The global steel doors market is experiencing robust growth, driven by increasing demand for durable, secure, and energy-efficient building materials across residential, commercial, and industrial sectors. According to Grand View Research, the global steel doors and frames market size was valued at USD 8.4 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is fueled by rising construction activities, stringent building codes emphasizing fire and security performance, and growing preference for low-maintenance materials. Painted steel doors, in particular, have gained traction due to their enhanced aesthetics, corrosion resistance, and customization options, making them a preferred choice in modern architectural design. With North America and Europe leading in market share and Asia-Pacific witnessing the fastest growth due to rapid urbanization, the competitive landscape is evolving rapidly. This report identifies the top 10 painted steel doors manufacturers leveraging innovation, scale, and quality to capture market share in this expanding industry.

Top 10 Painted Steel Doors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Steelcraft

Domain Est. 1995

Website: steelcraft.com

Key Highlights: Our commercial steel doors and frames set the standard for performance, reliability and style. Learn about our industry-trusted hollow metal door solutions….

#2 Therma

Domain Est. 1995

Website: thermatru.com

Key Highlights: The Therma-Tru retractable screen door allows fresh air and natural light inside while keeping debris and insects out….

#3 Dunbarton

Domain Est. 1995

Website: dunbarton.com

Key Highlights: The Original Pre-Finished Steel Bifold Door. SlimFold Doors are pre-finished and offered in four timeless designs that blend beautifully with décor. SlimFold is ……

