The global automotive refinishing market is experiencing robust growth, driven by increasing vehicle production and rising demand for high-quality surface finishing solutions. According to Grand View Research, the global automotive refinish coatings market size was valued at USD 13.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth underscores the critical role of precision tools in manufacturing and repair processes, particularly in paint preparation. As car manufacturers prioritize efficiency, consistency, and finish quality, the use of advanced paint sanders has become integral on production lines and in pre-paint surfacing operations. These tools ensure optimal surface平整度 and adhesion, reducing rework and improving throughput. With automation and ergonomics becoming key focus areas, manufacturers are increasingly adopting high-performance sanders tailored for automotive applications. In this context, selecting the right paint sander is no longer just about durability—it’s about integration, precision, and measurable impact on line efficiency. Below are the top 9 paint sanders trusted by leading car manufacturers for superior performance and reliability.

Top 9 Paint Sander For Car Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 3M Power Sanders for Automotive

Domain Est. 1988

Website: 3m.com

Key Highlights: Power tools which move an abrasive material at high speed, either by oscillation or by rotating a continuous loop. Power sanders are most commonly used for ……

#2 Abrasives

Domain Est. 1995

Website: rustoleum.com

Key Highlights: Gator Finishing offers innovative abrasive products for drywall, floors, vehicles and more. These tough yet easy-to-use abrasives are designed to increase ……

#3 Sanders

Domain Est. 1996

Website: boschtools.com

Key Highlights: Bosch sanders are designed for a range of materials, including wood, metal, and plastic. They’re also ideal for removing paint, varnish, and finishes. Whether ……

#4 Random Orbital Sanders

Domain Est. 1996

Website: hutchinsmfg.com

Key Highlights: Random Orbital Sanders are the most popular of all pneumatic sanding tools. Because they leave no repeating pattern, they are used for final preparation….

#5 Mirka

Domain Est. 1997

Website: mirka.com

Key Highlights: Dust-Free Pole Sander. The Mirka® DecoSander is designed for precision sanding of walls, ceilings, and tight corners, ensuring a flawless ……

#6 Brushless Electric Sander

Domain Est. 1997

#7

Domain Est. 1998

Website: nortonabrasives.com

Key Highlights: Norton Launches New Automotive Finishing System. Helping collision repair technicians achieve a real showroom finish that lasts is the purpose behind… 05 Dec ……

#8 Auto Body Air Sanders

Domain Est. 1998

Website: autobodytoolmart.com

Key Highlights: $400 deliveryWe carry automotive air sanders in a variety of configurations to meet your specific needs. From disc sanders to jitterbug air sanders, we have it all….

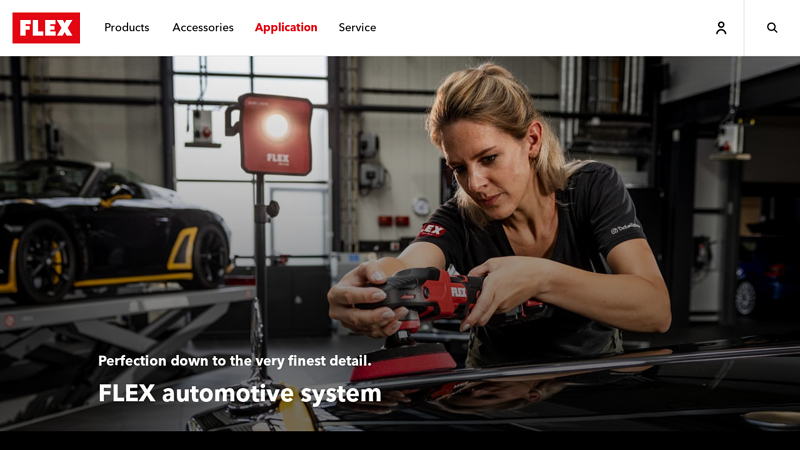

#9 Polishing, vacuuming, screwing » FLEX Automotive System

Domain Est. 1999

Website: flex-tools.com

Key Highlights: A bodywork mechanic sands paint on a car door using the orbital sander from FLEX. Body shop. Whether grinder, vacuum cleaner, cartridge press or hot air gun ……

