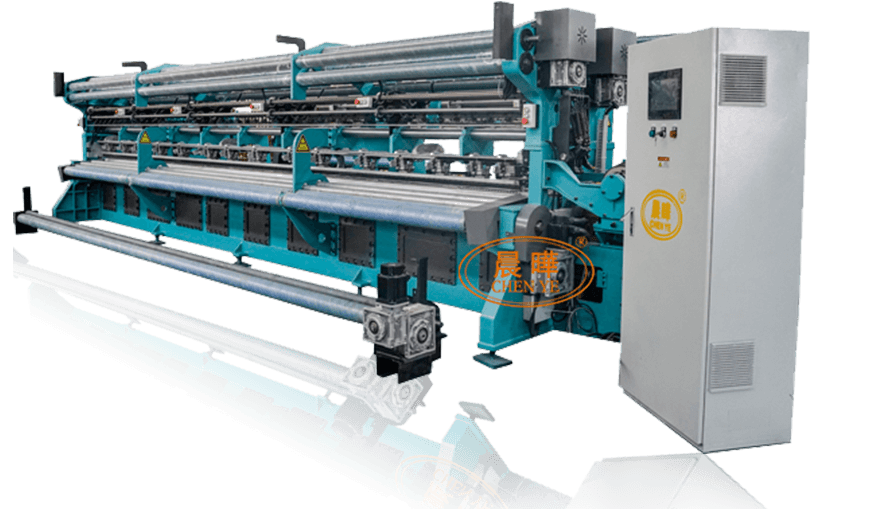

#3 PALLET NETWRAP

Domain Est. 2011

Website: chinanetwrap.com

Key Highlights: Pallet net wrap is a type of mesh netting that is designed to safely secure products on pallets during storage and transportation….

#4 Pallet Netting

Domain Est. 2023

Website: conwed.net

Key Highlights: Conwed manufactures pallet netting solutions that help manufacturers, distributors and retailers store, ship and deliver valuable merchandise….

#5 Pallet netting

Domain Est. 1997

Website: nnz.com

Key Highlights: NNZ offers standard extruded pallet wrap for maximum containment of unsteady loads. The netting can be applied as wrap around pallets or with a snake technique….

#6 3 ft. x 15 ft. • Pallet Wrap Net

Domain Est. 2002

Website: obecoinc.com

Key Highlights: Our Pallet Net Wrap replaces shrink wrap and is reusable over and over again saving the planet from excess plastic….

#7 Pallet packaging

Domain Est. 2004 | Founded: 1922

Website: nnzusa.com

Key Highlights: NNZ offers a wide range of Pallet packaging | Wrap | Netting | Boxes. NNZ is your packaging specialist since 1922. Contact us today!…

#8 Pallet Wraps

Domain Est. 2013

Website: tama-usa.com

Key Highlights: Tama highly ventilated Pallet Wraps are designed to ensure optimal airflow around your products, promoting freshness and reducing spoilage during transit….

#9 PRODUCTS

Website: karatzis.gr

Key Highlights: Designed as a superior alternative to stretch film, our Pallet net wrap protects while offering superior ventilation and condensation characteristics….

Expert Sourcing Insights for Pallet Net Wrap

H2: 2026 Market Trends for Pallet Net Wrap

The global pallet net wrap market is poised for steady growth and transformation by 2026, driven by evolving logistics demands, sustainability imperatives, and technological advancements. Key trends shaping the market landscape include:

-

Accelerated Focus on Sustainability and Circularity:

- Biodegradable & Compostable Films: Growing regulatory pressure (especially in Europe) and corporate ESG goals will significantly boost demand for net wraps made from bio-based polymers (e.g., PLA) or certified compostable materials. This trend will move beyond niche applications.

- Recycled Content Integration: Manufacturers will increasingly incorporate food-grade recycled polyethylene (rPE) into net wrap formulations, driven by packaging waste directives and brand owner targets. Ensuring consistent performance with higher rPE content will be a key challenge and differentiator.

- Lightweighting & Source Reduction: Continued innovation will focus on producing thinner, stronger films that maintain load integrity while using less raw material per roll, reducing both material cost and environmental footprint (lower transport emissions, less waste).

-

Demand for Performance Enhancement & Specialization:

- Higher Strength & Elasticity: The rise of e-commerce fulfillment centers handling diverse, often fragile goods, demands net wraps with superior puncture resistance, cling, and recovery to secure unstable loads and protect products during transit.

- UV & Weather Resistance: Growth in outdoor storage (retail, construction, agriculture) and longer supply chains will increase demand for UV-stabilized net wraps that maintain integrity during extended exposure.

- Specialty Applications: Growth in specific sectors like agriculture (bale wrapping, produce), construction (lumber, pipes), and cold chain logistics will drive demand for net wraps with specific properties (e.g., enhanced cling for cold temperatures, specific colors for identification).