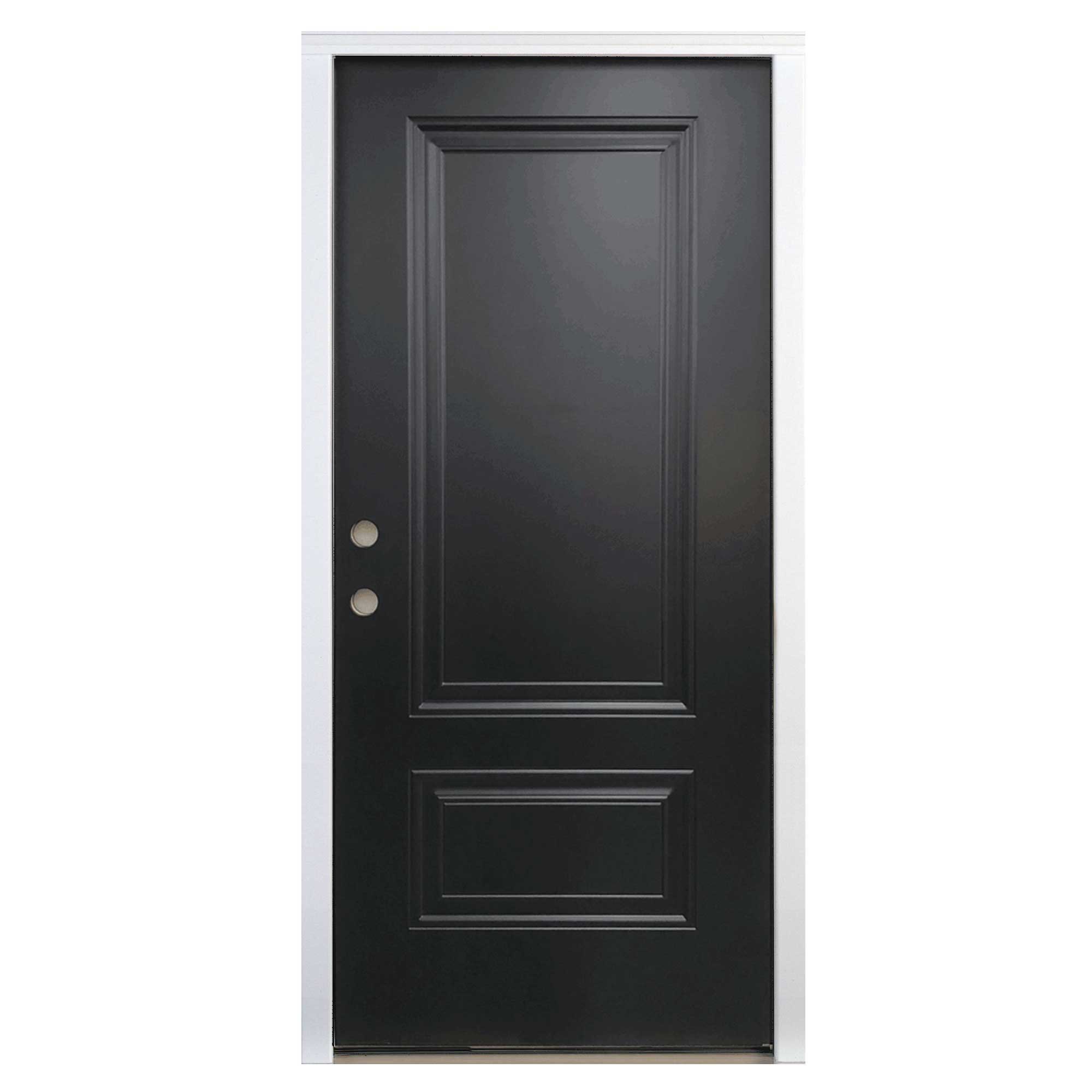

#4 Masonite Residential

Domain Est. 1995

Website: masonite.com

Key Highlights: Explore the best selection of interior and exterior doors for your home. Masonite doors are crafted from the highest quality materials for every home style….

#5 Steel Exterior Doors

Domain Est. 1996

Website: jeld-wen.com

Key Highlights: Strong, durable, and stylish, JELD-WEN steel exterior doors offer safety and security, with a broad selection of designs for residential and commercial use….

#6 Prefinished Steel Doors

Domain Est. 1996

Website: steeldoor.org

Key Highlights: Prefinished doors and frames are painted in a dust-free, environmentally-controlled setting for a quality coating with consistent adhesion….

#7 Front Doors by ODL

Domain Est. 1996

Website: odl.com

Key Highlights: Explore front doors and entry doors by material, style, and performance features. Choose from fiberglass, steel, ADA-compliant, impact-rated, and fire-rated ……

#8 Reeb

Domain Est. 2002

Website: reeb.com

Key Highlights: Exterior Doors · Exterior Doors Page · Fiberglass Doors · Wood Doors · Steel Doors · Storm Doors · Residential Fire Doors · Sliding Vinyl Patio Doors · Reeb® ……

#9 MASTERCRAFT Doors

Domain Est. 2004

Website: mastercraftdoors.com

Key Highlights: MASTERCRAFT doors are built from the finest materials to create the best and most stylish door for your home. Available in wood, fiberglass, or steel doors….

#10 MMI DOOR

Domain Est. 2013

Website: mmidoor.com

Key Highlights: We are the largest distributor of wood, steel and fiberglass exterior, interior, storm and patio doors and door products in the US today!…

Expert Sourcing Insights for Painted Steel Doors

2026 Market Trends for Painted Steel Doors

Rising Demand Driven by Aesthetic and Functional Advantages

In 2026, painted steel doors are expected to experience increased demand due to their dual appeal of durability and customizable aesthetics. Homeowners and commercial developers are increasingly prioritizing exterior products that combine security with visual appeal. Painted steel doors offer a wide range of color options and finishes—such as matte, gloss, and textured coatings—that mimic wood or modern designer styles, making them a versatile choice across residential and light commercial segments.

Growth in Residential Construction and Renovation

The continued expansion of the housing market, particularly in North America and Europe, supports strong demand for entry-level and mid-range doors. As urbanization and home renovation projects rise—fueled by low-interest refinancing and government incentives—painted steel doors remain a cost-effective alternative to fiberglass or solid wood. Their resistance to warping, denting, and weathering makes them ideal for climates with extreme temperature fluctuations.

