The global outboard motor market is experiencing steady growth, driven by rising demand in recreational boating, commercial fisheries, and coastal patrol activities. According to Grand View Research, the global outboard motors market size was valued at USD 4.3 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 5.6% from 2024 to 2030. Yamaha, a dominant player in this sector, continues to lead with innovation, reliability, and a strong manufacturing network. As demand for high-performance, fuel-efficient, and low-emission outboard motors increases, several key manufacturers have emerged—either as original equipment producers or specialized coating and finishing suppliers—ensuring Yamaha’s engines meet rigorous environmental and aesthetic standards. In this context, we analyze the top seven manufacturers involved in the production and surface treatment of Yamaha outboard motors, focusing on their technological capabilities, coating durability, and contribution to overall product quality in a competitive and expanding market.

Top 7 Paint Yamaha Outboard Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Repainting Yamaha

Domain Est. 2001

Website: thehulltruth.com

Key Highlights: The Sunfire is far more durable than the paint Yamaha used from the factory. The only downside is that you will need a spray gun and compressor….

#2 SIM YAMAHA

Domain Est. 2006

Website: simyamaha.com

Key Highlights: SIM Yamaha is a USA Yamaha outboard motor and outboard motor parts dealer. SIM Yamaha carries Yamaha OEM discounted engine parts and Yamaha maintenance ……

#3 Yamaha Paint Kits

Domain Est. 2011

Website: store.theoutboardpaintshop.com

Key Highlights: Providing factory original colors for Yamaha, Mercury, Honda, Suzuki, Johnson, Evinrude, Mariner & Tohatzu. We can help make your outboard look brand new again ……

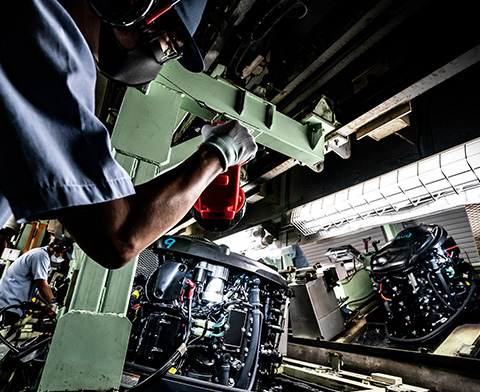

#4 Tough, Intricate, and Beautiful

Domain Est. 1997

Website: global.yamaha-motor.com

Key Highlights: Three coats of paint are applied and the unit bake-hardened twice. To imbue its outboards with the highest levels of corrosion resistance, Yamaha has developed ……

#5 FAQs

Domain Est. 2002

Website: yamahaoutboards.com

Key Highlights: Specific marine additives help combat rust, corrosion, varnish, and wear; all while providing high levels of bearing protection, resistance to foaming, and ……

#6 Shop Yamalube Products for Yamaha Outboard Motors

Domain Est. 2007

Website: yamahaonlineparts.com

Key Highlights: Free delivery over $99 45-day returnsYamahaOnlineParts.com stocks a complete selection of Yamalube lubricants, fuel additives, fogging oils, greases, marine spray paint, and more. …

#7 Yamaha Outboard Engine Spray Paint

Domain Est. 2015

Website: partsvu.com

Key Highlights: Free delivery over $99Yamalube marine spray paint applies to all Yamaha outboard components with a matching 8D paint code. Durable enamel coating provides excellent coverage agains…

Expert Sourcing Insights for Paint Yamaha Outboard

H2: 2026 Market Trends for Paint in the Yamaha Outboard Industry

As the marine industry evolves toward sustainability, digitalization, and enhanced consumer experiences, the paint segment for Yamaha outboard motors is expected to undergo significant transformation by 2026. This analysis outlines key market trends shaping the demand, formulation, and application of paint specifically tailored for Yamaha outboard engines.