Expert Sourcing Insights for Paint Sander For Car

H2: 2026 Market Trends for Paint Sander for Car

The global market for paint sanders used in automotive applications is poised for significant transformation by 2026, driven by technological innovation, rising demand for vehicle refinishing, and growing consumer expectations for high-quality finishes. Below are the key market trends expected to shape the paint sander for car industry in 2026:

1. Rising Demand for Precision and Efficiency in Auto Refinishing

As vehicle owners and repair shops prioritize faster turnaround times and flawless paint finishes, demand for advanced paint sanders with high precision and reduced vibration is increasing. By 2026, automated and semi-automated sanding systems are expected to gain traction, especially in collision repair centers and high-end detailing shops, improving consistency and reducing labor costs.

2. Adoption of Cordless and Battery-Powered Paint Sanders

With workshops emphasizing mobility and flexibility, cordless paint sanders are anticipated to dominate the market. Improvements in lithium-ion battery technology will enable longer runtimes and higher power output, making battery-operated tools ideal for both mobile detailing services and fixed repair facilities. This shift is also supported by environmental regulations limiting emissions from gasoline-powered tools.

3. Integration of Smart Technology and IoT Features

By 2026, smart paint sanders equipped with sensors and IoT connectivity are expected to enter the mainstream. These tools will offer real-time feedback on pressure, speed, and surface contact, helping technicians avoid over-sanding and ensuring uniform finishes. Data from these devices can also be used for training, quality control, and workflow optimization in professional settings.

4. Growth in the Aftermarket and Collision Repair Sectors

The expanding global vehicle parc, coupled with frequent accidents and weather-related damages, is fueling demand for automotive refinishing. As a result, the aftermarket and collision repair industries are investing heavily in efficient tools like paint sanders. Regions such as North America, Europe, and Asia-Pacific will lead adoption due to high vehicle ownership and advanced repair infrastructure.

5. Emphasis on Dust Extraction and Health Safety

Regulatory frameworks and workplace safety standards are increasingly mandating dust control in automotive workshops. Paint sanders with integrated HEPA filtration and vacuum systems will become standard by 2026, reducing health risks from inhaling paint particles and improving overall air quality in repair environments.

6. Expansion of E-commerce and Direct-to-Consumer Sales

Online platforms are becoming key distribution channels for automotive tools. By 2026, manufacturers will increasingly leverage e-commerce to reach DIY car enthusiasts and small repair shops, offering bundled kits, subscription models for sanding discs, and detailed tutorials to enhance user experience.

7. Sustainable and Eco-Friendly Product Development

Environmental concerns are driving innovation in sustainable tool manufacturing. Companies are expected to use recyclable materials, reduce energy consumption during production, and design longer-lasting tools to minimize waste. Additionally, water-based paint systems—which require gentler sanding—will influence sander design, favoring models with adjustable pressure settings.

Conclusion

By 2026, the paint sander for car market will be shaped by a convergence of technological advancements, regulatory demands, and evolving user needs. Manufacturers that focus on innovation, user safety, and sustainability will be best positioned to capture market share in this dynamic and competitive landscape.

Common Pitfalls When Sourcing a Paint Sander for Car (Quality and IP Considerations)

Logistics & Compliance Guide for Paint Sander For Car

Proper logistics planning and adherence to compliance standards are essential when shipping or importing paint sanders for car use. This guide outlines key considerations to ensure safe, legal, and efficient transportation and distribution.

Product Classification and HS Code

Identify the correct Harmonized System (HS) code for customs declaration. Paint sanders for car use typically fall under:

- HS Code Example: 8467.21.00 (Pneumatic hand tools, sanders and grinders)

Note: Exact classification may vary by country. Verify with local customs authorities or a licensed customs broker to ensure accurate tariff coding, which affects import duties and taxes.