Sustainability and Eco-Friendly Coatings

Environmental considerations are shaping material choices in 2026. Manufacturers are responding by adopting low-VOC (volatile organic compound) paints and powder coatings that reduce environmental impact and meet stringent regulations like REACH and LEED certification standards. Recyclable steel substrates further enhance the sustainability profile of these doors, appealing to environmentally conscious consumers and green building projects.

Technological Advancements in Coating and Manufacturing

Innovations in pre-painted steel and robotic application systems have improved finish consistency and longevity. Advanced galvanization and primer technologies enhance corrosion resistance, extending product life in coastal or high-humidity environments. Additionally, digital color-matching tools and online configurators allow customers to personalize door designs, improving user experience and reducing return rates.

Competitive Pressure from Alternative Materials

Despite growth, painted steel doors face competition from fiberglass and composites, which are gaining traction for their superior insulation and wood-like appearance. To stay competitive, steel door manufacturers are investing in thermal break technologies and better insulation cores to improve energy efficiency—a key selling point in markets with strict energy codes.

Regional Market Dynamics

North America remains the largest market, driven by new construction and replacement demand in single-family homes. In Asia-Pacific, urban development and infrastructure projects in countries like India and Vietnam are creating new opportunities. Meanwhile, European markets emphasize security and fire-rated solutions, where steel doors maintain a strong foothold due to compliance with safety standards.

Conclusion

By 2026, the painted steel door market is poised for steady growth, supported by aesthetic versatility, technological improvements, and sustainability trends. Success will depend on manufacturers’ ability to innovate in insulation performance, expand design options, and align with eco-conscious building practices while maintaining cost advantages over premium alternatives.

Common Pitfalls When Sourcing Painted Steel Doors (Quality & IP)

Sourcing painted steel doors involves navigating several potential challenges related to both product quality and intellectual property (IP). Overlooking these pitfalls can lead to performance issues, legal risks, and reputational damage. Below are key areas to watch:

Poor Paint and Coating Quality

One of the most frequent quality issues with painted steel doors is substandard coating application. Low-quality paint or improper surface preparation can result in premature chipping, peeling, or fading. This not only affects aesthetics but also compromises corrosion resistance, especially in harsh environments. Buyers must verify coating specifications (e.g., thickness, adhesion standards like ASTM D3359), and ensure pre-treatment processes like phosphating or e-coating are properly applied.

Inconsistent Finish and Color Matching

Variations in color or gloss level between production batches are common when working with lower-tier manufacturers. This inconsistency can be particularly problematic in large projects where multiple doors are installed together. Always request physical samples and insist on batch-specific color certification to minimize mismatches.

Use of Unauthorized or Counterfeit Designs

Many painted steel door designs are protected by intellectual property rights, including design patents and trademarks. Sourcing from unverified suppliers increases the risk of receiving counterfeit or unauthorized replicas. This exposes the buyer to legal liability, product recalls, and brand damage. Always verify that the supplier holds proper licensing for the designs they offer.

Lack of IP Due Diligence in Contracts

Procurement agreements often fail to clearly address IP ownership, usage rights, or warranty against infringement. Without explicit clauses, buyers may unknowingly assume liability for IP violations. Ensure contracts include IP indemnification clauses and require suppliers to certify the originality and legality of their designs.

Thin or Low-Grade Steel Substrates

To cut costs, some manufacturers use thinner or lower-grade steel than specified. This compromises the door’s structural integrity, security, and longevity. Verify material certifications (e.g., ASTM A653 for galvanized steel) and conduct random thickness testing to confirm compliance.

Inadequate Testing and Certification

Reputable painted steel doors should meet industry standards for fire resistance, security (e.g., ANSI/SDI, UL), and weather performance. Suppliers may claim compliance without proper third-party testing. Always request valid test reports and certification documents before finalizing procurement.