-

Automation & Integration in Logistics:

- Compatibility with High-Speed Systems: As automated palletizing and stretch wrapping lines become faster and more prevalent (especially in distribution centers), net wrap performance (consistent unwinding, predictable tension, machine compatibility) will be paramount. Suppliers will focus on optimizing film for high-speed applicators.

- Smart Packaging Integration (Emerging): While nascent, there is potential for integrating RFID tags or QR codes directly into net wrap or its core for improved load tracking and inventory management, though cost and practicality remain hurdles.

-

Supply Chain Resilience & Regionalization:

- Nearshoring/Reshoring: Geopolitical tensions and supply chain disruptions may encourage some manufacturers and users to source net wrap regionally or domestically, impacting global trade flows and potentially boosting local production capacity in key markets like North America and Europe.

- Raw Material Volatility Management: Fluctuations in polyethylene prices will continue to pressure margins. Suppliers will focus on long-term contracts, strategic sourcing, and material efficiency to mitigate this risk.

-

Consolidation and Innovation in Manufacturing:

- Technology Leadership: Companies investing in advanced blown film extrusion technology (e.g., multi-layer co-extrusion, precision gauge control) will gain a competitive edge by producing higher-performance, more consistent, and sustainable films.

- Mergers & Acquisitions: The market may see consolidation as larger players acquire innovative smaller firms to gain access to sustainable materials technology or specialized product lines, aiming for economies of scale and broader market reach.

Conclusion for H2 2026:

By the second half of 2026, the pallet net wrap market will be characterized by a strong dual imperative: delivering uncompromising performance for increasingly automated and demanding logistics environments while simultaneously advancing the sustainability agenda. Success will belong to manufacturers who can effectively innovate in material science (bioplastics, recycled content, lightweighting), ensure seamless integration with high-speed automation, and demonstrate tangible environmental credentials, all while navigating complex supply chains and raw material markets. The shift towards circularity will be a defining trend, moving from a differentiator to a baseline expectation in many regions.

Common Pitfalls When Sourcing Pallet Net Wrap (Quality, IP)

Sourcing pallet net wrap may appear straightforward, but overlooking key quality and intellectual property (IP) issues can lead to significant operational, financial, and legal risks. Being aware of these common pitfalls helps ensure you select a reliable, compliant, and high-performing product.

Poor Material Quality and Inconsistent Performance

Low-grade raw materials (such as recycled or off-spec polyethylene) can result in net wrap that lacks strength, elasticity, or UV resistance. This increases the risk of load instability, product damage during transit, and higher waste due to breakage. Inconsistent thickness or mesh density across production batches also undermines reliability, leading to unpredictable performance.

Inadequate Tensile Strength and Stretch Recovery

Net wrap that fails to meet required tensile strength or stretch recovery specifications may not adequately secure loads, especially during long-haul or multi-modal transport. Some suppliers exaggerate performance claims without third-party testing data. Always request independent test reports (e.g., ASTM D882) to verify stretch, load retention, and holding force.

Lack of UV and Weather Resistance

For outdoor storage or transport, UV degradation can cause net wrap to become brittle and fail prematurely. Sourcing net wrap without proper UV stabilizers leads to premature breakdown. Ensure the product is specifically formulated for outdoor use if required, and confirm UV resistance through accelerated weathering test data.

Non-Compliance with Industry or Safety Standards

Using net wrap that doesn’t meet regional or industry-specific standards (e.g., ISTA, OSHA, or EU safety directives) can result in compliance issues, rejected shipments, or liability in case of accidents. Verify that the supplier adheres to relevant certifications and provides documentation for traceability.

Intellectual Property Infringement Risks

Some suppliers may produce net wrap using patented manufacturing processes, machinery designs, or proprietary formulations without authorization. Sourcing such products exposes your business to potential IP litigation, especially if the infringing product enters regulated markets like the U.S. or EU. Conduct due diligence on suppliers and request proof of IP compliance or licensing.

Misrepresentation of Recyclability or Eco-Friendliness

Greenwashing is common—some suppliers claim their net wrap is “recyclable” or “eco-friendly” without substantiating these claims. In reality, contamination, additives, or mixed materials may render the net wrap non-recyclable. Demand transparency in material composition and certifications (e.g., recyclability logos, PCR content verification).

Inadequate Supplier Traceability and Documentation

Without clear batch traceability and material safety data sheets (MSDS/SDS), it becomes difficult to manage recalls, ensure workplace safety, or comply with customs regulations. Reputable suppliers should provide full documentation, including resin sources and production records.

Hidden Costs from Poor Compatibility

Net wrap that isn’t optimized for your specific wrapping equipment (e.g., pre-stretch ratios, core size, or tension settings) can lead to machine jams, increased downtime, and higher consumption rates. Always test samples with your existing machinery before large-scale procurement.

Avoiding these pitfalls requires thorough supplier vetting, sample testing, and clear contractual terms around quality assurance and IP indemnification. Prioritize transparency and technical support to ensure long-term reliability and compliance.

