The global paintbooth market is experiencing steady growth, driven by increasing demand from the automotive, aerospace, and industrial manufacturing sectors for efficient and environmentally compliant finishing solutions. According to Grand View Research, the global industrial paint booth market size was valued at USD 2.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is fueled by stricter environmental regulations, such as those governing volatile organic compound (VOC) emissions, and the rising adoption of energy-efficient, modular, and automated paintbooth systems. As manufacturers prioritize precision, safety, and sustainability, the competitive landscape has evolved, giving rise to innovative solutions from leading global players. In this data-driven environment, selecting the right paintbooth manufacturer is critical for operational efficiency and regulatory compliance—making it essential to evaluate the top nine manufacturers shaping the industry’s future.

Top 9 Paintbooth Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Spray Systems, Inc.: Spray Booths

Domain Est. 1997

Website: spraysystems.com

Key Highlights: With over 40 years of expertise, Spray Systems offers custom spray booths and finishing systems for aerospace, automotive, and equipment manufacturers….

#2 Industrial Painting Equipment

Domain Est. 2013

Website: bzbspraybooth.com

Key Highlights: 25+ Years Spray Painting Paint Booth & Finishing System. Specialize in the Engineering, Manufacture of Various Car Spray Booth, Bus Spray Bus, etc….

#3 Paint Booth, Industrial Spray Booths Installation

Domain Est. 2000

Website: paintbooth.com

Key Highlights: High-quality paint booth for auto, booths for truck & industrial finishing or powder coating – System Design sales service & installation….

#4 Paint Booths & Industrial Spray Application Systems

Domain Est. 2002

#5 Accudraft Paint Booths

Domain Est. 2003

Website: accudraftpaintbooths.com

Key Highlights: Accudraft Paint Booths is a leading paint booth manufacturer of paint booths, spray booths, prep stations, and finishing systems. Outfit your shop today!…

#6 Global Finishing Solutions

Domain Est. 2003

Website: globalfinishing.com

Key Highlights: GFS is a vertical manufacturer, dedicated to developing high quality paint booths and finishing environments for a wide variety of industries….

#7 Industrial Paint Booths

Domain Est. 2010

Website: blowtherm-usa.com

Key Highlights: Blowtherm USA is the exclusive source for quality automotive paint booths, industrial spray booths, paint prep stations, paint mixing booths and related ……

#8 Paint Booths, Spray Booths, Finishing Systems

Domain Est. 2011

Website: zparint.com

Key Highlights: We are an automated paint booth supplier located in the USA. We design and manufacture sturdy and durable work booths for various industrial-based businesses….

#9 Spray Booths And Finishing Solutions

Domain Est. 2016

Website: rttsolutions.com

Key Highlights: RTT Finishing Solutions by Clean Air Industries is a leader in paint booths, spray booths, powder booths, ovens, washers, AMU’s, and finishing system ……

Expert Sourcing Insights for Paintbooth

H2: 2026 Market Trends for Paintbooths

The global paintbooth market is poised for significant transformation by 2026, driven by technological innovation, environmental regulations, and evolving industrial demands. As industries increasingly prioritize efficiency, sustainability, and worker safety, paintbooth manufacturers and service providers are adapting to meet these challenges. Below are the key market trends expected to shape the paintbooth industry in 2026:

-

Increased Adoption of Energy-Efficient and Eco-Friendly Systems

By 2026, environmental regulations such as the EPA’s National Emission Standards for Hazardous Air Pollutants (NESHAP) and EU directives on VOC (volatile organic compound) emissions will be more stringent. As a result, industries are shifting toward paintbooths with advanced filtration systems, low-VOC coatings compatibility, and energy recovery technologies. Demand for water-wash and dry-filter paintbooths with integrated air recirculation will rise, minimizing energy consumption and reducing carbon footprints. -