Hidden Costs from Rework or Non-Compliance

Poor quality or IP issues often lead to project delays, rework, or rejected shipments. These hidden costs can significantly exceed initial savings from low-cost suppliers. Conduct thorough supplier audits and factory inspections to mitigate such risks early in the sourcing process.

By proactively addressing these pitfalls—through stringent quality checks, robust supplier vetting, and comprehensive IP safeguards—buyers can ensure reliable performance and legal compliance in their painted steel door procurement.

Logistics & Compliance Guide for Painted Steel Doors

Product Overview and Handling

Painted steel doors are precision-engineered building components designed for durability, insulation, and aesthetic appeal. Due to their weight, surface finish, and susceptibility to damage, proper handling and logistics are critical. The painted surface is especially vulnerable to scratches, dents, and chemical exposure, requiring careful packaging and handling throughout the supply chain.

Packaging Requirements

All painted steel doors must be packaged to prevent physical and environmental damage during transit and storage. Use moisture-resistant wrapping (e.g., polyethylene film) to protect against humidity and corrosion. Each door should be separated by non-abrasive spacers and secured within a sturdy wooden or metal frame crate. Corner protectors and edge guards are recommended to prevent impact damage. Label each package with: “Fragile,” “This Side Up,” product SKU, batch/lot number, and handling instructions.

Storage Conditions

Store painted steel doors indoors in a dry, well-ventilated area with temperatures between 50°F and 80°F (10°C–27°C) and relative humidity below 60%. Avoid direct sunlight and contact with concrete floors; elevate pallets at least 6 inches using wood blocks. Do not stack more than three high unless specifically designed for vertical stacking. Ensure doors are stored vertically whenever possible to prevent warping and paint stress.

Transportation Guidelines

Use enclosed, climate-controlled vehicles when possible, especially in extreme weather. Secure doors with straps or braces to prevent shifting during transit. Avoid exposure to rain, snow, or road salt. Transport vehicles must be clean and free of debris that could scratch surfaces. For international shipments, comply with ISPM 15 regulations for wooden packaging materials.

Regulatory Compliance

Painted steel doors must meet applicable national and international standards. In the U.S., doors should comply with ANSI/AWC A250.10 for steel doors and frames. Fire-rated models must meet UL 10C or NFPA 252 standards and carry appropriate certification labels. Paints used must conform to VOC regulations under EPA Method 24 and local air quality rules (e.g., SCAQMD Rule 1113). For export, ensure compliance with REACH (EU), TSCA (USA), and country-specific building codes.

Documentation and Traceability

Maintain complete documentation for each batch, including:

– Certificate of Conformance (CoC)

– Material Safety Data Sheets (MSDS/SDS) for paints and coatings

– Fire rating certification (if applicable)

– Test reports for durability, corrosion resistance, and performance

– Batch/lot numbers and manufacturing dates

Ensure all labels and markings on doors are legible and permanent for full traceability throughout the supply chain.

Installation and Final Inspection

Prior to installation, inspect doors for shipping damage. Report any defects immediately to the logistics provider and manufacturer. Installers must follow manufacturer guidelines to maintain warranty validity. After installation, conduct a final inspection to verify proper alignment, operation, and finish integrity. Retain inspection records for compliance audits and warranty claims.

In conclusion, sourcing painted steel doors requires a strategic approach that balances quality, cost, durability, and supplier reliability. These doors offer excellent security, longevity, and aesthetic versatility due to their customizable finishes. When selecting a supplier, it is essential to evaluate factors such as material quality, painting process (e.g., powder coating vs. pre-painted), compliance with industry standards, lead times, and after-sales support. Establishing long-term partnerships with reputable manufacturers or distributors can ensure consistent product performance and timely delivery. Additionally, considering sustainability aspects—such as eco-friendly coatings and recyclable materials—can enhance the overall value proposition. Ultimately, a well-informed sourcing decision will contribute to improved project outcomes, customer satisfaction, and long-term cost efficiency.