Logistics & Compliance Guide for Pallet Net Wrap

Overview

Pallet net wrap, also known as stretch hood film or pallet security netting, is used to stabilize and secure loads on pallets during transportation and storage. Proper handling, shipping, and compliance with safety and environmental regulations are essential for efficient logistics and regulatory adherence.

Material Specifications

- Material Type: Typically made from high-density polyethylene (HDPE) or linear low-density polyethylene (LLDPE)

- Weight & Dimensions: Varies by roll size; common widths range from 15″ to 30″, with lengths from 1,000 to 3,000 feet

- Color Options: Usually transparent, black, or custom colors for UV protection or branding

- Recyclability: Most net wraps are recyclable under resin code #2 or #4; confirm local recycling capabilities

Storage Guidelines

- Environment: Store in a dry, cool area away from direct sunlight and extreme temperatures (ideal range: 50°F–80°F / 10°C–27°C)

- Shelf Life: Up to 12 months when stored properly; prolonged UV exposure degrades material integrity

- Handling: Keep rolls on pallets or racks; avoid floor storage to prevent contamination and moisture damage

Transportation & Shipping

- Packaging: Rolls are typically individually wrapped and stacked on wooden or plastic pallets secured with strapping

- Load Securing: Use edge protectors and additional stretch film to prevent shifting during transit

- Forklift Safety: Ensure adequate clearance and use appropriate forklift attachments to avoid roll damage

- Stacking Limits: Do not exceed manufacturer-recommended stacking height (usually 2–3 layers high) to prevent crushing

Regulatory Compliance

- OSHA (Occupational Safety and Health Administration): Follow safe handling procedures to prevent strains and injuries during manual application

- DOT (Department of Transportation): Ensure loads wrapped with netting meet securement standards under 49 CFR Part 393, Subpart I

- FMCSA (Federal Motor Carrier Safety Administration): Confirm that net-wrapped pallets comply with cargo securement rules for commercial vehicles

- REACH & RoHS (EU Regulations): Verify that materials are free from restricted substances if exporting to the European Union

Environmental & Sustainability Requirements

- Waste Management: Dispose of used net wrap according to local plastic waste regulations

- Recycling Programs: Partner with certified recyclers for post-industrial plastic waste; maintain documentation for compliance audits

- Sustainable Alternatives: Consider biodegradable or recyclable net wraps where performance criteria allow

Safety Precautions

- Personal Protective Equipment (PPE): Use cut-resistant gloves and safety glasses when handling or cutting net wrap

- Machine Operation: Train personnel on proper use of net wrapping machinery to prevent entanglement or mechanical hazards

- Trip & Fall Hazards: Promptly clean up loose netting or offcuts from work areas

Documentation & Labeling

- Product Labels: Include material composition, roll dimensions, batch number, and manufacturer details

- SDS (Safety Data Sheet): Provide SDS if required under OSHA’s Hazard Communication Standard (HazCom)

- Shipping Documents: Accurately declare net wrap as non-hazardous freight; include weight, quantity, and packaging type

International Shipping Considerations

- ISPM 15 Compliance: Wooden pallets used for shipping net wrap rolls must be heat-treated and stamped if crossing international borders

- Customs Declarations: Clearly describe goods as “Plastic Pallet Netting” or “Stretch Hood Film” to avoid delays

- Import Regulations: Check destination country requirements for plastic imports, especially regarding single-use plastics or recyclability mandates

Best Practices for Efficient Logistics

- Inventory Management: Use FIFO (First In, First Out) stock rotation to prevent material degradation

- Supplier Audits: Verify that suppliers follow ethical labor and environmental practices

- Quality Checks: Inspect rolls upon receipt for damage, stretching inconsistencies, or contamination

By adhering to this guide, businesses can ensure safe, compliant, and efficient handling of pallet net wrap throughout the supply chain.

Conclusion for Sourcing Pallet Net Wrap:

Sourcing the right pallet net wrap is a critical component in ensuring efficient, secure, and cost-effective load stabilization during transportation and storage. After evaluating key factors such as material quality, stretchability, durability, gauge thickness, roll size, compatibility with wrapping equipment, and supplier reliability, it is clear that selecting a high-performance net wrap significantly reduces product damage, enhances operational efficiency, and supports sustainability goals through reduced material usage and waste.

Additionally, building relationships with reputable suppliers who offer consistent quality, competitive pricing, and responsive customer service contributes to long-term supply chain resilience. Whether prioritizing eco-friendly options or maximizing cost-efficiency, a strategic sourcing approach—supported by thorough supplier vetting, sample testing, and lifecycle cost analysis—enables businesses to achieve optimal protection for their palletized goods while maintaining operational excellence.

In conclusion, investing time and resources into the careful selection and sourcing of pallet net wrap delivers substantial returns in load security, operational efficiency, and overall supply chain performance.