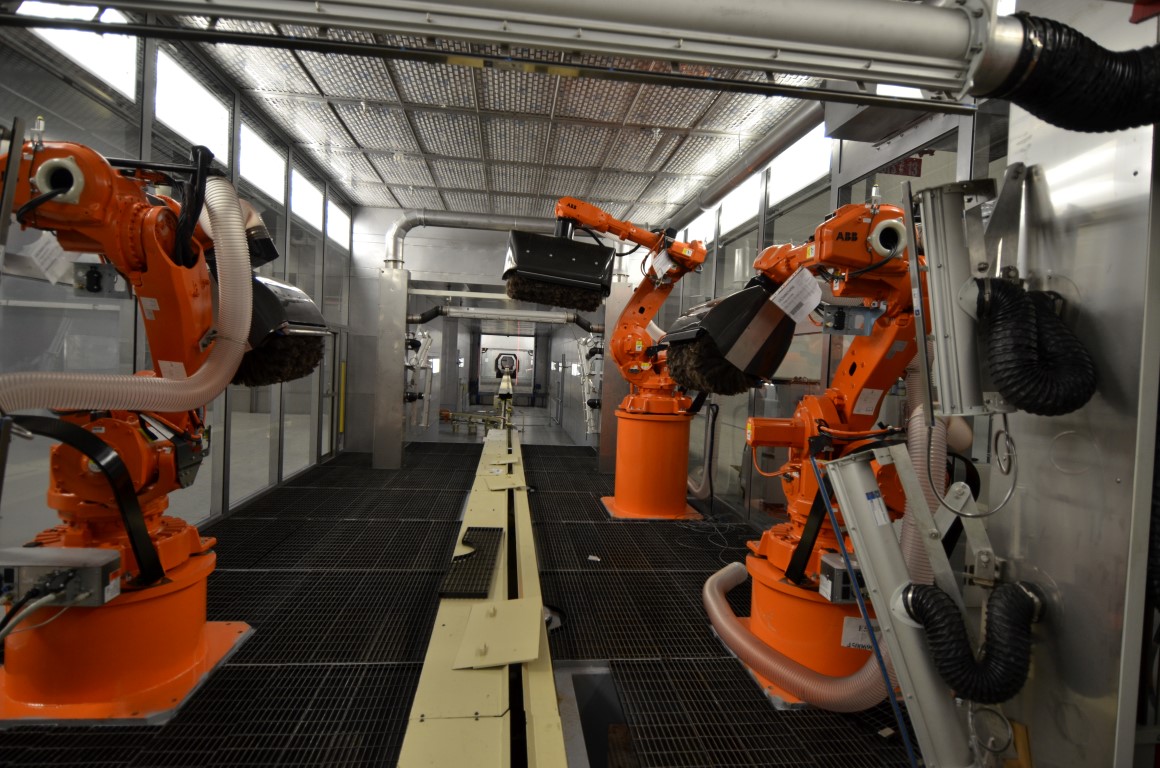

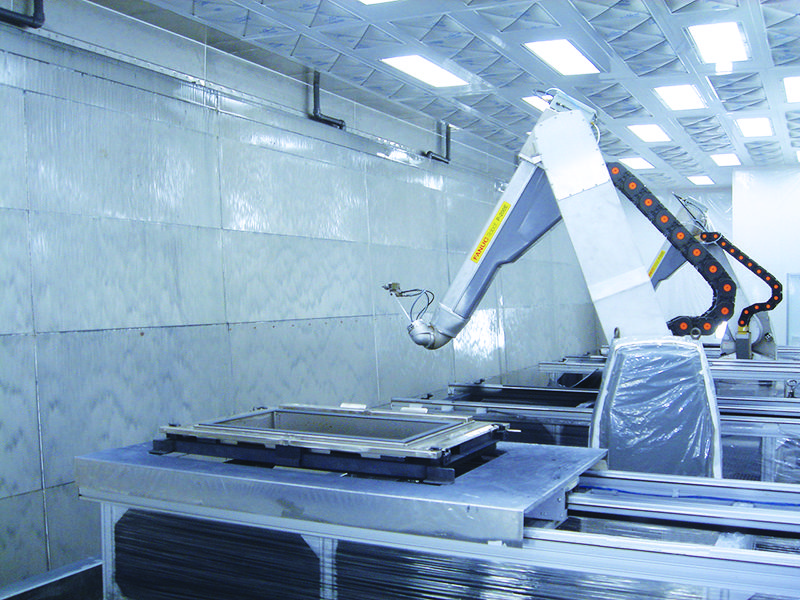

Growth in Automated and Smart Paintbooth Solutions

Automation is transforming the painting process, and by 2026, smart paintbooths equipped with IoT sensors, AI-driven monitoring, and predictive maintenance capabilities will become mainstream. These systems optimize airflow, humidity, and temperature in real time, improving finish quality and reducing waste. Integration with robotic painting arms in automotive and aerospace manufacturing will further boost demand for precision-engineered paintbooths. -

Expansion in Electric Vehicle (EV) Manufacturing

The rapid growth of the electric vehicle sector is creating new opportunities for the paintbooth market. EV production requires high-quality, corrosion-resistant finishes due to battery enclosures and unique material compositions. Paintbooths tailored for EV assembly lines—offering controlled environments for bonding and coating lightweight composites—will see increased investment, especially in North America, Europe, and China. -

Rising Demand in Emerging Markets

Developing economies in Southeast Asia, India, and Latin America are witnessing industrial expansion in automotive, aerospace, and heavy equipment sectors. This industrial growth is driving the need for modern paintbooth infrastructure. Local manufacturers are partnering with global suppliers to adopt compliant and efficient paintbooth technologies, accelerating market penetration. -

Modular and Portable Paintbooths Gaining Popularity

To support flexible manufacturing and on-site refinishing operations, modular and portable paintbooths are expected to gain traction by 2026. These units offer quick installation, scalability, and compliance with emission standards, making them ideal for repair shops, construction equipment maintenance, and remote industrial projects. -

Focus on Worker Safety and Ergonomics