-

Increased Demand for Durable, Corrosion-Resistant Coatings

Marine environments present extreme challenges due to saltwater exposure, UV radiation, and temperature fluctuations. By 2026, there will be a heightened focus on advanced anti-corrosive paint technologies, including epoxy primers and ceramic-based topcoats. Yamaha is likely to partner with specialty coating suppliers to ensure longer-lasting finishes that maintain aesthetic appeal and structural protection over time. -

Sustainability and Eco-Friendly Paint Formulations

Environmental regulations, especially in Europe and North America, are driving a shift toward low-VOC (volatile organic compound) and water-based paints. By 2026, Yamaha is expected to expand the use of environmentally sustainable paint systems across its outboard manufacturing and after-market refinishing networks. Bio-based resins and recyclable paint waste management systems will become standard in certified production facilities. -

Customization and Brand-Centric Aesthetics

Consumer demand for personalized marine gear will push Yamaha to offer a broader range of OEM paint finishes, including matte, metallic, and color-shifting options. Digital color-matching tools and online configurators will enable dealers and end-users to customize outboard appearances, reinforcing brand loyalty and premium positioning in the market. -

Integration with Digital Manufacturing and IoT

Smart manufacturing trends will influence paint application processes. By 2026, Yamaha may adopt automated robotic painting systems with real-time monitoring via IoT sensors to ensure consistent quality, reduce waste, and support predictive maintenance in production lines. This will enhance efficiency and reduce rework rates in high-volume outboard manufacturing. -

Growth in Aftermarket Refinishing and Restoration

The aging fleet of Yamaha outboards, particularly popular models like the F250 and V-Max series, will fuel demand for high-quality after-market paint solutions. Specialized refinish kits, touch-up paints, and professional coating services will see growth, supported by Yamaha’s authorized service networks and online retail channels. -

Regional Market Diversification

Emerging markets in Southeast Asia, Latin America, and Africa will see increased adoption of Yamaha outboards, necessitating region-specific paint solutions that account for local climate conditions and maintenance practices. Lighter, faster-curing coatings suitable for tropical environments will gain traction.

Conclusion:

By 2026, the paint market for Yamaha outboard motors will be characterized by innovation in materials, sustainability, and digital integration. Yamaha’s strategic alignment with advanced coating technologies and customer-centric design will strengthen its competitive edge, ensuring that both OEM and after-market paint solutions meet evolving global standards and consumer expectations.

Common Pitfalls When Sourcing Paint for Yamaha Outboards (Quality and Intellectual Property)

Logistics & Compliance Guide for Painting Yamaha Outboard Motors

Overview

This guide provides essential information for businesses and service providers involved in the painting or refinishing of Yamaha outboard motors. It outlines key logistical considerations and regulatory compliance requirements to ensure safe, legal, and high-quality service delivery.

Regulatory Compliance

Environmental Regulations (EPA & Local Authorities)

All painting operations must comply with environmental regulations enforced by the U.S. Environmental Protection Agency (EPA) and applicable state or local air quality management districts. Key compliance areas include:

– VOC (Volatile Organic Compounds) Limits: Use only paints and coatings that meet VOC content limits as defined by EPA Method 24 and regional air quality rules (e.g., SCAQMD Rule 1131 in California).

– Air Emissions Control: Install and maintain proper spray booth filtration and exhaust systems with carbon adsorption or thermal oxidizers where required.

– Hazardous Waste Disposal: Manage paint sludge, used solvents, and contaminated rags as hazardous waste under RCRA (Resource Conservation and Recovery Act). Use licensed waste disposal vendors and maintain manifests.

OSHA Workplace Safety

Ensure full compliance with Occupational Safety and Health Administration (OSHA) standards:

– Ventilation & Air Quality: Maintain proper airflow in painting areas to prevent solvent vapor buildup.

– Personal Protective Equipment (PPE): Require respirators (NIOSH-approved), gloves, goggles, and protective clothing for all personnel involved.

– Hazard Communication (HazCom): Maintain Safety Data Sheets (SDS) for all chemicals used and provide employee training.