Packaging and Labeling Requirements

Ensure packaging protects the tool during transit and meets regulatory standards:

- Use durable, shock-absorbent packaging to prevent damage.

- Include all necessary labels: product name, model number, voltage, power rating, manufacturer details, and safety warnings.

- Display compliance marks (e.g., CE, UKCA, RoHS) as required by destination market.

- Provide multilingual user manuals and safety instructions if exporting internationally.

Safety and Regulatory Compliance

Paint sanders must meet safety and environmental standards:

- CE Marking (EU): Required to demonstrate compliance with EU health, safety, and environmental protection standards under directives such as the Machinery Directive (2006/42/EC) and Low Voltage Directive (2014/35/EU).

- RoHS Compliance: Restricts the use of hazardous substances (e.g., lead, mercury) in electrical equipment.

- UKCA Marking (UK): Required for sale in Great Britain; similar to CE but specific to UK regulations.

- UL/ETL Certification (USA): Voluntary but often required by retailers; ensures product meets North American safety standards.

- EPA & Noise Regulations: Check local regulations regarding noise emissions and air quality, especially for pneumatic or dust-producing tools.

Shipping and Transportation

Follow best practices for domestic and international shipping:

- Mode of Transport: Choose air, sea, or ground based on urgency, cost, and volume. Air freight is faster but more expensive; sea freight is cost-effective for bulk shipments.

- Dangerous Goods Considerations: While most electric paint sanders are not classified as dangerous goods, check if the product includes lithium-ion batteries (common in cordless models). Battery-powered tools may fall under IATA Dangerous Goods Regulations (Class 9 – Miscellaneous) when shipped by air.

- Documentation: Prepare commercial invoice, packing list, bill of lading/air waybill, and certificate of origin. Include safety data sheets (SDS) if applicable.

- Insurance: Ensure adequate cargo insurance to cover loss or damage during transit.

Import Duties and Taxes

Understand the financial implications of cross-border trade:

- Determine applicable import tariffs using the correct HS code.

- Account for value-added tax (VAT), goods and services tax (GST), or sales tax based on destination country.

- Consider using a customs broker to streamline clearance and avoid delays.

Environmental and Disposal Compliance

Address end-of-life responsibilities:

- Comply with WEEE (Waste Electrical and Electronic Equipment) Directive in the EU, which mandates proper recycling and disposal of electronic tools.

- Provide take-back or recycling information to customers where required.

Quality Control and Documentation

Maintain compliance through consistent quality assurance:

- Implement internal quality checks to ensure each unit meets safety and performance standards.

- Keep records of certifications, test reports, and compliance documentation for audits or inspections.

By following this guide, businesses can ensure smooth logistics operations and full compliance when distributing paint sanders for car use globally.

Conclusion: Sourcing a Paint Sander for Car Refinishing

After evaluating various options, it is clear that sourcing the right paint sander is crucial for achieving a smooth, professional finish in car refinishing projects. When selecting a paint sander, key factors such as sanding type (orbital vs. rotary), dust extraction capability, ergonomics, power source (pneumatic vs. electric), and compatibility with different sandpaper grits must be carefully considered.

Cordless electric random orbital sanders offer versatility and ease of use for most home or small shop applications, while pneumatic sanders are preferred in professional environments for their power and durability. Dual-action (DA) sanders are particularly effective for paint removal and surface leveling due to their minimized swirl marks and even sanding action.

Investing in a high-quality sander from reputable brands ensures longevity, better performance, and improved finish quality. Additionally, purchasing models with integrated dust collection helps maintain a clean work environment and supports health and safety standards.

In conclusion, the ideal paint sander for car work balances performance, comfort, and precision. By sourcing a sander that matches your specific needs—whether for DIY repairs or professional detailing—you ensure efficient workflow, superior results, and long-term cost savings through reduced rework and tool replacement.