Occupational health and safety standards are evolving, with greater emphasis on reducing painter exposure to fumes and overspray. Paintbooths with enhanced ventilation, HEPA filtration, and ergonomic designs will be prioritized. Features such as improved lighting, noise reduction, and user-friendly control panels will enhance operator comfort and productivity. -

Consolidation and Innovation Among Key Players

The competitive landscape of the paintbooth market will likely see consolidation, as larger manufacturers acquire niche technology providers to expand their smart and sustainable offerings. Companies like Global Finishing Solutions, Dürr AG, and Eisenmann SE are expected to lead innovation, investing in R&D for next-generation coating environments.

In conclusion, the 2026 paintbooth market will be defined by sustainability, digitalization, and responsiveness to industry-specific needs. Stakeholders who embrace these trends—through innovation, compliance, and strategic partnerships—will be best positioned to capitalize on emerging opportunities across automotive, aerospace, industrial manufacturing, and beyond.

Common Pitfalls When Sourcing a Paint Booth (Quality and Intellectual Property)

Sourcing a paint booth involves significant investment and long-term operational impact, making it crucial to avoid common pitfalls related to quality and intellectual property (IP). Overlooking these areas can lead to safety hazards, compliance issues, reduced productivity, and legal risks.

Poor Build Quality and Material Selection

One of the most frequent issues is selecting a paint booth constructed with substandard materials or inadequate engineering. Low-quality steel, improper sealing, or weak filtration systems can compromise booth performance, increase maintenance costs, and create safety risks due to volatile organic compound (VOC) exposure or fire hazards. Always verify material specifications, structural integrity, and compliance with safety standards such as NFPA 33 or ATEX (in Europe).