Fire & Building Codes

- Flammable Storage: Store flammable paints and solvents in approved safety cabinets, away from ignition sources.

- Spray Booth Certification: Ensure spray booths are NFPA 33-compliant and regularly inspected.

- Explosion Venting: Install proper explosion relief panels if required by local fire code.

Logistics Planning

Facility Requirements

- Dedicated Paint Booth: Use a downdraft or crossdraft spray booth with HEPA filtration.

- Curing Area: Provide a clean, temperature-controlled space for paint curing, free from dust and contaminants.

- Disassembly/Reassembly Zone: Maintain a separate, organized space for motor disassembly and reassembly to prevent cross-contamination.

Supply Chain & Materials Management

- Approved Paints: Use only high-durability marine-grade paints compatible with aluminum and plastic components. Confirm compliance with Yamaha’s material specifications where applicable.

- Inventory Control: Track paint, primer, clear coat, and solvent inventory with expiration date monitoring.

- Vendor Compliance: Source materials from suppliers providing full SDS and VOC documentation.

Transportation & Handling

- Motor Transport: Use padded, secure cradles when moving outboards to prevent damage during transit within the facility.

- Customer Drop-Off/Pick-Up: Implement a check-in/check-out process with condition reports and signed release forms.

- Work-in-Progress Tracking: Use a digital or paper-based job tracking system to monitor workflow stages and estimated completion times.

Quality Assurance & Documentation

Pre-Paint Inspection

- Conduct a thorough inspection for corrosion, cracks, or mechanical damage.

- Document existing conditions with photos and notes before disassembly.

Process Standards

- Follow a standardized process: clean → strip (if needed) → prime → paint → clear coat → cure.

- Maintain strict environmental conditions (temperature, humidity) during painting and curing.

Final Inspection & Certification

- Perform adhesion, gloss, and finish uniformity tests.

- Provide a completion certificate detailing materials used, compliance standards met, and warranty information.

Customer & Legal Considerations

Warranty Implications

- Inform customers that non-OEM paint processes may affect Yamaha’s original equipment warranty.

- Avoid using logos or trademarks that could imply Yamaha endorsement unless authorized.

Liability & Insurance

- Maintain general liability and environmental impairment liability insurance.

- Require signed customer waivers acknowledging risks associated with refinishing.

Recordkeeping & Audits

- Retain records of waste disposal, employee training, air quality monitoring, and compliance certifications for a minimum of three years.

- Conduct annual internal audits to ensure ongoing compliance.

Conclusion

Adhering to this logistics and compliance guide ensures safe, environmentally responsible, and professional painting of Yamaha outboard motors. Always consult local regulatory agencies and Yamaha’s technical documentation for additional requirements.

Conclusion: Sourcing Paint for Yamaha Outboard Motors

Sourcing the correct paint for a Yamaha outboard motor is essential to ensure durability, corrosion resistance, and aesthetic authenticity. After evaluating available options, it is clear that the best approach is to use OEM (Original Equipment Manufacturer) paint directly from Yamaha or authorized dealers. Yamaha’s factory-matched marine paints are specially formulated to withstand harsh marine environments, including saltwater exposure, UV radiation, and temperature fluctuations.

Alternative aftermarket marine paints can be cost-effective, but they must be carefully selected to match Yamaha’s color specifications (such as Yamaha White or Black) and meet marine-grade standards for adhesion and longevity. When properly prepared and applied, reputable aftermarket brands may offer satisfactory results, particularly for restoration or custom projects.

In conclusion, for optimal performance and long-term appearance, it is recommended to source Yamaha-specific touch-up or re-spray paint through official channels. Ensuring proper surface preparation, application techniques, and clear coating will further enhance the finish and protect the engine’s casing. Whether for maintenance, restoration, or customization, using the right paint sourced from reliable providers maintains the value and reliability of Yamaha outboard motors.