Inadequate Airflow and Filtration Design

A poorly designed airflow system leads to overspray accumulation, inconsistent paint finishes, and longer curing times. Some suppliers may cut corners by using undersized fans or inefficient filter arrangements. Ensure the booth design includes proper airflow velocity (typically 100 ft/min), correct air changes per hour, and high-efficiency filtration (e.g., ISO 14644-1 cleanroom standards if required).

Lack of Certification and Compliance

Many suppliers, especially offshore manufacturers, may not adhere to regional safety and environmental regulations. Failure to provide certification (e.g., UL, CE, or local fire codes) can result in project delays, fines, or shutdowns. Always confirm that the paint booth meets applicable regulatory standards for your location and application.

Hidden Costs Due to Poor Installation and Commissioning Support

Some suppliers provide low initial quotes but lack the technical team or documentation for proper installation. This leads to delays, rework, and increased labor costs. Ensure the supplier offers comprehensive installation support, operator training, and post-commissioning service.

Intellectual Property Infringement Risks

Sourcing from unverified suppliers—particularly in regions with weak IP enforcement—can expose your business to legal liability. Some manufacturers may replicate patented designs, control systems, or filtration technologies without authorization. Using such equipment could result in cease-and-desist orders, litigation, or forced replacement of the booth.

Lack of Technical Documentation and IP Transparency

Reputable suppliers provide full technical documentation, including engineering drawings, control system schematics, and compliance certificates. Opaque suppliers may withhold this information, making future maintenance, upgrades, or regulatory audits difficult. Always request and review documentation before purchase.

No Warranty or After-Sales Support

Low-cost suppliers may offer little or no warranty, particularly for critical components like fans, lighting, or control panels. Without reliable after-sales service, downtime can escalate quickly. Verify warranty terms, spare parts availability, and the supplier’s track record for customer support.

By carefully vetting suppliers for quality standards and IP legitimacy, businesses can avoid costly mistakes and ensure a safe, compliant, and efficient paint finishing operation.

Logistics & Compliance Guide for Paint Booth Operations

Proper logistics and compliance are essential for the safe, efficient, and legally sound operation of a paint booth. This guide outlines key considerations to ensure regulatory adherence, worker safety, and operational effectiveness.

Regulatory Compliance Requirements

Paint booth operations are subject to a range of federal, state, and local regulations. Key compliance areas include:

- EPA Air Quality Standards (Clean Air Act): Ensure volatile organic compound (VOC) emissions are within permissible limits. Use high-efficiency filtration and approved coatings.

- OSHA Standards (29 CFR 1910): Comply with workplace safety regulations, including ventilation (1910.94), hazardous materials (1910.1200 – Hazard Communication), and fire protection (1910.157).

- NFPA 33: Standard for Spray Application Using Flammable and Combustible Materials: Follow guidelines for booth design, fire suppression systems, electrical classifications, and safe storage of flammable liquids.

- Permitting: Obtain necessary environmental and operational permits (e.g., air quality permits, fire department permits) before starting operations.

- Waste Management (RCRA): Classify, store, and dispose of hazardous waste (e.g., used filters, solvent-contaminated rags) in accordance with EPA Resource Conservation and Recovery Act rules.

Ventilation & Air Filtration Systems

Effective ventilation is critical for operator health and coating quality.

- Airflow Requirements: Maintain recommended airflow (typically 100 ft/min face velocity) to capture overspray and vapors.

- Exhaust Filtration: Use multi-stage filtration (pre-filters, main filters, and optional after-filters) to trap particulates and comply with emissions standards.

- Make-Up Air Units (MAUs): Ensure adequate conditioned air supply to balance exhaust and maintain temperature/humidity control.

- Regular Maintenance: Schedule filter changes and duct cleaning to prevent airflow restrictions and fire hazards.

Fire Prevention & Safety Protocols

Paint booths present significant fire risks due to flammable materials.

- Fire Suppression Systems: Install automatic fire suppression systems (e.g., wet chemical or CO₂) approved under NFPA 17 or NFPA 750.

- Electrical Safety: Use explosion-proof electrical fixtures and motors rated for Class I, Division 1 or 2 areas.

- No-Smoking Policy: Enforce strict no-smoking and open-flame rules in and around the booth.

- Flammable Storage: Store solvents and paints in approved containers and flammable storage cabinets away from ignition sources.

Hazardous Material Handling & Storage

Safe handling of paints, solvents, and thinners is essential.

- Secondary Containment: Use spill pallets or berms for liquid storage to contain leaks.

- Labeling & SDS Access: Clearly label all containers and maintain up-to-date Safety Data Sheets (SDS) accessible to all personnel.

- Spill Response Kits: Keep spill kits (absorbents, PPE, disposal bags) readily available near storage and usage areas.

- Inventory Management: Track chemical inventory and rotate stock (FIFO) to prevent degradation and expired materials.

Personnel Training & PPE

Proper training and protective equipment reduce injury and ensure compliance.

- Training Programs: Train employees on chemical hazards, emergency procedures, equipment use, and regulatory requirements.

- Required PPE: Provide and enforce use of respirators (NIOSH-approved), gloves (nitrile or neoprene), protective clothing, and eye protection.

- Respiratory Protection Program: If air-purifying respirators are used, implement a written program including fit testing and medical evaluations (per OSHA 1910.134).

Waste Disposal & Environmental Stewardship

Manage waste responsibly to minimize environmental impact.

- Hazardous Waste Determination: Test or evaluate waste streams to determine if they are hazardous (e.g., characteristic of ignitability, toxicity).

- Storage Compliance: Store waste in closed, labeled containers in a designated accumulation area with secondary containment.

- Licensed Disposal: Use licensed hazardous waste transporters and treatment facilities; maintain manifests and records for at least three years.

- Recycling Options: Explore paint sludge dewatering, solvent recycling, or filter reclamation to reduce waste volume.

Recordkeeping & Audits

Maintain documentation to demonstrate compliance.

- Maintenance Logs: Record filter changes, equipment servicing, and ventilation performance tests.

- Training Records: Document employee training dates, topics, and attendees.

- Permit & Inspection Files: Keep copies of permits, inspection reports, and correspondence with regulatory agencies.

- Internal Audits: Conduct periodic compliance audits to identify and correct deficiencies before regulatory inspections.

Emergency Preparedness

Be prepared for spills, fires, or exposure incidents.

- Emergency Shutdown Procedures: Clearly post steps for shutting down the booth and ventilation in an emergency.

- Evacuation Plans: Post evacuation routes and conduct regular drills.

- First Aid & Eyewash Stations: Ensure accessible, ANSI-compliant emergency equipment is tested weekly.

- Spill & Fire Response Drills: Train staff on using fire extinguishers and spill kits effectively.

By adhering to this logistics and compliance guide, paint booth operators can maintain a safe work environment, meet regulatory obligations, and support sustainable operations.

Conclusion for Sourcing a Paint Booth

Sourcing a paint booth is a critical decision that significantly impacts the quality, efficiency, and safety of painting operations. After evaluating various suppliers, technologies, and specifications, it is clear that selecting the right paint booth requires a balanced approach, considering factors such as booth type (down-draft, cross-draft, or semi-downdraft), airflow efficiency, filtration systems, compliance with environmental and safety regulations (such as VOC emissions and fire codes), and long-term operational costs.

Prioritizing energy efficiency, durability, and ease of maintenance will contribute to reduced downtime and lower total cost of ownership. Additionally, working with reputable suppliers who offer strong technical support, warranties, and compliance certifications ensures reliability and peace of mind.

In conclusion, the ideal paint booth solution aligns with the specific needs of the facility—whether for automotive refinishing, industrial manufacturing, or specialty coating applications—while supporting high-quality finishes, regulatory compliance, and operator safety. A well-informed sourcing decision today lays the foundation for improved productivity, environmental responsibility, and long-term success.